Anti-crack concrete mixture and preparation method thereof

A mixture and concrete technology, applied in the field of concrete, can solve problems affecting normal use, concrete cracking, etc., and achieve the effects of improving large drying shrinkage deformation, high bonding strength, and improving dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: A kind of anti-cracking concrete mixture, each component and its corresponding parts by weight are shown in Table 1, and are prepared through the following steps:

[0045] S1, fully mixing cement, sand, fine stone, silica fume and graphene-modified polypropylene fibers to form a mixture;

[0046] S2, adding the water reducer to water to form a mixed solution;

[0047] S3, adding the mixed solution into the mixture, and continuously stirring and mixing to obtain the crack-resistant concrete mixture.

[0048] Wherein the graphene modified polypropylene fiber is prepared by the following steps:

[0049] a, put polypropylene resin, graphene, octadecyl isocyanate, and polyvinylpyrrolidone into a ball mill at a weight ratio of 1:0.01:5:0.02, and perform ball milling for 2 hours at a speed of 280 rpm, and then add it to bis In the screw extruder, the temperature of the five stages from the feeding port to the machine head is set to 160°C, 175°C, 180°C, 180°C, 1...

Embodiment 2-6

[0051] Example 2-6: A crack-resistant concrete mixture, the difference from Example 1 is that each component and its corresponding parts by weight are shown in Table 1.

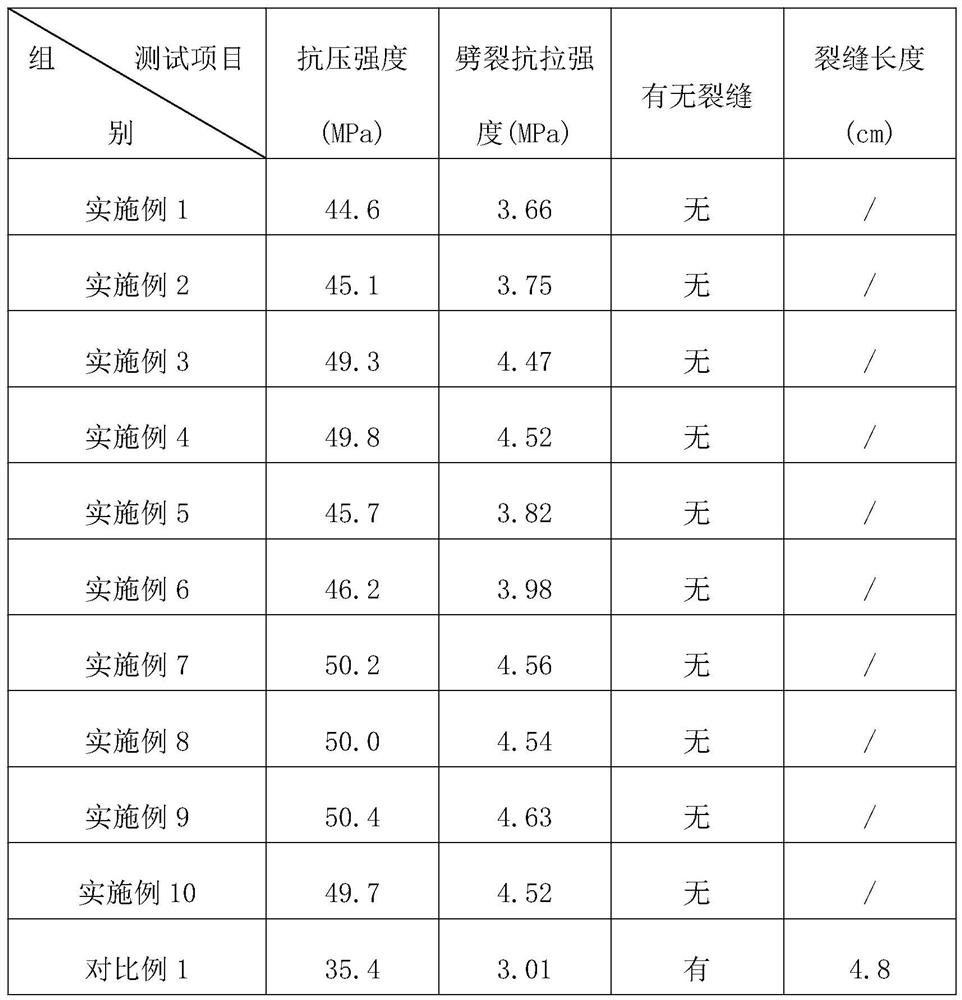

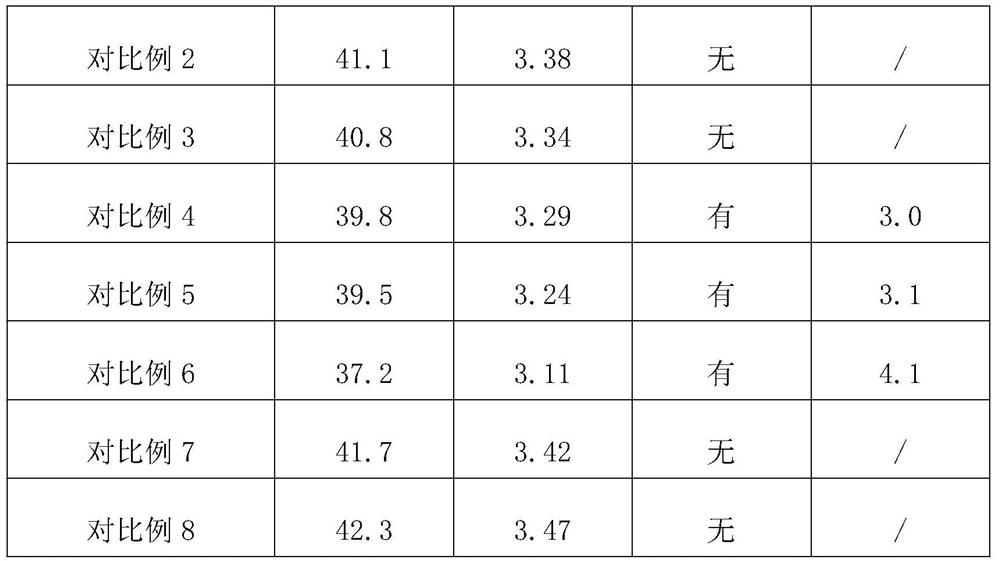

[0052] Each component and its weight (kg) in table 1 embodiment 1-6

[0053]

Embodiment 7

[0054]Embodiment 7: a kind of anti-cracking concrete mixture, the difference with embodiment 4 is, when preparing graphene modified polypropylene fiber, polypropylene resin, graphene, octadecyl isocyanate and polyvinylpyrrolidone The weight ratio is controlled at 1:0.05:10:0.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com