Cellulose nano fiber/polylactic acid composite material and preparation method thereof

A technology of nanofibers and composite materials, which is applied in the field of cellulose nanofiber/polylactic acid composite materials and its preparation, can solve the problems of certain difficulty in industrial scale-up and high requirements for experimental conditions, achieve fine size, improve hydrophobicity, and improve Dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] As shown in the figure, a cellulose nanofiber / polylactic acid composite material and its preparation method, the cellulose nanofiber / polylactic acid composite material includes the following components in weight percentage: polylactic acid: 60-99wt%, Cellulose nanofibers: 1-40wt%, other additives: 0.1-40wt%, characterized in that it comprises the following steps:

[0029] 1) Put the quantitative cellulose nanofiber puree in a flask, pour an appropriate amount of organic solvent, ultrasonically oscillate and stir for a period of time and then filter, repeat the process of stirring, dispersing and filtering 1 to 5 times until the organic solvent dissolves the cellulose nanofiber Most of the water in the fiber pulp is replaced, and the last filtration is to obtain a cellulose nanofiber filter cake;

[0030] 2) Place the cellulose nanofiber filter cake obtained in step 1) in a flask, add an appropriate amount of toluene solvent, ultrasonically oscillate and stir for a perio...

Embodiment 1

[0044] Take 10g of MFC puree into a three-necked flask, add 50ml of acetone, ultrasonically and mechanically stir for 2 hours, filter the resulting suspension with a Buchner funnel, add the filter cake into a three-necked flask, repeat the above steps three times, and finally obtain an MFC filter cake. Put this filter cake into a three-necked flask, add 50ml of toluene, stir and filter according to the above steps, and repeat twice. Then put the obtained filter cake into a three-necked flask, add 50ml of toluene, add 37.77g of acetic anhydride and 1.46g of pyridine, and react at 105°C for 2h. After the reaction is completed, filter, and the obtained filter cake is repeatedly washed with toluene solution to obtain acylated modified MFC (MMFC).

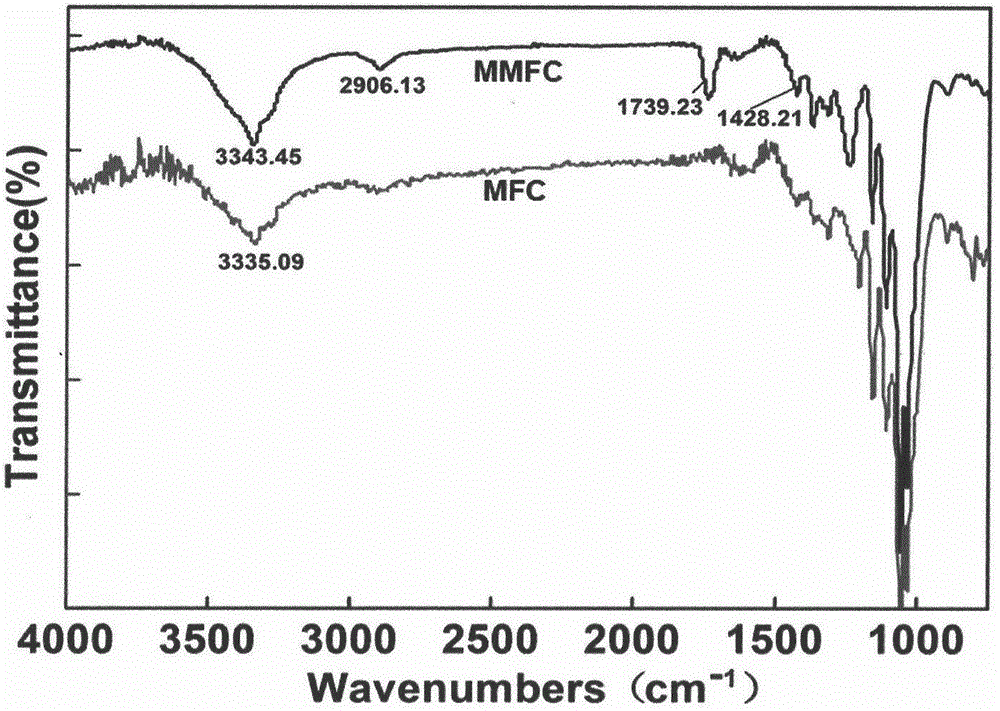

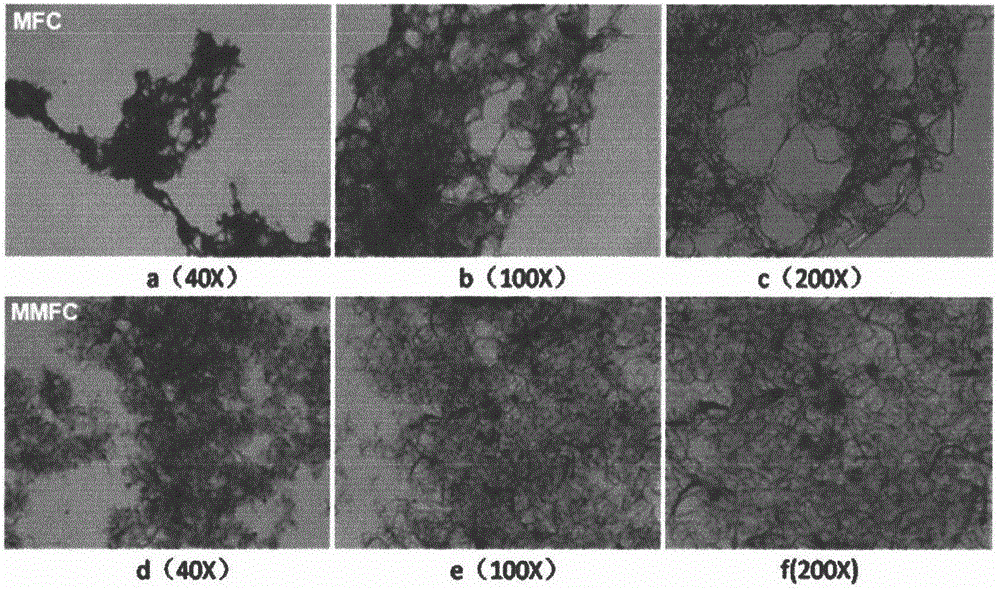

[0045] Dry the untreated MFC and MMFC for infrared analysis, figure 1 It is the FTIR spectrum of MFC and MFC after acylation, at 2906cm -1 , the acylated MFC has the C-H stretching vibration absorption peak of the methyl group, and at...

Embodiment 2

[0047] Take 10g of MFC puree into a three-necked flask, add 50ml of acetone, ultrasonically and mechanically stir for 2 hours, filter the resulting suspension with a Buchner funnel, add the filter cake into a three-necked flask, repeat the above steps three times, and finally obtain an MFC filter cake. Put this filter cake into a three-necked flask, add 50ml of toluene, stir and filter according to the above steps, and repeat twice. Then the obtained filter cake was added into a three-necked flask, 50 ml of toluene was added, 37.77 g of acetic anhydride and 1.46 g of pyridine were added, and the mixture was reacted at 105°C. A total of four groups of experiments were carried out, and the reaction times were 30min, 1h, 2h, and 10h. After the reaction is completed, filter, and the obtained filter cake is repeatedly washed with toluene solution to obtain acylated modified MFC.

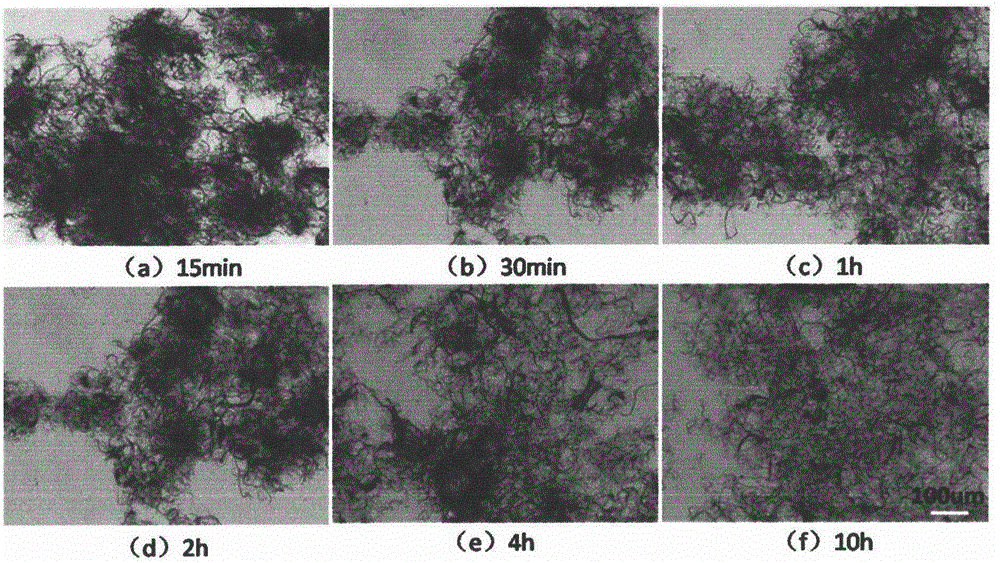

[0048] Take a small amount of the above-mentioned test samples, stir ultrasonically to evenly dispers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com