Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Catalytic activity does not decrease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for subjecting TiO2 photocatalyst to be supported on honeycomb ceramics surface

InactiveCN1962061ALarge specific surface areaGood light transmissionWater/sewage treatment by irradiationCatalyst activation/preparationOrthogonal methodHoneycomb

The invention relates to a method for preparing TiO2 catalyst on the surface carrier of three-dimension beehive ceramic network, wherein it uses orthogonal method to prepare the titanic acid gel and the titanic acid gel with silver, iron, or lanthanum ion; uses dichroite beehive cermai and beehive ceramic as carrier; using gel-sol method to carry the titanic acid gel on the carrier. The load amount of optical catalyst film on the ceramic carrier is 0.21mg / cm2; the TiO2 diameter is 15-20nm; the thickness of load film is 300-400nm; when using it to purify the formaldehyde, and the initial density is 0.42-0.49mg / m3, the formaldehyde density will be lower than 72.2-74% after seven hours; when using it to disinfect, and the initial virus density is 554-924cfu / m3, the virus number is reduced 67.0-75.9% after 14.5h.

Owner:JIANGSU GAOCHUN CERAMICS

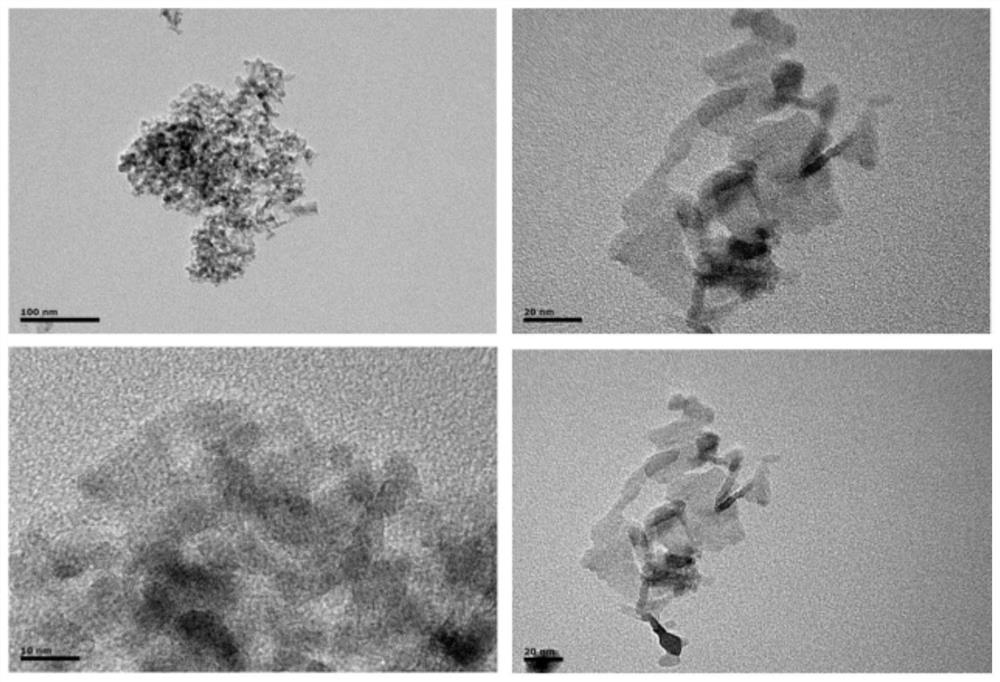

Graphene/molecular sieve composite catalyst and preparation method thereof

ActiveCN106475131AStrong interfacial interactionHigh yieldMolecular sieve catalystsMolecular sieve catalystMolecular sieveMicrometer

The invention discloses a graphene / molecular sieve composite catalyst and a preparation method thereof. The composite catalyst comprises, by weight, 5-40% of graphene and 60-95% of molecular sieve. The composite material has a quasi-two-dimensional lamellar structure, the ratio of the area of a single lamella to the thickness of the single lamella is more than 100 micrometers, the molecular sieve is evenly loaded on the surface of the graphene, and mesopore diameter is 2-30 nanometers. The preparation method includes: mixing the graphene, a silicon source, an aluminum source and a surfactant, separating out a graphene-containing part, crystalizing, purifying, and removing the surfactant. The graphene / molecular sieve composite catalyst has the advantages that the composite catalyst serving as a solid acid catalyst has enhanced catalytic activity, product yield and reusability can be evidently increased while the catalytic activity is not lowered when the catalyst is used in CBG and EHB reaction, and accordingly the catalyst is promising in application prospect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

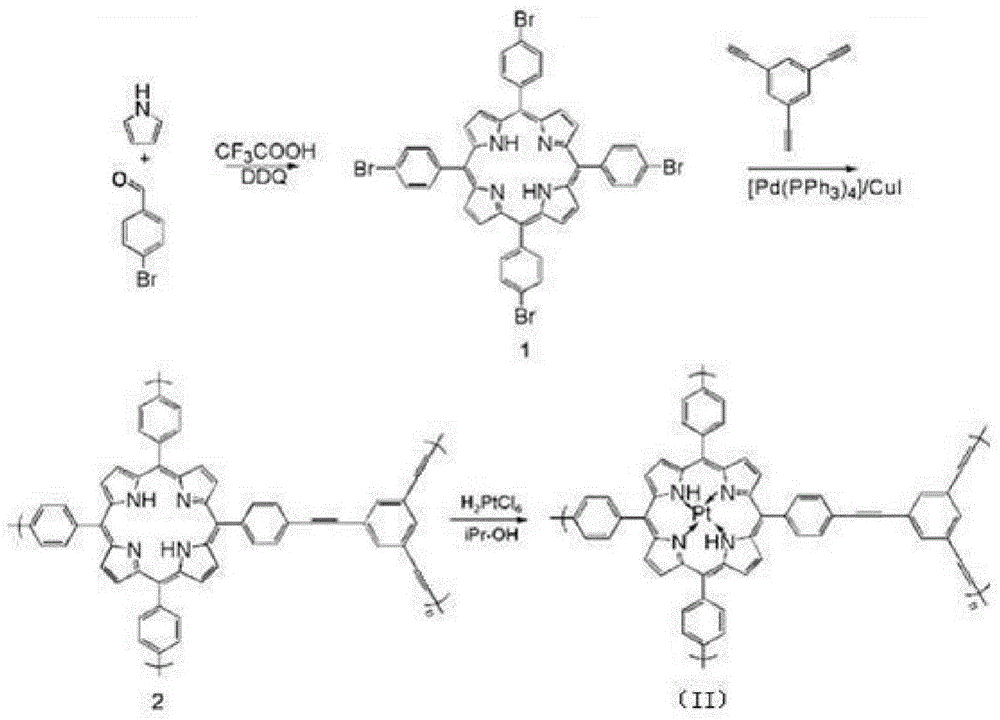

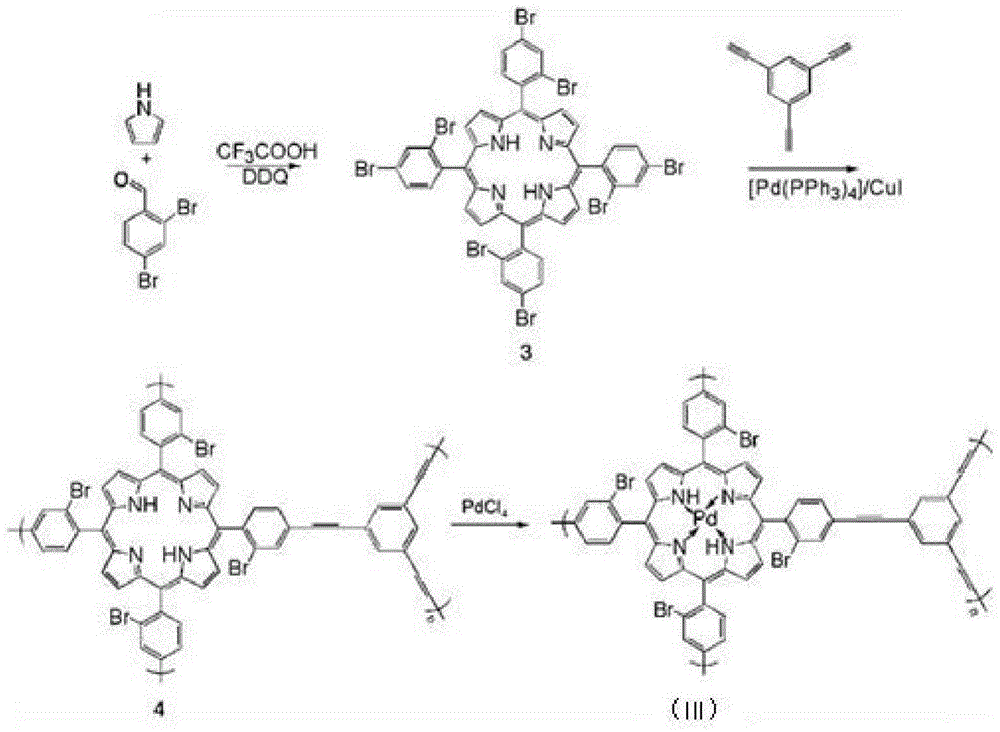

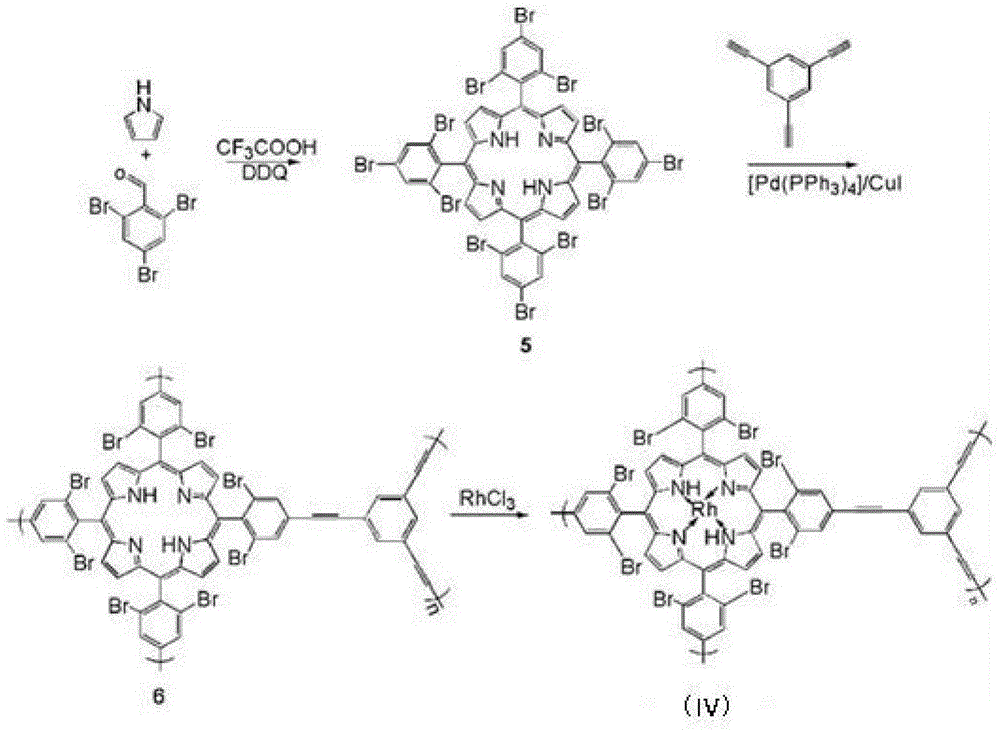

Method for preparing polyether-modified silicone oil in presence of MOFs (metal-organic frameworks) supported catalyst

ActiveCN104817700AEfficient separationNo residueChemical recyclingMetal-organic frameworkHydrosilylation

The invention belongs to the technical field of organic silicon synthesis, and particularly relates to a method for preparing polyether-modified silicone oil in presence of an MOFs (metal-organic frameworks) supported catalyst. The preparation method includes the steps: performing hydrosilylation reaction of hydrogen containing silicone oil and allyl polyether without solvents in presence of the MOFs supported catalyst; filtering and separating the catalyst after reaction to obtain the polyether-modified silicone oil. The MOFs supported catalyst has a structural formula indicated in a formula (I), M refers to platinum, rhodium, palladium or ruthenium, and R1 and R2 are same or different H or Br. The hydrosilylation reaction of the hydrogen containing silicone oil and the allyl polyether is catalyzed by the MOFs supported catalyst which can be recycled by a simple method, and the quality of the polyether-modified silicone oil and the use ratio of precious metals can be effectively improved.

Owner:GUANGZHOU TINCI MATERIALS TECH

Ion liquid catalyst for producing alkylated oil and its preparation method

InactiveCN1836780AReduce manufacturing costCatalytic activity does not decreaseOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from saturated and unsaturated hydrocarbon additionBenzeneAlkyl transfer

The present invention is one kind of ionic liquid catalyst for produce alkylated oil and its preparation process. The catalyst is ionic liquid modified with sulfur or oxygen containing organic compound, benzene or alkyl derivative of benzene, and is used in preparing alkylated oil. It possesses alkylation selectivity, and the alkylated oil product has high octane number, C8 component accounting for 70-90 %, and the outstanding advantage of trimethylpentane proportion in the C8 component over 90 %. In addition, the catalyst can result in product yield up to 170-180 vol% of olefin feed.

Owner:BEIJING UNIV OF CHEM TECH

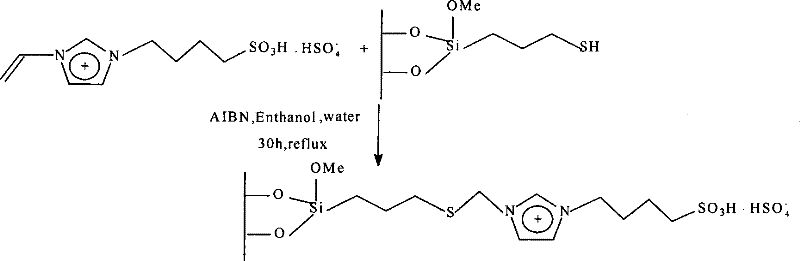

1-vinyl-3-sulfobutyl imidazole bisulfate and preparation method thereof

InactiveCN101397273AStrong acidReduce lossesOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfatePtru catalyst

The invention relates to 1-ethylene-3-methylimidazolium hydrogen sulfate and a preparation method thereof, belonging to the acid ion liquid. The molecular formula is as above; the preparation method comprises the following steps: (1) 1-vinylimidazole and 1,4-butanesultone with a molar ratio of 1:1.1 are adopted for an reaction under the room-temperature of about 50 DEG C; and then zwitterionic 1-ethylene-3-methylimidazolium hydrogen sulfate is obtained after washing and drying; (2) a concentrated sulphuric acid is dropped onto the 1-ethylene-3-methylimidazolium hydrogen sulfate under the temperature less than 10 DEG C and with the molar ratio of 1:0.96 to 1.04 between the 1-ethylene-3-methylimidazolium hydrogen sulfate and the concentrated sulphuric acid, the reaction is carried out for 3 to 6 hours; then the target product is obtained after washing and drying. The 1-ethylene-3-methylimidazolium hydrogen sulfate prepared by the method contains -SO3H and HSO4<-> and is provided with two proton bits, and therefore has good Br nsted acidity; the double-bond functional group on the side chain of the product can be adopted for chemical bond combination so as to anchor the product on sold carriers and is used for preparinge solid acid catalysts.

Owner:HEBEI UNIV OF TECH

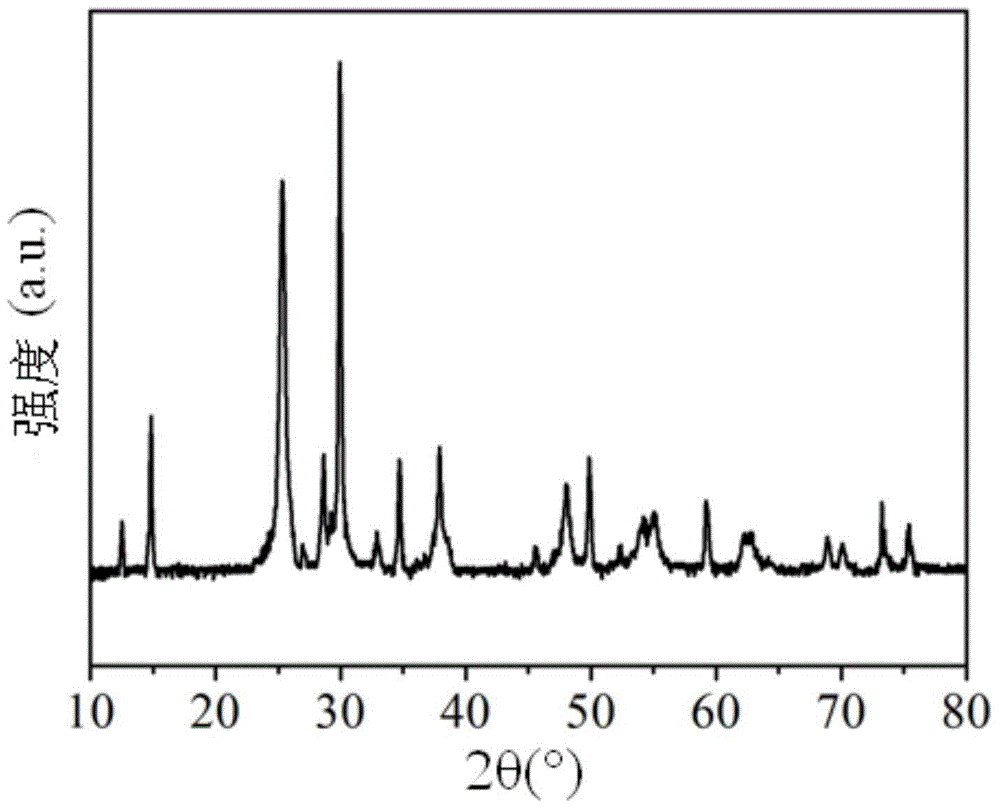

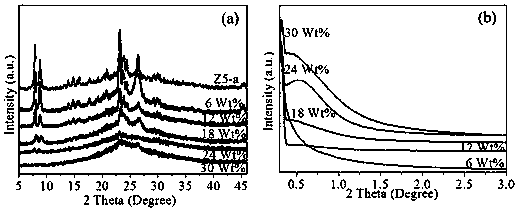

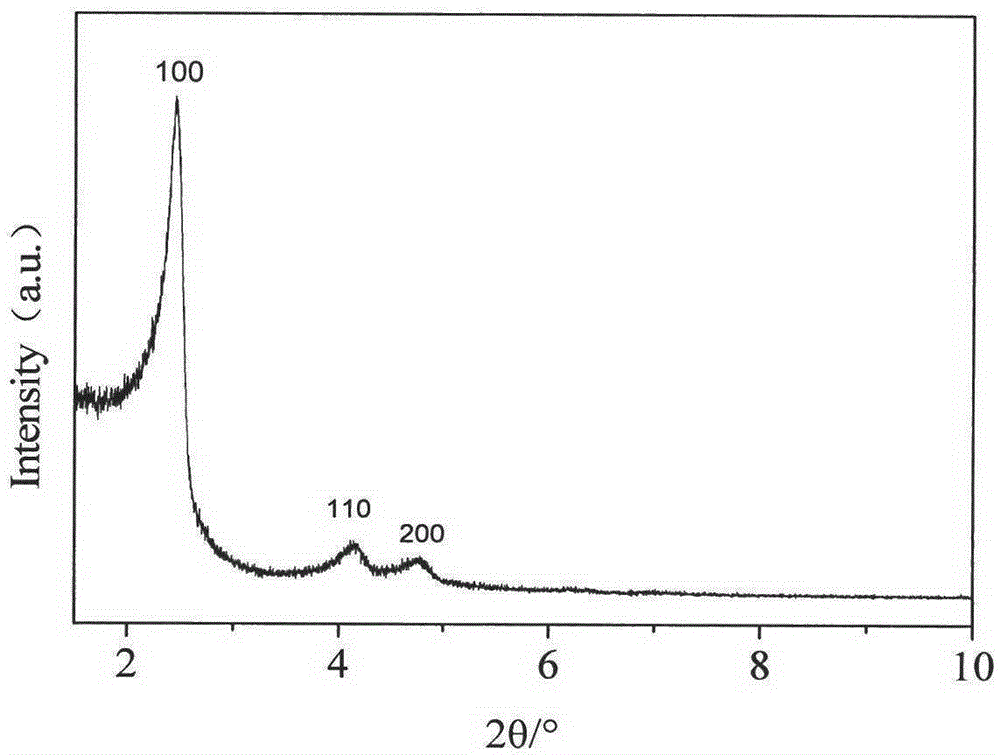

Mesoporous molecular sieve of in-situ doped metal and application thereof

ActiveCN103803578AHigh activityGood choiceHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveMicrowave

The invention relates to a mesoporous molecular sieve of doped metal and an application thereof. The mesoporous molecular sieve is formed by mixing a template, an alkali source, a silicon source and a metal source at the molar ratio of (0.06-0.24):(0.1-0.3):1:(0.01-0.20), and stirring at 20-40 DEG C for 0.5-24 hours to obtain emulsion; carrying out hydrothermal reaction on the emulsion at 80-180 DEG C for at least 12 hours (or reacting in a microwave reactor at the power of 200-2100w for 1-10h), then successively cooling, filtering, washing to be neutral and drying to obtain solid matters; and roasting the solid matters at 400-800 DEG C for 1-15 hours to obtain the molecular sieve, wherein the molecular sieve has a specific area of (BET)200-1500m2 / g, pore volume of 0.5-3.0cm3 / g and aperture of 2-15nm. The mesoporous molecular sieve has catalytic activity at 200-550 DEG C and the catalytic activity does not decline after roasting at 700 DEG C for 20 hours. The molecular sieve can be used as a catalyst for reaction during methane preparation by synthesis gas, and has commercial value.

Owner:EAST CHINA UNIV OF SCI & TECH

Loaded dual-function catalyst and preparation method and use thereof

InactiveCN101391228AImprove stabilityGood repeatabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsSolid acidP-Aminophenol

The invention provides a supported bi-functional catalyst as well as a preparation method and applications thereof, belonging to the catalyst containing platinum and an organic compound simultaneously. The catalyst has the compositions: an acidic ionic liquid of 1-vinyl-3-sulfobutyl imidazole hydrosulfate ([HSO3-bvim]HSO4), an active metal Pt and a carrier silica gel. The preparation method comprises the steps: the acidic ionic liquid of 1-vinyl-3-sulfobutyl imidazole hydrosulfate and the modified silica gel are added in a weight ratio of 0.05 to 1:1, then a mixed solution of solvent and deionized water as well as azo-bis-isobutryonitrile (AIBN) are added thereto, and then the [HSO3-bvim]HSO4 / SiO2 solid-acid catalyst is obtained after the reaction; and finally the target product of supported bi-functional catalyst is obtained after the reaction by adding chloroplatinic acid and an alcohol-water mixed solution in a weight ratio of 0.0001 to 0.01:1 of the metal platinum to the solid-acid catalyst. The supported bi-functional catalyst is used in the nitrobenzene catalytic hydrogenation synthesis p-aminophenol reaction, and has advantages of extreme high stability, high mechanical strength, abrasion resistance and low loss of active components.

Owner:HEBEI UNIV OF TECH

Solid base catalyst for preparing biodiesel

InactiveCN104107705AImprove conversion rateEfficient exchange reactionPhysical/chemical process catalystsFatty acid esterificationTransesterificationManganese

The invention discloses a solid base catalyst for preparing biodiesel. The solid base catalyst is prepared by adopting the method comprising the steps of respectively dissolving ZnCl2, MnCl2 and K2CO3 in deionized water; mixing a mixed solution of ZnCl2 and MnCl2 with a K2CO3 solution to obtain a sediment; and aging the sediment, then filtering, washing and drying, and then calcining to obtain a manganese carbonate / zinc oxide compound solid base catalyst, wherein raw materials comprise 5.7-8.5 parts by weight of ZnCl2, 10-16.5 parts of MnCl2, and 18-22 parts of K2CO3. The solid base catalyst disclosed by the invention is capable of efficiently catalyzing transesterification reaction under the reaction condition of subcritical methanol, wherein the conversion rate is maximally more than 99 percent. Meanwhile, the solid base catalyst has the advantages of heterogeneous catalysis and supercritical reaction, and is easy to separate; glycerinum and biodiesel are easily refined; the transesterification rate is high.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Ionic-like liquid and preparation method and application thereof in preparation of alkylated oil

ActiveCN105536866AStrong water resistanceHigh Lewis acidityOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsAlkaneIonic liquid

The invention provides an ionic-like liquid and a preparation method and an application thereof in preparation of alkylated oil. An amide compound undergoes a reaction with a first metal compound and more than one second metal compound to obtain the ionic-like liquid. With the ionic-like liquid as a catalyst, isoparaffin and olefin are subjected to an alkylation reaction, the ionic-like liquid is separated, and thus the alkylated oil is prepared. The ionic-like liquid has the advantages of easily obtained synthetic raw materials, simple synthetic method and cheap price, the alkylation reaction with the ionic-like liquid as the catalyst has high selectivity, and the proportion of C8 components and trimethyl pentane and the octane number of the alkylated oil are both greatly improved.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

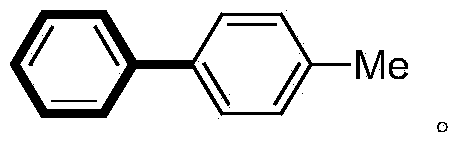

Synthesis method for biphenyl compounds

InactiveCN103804105AAvoid reunionMaintain catalytic activityCarboxylic acid nitrile preparationOrganic compound preparationSynthesis methodsOrganic synthesis

The invention relates to the field of organic synthesis, and discloses a synthesis method for biphenyl compounds. The method comprises the following steps: in the presence of an inorganic base, in a mixed solvent of ethanol and water, adding arylboronic acid, aryl halide and a heterogeneous catalyst ZrO2-Pd(OAc)2; reacting 30-180 min while the temperature is controlled at 60-120 DEG C; after reaction liquid is cooled to room temperature, filtering the reaction liquid, washing, and recovering the catalyst; adding a NaOH aqueous solution into filtrate, and carrying out extraction, drying and concentration on the obtained product so as to obtain a high-purity biphenyl compound. According to the invention, the heterogeneous catalyst ZrO2-Pd(OAc)2 which is high in catalytic activity and reusable is used for the first time, the quick coupling of aryl halide and arylboronic acid is realized by taking green and non-toxic ethanol and water as solvents under mild conditions, and then excessive arylboronic acid is removed by using the NaOH aqueous solution, so that the high-purity biphenyl compound is obtained. The method is good in catalytic effect, simple in operation, and environment-friendly.

Owner:SHAOXING UNIVERSITY

Preparation method of self-cleaning Bi2Ti2O7/TiO2 nanowire array composite film with visible-light response

InactiveCN104445995AThe synthesis method is simpleLow costCoatingsMetal/metal-oxides/metal-hydroxide catalystsComposite filmSynthesis methods

The invention discloses a preparation method of a self-cleaning Bi2Ti2O7 / TiO2 nanowire array composite film with visible-light response, relating to a preparation method of a nanowire array composite film. The invention aims at solving the problem that the glass cleaning of the modern high buildings needs to be completed manually so that the resources are consumed, relatively high risk exists and the elements of sunshine and rainwater cannot be utilized to maintain the surface cleaning. The preparation method comprises the following steps: 1, preparing a titanium dioxide nanowire array precursor film-loaded glass substrate; and 2, preparing a Bi2Ti2O7 / TiO2 nanowire array composite film so as to obtain the self-cleaning Bi2Ti2O7 / TiO2 nanowire array composite film with visible-light response. The preparation method is completed under simple hydrothermal conditions, so that the synthesis method is simple and the cost is low. According to the preparation method, the self-cleaning Bi2Ti2O7 / TiO2 nanowire array composite film with visible-light response can be obtained.

Owner:HEILONGJIANG UNIV

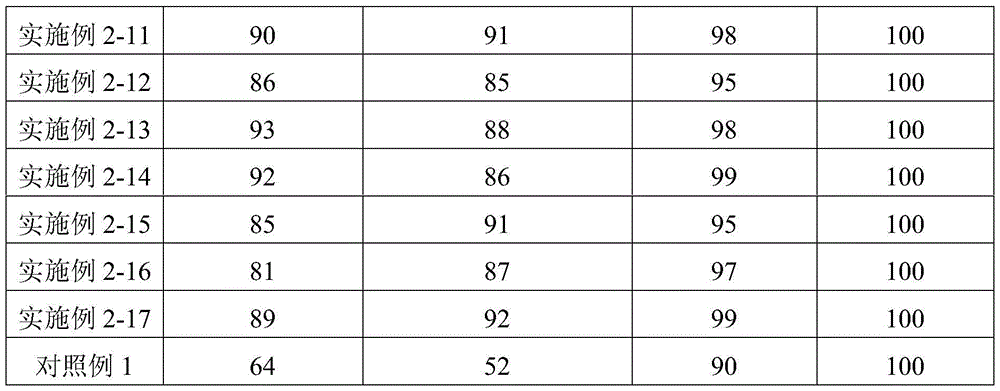

MOFs supported catalyst, preparation method thereof, and application in olefin hydrosilylation reaction

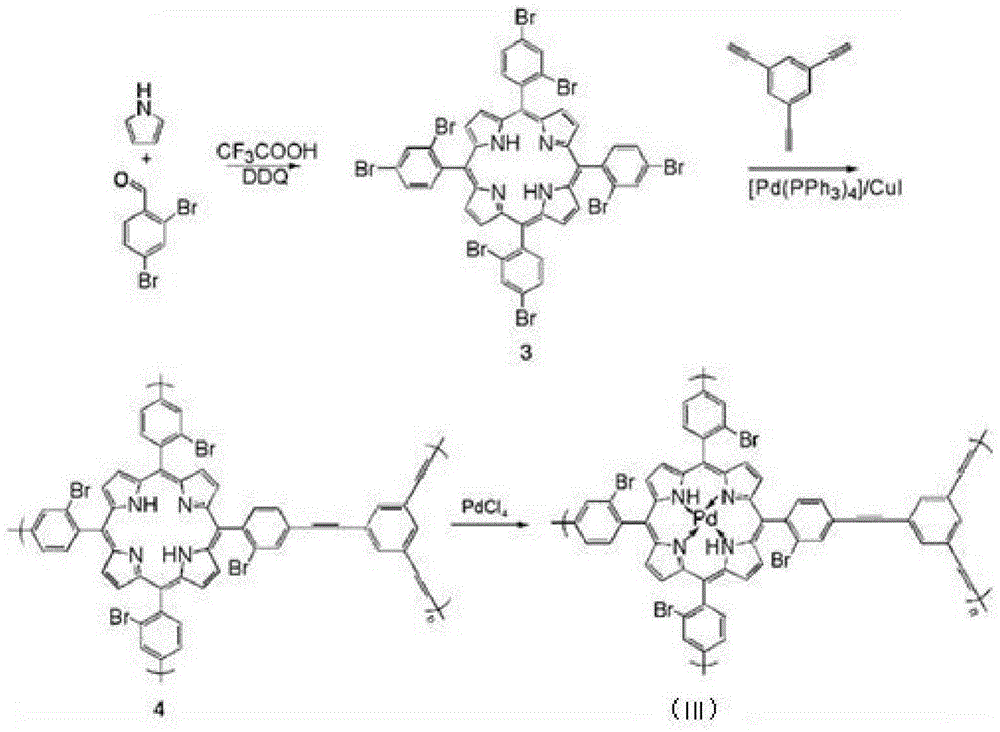

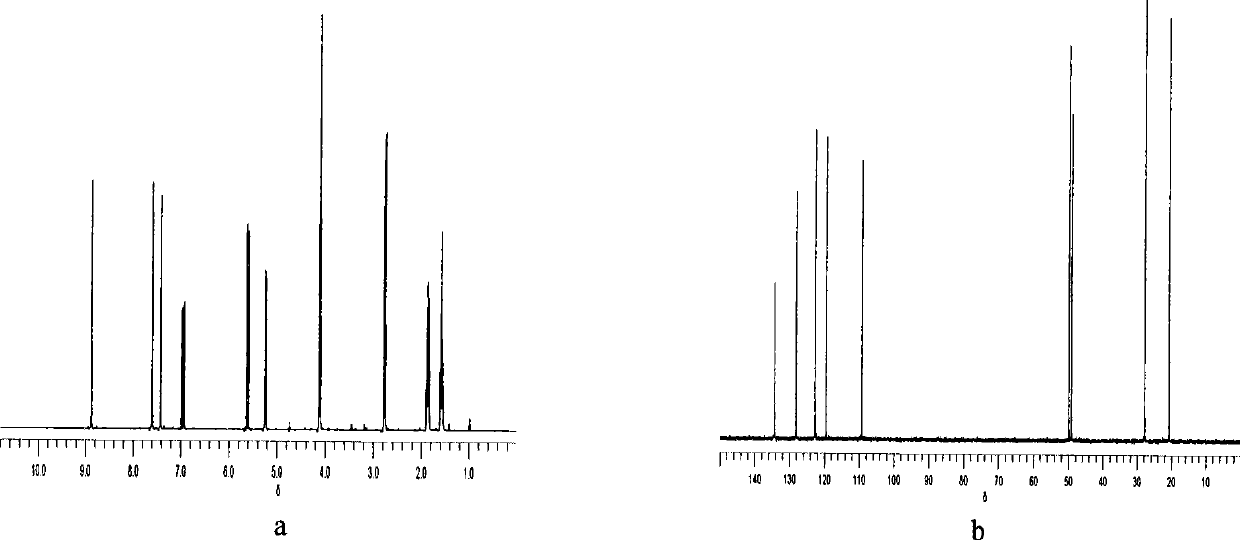

ActiveCN104907096AEfficient separationNo residueSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsOrganometallic catalysisBenzaldehyde

The invention belongs to the technical field of organic metal catalysis, and concretely relates to an MOFs supported catalyst, a preparation method thereof, and an application in an olefin hydrosilylation reaction. The catalyst has a structure represented by formula (I); and in the formula (I), M is metallic platinum, rhodium, palladium or ruthenium, and R1 and R2 can be H or Br, and can be same to or different from each other. The preparation method of the catalyst comprises the following steps: adding pyrrole, bromine-substituted benzaldehyde and a solvent into a reactor, adding trifluoroacetic acid and DDQ, and reacting to obtain an organic framework monomer; reacting the organic framework monomer with 1,3,5-triethynylbenzene to obtain an organic framework polymer; and reacting a homogeneous solution of the metallic platinum, rhodium, palladium or ruthenium with the organic framework polymer to obtain the catalyst. The MOFs supported catalyst can efficiently catalyze the hydrosilylation reaction of hydrogen-containing silane and olefin, can be recycled through a simple technology, and can effectively improve the utilization rate of precious metals.

Owner:GUANGZHOU TINCI MATERIALS TECH

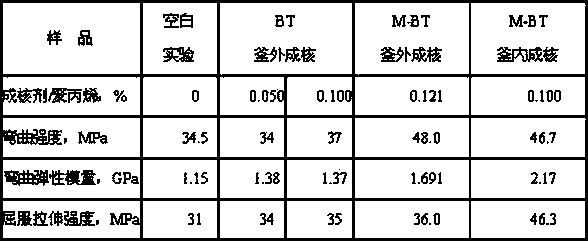

Nucleating agent modifying and preparing method of high-performance polypropylene

ActiveCN103724464AImprove performanceCatalytic activity does not decreaseElectron donorBULK ACTIVE INGREDIENT

The invention provides a nucleating agent modifying and preparing method of high-performance polypropylene. The method, under a circumstance of not changing polymerization conditions, can modify a nucleating agent or adopt special feeding ways to shield deactivated components after poisoning of a catalyst, so that active ingredients of the nucleating agent are completely released in reaction nucleating and polymerizing processes to the greatest extent; functional group of the modified nucleating agent is free from adverse effect on activity of a main catalyst and free from reaction with a catalyst promoter and an electron donor, so that catalytic activity is basically not reduced, and the modified polypropylene is excellent in performance and obvious in nucleating action in a kettle; the prepared polypropylene is high in comprehensive performance.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

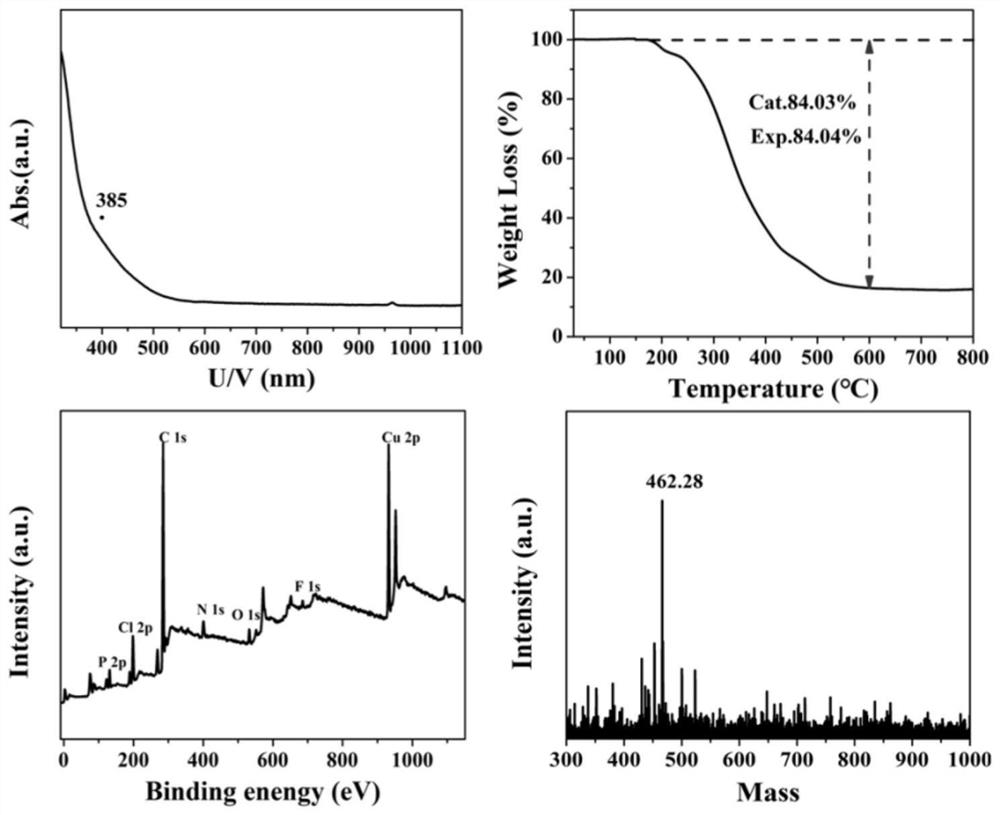

Non-noble metal copper-based catalyst and application thereof in benzylamine oxidative coupling reaction

PendingCN114011473AEasy to prepareStable performanceOrganic-compounds/hydrides/coordination-complexes catalystsCatalytic reactionsBenzylamineNon noble metal

The invention discloses a non-noble metal copper-based catalyst and application thereof in benzylamine oxidative coupling reaction, the non-noble metal copper-based catalyst is obtained by loading a copper complex on a gamma-Al2O3 carrier, the molecular formula of the copper complex is [Cu2 (C17H14NP) 2Cl4], and the molecular formula of the non-noble metal copper-based catalyst is Cu2 (C17H14NP) 2Cl4 / gamma-Al2O3, which is simply recorded as Cu2 / gamma-Al2O3. The Cu2 / gamma-Al2O3 catalyst can catalyze the oxidative coupling reaction of benzylamine under mild conditions, and meanwhile, the catalyst can be recycled for at least five times, the activity is kept unchanged, the substrate universality is relatively good, and the catalyst has very good practicability.

Owner:ANHUI UNIVERSITY

Metal and/or its oxide in situ doped silica compound and its use

ActiveCN104107715AHigh catalytic activityImprove catalytic selectivityHydrocarbon from carbon oxidesMolecular sieve catalystsIn situ dopingRare earth

The invention relates to a metal and / or its oxide in situ doped silica compound and its use. The target product is prepared through metal or / and its oxide in situ doping of a silica compound and a hydrothermal synthesis process, and the specific surface area (BET) of the target product is 100-800m<2> / g. 100% of the metal or / and its oxide in situ doped silica compound contains 1-20wt% of metallic nickel or / and its oxide, 0-5wt% of rare earth metals or / and oxides thereof, 0-10wt% of rare earths or / and oxides thereof, 0-5wt% of alkali metals or / and oxides thereof, and the balance silica. The invention also provides an application of the metal or / and its oxide in situ doped silica compound as a catalyst for preparing methane from synthetic gas.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of graphene/molecular sieve composite catalyst and preparation method thereof

ActiveCN106475131BStrong interfacial interactionHigh yieldMolecular sieve catalystsOrganic compound preparationMolecular sievePtru catalyst

The invention discloses a graphene / molecular sieve composite catalyst and a preparation method thereof. The composite catalyst comprises, by weight, 5-40% of graphene and 60-95% of molecular sieve. The composite material has a quasi-two-dimensional lamellar structure, the ratio of the area of a single lamella to the thickness of the single lamella is more than 100 micrometers, the molecular sieve is evenly loaded on the surface of the graphene, and mesopore diameter is 2-30 nanometers. The preparation method includes: mixing the graphene, a silicon source, an aluminum source and a surfactant, separating out a graphene-containing part, crystalizing, purifying, and removing the surfactant. The graphene / molecular sieve composite catalyst has the advantages that the composite catalyst serving as a solid acid catalyst has enhanced catalytic activity, product yield and reusability can be evidently increased while the catalytic activity is not lowered when the catalyst is used in CBG and EHB reaction, and accordingly the catalyst is promising in application prospect.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Lanthanum-silicon composite oxide catalyst and method for treating high-concentration formaldehyde wastewater by using lanthanum-silicon composite oxide catalyst

PendingCN114082414AEasy to prepareImprove stabilityWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSilicic acid

The invention relates to a lanthanum-silicon composite oxide catalyst and a method for treating high-concentration formaldehyde wastewater by using the lanthanum-silicon composite oxide catalyst, and belongs to the technical field of wastewater treatment. The lanthanum-silicon composite oxide catalyst is prepared by dropwise adding a lanthanum nitrate solution into an ethyl orthosilicate ethanol solution, reacting, drying and roasting. According to the prepared lanthanum-silicon composite oxide catalyst, the catalytic activity of the active component lanthanum oxide in the lanthanum-silicon composite oxide is improved, the activation energy of formaldehyde oxidation reaction is reduced, and the formaldehyde oxidation capability of potassium hydrogen persulfate is enhanced. The method comprises the following steps of: by taking the lanthanum-silicon composite oxide as a catalyst and potassium hydrogen persulfate as an oxidizing reagent, stirring and reacting at 25-45 DEG C for 5-60 minutes, and catalytically oxidizing formaldehyde into carbon dioxide and water. According to the method, high-concentration formaldehyde wastewater can be effectively treated, and the catalyst is easy to recover, reusable, environment-friendly, safe and non-toxic.

Owner:TAIYUAN INST OF TECH

In-situ metal-doped mesoporous molecular sieves and their uses

ActiveCN103803578BHigh activityGood choiceHydrocarbon from carbon oxidesMolecular sieve catalystsMolecular sieveEmulsion

The invention relates to a mesoporous molecular sieve of doped metal and an application thereof. The mesoporous molecular sieve is formed by mixing a template, an alkali source, a silicon source and a metal source at the molar ratio of (0.06-0.24):(0.1-0.3):1:(0.01-0.20), and stirring at 20-40 DEG C for 0.5-24 hours to obtain emulsion; carrying out hydrothermal reaction on the emulsion at 80-180 DEG C for at least 12 hours (or reacting in a microwave reactor at the power of 200-2100w for 1-10h), then successively cooling, filtering, washing to be neutral and drying to obtain solid matters; and roasting the solid matters at 400-800 DEG C for 1-15 hours to obtain the molecular sieve, wherein the molecular sieve has a specific area of (BET)200-1500m2 / g, pore volume of 0.5-3.0cm3 / g and aperture of 2-15nm. The mesoporous molecular sieve has catalytic activity at 200-550 DEG C and the catalytic activity does not decline after roasting at 700 DEG C for 20 hours. The molecular sieve can be used as a catalyst for reaction during methane preparation by synthesis gas, and has commercial value.

Owner:EAST CHINA UNIV OF SCI & TECH

Loaded dual-function catalyst and preparation method and use thereof

InactiveCN101391228BImprove stabilityGood repeatabilityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsM-aminophenolPtru catalyst

The invention provides a supported bi-functional catalyst as well as a preparation method and applications thereof, belonging to the catalyst containing platinum and an organic compound simultaneously. The catalyst has the compositions: an acidic ionic liquid of 1-vinyl-3-sulfobutyl imidazole hydrosulfate ([HSO3-bvim]HSO4), an active metal Pt and a carrier silica gel. The preparation method comprises the steps: the acidic ionic liquid of 1-vinyl-3-sulfobutyl imidazole hydrosulfate and the modified silica gel are added in a weight ratio of 0.05 to 1:1, then a mixed solution of solvent and deionized water as well as azo-bis-isobutryonitrile (AIBN) are added thereto, and then the [HSO3-bvim]HSO4 / SiO2 solid-acid catalyst is obtained after the reaction; and finally the target product of supported bi-functional catalyst is obtained after the reaction by adding chloroplatinic acid and an alcohol-water mixed solution in a weight ratio of 0.0001 to 0.01:1 of the metal platinum to the solid-acid catalyst. The supported bi-functional catalyst is used in the nitrobenzene catalytic hydrogenation synthesis p-aminophenol reaction, and has advantages of extreme high stability, high mechanical strength, abrasion resistance and low loss of active components.

Owner:HEBEI UNIV OF TECH

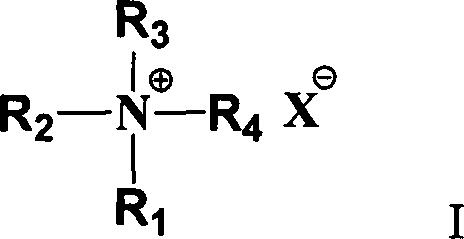

Homogeneous phase dual-function catalyst for synthesizing p-aminophenol and preparation and use method thereof

InactiveCN101391227BActs as an acid catalystEasy to prepareOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfateDistillation

The invention provides a homogeneous phase bi-functional catalyst used for the synthesis of p-aminophenol as well as a preparation and application process thereof, belonging to a platinum-bearing nano-particle and an acidic ionic liquid at the same time. The catalyst has the compositions: one active component: the acidic ionic liquid N, N, N-trimethyl-N-sulfobutyl-ammonium hydrogen sulfate, the other active component: the active metal Pt nano-particle, wherein, the acidic ionic liquid N, N, N-trimethyl-N-sulfobutyl-ammonium hydrogen sulfate and the metal Pt are present in a molar ratio of 1000 to 6000:1. The preparation method comprises: positioning the acidic ionic liquid N, N, N-trimethyl-N-sulfobutyl-ammonium hydrogen sulfate and chloroplatinic acid in three flasks, then adding alcoholand deionized water thereto, magnetically stirring the mixture for 0.5 to 5 hours, and finally preparing the catalyst after decompression and distillation. The homogeneous phase bi-functional catalyst used for the synthesis of p-aminophenol has advantages of mild process conditions, simple and convenient operation and rather high catalytic activity, the maximum nitrobenzene conversion rate can reach 100 percent, the maximum p-aminophenol yield is 90 percent, and the maximum p-aminophenol selectivity is 92 percent.

Owner:HEBEI UNIV OF TECH

Hydro-desulfurization and denitrification process of diesel oil

InactiveCN106350102ARealize synergistic improvementCatalytic activity does not decreaseMolecular sieve catalystsTreatment with hydrotreatment processesHydrodesulfurizationReaction temperature

The invention discloses a hydro-desulfurization and denitrification process of diesel oil. The hydro-desulfurization and denitrification process is characterized in that the process uses a fixed bed reactor filled with a hydro-desulfurization and denitrification catalyst, the hydro-desulfurization and denitrification catalyst comprises a carrier and an active component, the carrier is the compound or mixture of MSU-G, SBA-15 and HMS, and the active component is the mixture of dimolybdenum nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC; the reaction condition of the fixed bed reactor includes: reaction temperature is 320-360 DEG C, reaction pressure is 6-8MPa, hydrogen to oil volume ratio is 300-600, and volume space velocity is 1.0-2.5h<-1>. By the hydro-desulfurization and denitrification process, the total sulfur content of the diesel oil can be controlled to be lower than 5ppm, and the total nitrogen content of the diesel oil can be controlled within 10ppm at the same time.

Owner:锡山区绿春塑料制品厂

Synthesis method for calix [4] arenes substituted by 2-diphenylphosphine benzoyl and application

ActiveCN102408442BHigh synthesis efficiencyHigh yieldOrganic-compounds/hydrides/coordination-complexes catalystsGroup 5/15 element organic compoundsSynthesis methodsReaction speed

The invention discloses a synthesis method for calix [4] arenes substituted by 2-diphenylphosphine benzoyl as shown in drawings and discloses the application of calix [4] arenas serving as a catalyst in aza-Baylis-Hillman reaction for effectively preparing aza-Baylis-Hillman reaction affixture. The invention has the advantages of simple preparation technique for catalyst, low catalyst consumption, rapid reaction speed, gentle reaction conditions, etc.

Owner:ZHEJIANG UNIV OF TECH

Method for preparing high-modulus water glass from iron tailings

ActiveCN112408407AHigh catalytic activityCatalytic activity does not decreaseSolid waste managementAlkali metal silicatesPtru catalystEnvironmental engineering

The invention aims to improve the utilization rate of waste iron tailings, provides a method for preparing high-modulus water glass from iron tailings, and belongs to the technical field of water glass preparation. The method comprises the steps of 1) adding the iron tailings and liquid alkali into a reaction kettle in proportion, adding an activated catalyst SY-1, and carrying out closed reaction, wherein the catalyst SY-1 is a compound containing vanadium and phosphorus; and 2) filtering the material after the reaction is finished to obtain a liquid, namely, a water glass product with the modulus of 2.5-3.5. The method is low in energy consumption and simple to operate, and solves the environmental and recycling problems of the industrial solid waste iron tailings. The modulus range of the water glass prepared by the method is 2.5-3.5, so that the comprehensive utilization degree of the iron tailings is improved, and a new way is provided for effective utilization of silicon dioxidein the iron tailings.

Owner:ANSTEEL GRP MINING CO LTD

In-kettle nucleating method for preparing high-performance polypropylene

InactiveCN103772563AImprove performanceCatalytic activity does not decreasePolymer sciencePtru catalyst

The invention discloses an in-kettle nucleating method for preparing high-performance polypropylene. A defined amount of triethyl aluminum, an external electron donor, a nucleating agent, and a catalyst are added in a kettle, and react at a set temperature and a pressure, wherein the mol ratio of the catalyst to a cocatalyst to the external electron donor, namely Ti:Al:Si, is (1-20):(250-300):(20-100), the polypropylene is prepared through in-kettle nucleating; and the prepared polypropylene has modulus of elasticity in static bending of above 2 MPa, tensile strength of above 34 MPa, high combination property, and better economy and application values.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

Paraffin hydrofining process

InactiveCN106281461AReduce sulfur contentRealize synergistic improvementMolecular sieve catalystsPetroleum wax refiningParaffin waxChemistry

The invention discloses a paraffin hydrofining process. In the process, a fixed bed reactor is adopted and is filled with a hydrogenation desulfurization and denitrification catalyst, the catalyst comprises a carrier and an active component, the carrier is a compound or mixture of MSU-G, SBA-15 and HMS, the active component is a mixture of dimolybdenum nitride MO2N, tungsten nitride W2N, molybdenum carbide Mo2C and tungsten carbide WC, and reaction conditions of the fixed bed reactor are as follows: reaction temperature is 250-300 DEG C, hydrogen partial pressure is 2.8-3.6 MPa, hydrogen-paraffin volume ratio is 150-300, and volume space velocity is 0.6-2.0 h<-1>. By the process, the total sulfur content of paraffin can be controlled to be lower than 5 ppm, and meanwhile, the total nitrogen content in the paraffin is controlled to be within 10 ppm.

Owner:锡山区绿春塑料制品厂

Preparing method of denitration catalyst regeneration intensity repair fluid and repair fluid and regeneration denitration catalyst thereof

InactiveCN106345538AIncrease acidic sitesImprove the mechanical strength of the repairGas treatmentDispersed particle separationVanadyl sulfateAmmonium metavanadate

The invention provides a preparing method of denitration catalyst regeneration intensity repair fluid according to the problems existing in the conventional catalyst regeneration technology, comprising the steps of: (1) 8- 10 parts by weight of titanium dioxide containing tungsten or molybdenum, 2-3 parts of silica solution, 0.5-1 part of suspension from being mixed and stirred evenly with 70-100 parts of deionized water; (2) 0.05-0.1 part by weight of binder is then added in the suspension obtained in step (1), and stirred until the complete dissolution of the binder, after which the pH of the suspension is regulated as 1-3. Then 0.1-1 part by weight of ammonium metavanadate or vanadyl sulfate is added and ball ground to obtain the intensity repair liquid, and then the same is used for regenerating the inactivated denitration catalyst. The mechanical properties of the regenerated catalyst are improved obviously while the activity thereof is improved.

Owner:河南康宁特环保科技股份有限公司

A kind of mofs supported catalyst and its preparation method and its application in olefin hydrosilylation reaction

ActiveCN104907096BEfficient separationNo residueSilicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceOrganometallic catalysis

The invention belongs to the technical field of organic metal catalysis, and concretely relates to an MOFs supported catalyst, a preparation method thereof, and an application in an olefin hydrosilylation reaction. The catalyst has a structure represented by formula (I); and in the formula (I), M is metallic platinum, rhodium, palladium or ruthenium, and R1 and R2 can be H or Br, and can be same to or different from each other. The preparation method of the catalyst comprises the following steps: adding pyrrole, bromine-substituted benzaldehyde and a solvent into a reactor, adding trifluoroacetic acid and DDQ, and reacting to obtain an organic framework monomer; reacting the organic framework monomer with 1,3,5-triethynylbenzene to obtain an organic framework polymer; and reacting a homogeneous solution of the metallic platinum, rhodium, palladium or ruthenium with the organic framework polymer to obtain the catalyst. The MOFs supported catalyst can efficiently catalyze the hydrosilylation reaction of hydrogen-containing silane and olefin, can be recycled through a simple technology, and can effectively improve the utilization rate of precious metals.

Owner:GUANGZHOU TINCI MATERIALS TECH

Ion liquid catalyst for producing alkylated oil and its preparation method

InactiveCN100348320CReduce manufacturing costCatalytic activity does not decreaseOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon from saturated and unsaturated hydrocarbon additionBenzeneAlkyl transfer

Owner:BEIJING UNIV OF CHEM TECH

Self-cleaning bi with visible light response 2 ti 2 o 7 /tio 2 Preparation method of nanowire array composite thin film

InactiveCN104445995BThe synthesis method is simpleLow costCoatingsMetal/metal-oxides/metal-hydroxide catalystsComposite filmSynthesis methods

The invention discloses a preparation method of a self-cleaning Bi2Ti2O7 / TiO2 nanowire array composite film with visible-light response, relating to a preparation method of a nanowire array composite film. The invention aims at solving the problem that the glass cleaning of the modern high buildings needs to be completed manually so that the resources are consumed, relatively high risk exists and the elements of sunshine and rainwater cannot be utilized to maintain the surface cleaning. The preparation method comprises the following steps: 1, preparing a titanium dioxide nanowire array precursor film-loaded glass substrate; and 2, preparing a Bi2Ti2O7 / TiO2 nanowire array composite film so as to obtain the self-cleaning Bi2Ti2O7 / TiO2 nanowire array composite film with visible-light response. The preparation method is completed under simple hydrothermal conditions, so that the synthesis method is simple and the cost is low. According to the preparation method, the self-cleaning Bi2Ti2O7 / TiO2 nanowire array composite film with visible-light response can be obtained.

Owner:HEILONGJIANG UNIV

Hydrofining process of straight-run naphtha

InactiveCN106221733ARealize synergistic improvementCatalytic activity does not decreaseMolecular sieve catalystsTreatment with hydrotreatment processesNaphthaHydrogen

The invention discloses a hydrofining process of straight-run naphtha. The process is carried out with a fixed bed reactor filled with a hydrogenation desulfurization and denitrification catalyst that includes a carrier and an active component, wherein the carrier is a composite or a mixture of MSU-G, SBA-15 and HMS; and the active component is a mixture including Mo2N, W2N, Mo2C and WC. Reaction conditions of the fixed bed reactor are described as follows: reaction temperature is 250-300 DEG C, partial pressure of hydrogen is 1.5-2.0 MPa, hydrogen-oil volume ratio is 80-150 and volume space velocity is 9-14 / h. The process can control the total sulfur content of the straight-run naphtha to be lower than 0.5 ppm.

Owner:锡山区绿春塑料制品厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Synthesis method for calix [4] arenes substituted by 2-diphenylphosphine benzoyl and application Synthesis method for calix [4] arenes substituted by 2-diphenylphosphine benzoyl and application](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/3529f735-cf12-48ee-8e44-266c9bbb44d6/BDA0000098423770000021.PNG)

![Synthesis method for calix [4] arenes substituted by 2-diphenylphosphine benzoyl and application Synthesis method for calix [4] arenes substituted by 2-diphenylphosphine benzoyl and application](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/3529f735-cf12-48ee-8e44-266c9bbb44d6/BDA0000098423770000031.PNG)

![Synthesis method for calix [4] arenes substituted by 2-diphenylphosphine benzoyl and application Synthesis method for calix [4] arenes substituted by 2-diphenylphosphine benzoyl and application](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/3529f735-cf12-48ee-8e44-266c9bbb44d6/BDA0000098423770000032.PNG)