Method for preparing organic polymer/silica sound-absorbing thermal insulation material

A technology of silica and thermal insulation materials, applied in the field of materials, can solve the problems of low penetration rate of micropores and general sound absorption effect of materials, and achieve the effects of excellent sound absorption performance, excellent thermal insulation performance, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

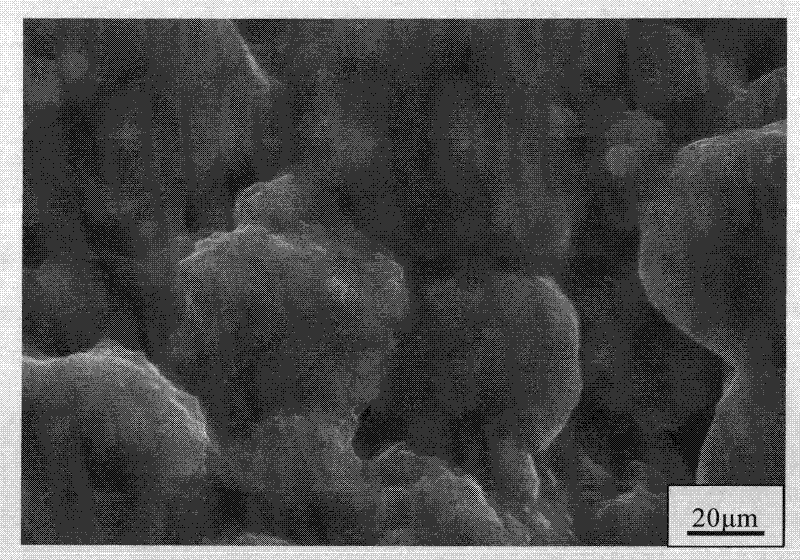

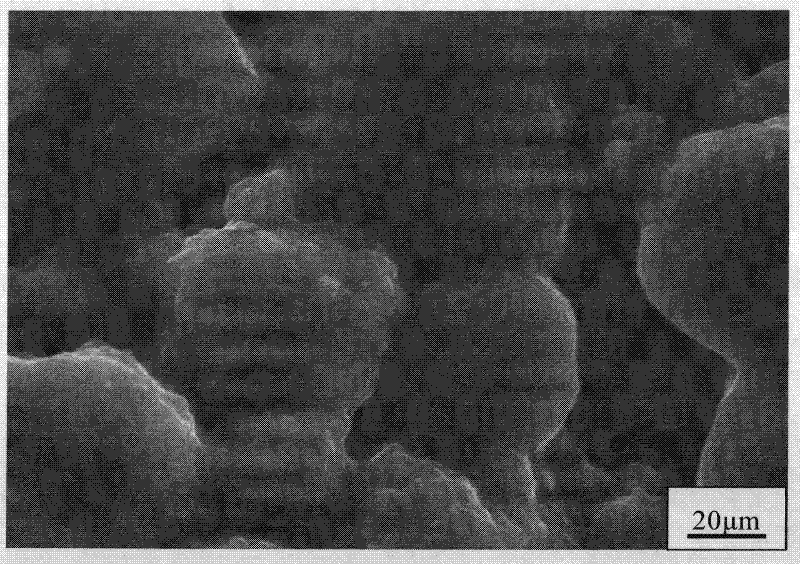

Image

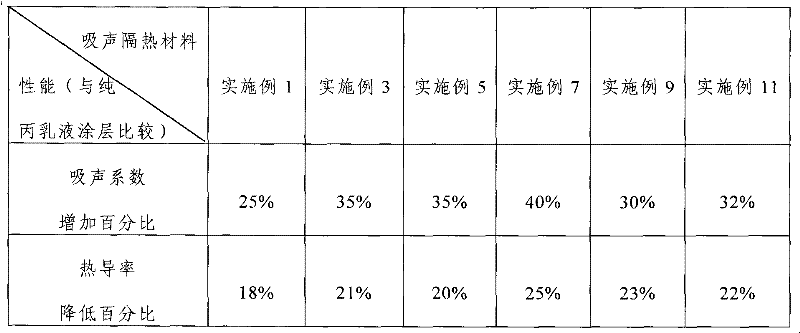

Examples

Embodiment 1

[0022] (1) Mix deionized water and water glass with a modulus of 3.2 at a volume ratio of 1:1, stir and heat to 80°C at a stirring rate of 200 rpm, then settle for 24 hours, and take the supernatant ;

[0023] (2) mixing the initiator, the organic polymer monomer and the inorganic acid uniformly to obtain a preset liquid; the initiator is ammonium persulfate, and the organic polymer monomer is acrylic acid, ethyl acrylate and methyl methacrylate, The inorganic acid is hydrochloric acid, and the mass concentration of the inorganic acid is 10%; the mass percentage of the initiator in the preset solution is 0.1%, the mass percentage of the organic polymer monomer is 99%, and the inorganic acid is the balance;

[0024] (3) Under the protection of nitrogen, heat the supernatant liquid described in step (1) to 55°C, and then slowly add the preset liquid described in step (2) dropwise at a stirring rate of 100 rpm A mixed solution is formed, and the dripping is stopped when the mixe...

Embodiment 2

[0029] The preparation process of this example is the same as that of Example 1, except that the initiator is azoisobutyronitrile or azoisobutyronitrile and ammonium persulfate, and the organic polymer monomers are acrylic acid and ethyl acrylate or a mixture of acrylic acid and butyl acrylate, or a mixture of acrylic acid and methyl methacrylate, or a mixture of acrylic acid, ethyl acrylate and butyl acrylate, or acrylic acid, butyl acrylate and methacrylic acid Mixtures of methyl esters, or mixtures of acrylic acid, ethyl acrylate, butyl acrylate and methyl methacrylate, or mixtures of methacrylic acid and acrylates, or mixtures of acrylic acid, methacrylic acid and acrylates , the acrylates are one or more of ethyl acrylate, butyl acrylate and methyl methacrylate, and the inorganic acid is sulfuric acid, nitric acid or phosphoric acid, or hydrochloric acid, sulfuric acid, nitric acid and phosphoric acid At least two.

Embodiment 3

[0031] (1) Mix deionized water and water glass with a modulus of 3.0 at a volume ratio of 1:3, stir and heat to 90°C at a stirring rate of 500 rpm, then settle for 36 hours, and take the supernatant ;

[0032] (2) mixing the initiator, the organic polymer monomer and the inorganic acid uniformly to obtain a preset liquid; the initiator is ammonium persulfate, and the organic polymer monomer is acrylic acid, butyl acrylate and methyl methacrylate, The inorganic acid is hydrochloric acid, and the mass concentration of the inorganic acid is 10%; the mass percentage of the initiator in the preset solution is 2.5%, the mass percentage of the organic polymer monomer is 72%, and the inorganic acid is the balance;

[0033] (3) Under the protection of argon, heat the supernatant solution described in step (1) to 95°C, and then slowly add the preset solution described in step (2) dropwise at a stirring rate of 200 rpm. The liquid forms a mixed solution, and the dripping is stopped when...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com