Hydrotalcite-containing stiffening nucleating agent composition

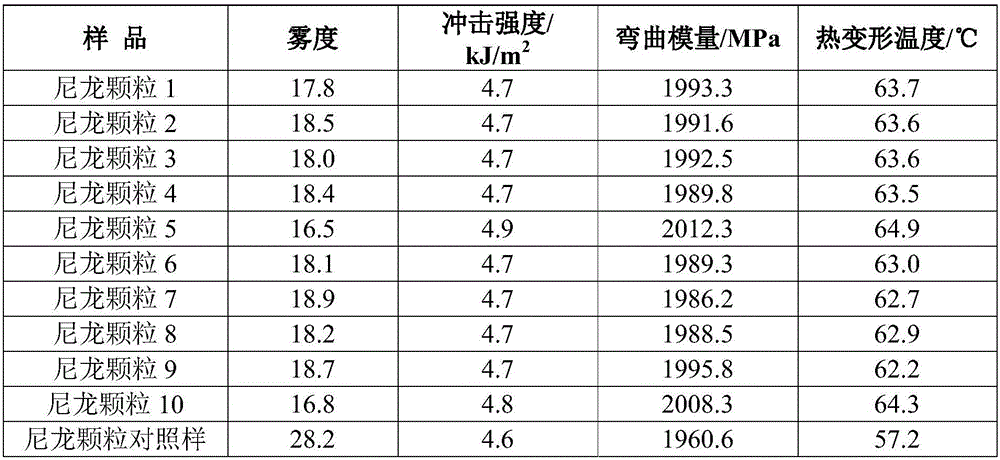

A technology of nucleating agent and composition, applied in the field of nucleating agent, can solve the problem of not knowing which substance and so on, and achieve the effects of shortening the injection molding cycle, increasing the heat-resistant temperature, and improving the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

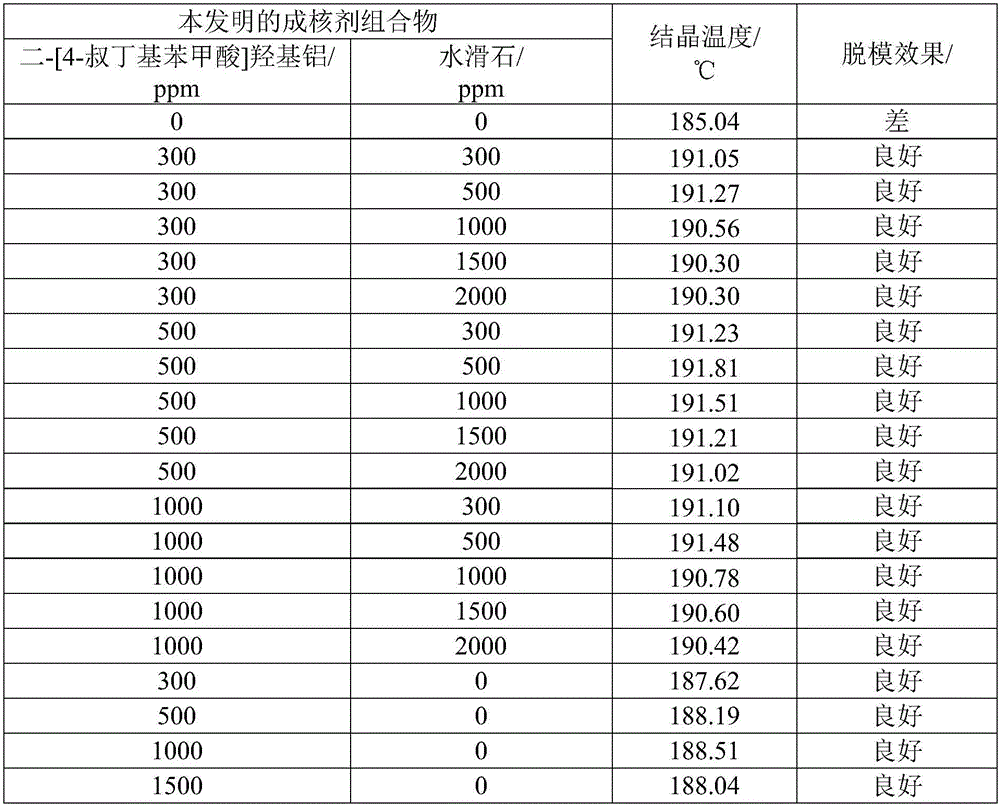

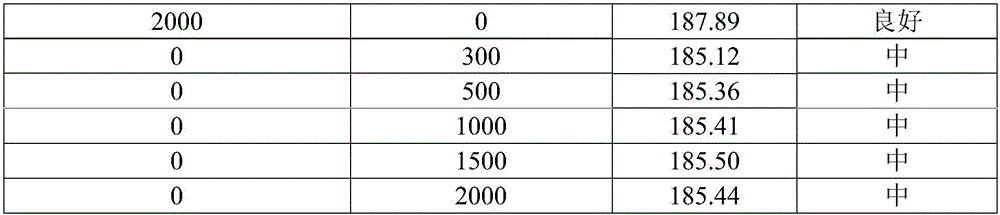

Method used

Image

Examples

Embodiment 1

[0032] Accurately weigh 8.3 g of bis-[4-tert-butylbenzoic acid] hydroxyaluminum and 1.7 g of hydrotalcite respectively, and then uniformly mix them in a stirrer to obtain the nucleating agent 1 of the present invention.

Embodiment 2

[0034] Accurately weigh 1.7 g of bis-[4-tert-butylbenzoic acid] hydroxyaluminum and 8.3 g of hydrotalcite respectively, and then uniformly mix them in a stirrer to obtain the nucleating agent 2 of the present invention.

Embodiment 3

[0036] Accurately weigh 7.5 g of di-[4-tert-butylbenzoic acid] hydroxyaluminum and 2.5 g of hydrotalcite respectively, and then uniformly mix them in a stirrer to obtain the nucleating agent 3 of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com