Ceramic microcrystal diamond wheel for grinding titanium alloy and preparation method thereof

A technology of ceramic microcrystals and titanium alloys, applied in grinding/polishing equipment, grinding devices, metal processing equipment, etc., can solve the problems of reduced surface integrity, grinding of titanium alloy materials, and low durability of grinding wheels, achieving Increased strength, low grinding cost, and high grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

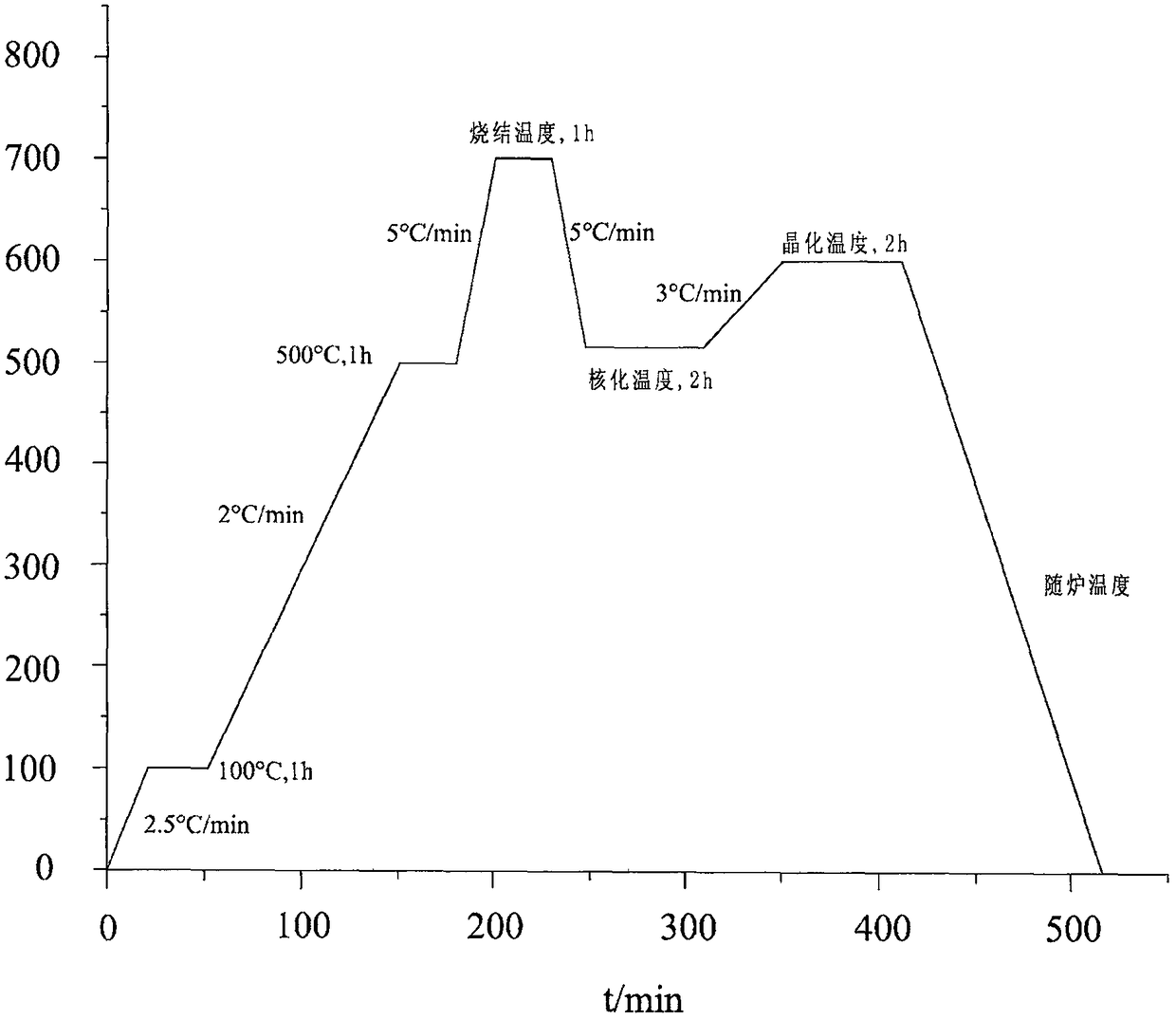

Embodiment 1

[0035] The present embodiment adopts following proportioning and process step to realize:

[0036] 1) The honeycomb diamond abrasive has a particle size of 170 / 200#, and its size distribution is tested by a particle size analyzer in accordance with GB / T6406 distribution.

[0037] 2) Preparation of ceramic microcrystalline binder: keep the following chemical reagents in parts by weight at 1500°C for 3 hours, then pour them into water for quenching, dry at 70°C for 10 hours, and put them into a planetary ball mill corundum In the tank, add zirconia ball mixture at the same time, and the zirconia ball mixture is formed by mixing φ15mm and φ10mm zirconia balls with a weight ratio of 1:1, wherein the zirconia ball mixture is 23.3 parts , after grinding for 20 hours, filter through a 500-mesh sieve for later use.

[0038]

[0039] 3), dextrin liquid: add cyclodextrin powder to boiling distilled water, stir evenly, and cool naturally for later use. The mass ratio of cyclodextrin ...

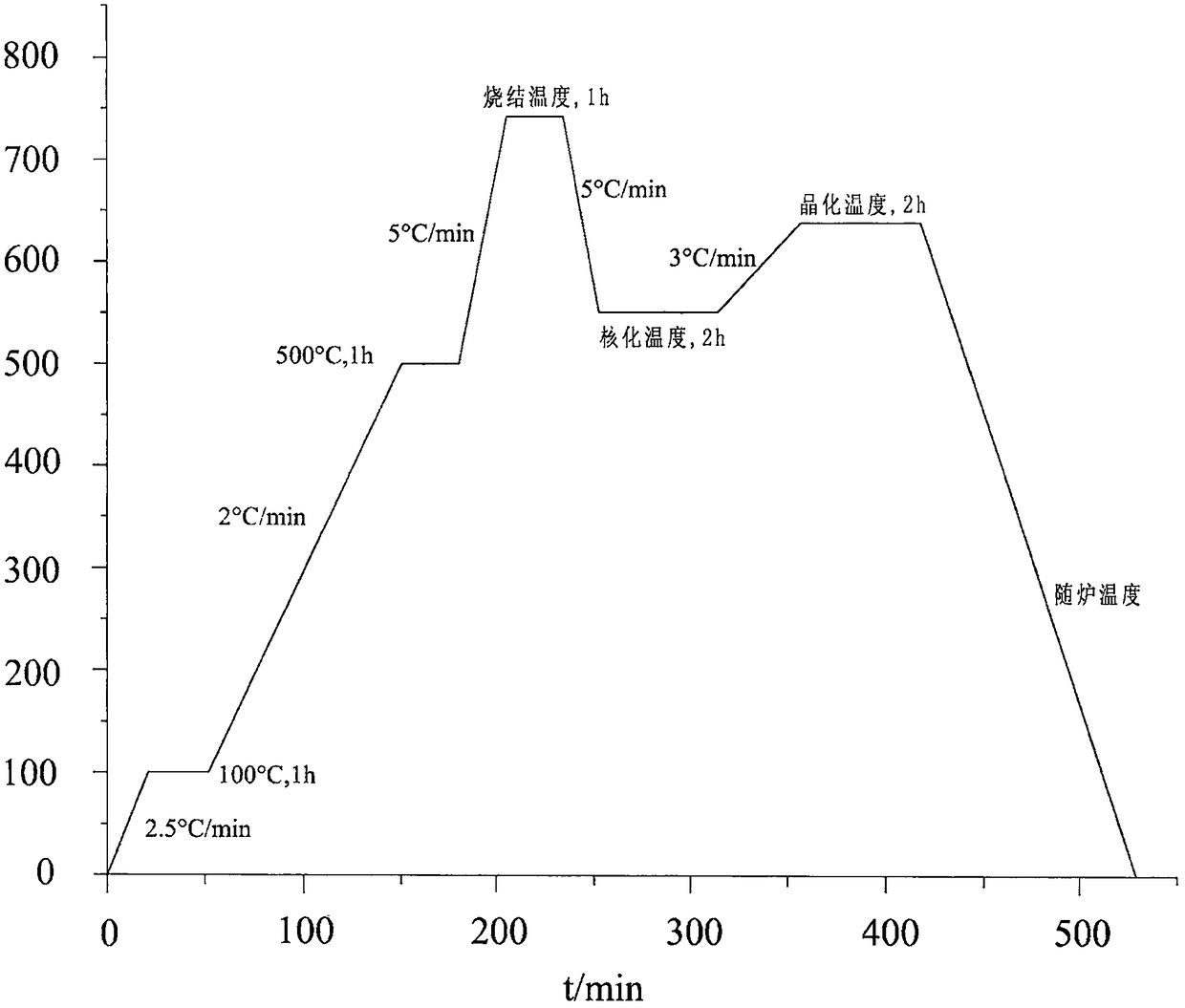

Embodiment 2

[0047] The present embodiment adopts following proportioning and process step to realize:

[0048] 1) The honeycomb diamond abrasive has a particle size of 170 / 200#, and its size distribution is tested by a particle size analyzer in accordance with GB / T6406 distribution.

[0049]2) Preparation of ceramic microcrystalline binder: keep the following chemical reagents in parts by weight at 1500°C for 3 hours, then pour them into water for quenching, dry at 70°C for 10 hours, and put them into a planetary ball mill corundum In the tank, add zirconia ball mixture at the same time, the zirconia ball mixture is mixed by φ15mm and φ10mm zirconia balls with a weight ratio of 1:1, wherein the zirconia ball mixture is 52 parts , after grinding for 20 hours, filter through a 500-mesh sieve for later use.

[0050]

[0051] 3), phenolic resin liquid: add phenolic resin powder to boiling distilled water, stir evenly, cool naturally for later use, the mass ratio of described phenolic resi...

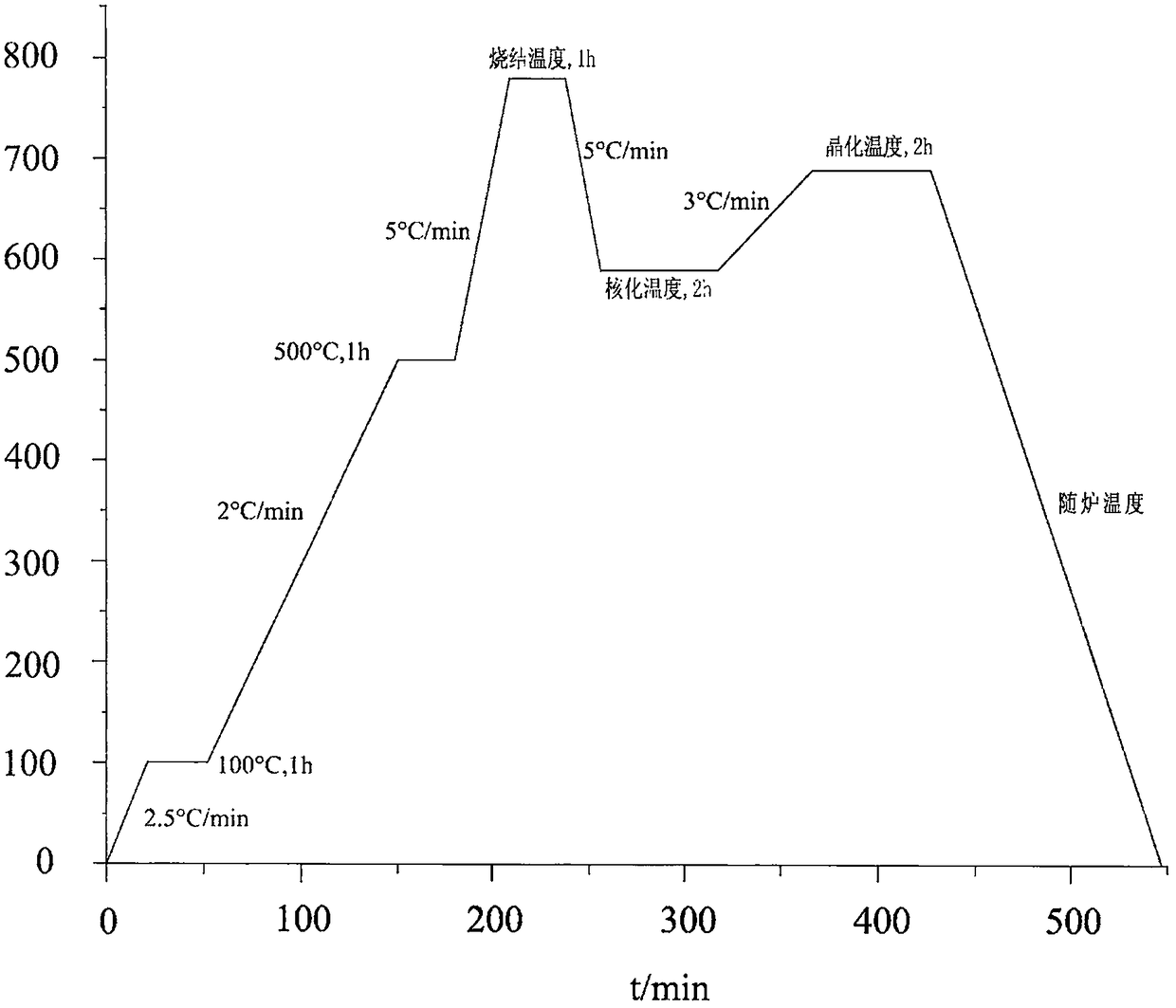

Embodiment 3

[0059] The present embodiment adopts following proportioning and process step to realize:

[0060] 1) The honeycomb diamond abrasive has a particle size of 170 / 200#, and its size distribution is tested by a particle size analyzer in accordance with GB / T6406 distribution.

[0061] 2) Preparation of ceramic microcrystalline binder: keep the following chemical reagents in parts by weight at 1500°C for 3 hours, then pour them into water for quenching, dry at 70°C for 10 hours, and put them into a planetary ball mill corundum In the tank, add zirconia ball mixture at the same time, the zirconia ball mixture is mixed by φ15mm and φ10mm zirconia balls with a weight ratio of 1:1, wherein the zirconia ball mixture is 35 parts , after grinding for 20 hours, filter through a 500-mesh sieve for later use.

[0062]

[0063] 3), dextrin liquid: add cyclodextrin powder to boiling distilled water, stir evenly, and cool naturally for later use, the mass ratio of described cyclodextrin powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com