Environmental-friendly type fluorescent powder

A fluorescent powder and environment-friendly technology, applied in the field of lighting, can solve the problems of large pollution of fluorescent powder, and achieve the effects of simple production process, guaranteed production quality, and reduced pollutant discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

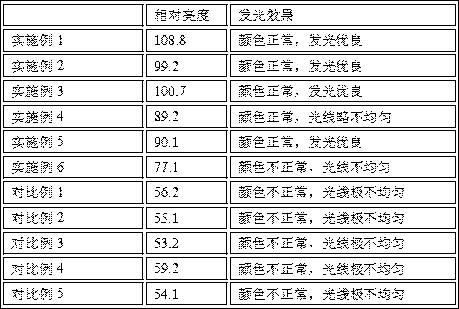

Examples

Embodiment 1

[0022] An environment-friendly fluorescent powder, comprising fluorescent powder and calcium carbonate, wherein the fluorescent powder is 2 parts by mass, and the calcium carbonate is 25 parts by mass. The phosphor powder includes 630 parts by mass of aluminum oxide, 285 parts by mass of yttrium oxide, and 5 parts by mass of cerium oxide. The fluorescent powder is prepared by the following method: take 300 parts by mass of the combustion agent, mix it with alumina, yttrium oxide, and cerium oxide, and heat it after ball milling; °C, reacted at this temperature for 3.5 hours, and gradually lowered to room temperature to obtain an intermediate powder, and the intermediate powder was ball milled to obtain a YAG-Ce phosphor. The combustion agent is a mixture of urea, oxalic acid and ethylene glycol. The modified calcium carbonate is prepared by the following method: after mixing 12 parts by mass of nano-calcium carbonate with 1250 parts by mass of deionized water, add 0.15 parts ...

Embodiment 2

[0028] The difference between embodiment 2 and embodiment 1 is that it includes fluorescent powder and calcium carbonate, 1 part by mass of the fluorescent powder, and 2 parts by mass of the calcium carbonate. The fluorescent powder is YAG-Ce fluorescent powder; the fluorescent powder includes 530 parts by mass of aluminum oxide, 215 parts by mass of yttrium oxide, and 2-21 parts by mass of cerium oxide. The fluorescent powder is prepared by the following method: take 270 parts by mass of the combustion agent, mix it with alumina, yttrium oxide, and cerium oxide, and heat it after ball milling; °C, reacted at this temperature for 3 hours, and gradually lowered to room temperature to obtain an intermediate powder, and the intermediate powder was ball milled to obtain a YAG-Ce phosphor. The combustion agent is a mixture of urea, oxalic acid and ethylene glycol. Described calcium carbonate is modified calcium carbonate, and described modified calcium carbonate is obtained by the...

Embodiment 3

[0030]The difference between embodiment 3 and embodiment 1 is that it includes fluorescent powder and calcium carbonate, the phosphor powder is 3 parts by mass, and the calcium carbonate is 40 parts by mass. The fluorescent powder is YAG-Ce fluorescent powder; the fluorescent powder includes 710 parts by mass of aluminum oxide, 395 parts by mass of yttrium oxide, and 21 parts by mass of cerium oxide. The fluorescent powder is prepared by the following method: take 310 parts by mass of the combustion agent, mix it with alumina, yttrium oxide, and cerium oxide, and heat it after ball milling; °C, reacted at this temperature for 4 hours, and gradually lowered to room temperature to obtain an intermediate powder, and the intermediate powder was ball milled to obtain a YAG-Ce phosphor. The combustion agent is a mixture of urea, oxalic acid and ethylene glycol. Described calcium carbonate is modified calcium carbonate, and described modified calcium carbonate is obtained by the fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com