Rapid cooling solidification fine crystal device and welding method for thin plate NiTi alloy electron beam welding

An electron beam welding, rapid cooling and solidification technology, applied in the direction of electron beam welding equipment, welding/welding/cutting items, auxiliary devices, etc., can solve problems such as coarse grains, reduce violent evaporation, reduce spatter, increase The effect of contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

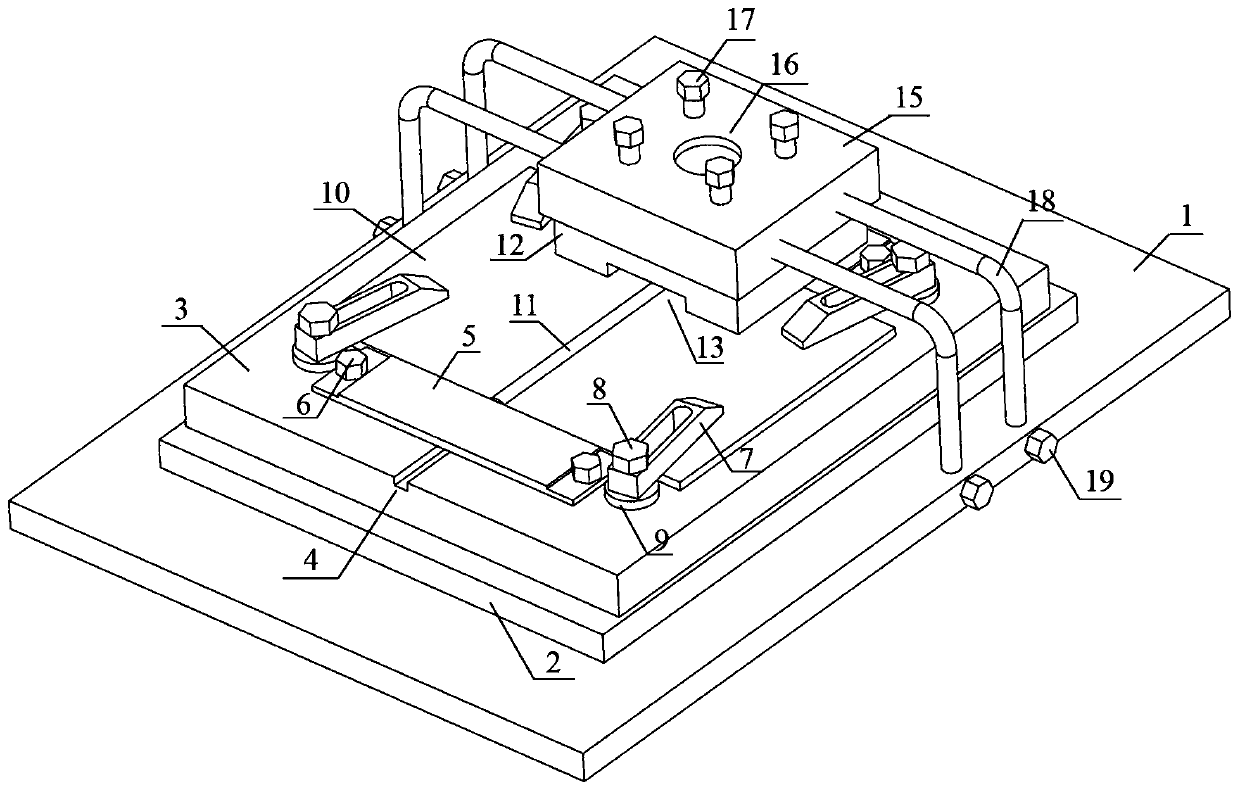

[0027] Specific implementation mode one: combine Figure 1 to Figure 3 This embodiment is described. This embodiment is a thin-plate NiTi alloy electron beam welding rapid cooling and solidification fine-grain device, which includes a clamping body, a cooling copper 12 and a cooling copper fastening mechanism. The cooling copper 12 is arranged on the cooling copper fastening mechanism. Immediately above the snap grip body.

[0028] The welding object to be welded by the device 10 is a thin plate weldment, its length l can range from 85mm to 105mm, its width w can range from 125mm to 145mm, and its thickness h can range from 2mm to 5mm; the length, width and height of the device The ranges are L (300mm ~ 400mm), W (218mm ~ 225mm), H (80mm ~ 90mm).

specific Embodiment approach 2

[0029] Specific implementation mode two: combination figure 1 Describe this embodiment. This embodiment is a press-and-grab type clamp that specifically includes a clamp body 3, two support baffles 5 and four pressure grips 7. The middle parts of the upper end of the clamp body 3, the front, the rear, and both sides are respectively fixed with a support baffle. Plate 5, each supporting baffle plate 5 is provided with a pressure catch 7 on the outer side of both ends respectively, and the root of the pressure catch 7 is fixed on the upper end surface of the fixture main body 3 through fastening bolts 8 . The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0030] In this embodiment, when assembling the base metal 10 to be welded, the press-and-grab clamp body puts the base metal 10 close to the support baffle 5 on one side, and keeps a distance of 9 to 10 mm from the support baffle 5 on the other side. .

[0031] In this embod...

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 This embodiment will be described. In this embodiment, the middle part of the upper end surface of the clamp main body 3 is provided with a protective groove 4 along the length direction. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

[0033] The size of the protective groove 4 in this embodiment is 5mm×3mm×200mm. The protection groove 4 can prevent the electron beam from penetrating the sample and acting on the fixture, so as to protect the fixture main body 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com