A kind of graphene/molecular sieve composite catalyst and preparation method thereof

A composite catalyst and graphene technology, applied in molecular sieve catalysts, including molecular sieve catalysts, carbon compound catalysts, etc., can solve the problems of HZSM-5 and graphene acid catalytic activity and catalytic performance that have not been reported, and achieve enhanced The effect of catalytic activity and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

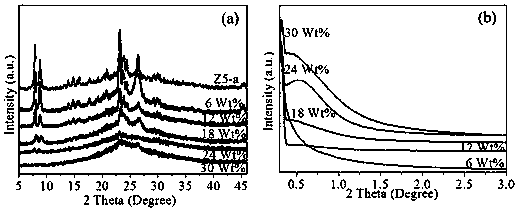

Embodiment 1

[0059] In this example, mesoporous ZSM-5 / graphene composites were prepared in the following manner, and the steps are as follows.

[0060] Weigh 120 mg of graphene, add 6 ml of deionized water, ultrasonically disperse evenly, weigh 1 g of tetrapropylammonium hydroxide and add it to the graphene aqueous solution, stir for 30 min to mix evenly, and record it as A solution; Add 60 mg of aluminum isopropoxide and 2 ml of tetraethyl orthosilicate in sequence and stir evenly, and record it as solution B; firstly stir solution B at 30 °C for 1 h, then raise the temperature to 90 °C and stir for 24 h; then use this solution B with After repeated washing with ethanol and deionized water for 2 to 3 times, it was transferred to a polytetrafluoroethylene-lined autoclave for crystallization at 180 °C for 3 days to obtain ZSM-a / graphene composites. After the product was washed with ethanol and deionized water for 3–5 times, it was vacuum-dried at 100 °C for 12 h, calcined at 600 °C for 5 h,...

Embodiment 2

[0064] Weigh 120 mg of graphene, add 8 ml of deionized water, ultrasonically disperse evenly, weigh 2 g of tetrapropylammonium hydroxide and add it to the graphene aqueous solution, stir for 30 min to mix evenly, and record it as A solution; Add 13.4 mg of sodium metaaluminate and 2 ml of tetraethyl orthosilicate in sequence and stir evenly, and record it as solution B; first stir solution B at 30 °C for 1 h, then at 60 °C for 2 h, then raise the temperature to 80 °C and stir for 6 h, then The B solution was repeatedly washed with ethanol and deionized water for 2 to 3 times, and then transferred to a polytetrafluoroethylene-lined autoclave for crystallization at 170 °C for 2 days to obtain the ZSM-b / graphene composite. After the product was washed with ethanol and deionized water for 3–5 times, it was vacuum-dried at 100 °C for 12 h, calcined at 600 °C for 5 h, and then treated with 0.2 mol / L NH 4 NO 3 The solution was exchanged at 80 °C for 6 h, and then washed, dried, and ...

Embodiment 3

[0069]Weigh 120 mg of graphene, add 6 ml of deionized water, ultrasonically disperse evenly, weigh 3.7 g of tetrapropylammonium hydroxide and add it to the graphene aqueous solution, stir for 30 min to mix evenly, and record it as A solution; Add 222 mg of aluminum isopropoxide and 7.4 ml of tetraethyl orthosilicate in sequence and stir evenly, and record it as solution B; firstly stir solution B at 30 °C for 1 h, then raise the temperature to 90 °C and stir for 24 h; then use this solution B with After repeated washing with ethanol and deionized water for 2 to 3 times, it was transferred to a polytetrafluoroethylene-lined autoclave for crystallization at 180 °C for 3 days to obtain ZSM-a / graphene composites. After the product was washed with ethanol and deionized water for 3–5 times, it was vacuum-dried at 100 °C for 12 h, calcined at 600 °C for 5 h, and then treated with 0.2 mol / L NH 4 NO 3 The solution was exchanged at 80°C for 6 h, and then washed, dried, and calcined to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com