Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

76results about How to "Improve willfulness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

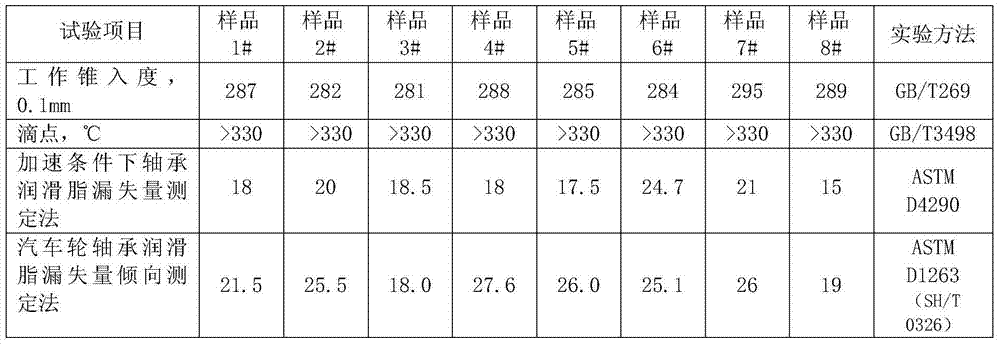

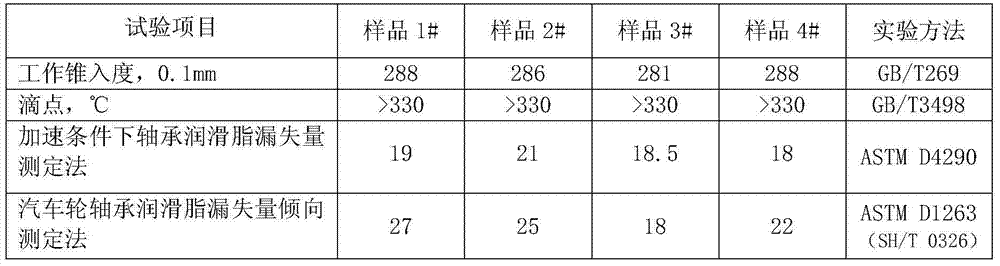

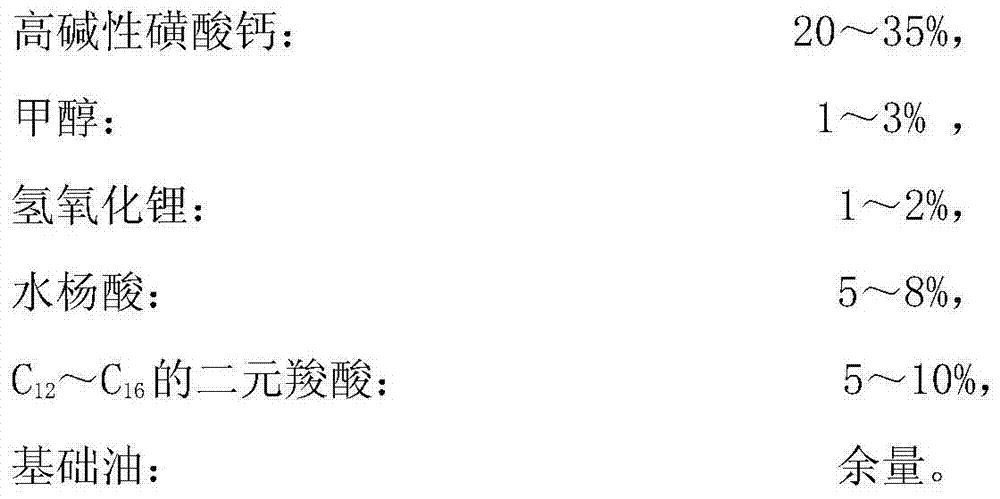

Composition of compound calcium sulfonate-based lubricating grease for improving high-temperature performance and preparation method thereof

InactiveCN104327906AGood high temperature resistanceImprove retentionThickenersTemperature resistanceSalicylic acid

The invention relates to a composition of compound calcium sulfonate-based lubricating grease for improving high-temperature performance and a preparation method thereof. The composition is prepared from a high-alkalinity calcium sulfonate cleaner, methanol, lithium hydroxide, salicylic acid, C12-C16 salicylic acid and base oil. The lubricating grease provided by the invention has relatively good high-temperature resistance and meets the seepage loss of ASTM D4290 and ASTM D1263 (industrial standard is SH / T0326). Experiments show that the seepage loss ranges from 5 to 10 which is obviously better than that (15-35g) of marketed products. The improving method provided by the invention can be used for prolonging the retentivity of the lubricating grease in a friction pair so as to ensure the operating reliability of equipment. The high-temperature performance of the prepared sample is obviously better than that of the marketed products.

Owner:CHINA PETROLEUM & CHEM CORP

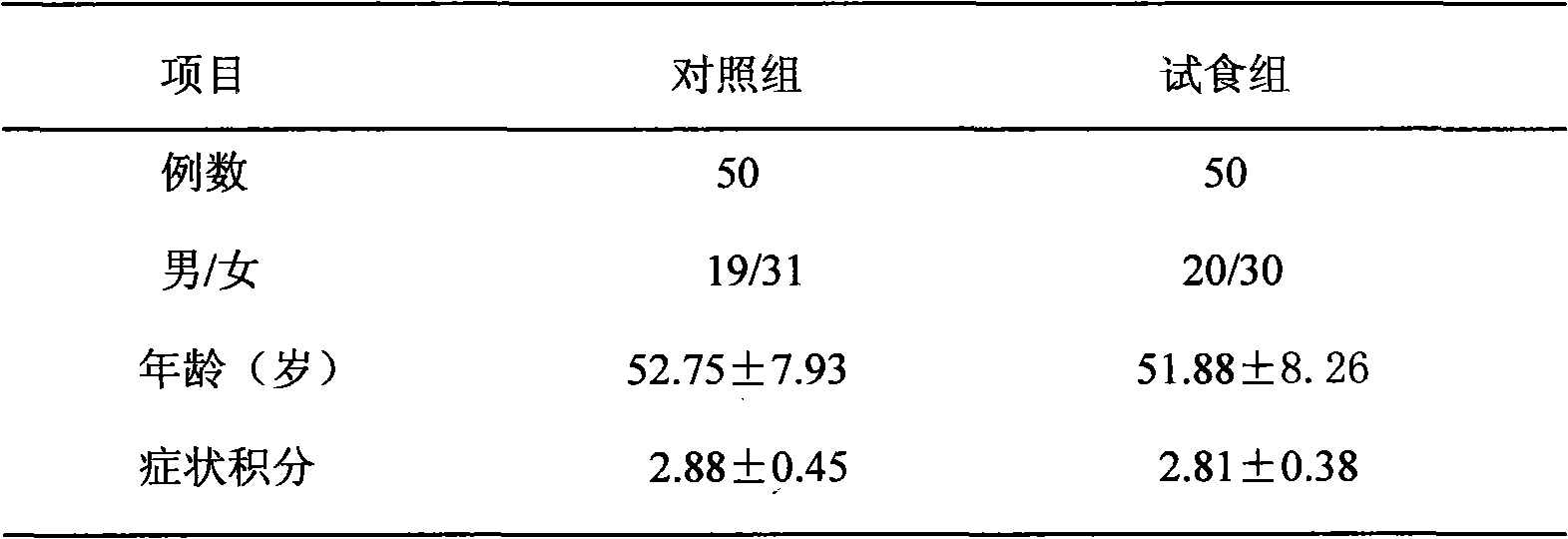

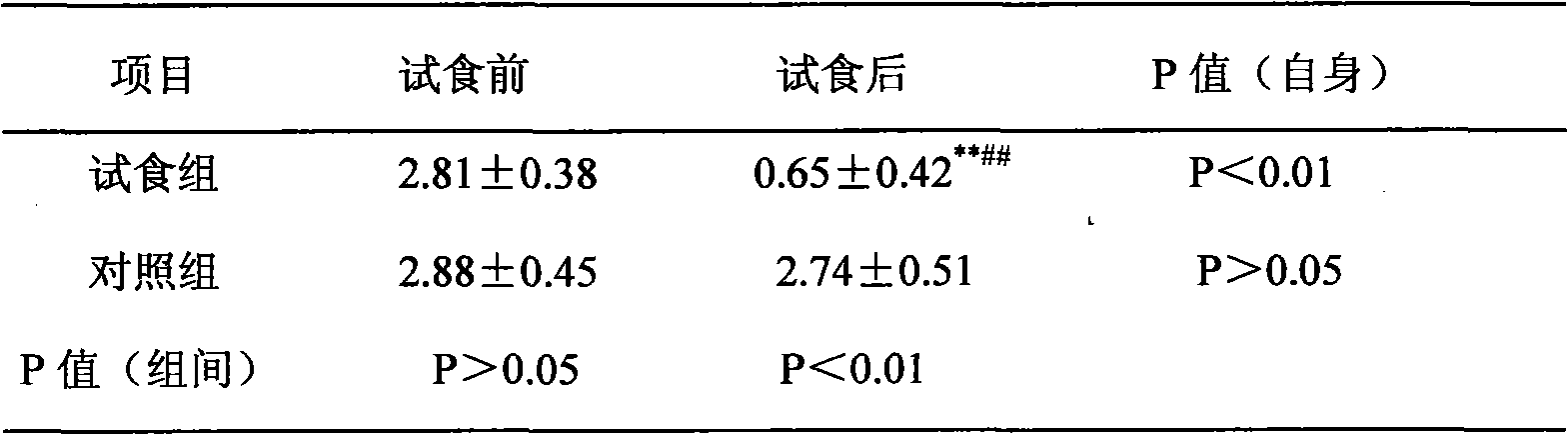

Preparation for increasing bone mineral density, preventing osteoarthrosis and enhancing immunity

InactiveCN102178934APromote absorptionAnti agingOrganic active ingredientsPeptide/protein ingredientsBone densityAdditive ingredient

The invention provides a health care food used for increasing bone mineral density, preventing osteoarthrosis and enhancing immunity. The health care food is prepared from the following materials in parts by mass: 1500-2500 parts of marine fish bone collagen oligopeptide, 1500-2500 parts of fish bone powder, 200-400 parts of eucommia bark extract and 0.005-0.01 part of vitamin D and a proper amount of pharmaceutic adjuvants such as xylitol, dry skim milk, vegetable fat powder, essences, trichlorosucrose and the like. The health care food is prepared into a granular preparation by the following process steps of: premixing, granulating, total mixing and the like. The invention has the beneficial effects that the raw materials, i.e., marine fish bone collagen oligopeptide and fish bone whichcontain a large quantity of peptide, bone collagen and calcium, work together with eucommia bark extract and vitamin D in the health care food so that a human body can absorb effective ingredients better to increase bone mineral density, slow down bone marrow aging, enhance toughness of bones, and prevent and treat osteoporosis; in addition, peptide also has the functions of adjusting immunity and resisting bacteria and oxidation, thereby improving the immunity of the human body.

Owner:WEIHAI BOLI BIOLOGICAL ENG +1

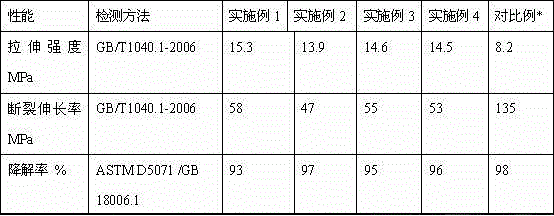

High-strength thermoplastic starch composite material and preparation method thereof

The invention discloses a high-strength thermoplastic starch composite material. The material comprises the following components in parts by mass: 25-35wt% of thermoplastic starch, 5-15wt% of calcium carbonate, 15-30wt% of hemicelluloses, 5-15wt% of vegetable protein, 15-30wt% of polyethylene, and 3-8wt% of auxiliaries. The invention further discloses a preparation method of the high-strength thermoplastic starch composite material at the same time. The preparation method comprises the steps of modifying the calcium carbonate, pre-treating the hemicelluloses, premixing and forming processing. The obtained composite material is good in mechanical property, high in strength, environment-friendly and easy to degrade.

Owner:SUZHOU YUNSHU NEW MATERIAL TECH

High-strength high-toughness ultra-fine grain wrought aluminum alloy and preparation method thereof

The invention discloses high-strength high-toughness ultra-fine grain wrought aluminum alloy. The high-strength high-toughness ultra-fine grain wrought aluminum alloy is prepared from, by weight, 0.4%-0.8% of Si, 0.6%-0.8% of Fe, 0.15%-0.35% of Cu, 0.10%-0.20% of Mn, 0.8%-1.2% of Mg, 0.15%-0.35% of Cr, 0.15%-0.35% of Zn, 0.1%-0.3% of Ti and the balance Al. The invention further provides a preparation method of the high-strength high-toughness ultra-fine grain wrought aluminum alloy. The prepared aluminum alloy has excellent strength and toughness.

Owner:TONGLING ZEHUI ELECTRONICS

Selenium-enriched dark-red enameled pottery pug and preparation method thereof

InactiveCN111410511AGood health effectEnhance immune functionClaywaresPhysical chemistryDistilled water

The invention discloses a selenium-rich dark-red enameled pottery pug and a preparation method thereof. The dark-red enameled pottery pug comprises the following raw materials: dark-red enameled pottery pug, selenium powder, a selenium powder stabilizer, medical stone powder, tourmaline powder and mineral substance powder. The preparation method of the dark-red enameled pottery pug comprises the following steps: selecting a dark-red enameled pottery pug raw material; weathering the dark-red enameled pottery pug raw material; removing heavy metals; uniformly mixing the rest raw materials; uniformly mixing the dark-red enameled pottery pug raw material dry powder and the mixed powder, and soaking to obtain mixed pug; fishing out the mixed pug, and absorbing water; aging, hammering and pressing the mixed mud into mud blocks or mud strips for preparing the dark-red enameled pottery. The dark-red enameled pottery fired by the dark-red enameled pottery pug is high in yield, smooth in hand feeling, not easy to deform and natural in color; the distilled water brewed by the dark-red enameled pottery can dissolve out various trace elements, especially selenium elements, necessary for human bodies; the standing drinking water for the dark-red enameled pottery has the effect of remarkably reducing the content of toxic heavy metals.

Owner:JIANGSU BICHENG PURPLE SANDS TECH CO LTD

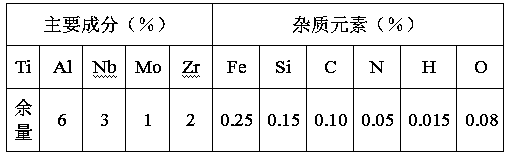

Preparation process of Ti alloy wire rope for marine engineering

InactiveCN110387486AIntensity exceedsStrong corrosion resistanceTextile cablesCorrosion resistantWire rope

The invention provides a preparation process of a Ti alloy wire rope for marine engineering. The preparation process comprises the following steps: step 1, electing sponge Ti, sponge Zr, Al shots, anAl-Mo intermediate alloy and an Al-Nb intermediate alloy according to the composition amount, and uniformly mixing the above raw materials; step 2, preparing an electrode by extruding the mixed materials obtained in step 1, cutting off a riser after smelting, and preparing a polished ingot by the adoption of machining; step 3, carrying out wire material preparation by subjecting the polished ingotprepared in step 2 to two stages: hot drawing of a coarse wire and hot drawing at room temperature, so as to obtain alloy fine wires; and step 4, stranding and braiding the alloy fine wires obtainedin step 3 in the form of point contact, so as to obtain the Ti alloy wire rope finally. According to the preparation process provided by the invention, the Ti alloy wire rope is prepared by adopting the Ti alloy material; the corrosion-resistance performance of the Ti alloy wire rope is relatively strong; compared with a steel wire rope, the Ti alloy wire rope has the advantages that the corrosionproblem is solved and the equipment running safety is guaranteed; meanwhile, the maintenance and replacement cost is greatly reduced; and the Ti alloy wire rope is widely applicable to marine engineering and other corrosion environments.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Hot forging process of mould

The invention provides a hot forging process of a mould. The process comprises the following steps that blanking is performed, specifically, bars of Cr12 steel are prepared; billets are manufactured, specifically, scale cinders and fine cracks on the surfaces of the bars are removed in a turning manner, so that bar billets with the high-quality surfaces are obtained; heat treatment is performed before forging, specifically, a heating furnace is used for heating the bar billets, so that stress of the billets is removed; forging is performed, specifically, hot forging equipment is used for forging the bar billets, so that a mould in a predetermined shape is obtained; quenching is performed, specifically, a quenching furnace is used for quenching the mould, wherein the quenching oil temperature is 1080-1150 DEG C, and the quenching duration is 10-15 minutes; primary tempering is performed, specifically, the heating furnace is used for heating the mould to 480-500 DEG C, heat preservation is performed for 2-2.5 hours, and then the mould is taken out of the furnace to be naturally cooled; subzero treatment is performed, specifically, a cooling device is used for cooling the mould to minus 198 DEG C, and heat preservation is performed for 2-2.5 hours; and secondary tempering is performed, specifically, the mould is heated to 400 DEG C, heat preservation is performed for 24 hours, and then the mould is taken out of the furnace to be naturally cooled.

Owner:JIANGSU SUNWAY PRECISION FORGING

Method for processing boiling tofu

The invention discloses a method for processing boiling tofu, which comprises the steps of screening soy beans, soaking, cleaning, grinding the soy beans into milk, cooking the soybean milk, filtering, cooking, mixing and curdling, stirring, filling, heating and boiling, and cooling and forming. By using the method for processing the boiling tofu with the scheme, the produced boiling tofu not only maintains the original flavor and nutrition, but also has the greatly-improved tenacity, can maintain complete under high-temperature cooking, or even can be used as a new product which can maintain complete when the boiling tofu is processed into a noodle shape; the boiling tofu can be used for cooking soup, cold and dressed with sauce and sliced; and the boiling tofu has the characteristics of high tenacity and completeness maintenance under high-temperature cooking.

Owner:金兴仓

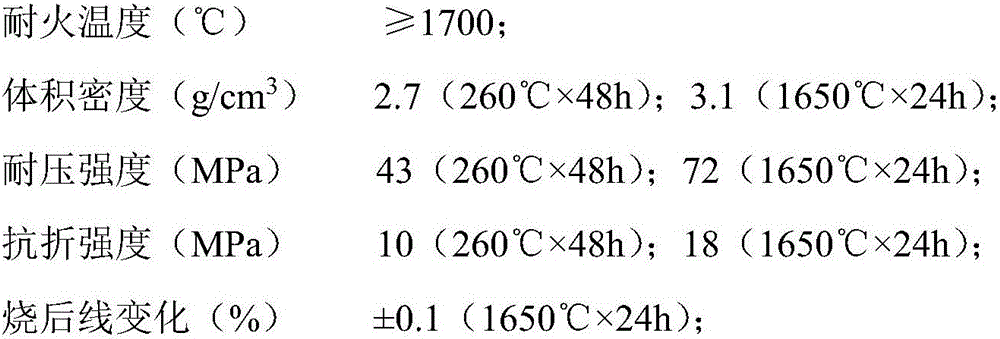

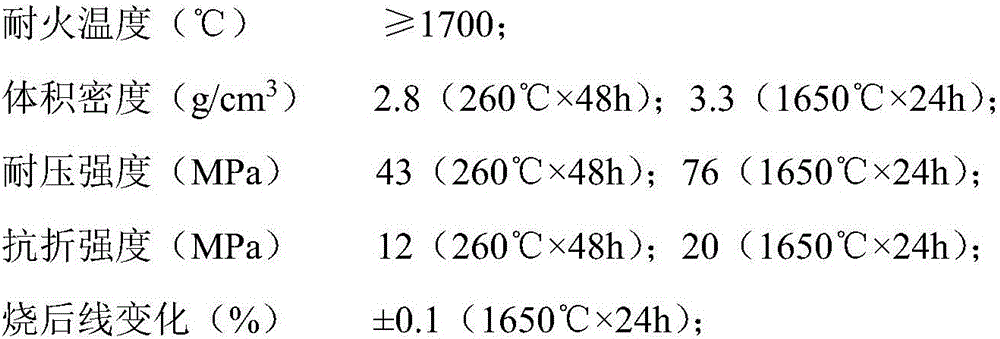

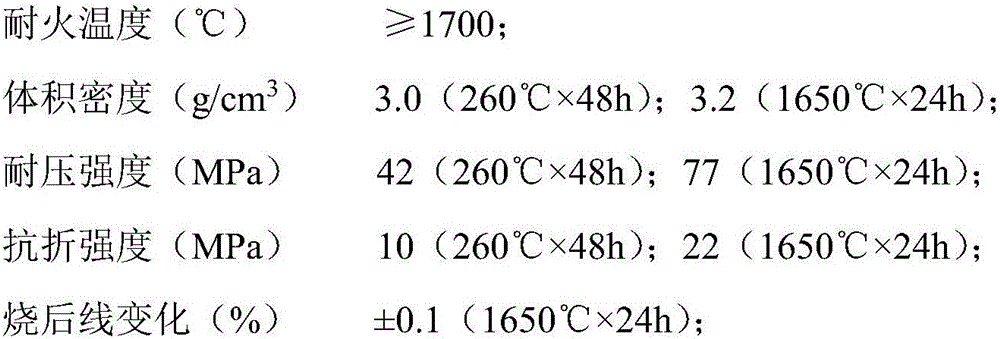

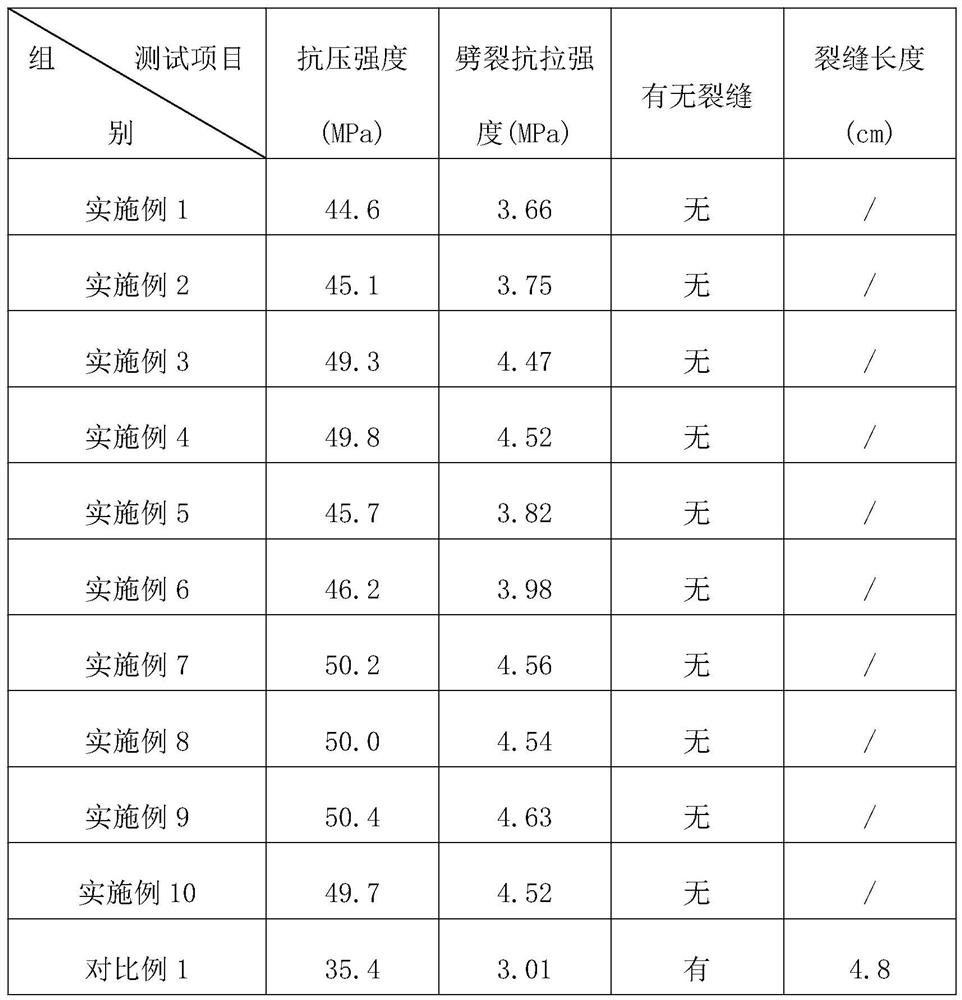

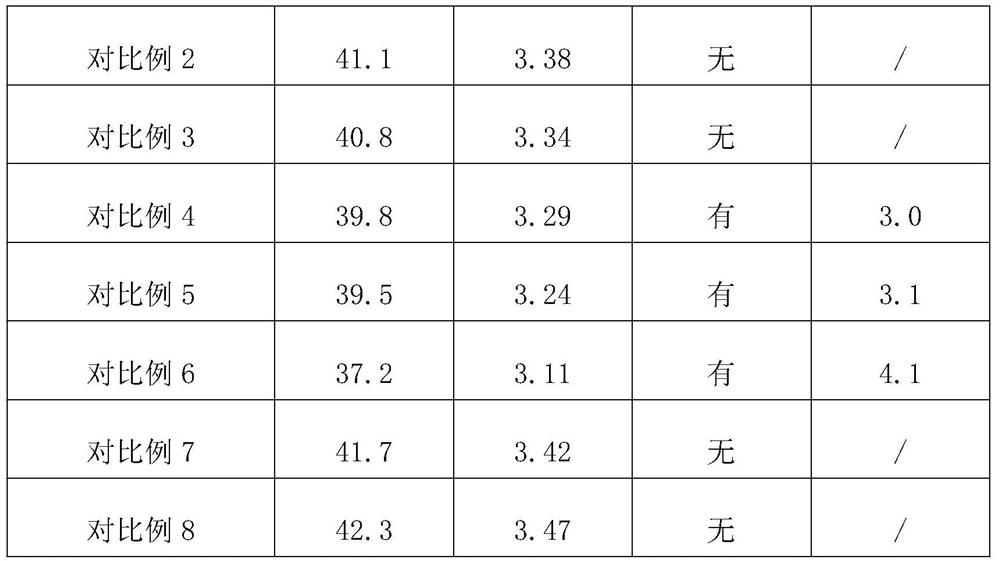

Castable, current stabilization slag ladle prepared from same as well as preparation methods thereof

ActiveCN106007753AGood high temperature chemical stabilityGood high temperature corrosion resistanceSlagGranularity

The invention discloses a castable, a current stabilization slag ladle prepared from the same as well as preparation methods thereof. The castable is prepared form the following raw material ingredients in percentage by weight: 15-30% of Al-Mg spinel with granularity of 5-8mm, 10-30% of forsterite with granularity of 3-5mm, 10-15% of kyanite with granularity of 1-3mm, 7-20% of fused corundum with granularity of 1-3mm, 5-20% of Si2ON2 with granularity less than or equal to 1mm, 5-15% of TiO2 with granularity less than or equal to 1mm, 1-5% of Fe2O3 with granularity of 180 meshes and 2-8% of silicon micropowder with granularity less than 0.088mm, as well as a water reducer which accounts for 0.1-0.3% of the total weight of the above raw material ingredients. The repairing material has the advantages of high strength, long service life, high temperature resistance, scouring resistance, erosion resistance, high peeling capability and the like.

Owner:SHANDONG IRON & STEEL CO LTD

Anti-crack concrete mixture and preparation method thereof

The invention relates to the technical field of concrete, in particular to an anti-crack concrete mixture and a preparation method thereof, and the anti-crack concrete mixture comprises the followingcomponents in parts by weight: 200-300 parts of cement; 800-900 parts of sand; 900-1200 parts of fine stone; 200-300 parts of water; 200-300 parts of silica fume; 5-7 parts of a water reducing agent;and 30-50 parts of graphene modified polypropylene fiber. The preparation method comprises the following steps: S1, fully mixing the cement, the sand, the fine stone, the silicon powder and the graphene modified polypropylene fiber to form a mixture; S2, adding a water reducing agent into water to form a mixed solution; and S3, adding the mixed solution into the mixture, and continuously stirringand mixing to obtain the anti-crack concrete mixture. The anti-crack concrete prepared by the invention has good anti-crack capability.

Owner:上海百基混凝土有限公司

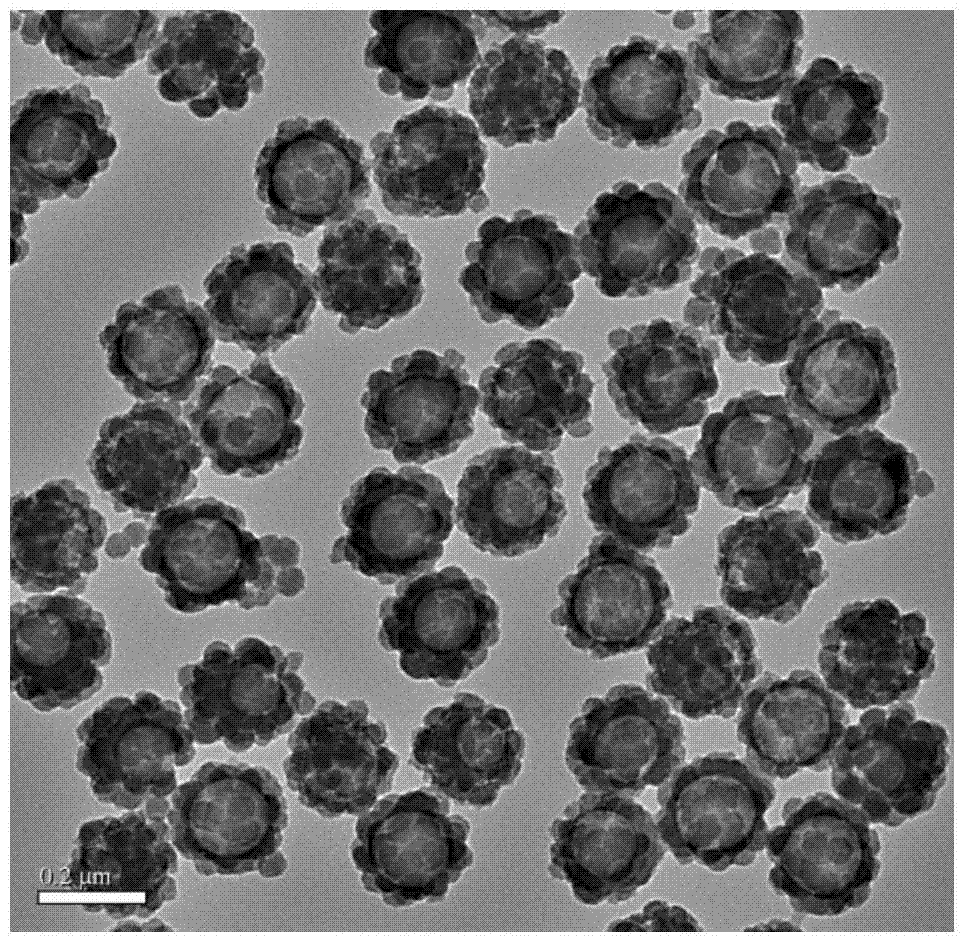

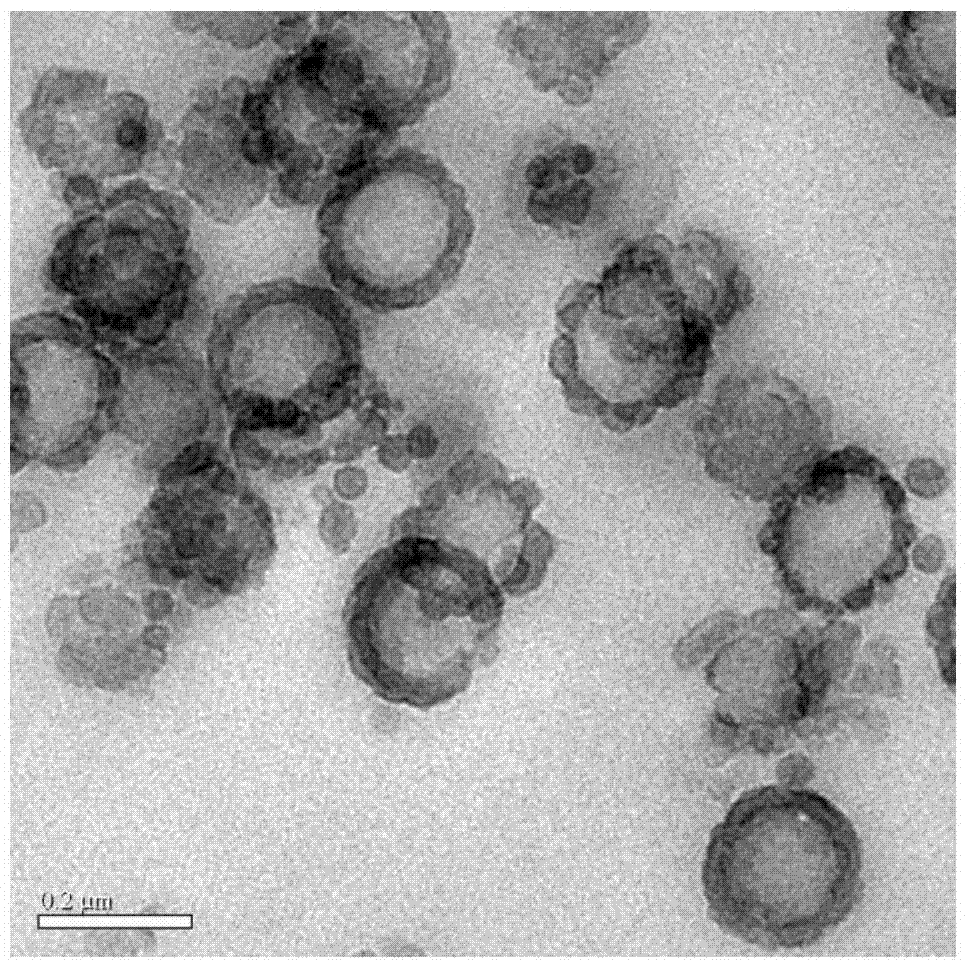

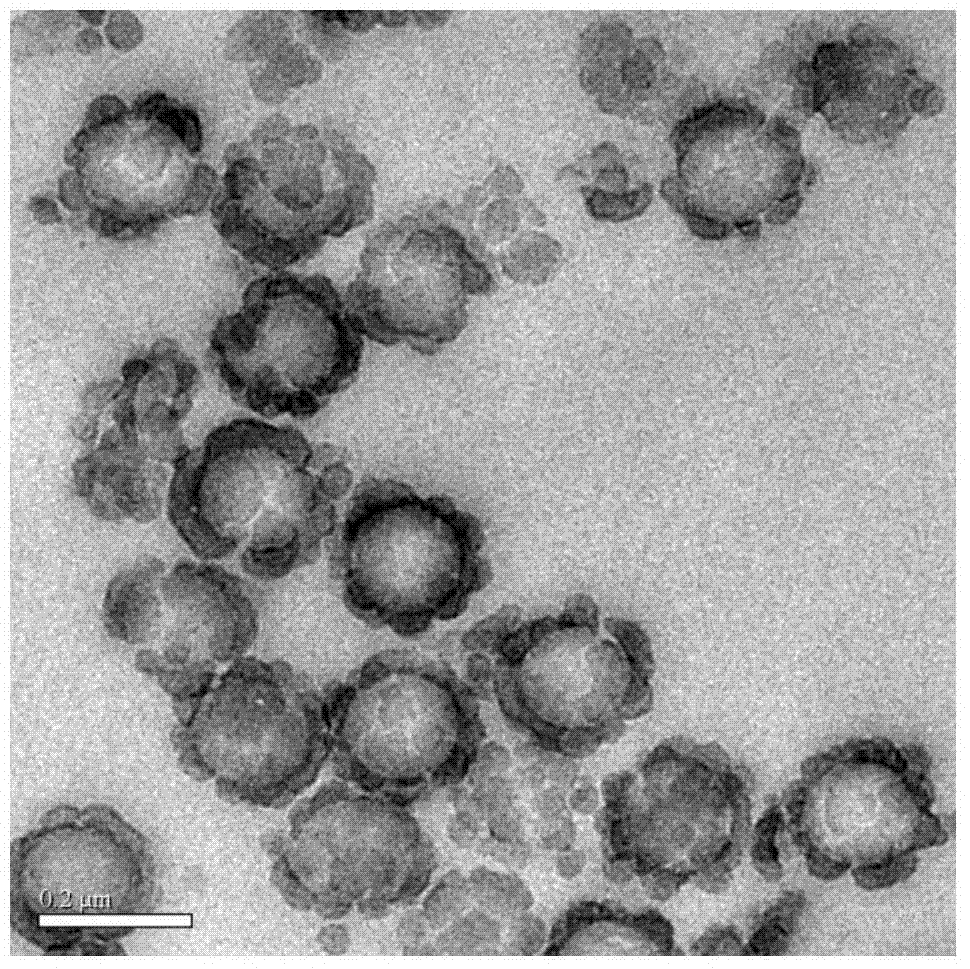

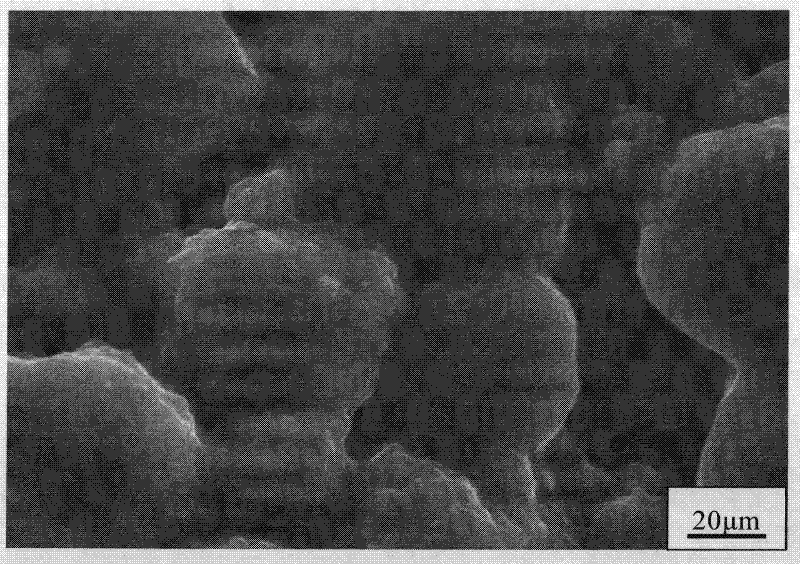

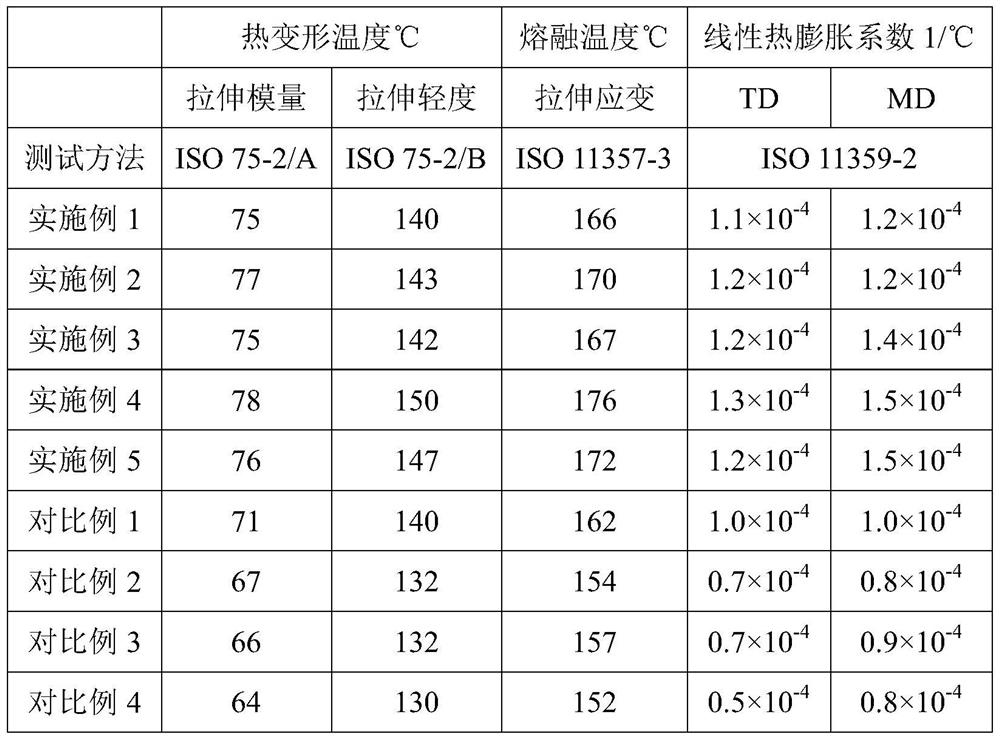

Polymer-matrix composite material and preparation method thereof

The invention discloses a polymer-matrix composite material and a preparation method thereof. The composite material comprises silicon dioxide hollow nanospheres and a polymer-matrix material, wherein the silicon dioxide hollow nanospheres are dispersed into the polymer-matrix material; the adding amount of the silicon dioxide hollow nanospheres is 0.1wt.% to 10wt.%; the preparation method of the composite material comprises the following steps: (1) preparing the silicon dioxide hollow nanospheres by a sol-gel method; (2) dispersing the silicon dioxide hollow nanospheres prepared from the step (1) into the polymer-matrix material, and forming a polymer-matrix material-silicon dioxide hollow nanosphere uniform dispersion system; (3) adding a curing agent, and solidifying the polymer-matrix material obtained from the step (2). The polymer-matrix material-silicon dioxide hollow nanosphere composite material disclosed by the invention has excellent mechanical property and acoustic damping property, and is simple in preparation method and mild in reaction condition.

Owner:HUAZHONG UNIV OF SCI & TECH

Plastic packaging film used for laser moulds

ActiveCN104999755AImprove wear resistanceHigh tensile strengthFlexible coversWrappersLow-density polyethyleneCalcium silicate

The invention provides a plastic packaging film used for laser moulds. The plastic packaging film is composed of an inner film, a buffer layer, and an outer film; the inner film comprises, by weight, 80 to 120 parts of polyethylene resin, 60 to 90 parts of Low density polyethylene, 30 to 60 parts of high density polyethylene, 20 to 40 parts of polyvinyl chloride, 10 to 30 parts of nylon, 10 to 30 parts of an aluminum-based layered nanomaterial, 15 to 35 parts of cellulose, 2 to 8 parts of a phosphite ester stabilizer, 3 to 8 parts of acetyl tributyl citrate, 1 to 6 parts of benzoyl peroxide; the buffer layer is prepared from polystyrene foam plastic; and the outer film is prepared from, by weight, 60 to 90 parts of a polyolefin copolymer, 15 to 35 parts of polypropylene, 20 to 40 parts of polyolefin elastomer, and 5 to 15 parts of calcium silicate. The plastic packaging film is high in tensile strength, hardness, and wear resistance, and can be used for packaging moulds, such as laser moulds, with corner angles so as to protect the moulds from pollution and wearing.

Owner:浙江宝伦新材料科技有限公司

Preparing method for automobile air conditioner pipe

InactiveCN106756273AReduce porosityReduce tensionFoundry mouldsFoundry coresAutomobile air conditioningCorrosion

Owner:苏州富艾姆工业设备有限公司

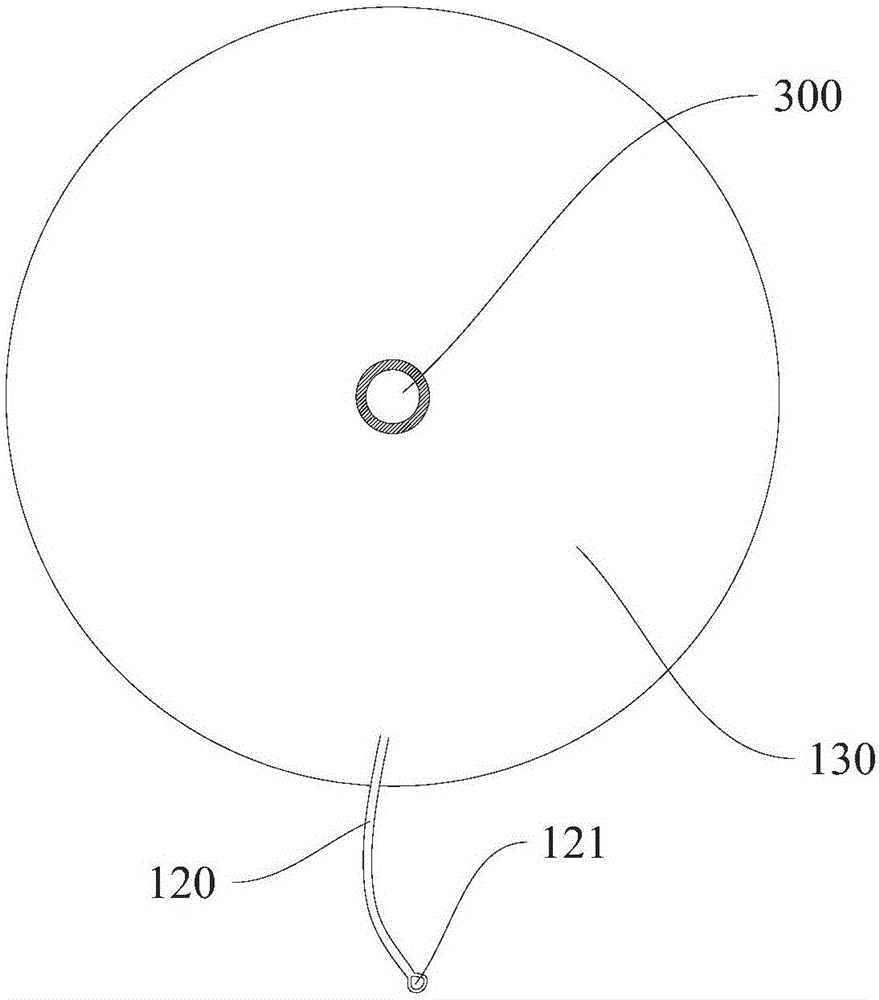

Multifunctional Yoga ball and multifunctional Yoga ball suite

InactiveCN106512334AVarious ways to useImprove user experienceHollow inflatable ballsStiltsEngineeringExercise equipment

The invention provides a multifunctional Yoga ball and a multifunctional Yoga ball suite, and belongs to the field of Yoga fitness equipment. The multifunctional Yoga ball comprises a first hemisphere, a second hemisphere and a connecting column, wherein the first hemisphere and the second hemisphere can be combined and separated, and the connecting column is used for connecting the first hemisphere with the second hemisphere. By dividing the Yoga ball into the first hemisphere and the second hemisphere, interesting playing methods of the Yoga ball can be increased, coordinated exercises of multiple parts of a body are enhanced, and a device foundation is provided for the common practice of two persons. An elastic tape is arranged between the first hemisphere and the second hemisphere, an exercise method of strength training is enhanced, and a device foundation of elastic stretching movements is provided. The multifunctional Yoga ball suite is a flexible bag body which can contain multifunctional Yoga ball, when the multifunctional Yoga ball is contained in the multifunctional Yoga ball suite, the cohesive force between the first hemisphere and the second hemisphere is improved, and the service life of the multifunctional Yoga ball is prolonged.

Owner:YANCHENG INST OF TECH

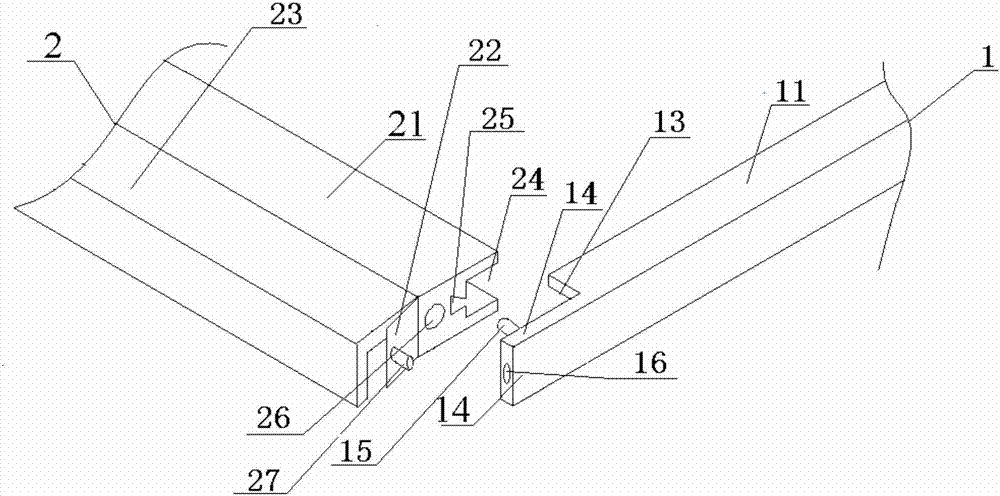

Combined photovoltaic module aluminium frame and production process thereof

PendingCN107196591AImprove performancePlay the effect of purifying castingsPhotovoltaicsPhotovoltaic energy generationEngineeringPhotovoltaics

The invention discloses a combined solar photovoltaic module frame. The combined solar photovoltaic module frame comprises a main body frame; the main body frame is composed of a long frame, a short frame and a U-shaped fixing block; the long frame and the short frame are matched; the short frame is composed of a first concave profile, fixing edges and a first connection block; the fixing edges are arranged at two ends of the first concave profile; the first connection block is formed by extension from one side of the first concave profile; a first groove and a glue injecting groove are also arranged at the notch of the first concave profile; locating holes are also arranged at two ends of the first concave profile; a fixing block is also arranged on the fixing edge; the long frame mainly comprises a second concave profile; a second groove is arranged at the notch of the second concave profile; extension plates extend from two ends of the second concave profile; a locating column is arranged on the extension plate; and a fixing hole is also formed on the side surface of the extension plate. The invention further designs a production process of the combined solar photovoltaic module frame. The aluminium frame is simple in structure, good in protection performance, low in cost and convenient to disassemble and install; furthermore, the aluminium frame can be individually used; and furthermore, multiple aluminium frames can be used in a combined manner.

Owner:镇江神飞新能源科技有限公司

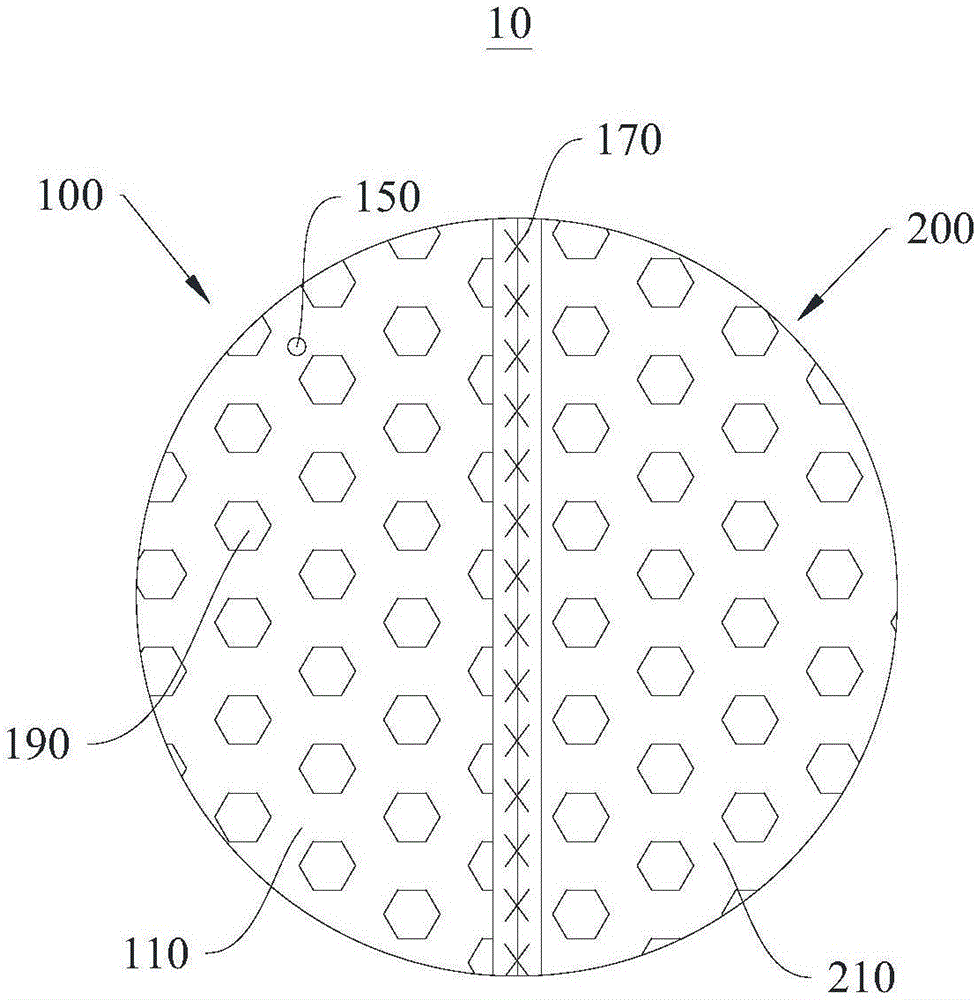

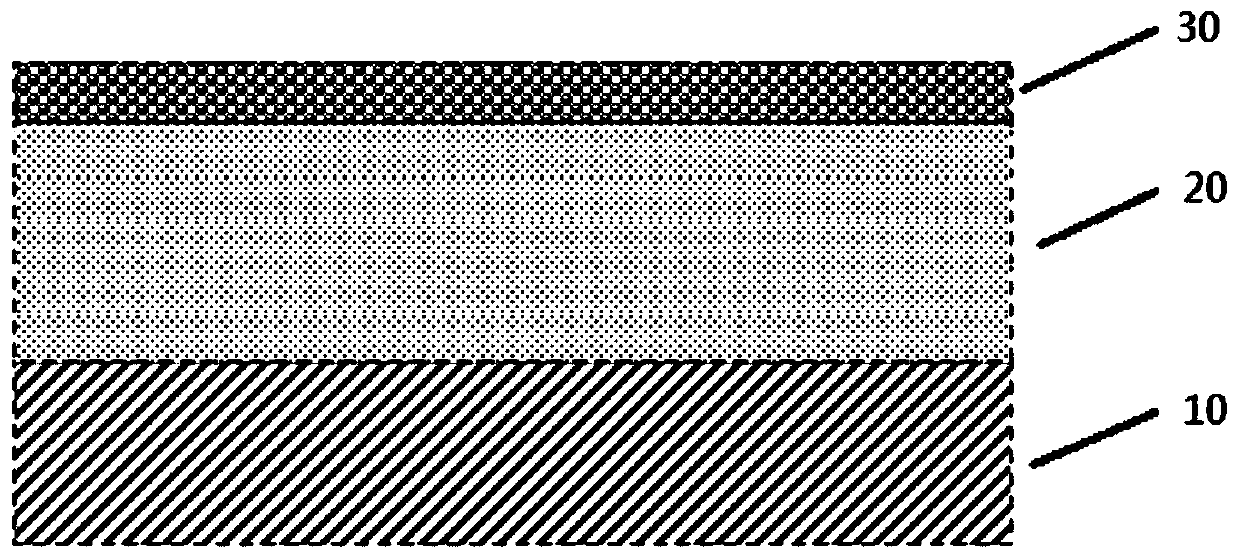

Composite negative plate and preparation method and application thereof

PendingCN111312994AImprove willfulnessImprove Coulombic efficiencyCell electrodesSecondary cellsElectrochemical responseSolid state electrolyte

The invention provides a composite negative plate. The composite negative plate comprises a metal foil simultaneously used as a negative current collector and a negative active material, a solid electrolyte thin film layer arranged on one surface of the metal foil, and a diamond-like film layer arranged on the surface, deviating from the metal foil, of the solid electrolyte thin film layer. The solid electrolyte layer has good lithium conduction performance, improves the interface ion diffusion rate of the composite metal negative electrode / electrolyte, and improves the rate capability of thebattery. The solid electrolyte layer can effectively isolate the contact between the surface of the composite metal and the electrolyte, so that the side reaction process is reduced, and the coulombicefficiency of the battery is improved; and the solid electrolyte layer can also provide an effective mechanical protection effect for the composite metal negative electrode, and the pulverization problem of the composite metal negative electrode caused by volume change in the electrochemical reaction process is improved, so that the cycle performance of the battery is effectively improved.

Owner:SHENZHEN INST OF ADVANCED TECH

Method for planting mountain gardenia tree through biomass straw

InactiveCN104956985AReduce harmImprove the immunityHops/wine cultivationTurf growingLand preparationPollution

The invention provides a method for planting a mountain gardenia tree through biomass straw, and relates to the technical field of gardenia cultivation. The method includes the steps of pruning, land preparation, cuttage, transplanting and maintenance conducted after transplanting. In the land preparation step, land is ploughed three times repeatedly, different nutrients are added, the ploughing depth each time is controlled to range from 10 cm to 20 cm, the land is covered with plastic films in the cuttage process, calcium superphosphate, citric acid and the like are used for conducting nutrient supplementation on the gardenia tree, treatment such as ditching and straw power scattering needs to be conducted on the land where the gardenia tree is transplanted, a cuttage branch is then inserted and planted, regular maintenance is conducted after transplanting, and the gardenia tree can be harvested the next year. The disease and pest resistance of the gardenia tree is improved, the yield of gardenia fruits is increased, the lodging resistance rate and the disease resistance rate of the gardenia tree are increased, and the problems of country crop straw pollution and waste are solved.

Owner:ANHUI XIANGHUA AGRI & FORESTRY

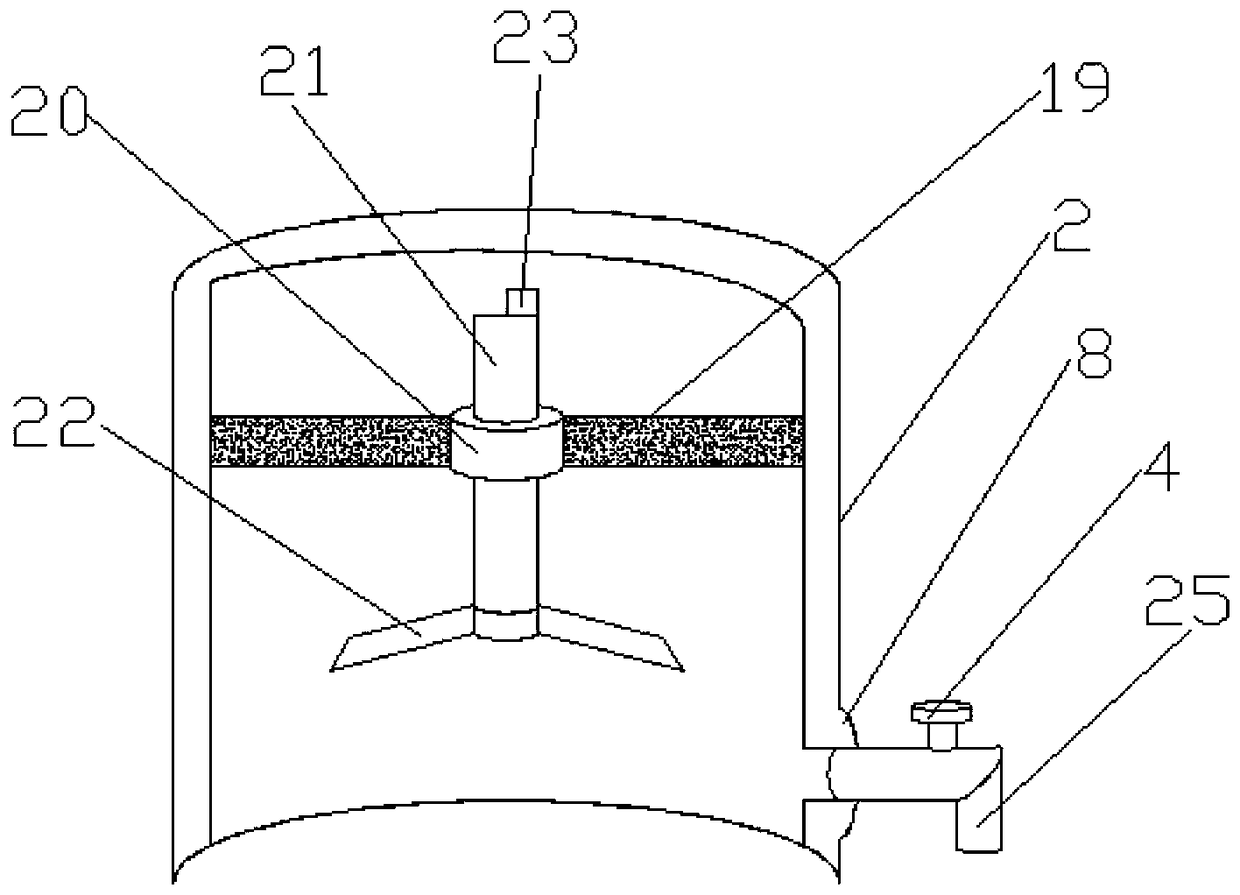

Special essence reaction equipment

PendingCN107597048ASimple structureEasy to operateRotary stirring mixersMixer accessoriesReagentFastener

Owner:浙江杭曼食品科技有限公司

Dangling runner for fitness and wear-resisting treatment process thereof

InactiveCN108048722AImprove the extrusion effectGrain refinementCoatingsMovement coordination devicesRare-earth elementMetallurgy

The invention discloses a dangling runner for fitness. The runner comprises, by mass, 4-7% of Al, 0.12-0.13% of C, 3-6% of Mn, 10-13% of Zn, 1-3% of Ni, 1-3% of Cu, 2-3% of Sc, 0.005-0.008% of P, 0.01-0.02% of S, 1-3% of Zr, 2-5% of Ca, 0.01-0.05% of Nb, 0.2-0.4% of B, 2-5% of Sr, 2-4% of Co, 0.01-0.03% of V, 0.15-0.17% of Ti, 0.01-0.02% of Na, 0.02-0.03% of Be, 0.1-0.3% of rare earth elements, and the balance Mg and trace impurities; and the sum of the components is 100%. A wear-resisting treatment process of the dangling runner for fitness is simple and practicable, the dangling runner afterprocessing has good performance, the service life is prolonged, and the cost is reduced.

Owner:苏州胤宗智能科技有限公司

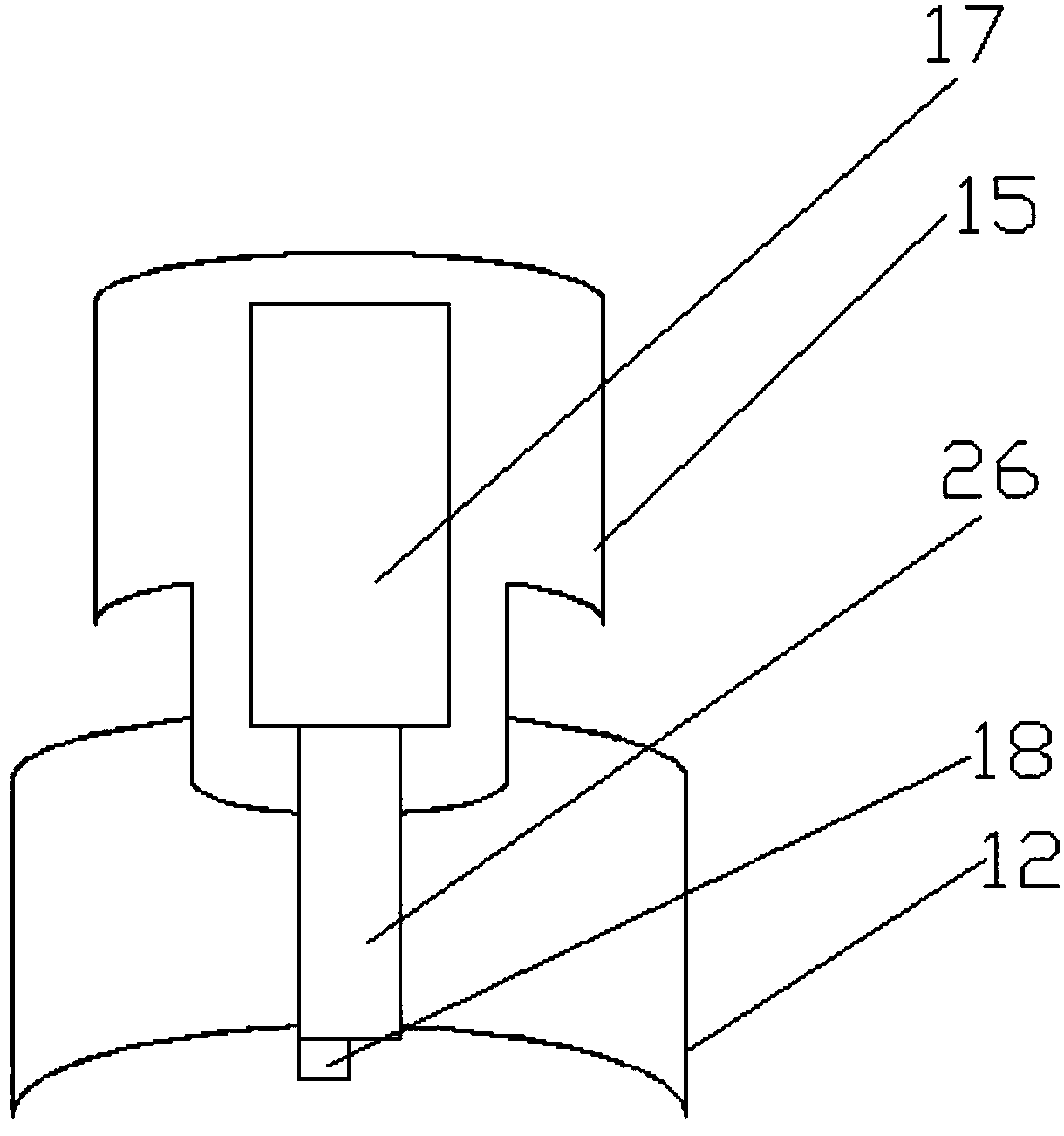

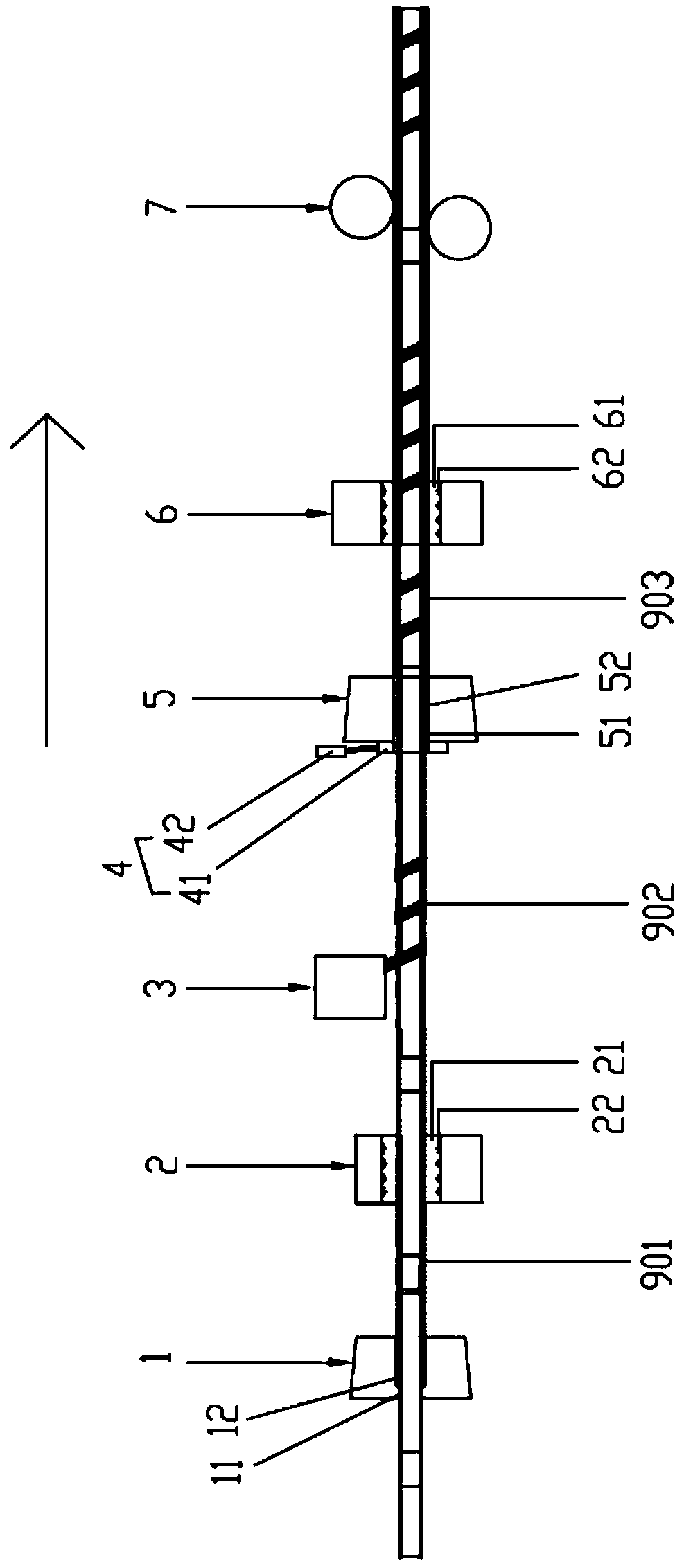

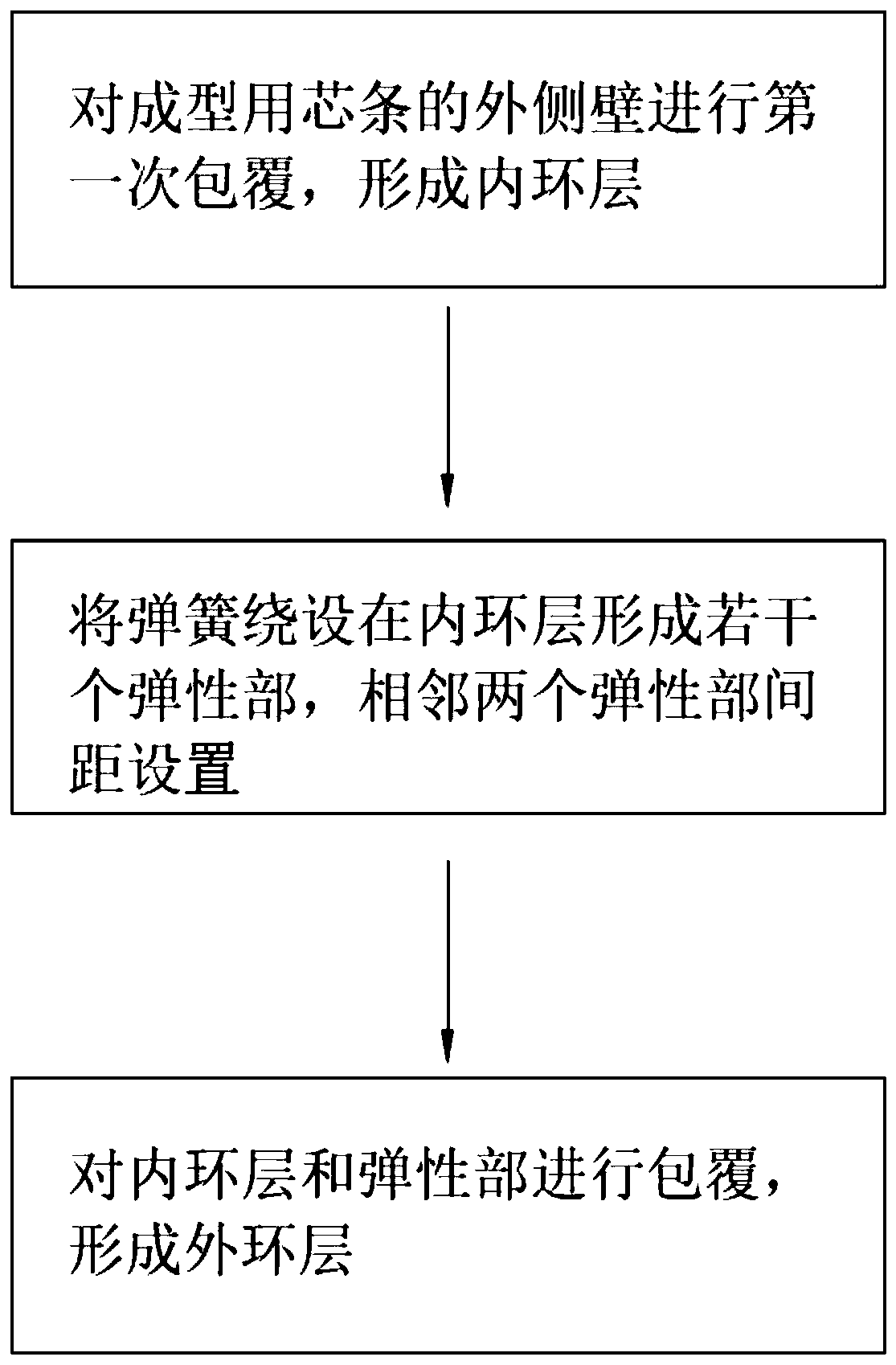

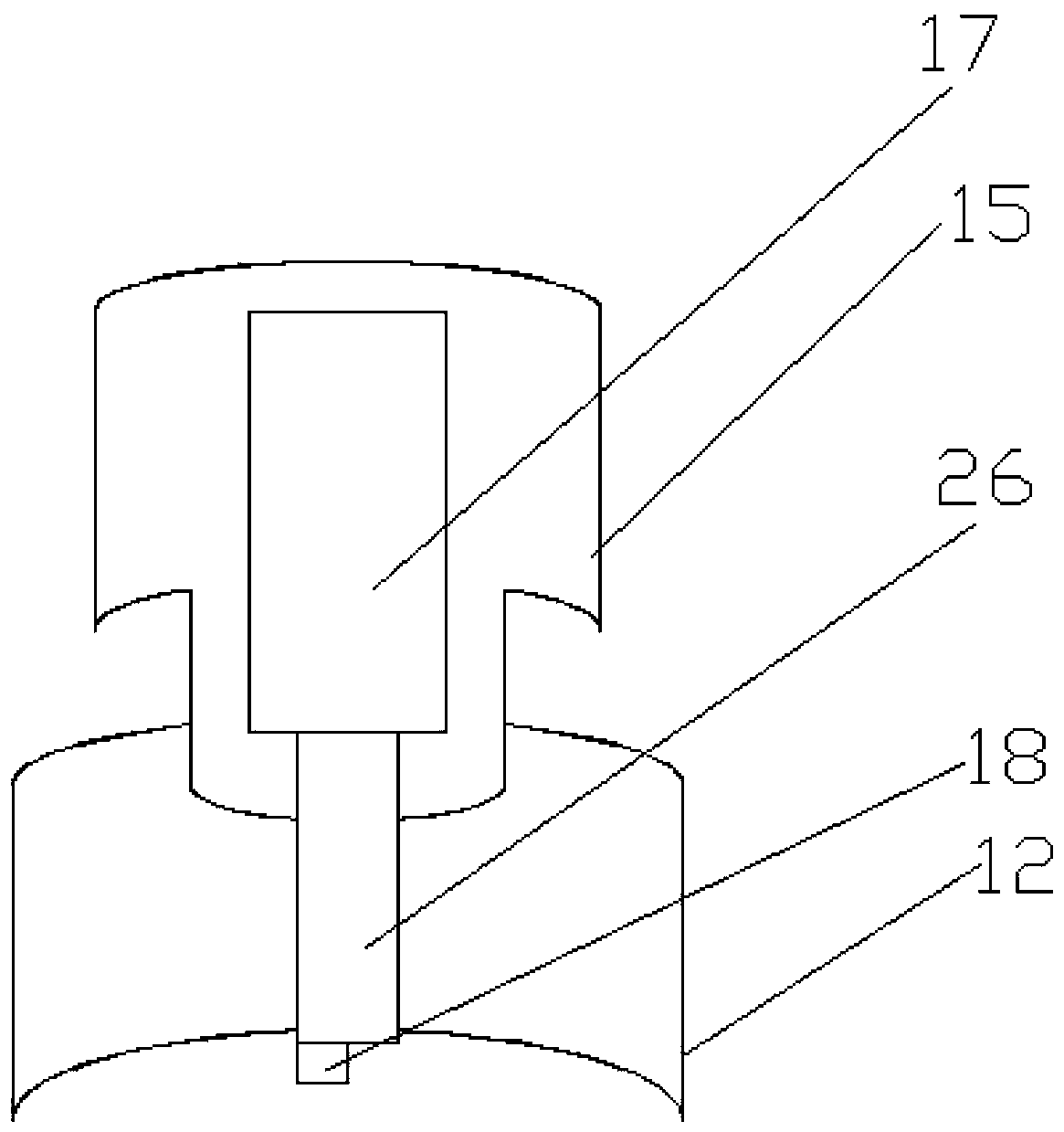

Forming equipment for medical reinforced catheter and forming method thereof

The invention relates to the technical field of medical devices, in particular to forming equipment for a medical reinforced catheter and a forming method thereof. The forming equipment comprises a first extruder, a torsion machine, a second extruder and a dragger which are successively arranged along the conveying direction of a formed core strip and are independent. The first extruder comprisesa first channel and a first cavity along the conveying direction, the first channel penetrates the first cavity, and the first extruder is used for forming an inner annular layer; the torsion machineis used for winding a spring to the outer wall of the inner annular layer to form an elastic part, the second extruder is provided with a second channel and a second cavity formed along the conveyingdirection, and the second channel penetrates the second cavity; the second extruder is used for forming an outer annular layer, the core strip moves linearly under the action of the dragger by arranging the first extruder, the torsion machine, the second extruder and the dragger to successively form the inner annular layer, the elastic part and the outer annular layer so as to finally form the medical reinforced catheter. The medical reinforced catheter meets the using demands of high precision, high toughness and high flexibility.

Owner:东莞市世和塑胶五金有限公司

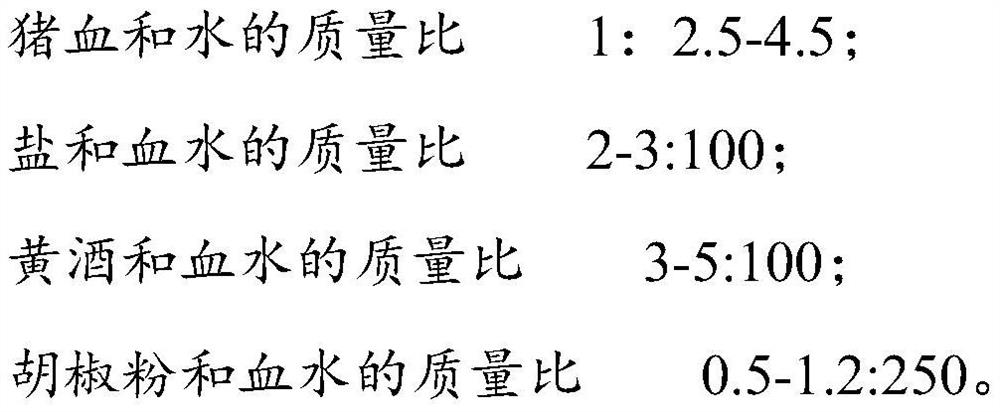

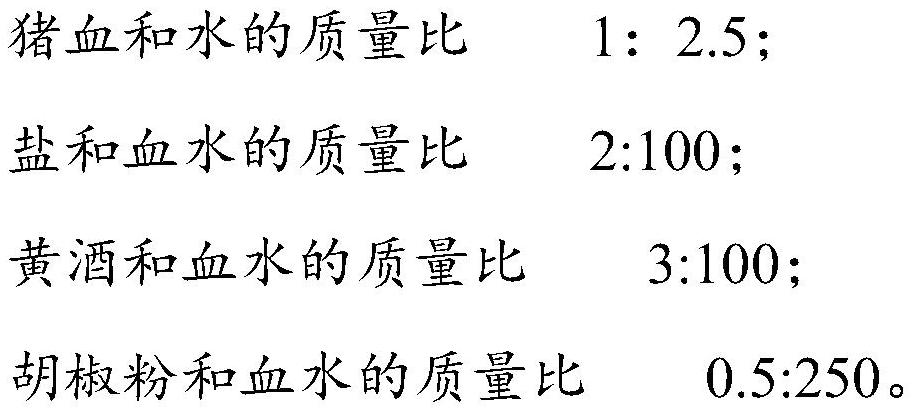

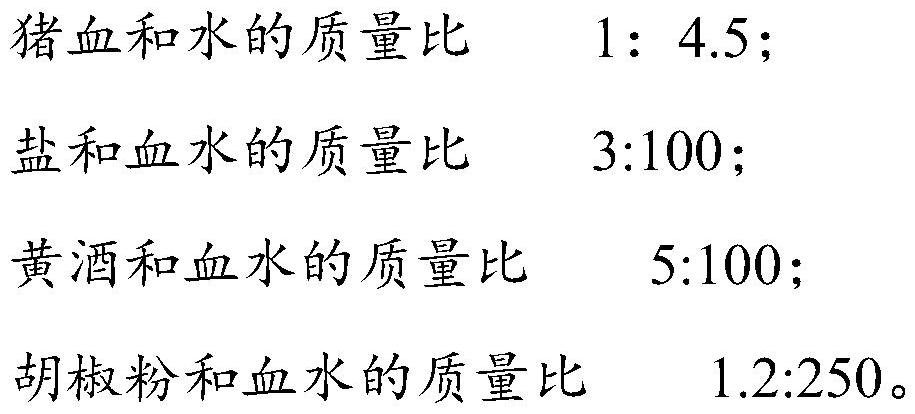

Pig blood bean curd and preparation method thereof

PendingCN111802593AWith fresh lusterTight tissueFood ingredient as flavour affecting agentFood ingredient as coagulantBiotechnologyBotany

The invention discloses pig blood bean curd and a preparation method thereof. The pig blood bean curd is prepared from bloody water, salt, yellow rice wine and pepper powder, the bloody water is prepared from pig blood and water, and the mass ratio of the pig blood to the water is 1:(2.5-4.5); the mass ratio of the salt to the bloody water is (2-3):100; the mass ratio of the yellow rice wine to the blood water is (3-5):100; and the mass ratio of the pepper powder to the blood water is (0.5-1.2):250. Compared with traditional pig blood bean curd, the prepared blood bean curd has the advantagesthat: the product is red brown in appearance, fresh and glossy, obvious in inherent flavor of pig blood, compact in section tissue, free of large pores, but provided with a plurality of tiny and uniform small pores, good in toughness and restorability, not prone to breakage, high in elasticity, good in crispness, good in water-retaining property and long in quality guarantee period, and industriallarge-scale production can be achieved.

Owner:周晓娟

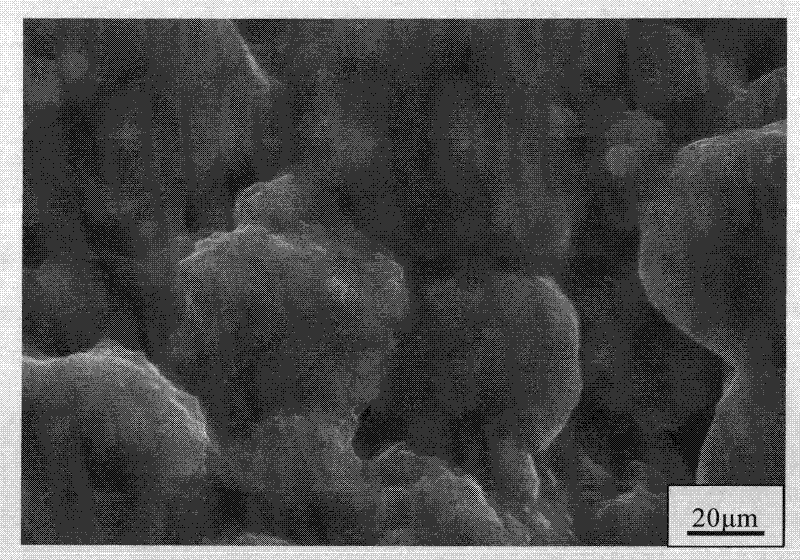

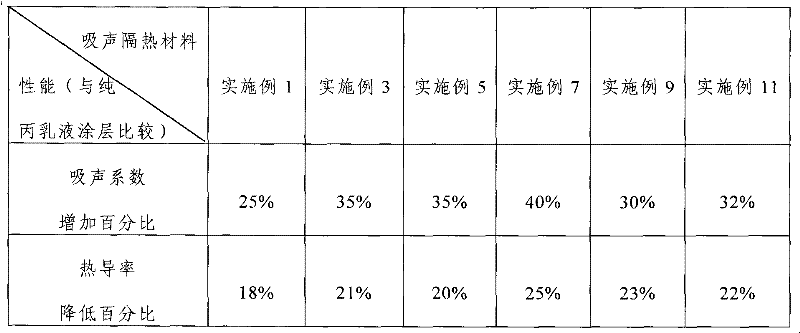

Method for preparing organic polymer/silica sound-absorbing thermal insulation material

The invention discloses a method for preparing an organic polymer / silica sound-absorbing thermal insulation material, which comprises the following steps of: 1, mixing water and water glass, precipitating and taking supernate; 2, preparing preset solution; 3, slowly dripping the preset solution into the supernate to obtain a gel substance; 4, ageing and performing suction filtration; 5, washing and performing suction filtration; and 6, drying and crushing to obtain the organic polymer / silica sound-absorbing thermal insulation material. Porous silica is used as a framework material and interpenetrates with crylic acids to form a porous structure of an organics and inorganics interpenetrating network. The organic polymer / silica sound-absorbing thermal insulation material prepared by the method has high sound-absorbing performance and also has excellent heat preservation and thermal insulation performance.

Owner:XIAN UNIV OF SCI & TECH

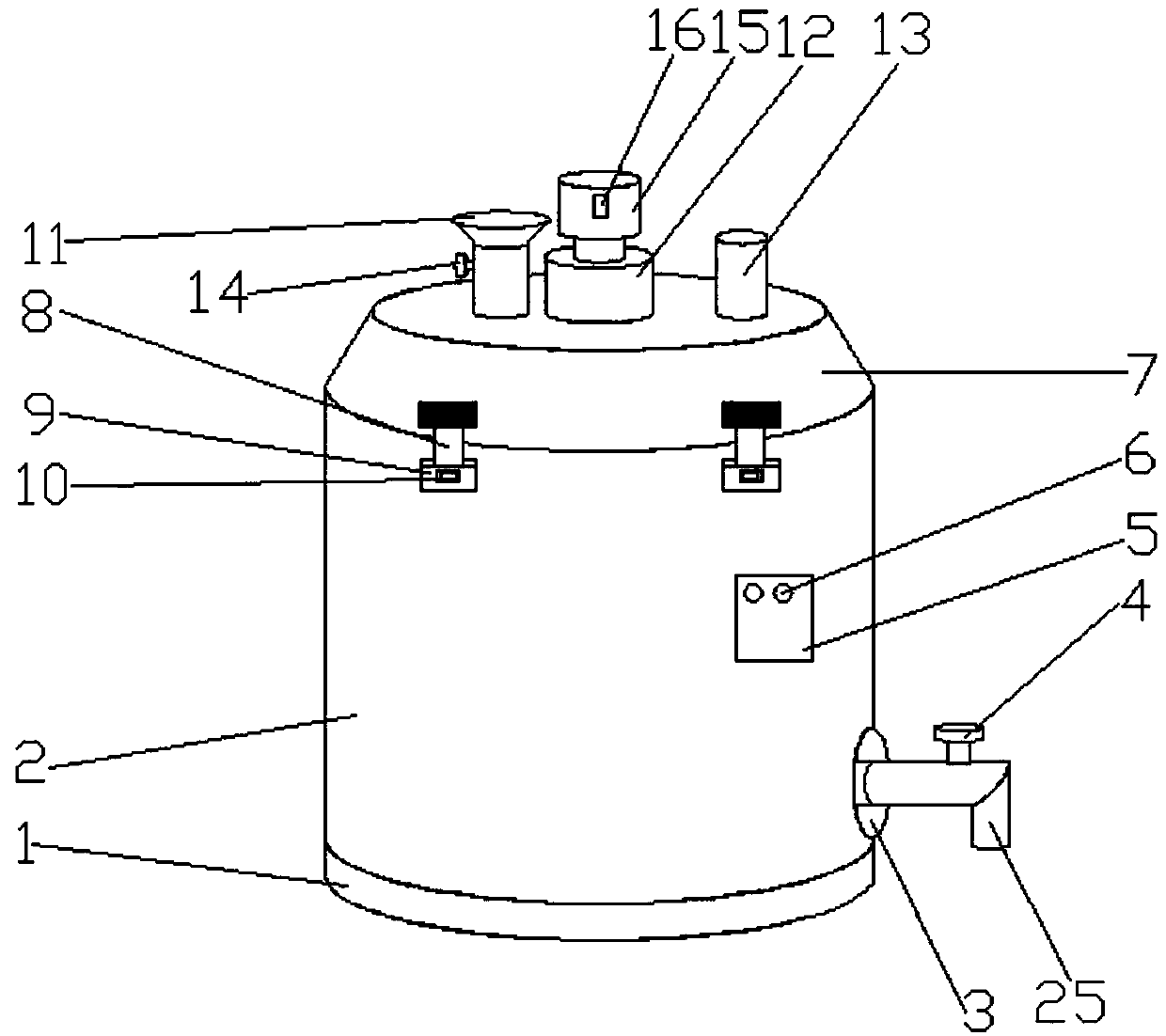

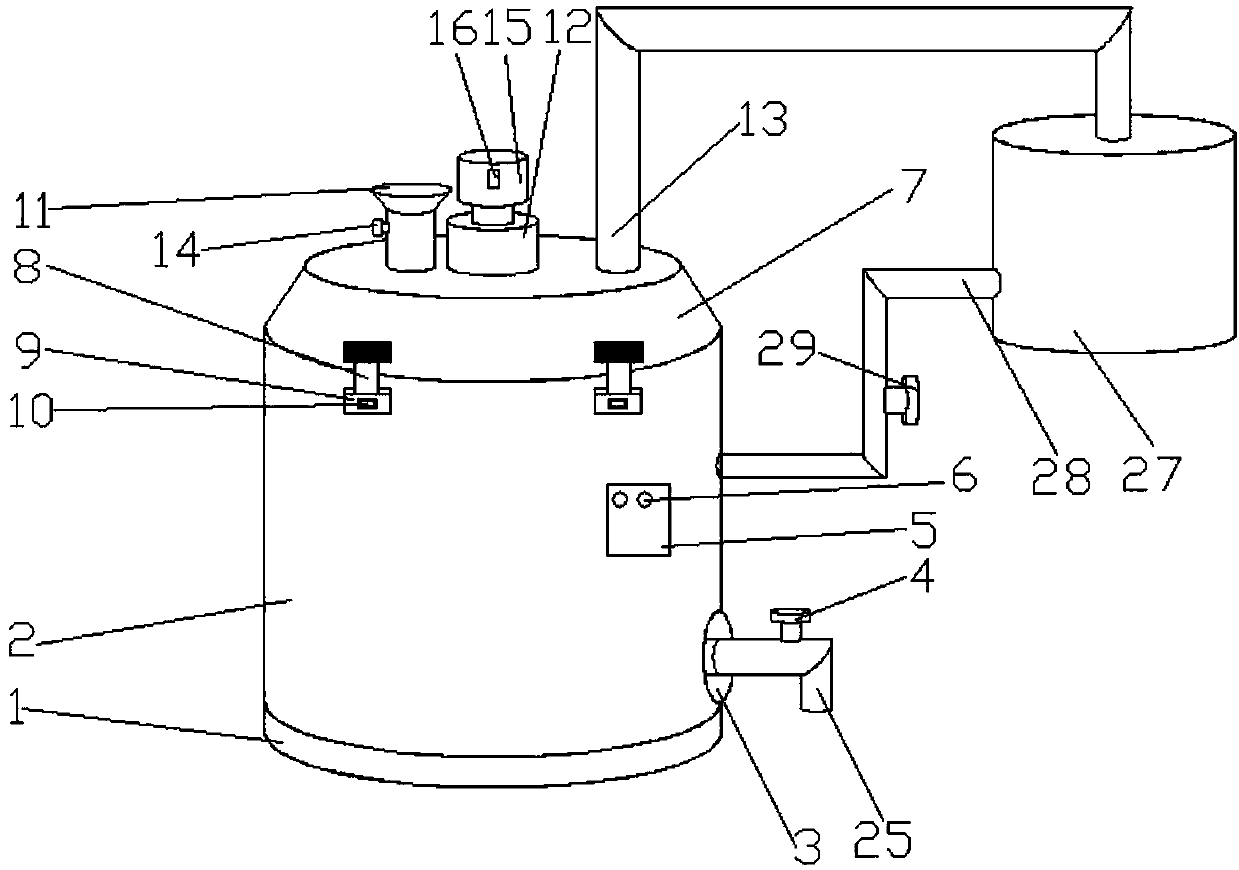

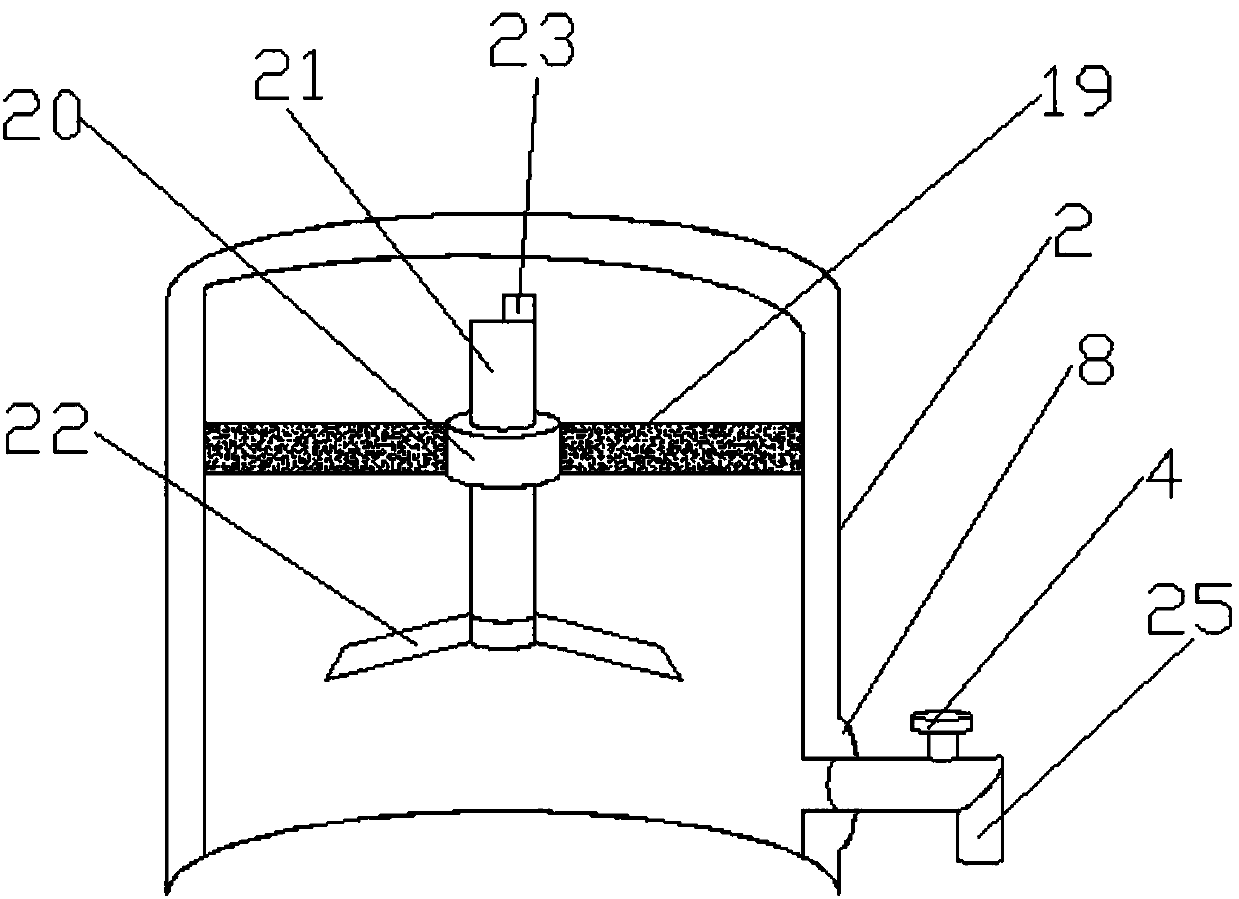

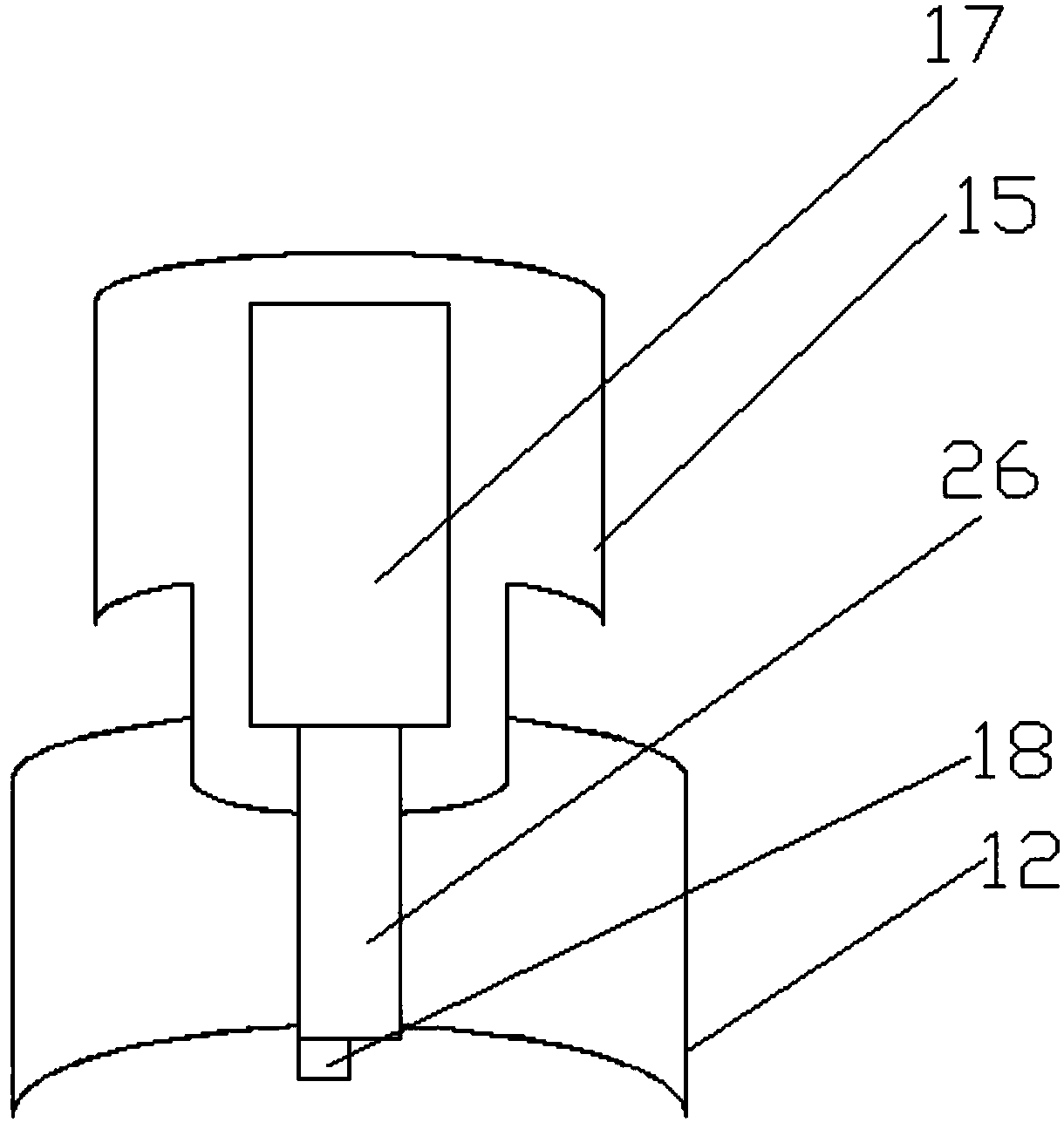

Device for agitating edible essence

PendingCN107551979AStir wellImprove stirring efficiencyChemical/physical/physico-chemical stationary reactorsEngineeringRaw material

The invention relates to the technical field of the agitation of raw materials, and particularly discloses a device for agitating edible essence. The device comprises a base, wherein the top of the base is fixedly connected with an agitating kettle; the top of the agitating kettle is provided with an agitating kettle cover; a side part of the agitating kettle cover is fixedly connected with a bayonet lock; a side part of the agitating kettle is fixedly connected with a fastener; the interior of a motor cover is provided with a motor; the motor comprises a main shaft; one end, which is far awayfrom the motor, of the main shaft is provided with a main shaft connecting buckle; the interior of the agitating kettle is fixedly connected with a baffle plate; one end, which is far away from an agitating vane, of an agitating shaft is provided with an agitating shaft connecting buckle. According to the device, through arranging the agitating shaft in the interior of the agitating kettle and arranging the agitating vane at one end of the agitating shaft, while a material reacts in the agitating kettle, the agitating shaft, under the driving of the power of the motor arranged at the top of the agitating kettle cover, accordingly transmits the power of the motor to the agitating vane through the agitating shaft to realize the sufficient agitation on the material and the device is great innovation to the improvement of the agitation efficiency of the material.

Owner:浙江杭曼食品科技有限公司

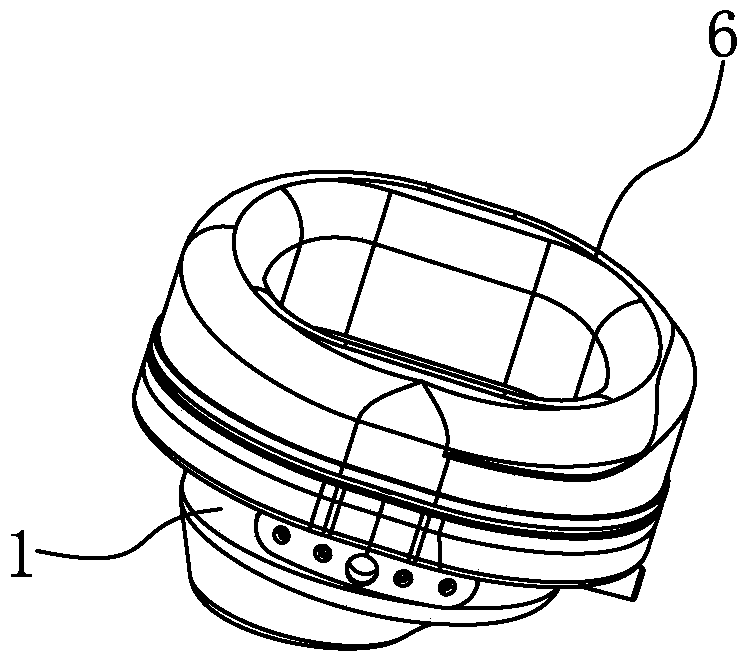

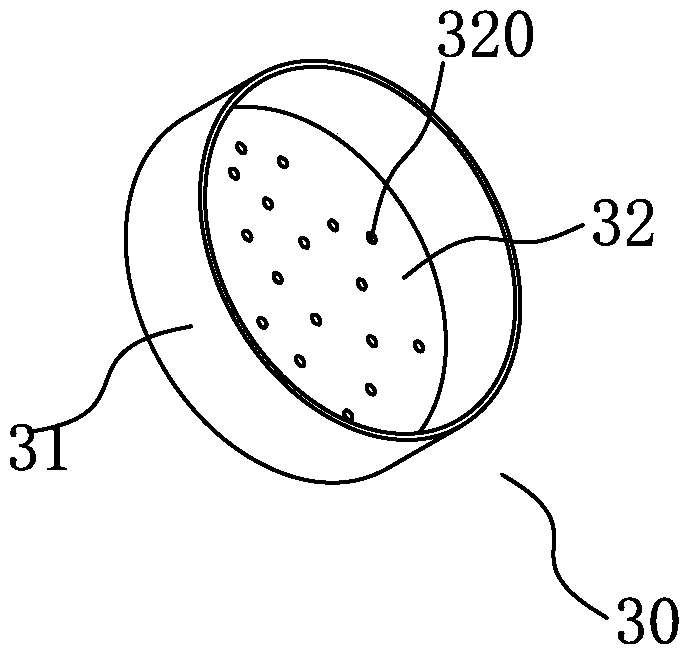

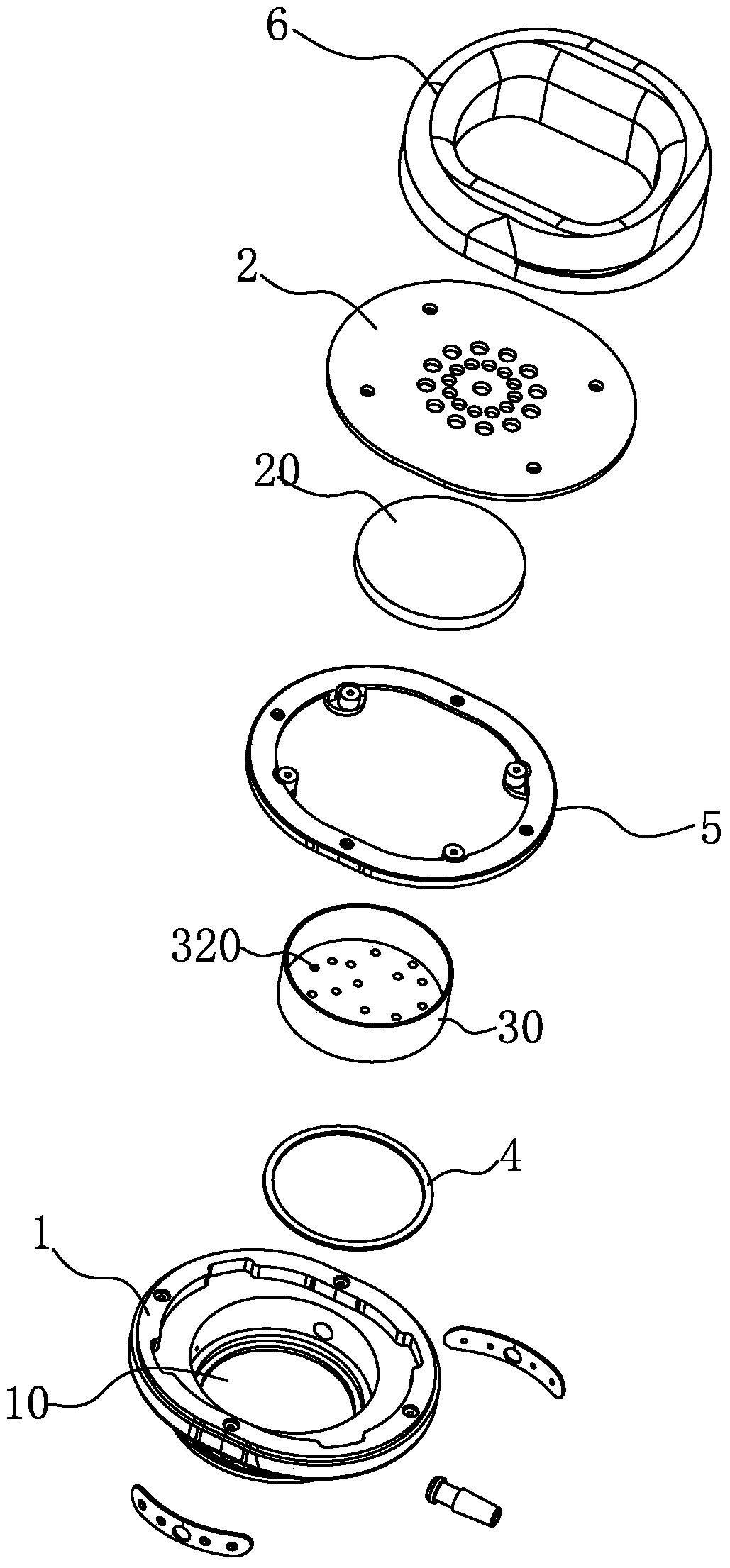

An earphone sounding cavity capable of improving timbre and a shock-absorbing diaphragm used in the sounding cavity

ActiveCN105163231BImprove sound qualityReduce reflectionPlane diaphragmsFrequency/directions obtaining arrangementsRubber ringEpoxy

The invention discloses an earphone sounding cavity capable of improving tone quality and a damping diaphragm used in the sounding cavity. The earphone sounding cavity is composed of an earphone casing and a speaker support, wherein an accommodation space is formed in the earphone casing, and the speaker support is fixed at the port portion of the earphone casing; and an electroacoustic damping diaphragm is arranged to be attached to the accommodation space, the damping diaphragm forms an electroacoustic inner container cavity corresponding to the shape of the accommodation space, and a damping rubber ring is arranged between the bottom surface of the electroacoustic inner container cavity and the bottom surface of the accommodation space. The damping diaphragm is formed by a damping layer and a thin film layer in a compound manner, and the raw material of the damping layer is prepared by a mixture of mica powder, silicone rubber and an epoxy resin. According to the invention, the electroacoustic inner container cavity formed through the electroacoustic damping diaphragm is formed in the accommodation space of the earphone casing, the electroacoustic inner container cavity forms a sound cavity of an earphone, and due to the existence of the damping diaphragm, sound waves penetrating the sound cavity are absorbed and reflection of high-frequency waves and diffraction of low-frequency waves are reduced, such that noise is effectively reduced, and the sounding tone quality of the earphone is improved.

Owner:DONGGUAN MOCROX ELECTRONICS TECH CO LTD

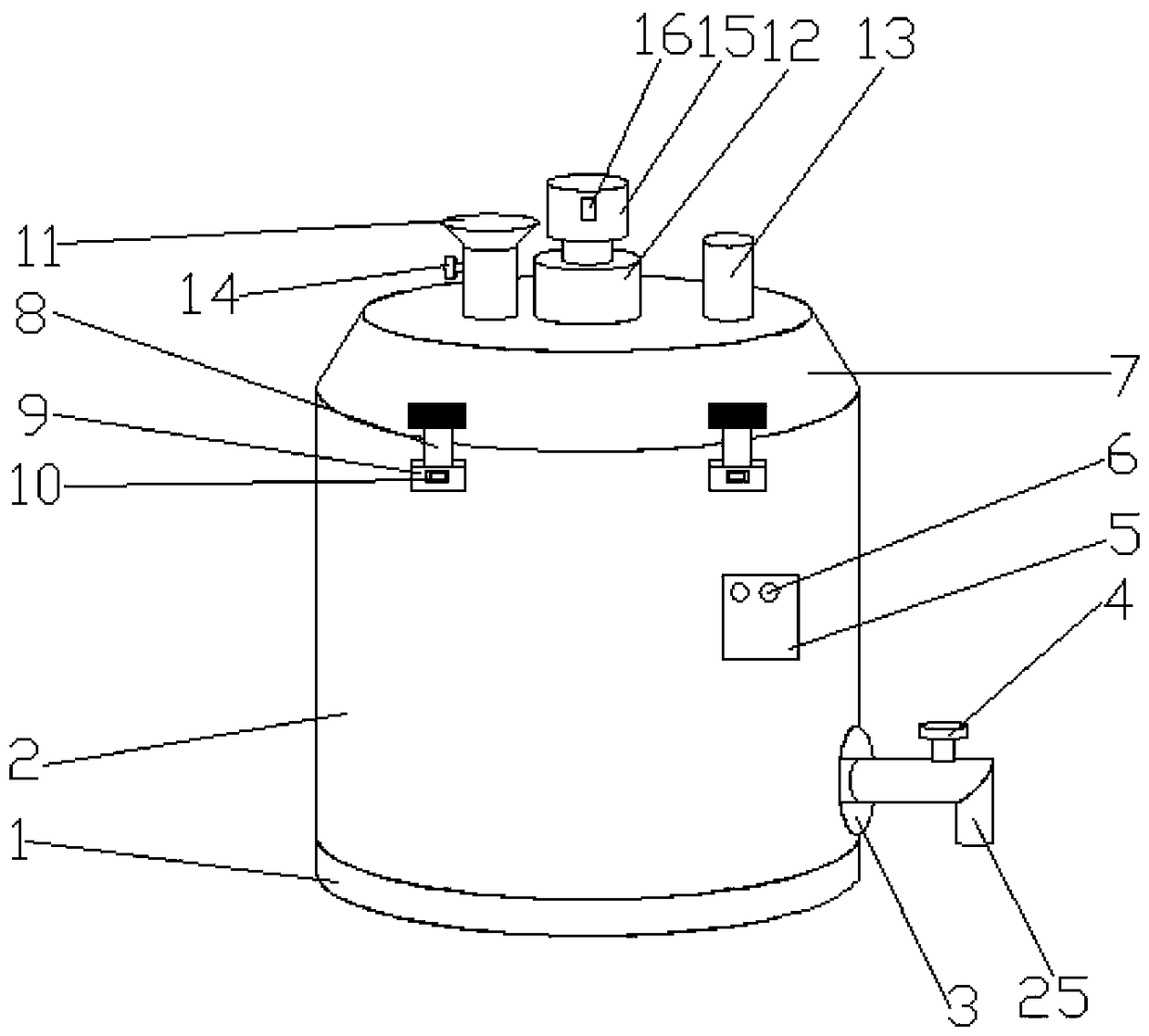

Edible mushroom fermenting tank

InactiveCN108060060AStir wellImprove filtration efficiencyBioreactor/fermenter combinationsBiological substance pretreatmentsAgricultural engineeringEdible mushroom

The invention discloses an edible mushroom fermenting tank. The edible mushroom fermenting tank comprises a base, wherein a fermentation tank is fixedly connected to the top of the base; a fermentation tank cover is arranged on the top of the fermentation tank; clamping pins are fixedly connected to the side part of the fermentation tank cover; clamping buckles are fixedly connected to the side part of the fermentation tank; a motor is arranged inside a motor hood; the motor comprises a main shaft; a main shaft connecting buckle is arranged at one end, away from the motor, of the main shaft; abaffle plate is fixedly connected into the fermentation tank; stirring shaft connecting buckle is arranged at one end, away from stirring blades, of a stirring shaft. Through arrangement of the stirring shaft inside the fermentation tank and arrangement of the stirring blades at one end of the stirring shaft, while a substance is fermented inside the fermentation tank, under the driving of powerof the motor arranged on the top of the fermentation tank cover, the stirring shaft transmits the power of the motor to the stirring blades through the stirring shaft so as to achieve sufficient stirring of the fermented substance, so that the edible mushroom fermenting tank is a great innovation for improving the fermentation efficiency of the fermented substance.

Owner:曾华明

Environment-friendly novel building block material

The invention belongs to the technical field of environment-friendly building block materials, and particularly relates to an environment-friendly novel building block material. The environment-friendly novel building block material is prepared from the following raw materials in parts by weight: 70-90 parts of magnesium cement, 30-40 parts of corn stalk particles, 20-25 parts of coal ash, 34-38 parts of kieselguhr, 10-15 parts of slag powder, 10-14 parts of methyl sodium silicate, 22-26 parts of standard sand, and 4-6 parts of urea formaldehyde resin. A prepared building block is low in weight, the weight is only 610 kg / m<3>, in addition, the compressive strength and the bending strength are excellent, and toughness and crack resistance of the material are improved; the slag powder with the specific surface area being 8000 cm<2> / g is added into the prepared building block, and thus mechanical properties and water resistance of the material are effectively improved; and the corn stalkparticles are adopted to prepare the building block material, the thermal conductivity of the material is significantly decreased, and heat preservation performance is improved.

Owner:淮安市冰青建设工程管理有限公司

Modified POM copolymer resin and preparation process thereof

The invention belongs to the technical field of resin modification, and particularly relates to modified POM copolymer resin and a preparation process thereof. The POM copolymer resin is prepared from homopolyformaldehyde, copolyformaldehyde, a composite nucleating agent, rubber particles, a fiber filler and a stabilizer. The composite nucleating agent comprises a mixture of an inorganic nucleating agent and an organic nucleating agent, the inorganic nucleating agent comprises one or more of nano silicon dioxide, nano calcium carbonate and boron nitride, and the organic nucleating agent comprises one of melamine formal, polyamide and a carbon nanotube. The resin is reinforced and modified through a re-checking nucleating agent, rubber particles and a fiber filler, the crystallinity of the resin is improved, the toughness of the resin is improved, the impact strength, flexibility, rigidity and creep resistance of the resin material are remarkably improved, the wear resistance and heat resistance of the resin material are improved, and the used material has the characteristic of low VOC; and the modified POM copolymer resin disclosed by the invention is applied to the field of automobiles and can meet the ultralow emission performance required by the automobile market.

Owner:广州搜料信息技术有限公司

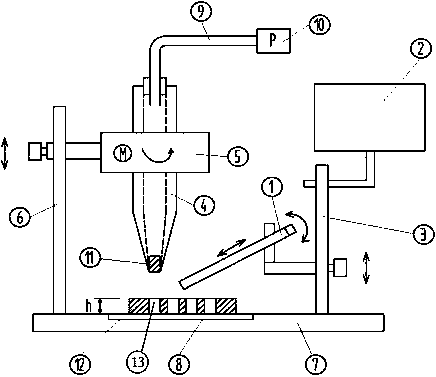

Automatic sampling instrument of single cells

PendingCN110736639APrecise positioningExact coordinate positionWithdrawing sample devicesMedicineDisplay device

The invention discloses an automatic sampling instrument of single cells. The instrument comprises an upright imaging system, a microdissection system, a sample table system and a sample extraction system; the upright imaging system comprises a high-definition imaging CCD and a display which are arranged on a CCD adjusting bracket; the microdissection system comprises a hollow cutting needle head,a cutting probe adjusting frame, and a high-speed motor connected with the hollow cutting needle head; the hollow cutting needle head and the high-speed motor are arranged on the cutting probe adjusting frame; the sample table system comprises a sample table and a sample heating table arranged on the sample table; a sample sheet is arranged on the sample heating table; the hollow cutting needle head is aligned to the position over a to-be-cut area of the sample sheet through the cutting probe adjusting frame; the high-definition imaging CCD is adjusted through the CCD adjusting bracket to image the to-be-cut area on the display; and the sample extraction system comprises a suction pipe connected with the hollow cutting needle head and a vacuum pump connected with the suction pipe. A graduated scale is arranged on the sample heating table. The instrument has the advantages of precise cutting of tiny areas, no influence on the activity of cells and tissues in a cutting area, simplicityand convenience in operation, high cutting efficiency, low use cost and the like.

Owner:JIANGSU RAYME BIOTECH

Health-care plant blend oil capable of preventing high blood pressure, high blood sugar and high blood lipid, and preparation method of health-care plant blend oil

The invention provides health-care plant blend oil capable of preventing high blood pressure, high blood sugar and high blood lipid, and a preparation method of the health-care plant blend oil, and relates to the field of edible oil. The health-care plant blend oil is prepared from the following components in parts by weight of 40-60 parts of corn germ oil, 10-20 parts of safflower seed oil, 8-15parts of wheat germ oil, 5-12 parts of fructus perillae oil, 4-10 parts of hemp seed oil, 10-20 parts of olive oil and 2-8 parts of pumpkin seed oil. The health-care plant blend oil has the advantagesof being balanced in fatty acid compounding ratio, rich in nutrients, rich in alpha-linolenic acids and capable of preventing high blood pressure, high blood sugar and high blood lipid.

Owner:ANHUI HUAAN FOOD CO LTD

Polyester silk with function of preventing radiation

InactiveCN105297154AHigh strengthImprove wear resistanceSpinnerette packsFilament forming substance formingPolyesterEngineering

A polyester silk with a function of preventing radiation relates to the technical field of polyester silk production and can be machined according to the following steps of (1) preparing basic filaments, (2) pre-orientating POY filaments and polyester full-stretch filaments PDY on the same rolling rack, (3) forming six equal-side and angle filament spraying slits on a filament spraying plate, (4) enabling PDY to enter a traction area from the same side of a pair of traction rollers, (5) compositing the basic filaments, the POY and the PDY filaments in the step (4) to a filament guide roller, (6) compositing the basic filaments, the POY and the PDY filaments to a beam of fialments and tracting the beam of filaments to polyester filaments via a heating large-diameter roller and a non-heating small-diameter roller. The side interval of two adjacent filament spraying slits is 0.05 to 0.07mm. The polyester filament has high strength, great wear-resistance and excellent radiation-proof effect.

Owner:LANGXI HEXIN CHEM FIBER WEAVING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com