Polymer-matrix composite material and preparation method thereof

A composite material and polymer technology, applied in the field of polymer-based composite materials and their preparation, can solve the problems of increased density, poor toughness, and poor sound damping effect of composite materials, and can overcome the greatly increased density and improved strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of described composite material, comprises the following steps:

[0040] (1) Preparation of hollow silica nanospheres by sol-gel method:

[0041](1-1) Preparation of polystyrene emulsion: add styrene to deionized water, add an emulsifier such as polyvinylpyrrolidone, stir to make it evenly mixed, and obtain a mixed system, the mass of styrene per gram of deionized water is 0.06 grams ~0.16 g; under the condition of no oxygen, keep the temperature of the system at 50°C ~ 80°C, then add the aqueous solution of potassium persulfate, each gram of deionized water corresponds to 0.5 mg ~ 2 mg of potassium persulfate; react for 8 hours After 12 hours, add 0.01mL~0.05mL of methacryloyloxyethyltrimethylammonium chloride dropwise, continue the reaction until complete, and obtain a functionalized polystyrene emulsion; preferably polyvinylpyrrolidone is used as an emulsifier At the same time, the mass of polyvinylpyrrolidone contained in each gram of deioniz...

Embodiment 1

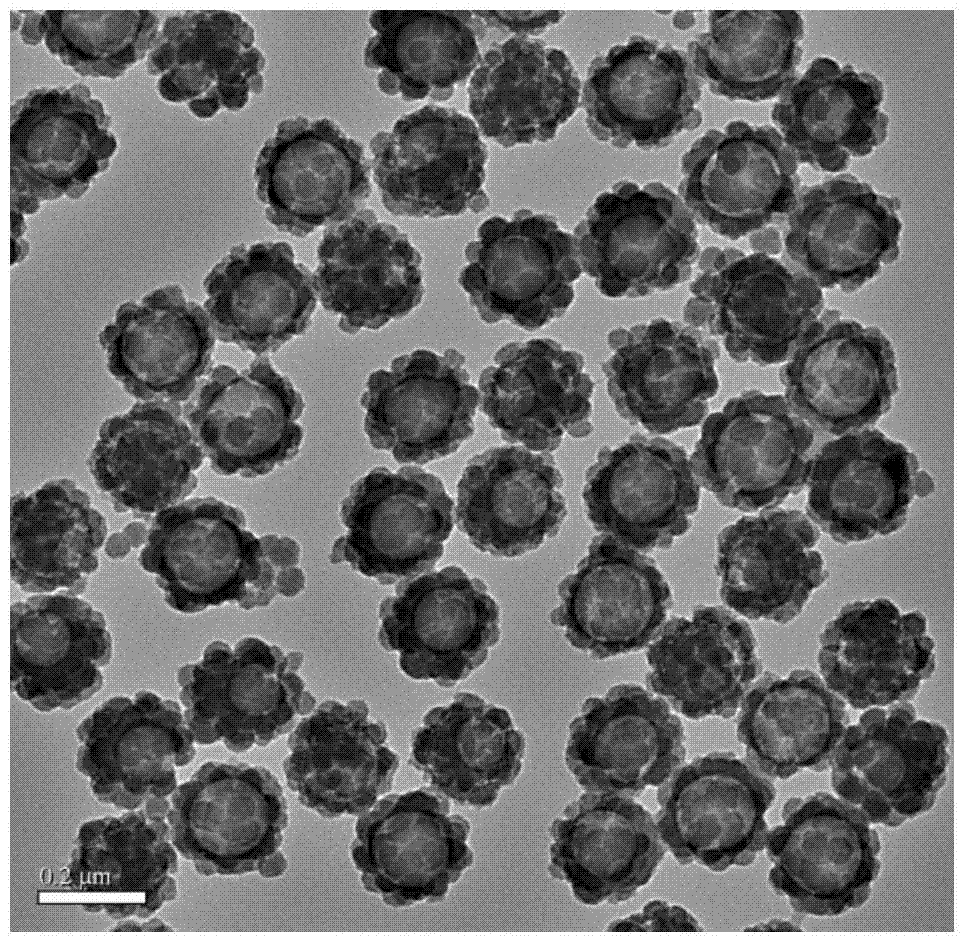

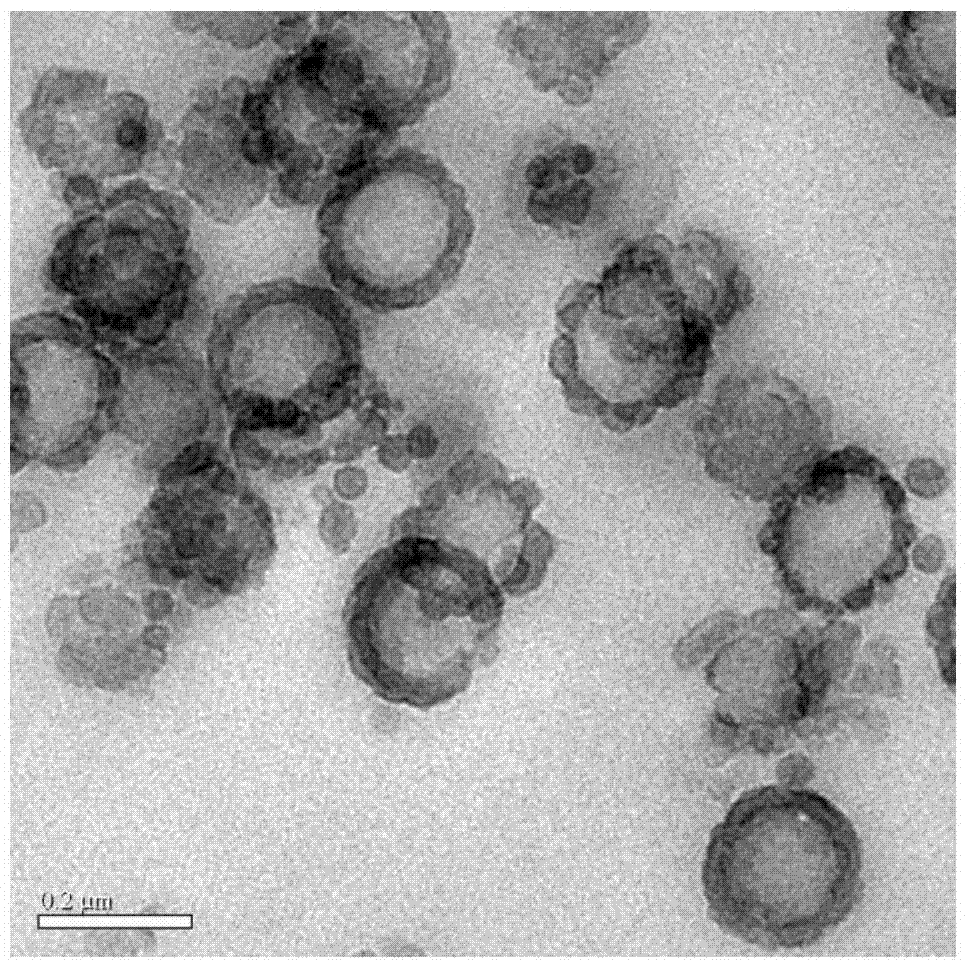

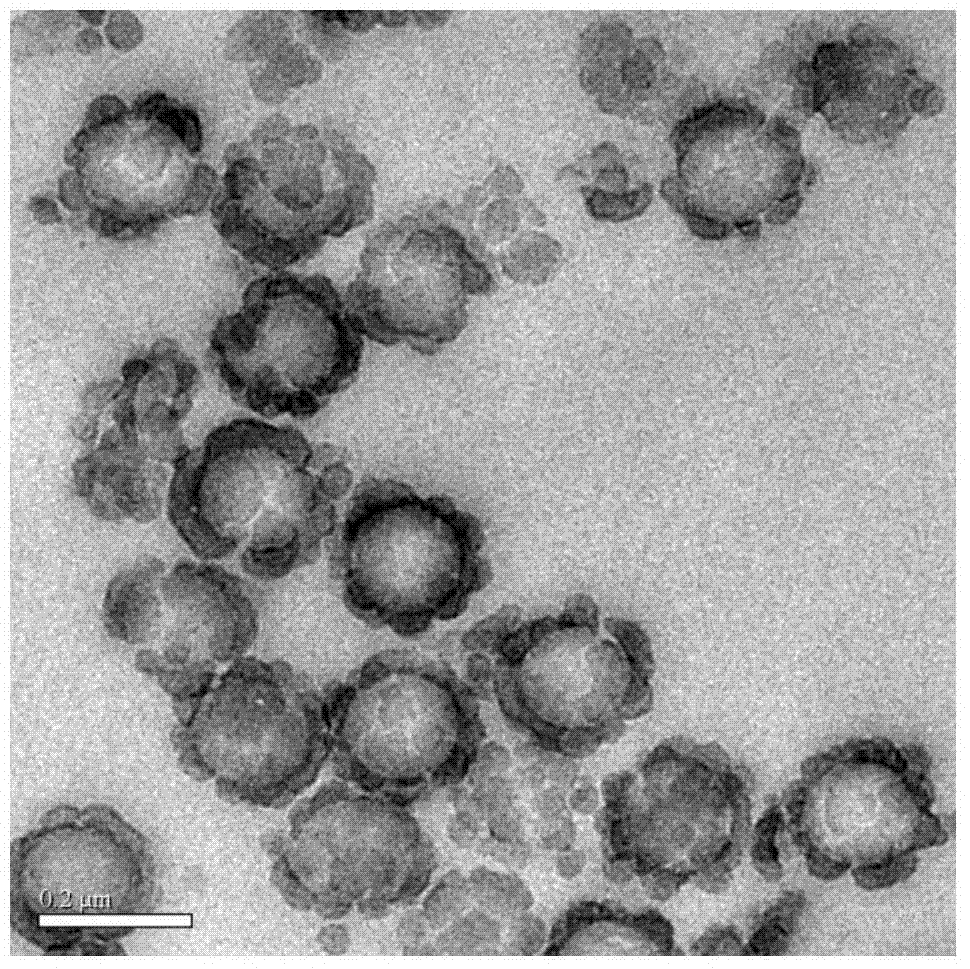

[0055] An epoxy resin-silica hollow sphere composite material, comprising silica hollow nanospheres and E-51 bisphenol A type epoxy resin matrix, the silica hollow nanospheres are dispersed in epoxy resin, Its addition amount is 2wt.% of epoxy resin. The silica hollow nanospheres are hollow silica nanospheres surface-modified by KH-550 silane coupling agent, the length of the outer diameter is about 210nm, the length of the inner diameter is about 90nm, and the specific surface area is about 61m 2 / g.

[0056] The preparation method of the epoxy resin-silicon dioxide hollow sphere composite material comprises the following steps:

[0057] (1) Preparation and modification of silica hollow nanospheres:

[0058] (1-1) Preparation of polystyrene emulsion: adding styrene to deionized water, adding an emulsifier and stirring to make it evenly mixed to obtain a mixed system, the quality of styrene per gram of deionized water is 0.05 grams; Under these conditions, keep the tempera...

Embodiment 2

[0068] An epoxy resin-silica hollow sphere composite material, comprising silica hollow nanospheres and E-54 bisphenol A epoxy resin, the silica hollow nanospheres are dispersed in the epoxy resin, and The added amount is 3wt.% of the epoxy resin. The silica hollow nanospheres are hollow silica nanospheres surface-modified by KH-550 silane coupling agent, the length of the outer diameter is about 210nm, the length of the inner diameter is about 90nm, and the specific surface area is about 61m 2 / g.

[0069] The preparation method of the epoxy resin-silicon dioxide hollow sphere composite material comprises the following steps:

[0070] (1) Preparation and modification of silica hollow nanospheres:

[0071] (1-1) Preparation of polystyrene emulsion: add styrene to deionized water, add polyvinylpyrrolidone and stir to make it evenly mixed to obtain a mixed system, the mass of styrene per gram of deionized water is 0.1 gram; Under certain conditions, keep the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com