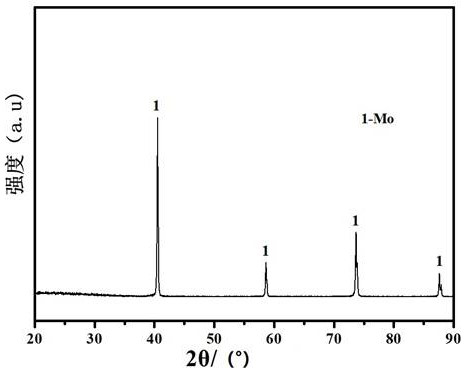

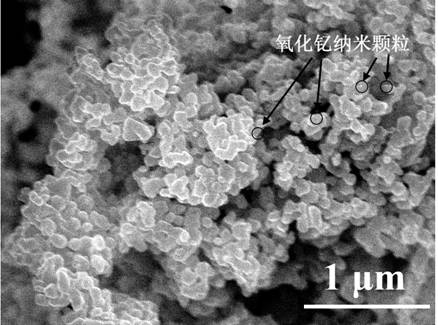

Preparation method and application of nano-molybdenum powder doped with yttrium oxide nano-particles

A nanoparticle and nanomolybdenum powder technology, applied in the direction of nanotechnology, can solve the problems of large particle size, poor uniformity, high efficiency and low-cost preparation of nanomolybdenum powder, so as to achieve fine particle size and increase the number of nucleation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

[0033] Step 1. Ultrasonic dispersion of commercial micron-sized molybdenum trioxide and carbon nanoparticles in ethanol solution with the assistance of surfactant PVP, and then stirring and evaporating to dryness at 70°C to obtain composite powder;

[0034] The average particle size of the commercial micron grade molybdenum trioxide is 4.5 μm, and the mass purity is 99.8%;

[0035] The average particle size of the carbon nanoparticle is 20nm, and the mass content of carbon in the carbon nanoparticle is 99%, and the added quality of the carbon nanoparticle is 4.0% of the commercial micron grade molybdenum trioxide quality; the surfactant PVP The added quality is 0.3% of the total mass of carbon nanoparticles and commercial micron molybdenum trioxide;

[0036] Step 2: Use an ultrasonic nano atomizer to ultrasonically atomize 0.02g / mL of yttrium nitrate solution into ultrafine / nano yttrium salt droplets, and then add 15mL of...

Embodiment 2

[0043] This embodiment includes the following steps:

[0044] Step 1. Ultrasonic dispersion of commercial micron-sized molybdenum trioxide and carbon nanoparticles in ethanol solution with the assistance of surfactant PEG-1000, and then stirring and evaporating to dryness at 75°C to obtain composite powder;

[0045] The average particle size of the commercial micron grade molybdenum trioxide is 1.5 μm, and the mass purity is 99.99%;

[0046] The average particle size of the carbon nanoparticles is 10nm, and the mass content of carbon in the carbon nanoparticles is 99.5%, and the added quality of the carbon nanoparticles is 3.8% of the commercial micron grade molybdenum trioxide quality; the surfactant PEG- The added quality of 1000 is 0.2% of the total mass of carbon nanoparticles and commercial micron-sized molybdenum trioxide;

[0047] Step 2: Use an ultrasonic nano atomizer to ultrasonically atomize 0.01g / mL of yttrium nitrate solution into ultrafine / nano yttrium salt drop...

Embodiment 3

[0052] This embodiment includes the following steps:

[0053] Step 1. Ultrasonic dispersion of commercial micron-sized molybdenum trioxide and carbon nanoparticles in ethanol solution with the assistance of surfactant PVP, and then stirring and evaporating to dryness at 70°C to obtain composite powder;

[0054] The average particle size of the commercial micron grade molybdenum trioxide is 1.5 μm, and the mass purity is 99.99%;

[0055] The average particle size of the carbon nanoparticle is 20nm, and the mass content of carbon in the carbon nanoparticle is 99%, and the added quality of the carbon nanoparticle is 3.9% of the commercial micron grade molybdenum trioxide quality; the surfactant PVP The added quality is 0.3% of the total mass of carbon nanoparticles and commercial micron molybdenum trioxide;

[0056] Step 2: Use an ultrasonic nano atomizer to ultrasonically atomize 0.03g / mL of yttrium nitrate solution into ultrafine / nano yttrium salt droplets, and then add 20mL o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com