Preparation process of Ti alloy wire rope for marine engineering

A technology of marine engineering and preparation technology, applied in textile cables, textiles and papermaking, etc., can solve the problems of poor corrosion resistance of steel wire ropes, affecting the stability and reliability of equipment, achieve strong corrosion resistance, reduce maintenance and replacement costs, and solve corrosion. effect of the problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A preparation process for titanium alloy wire ropes for ocean engineering, comprising the following specific steps:

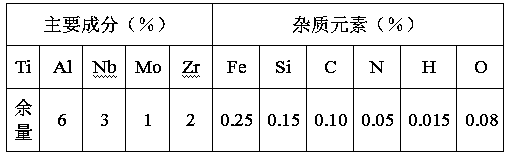

[0036] Step 1. According to the formula quantity, select the chemical components of the following weight proportions and mix them evenly. See Table 1 below for the chemical component distribution ratios.

[0037] Table 1 Raw material composition ratio

[0038]

[0039] Step 2. Extrude the mixed material in step 1 to prepare an electrode, cut off the riser after smelting, and prepare a light ingot by machining. The light ingot is blanked, forged, and rolled at a temperature of 1100 ° C to obtain a diameter of Φ8. .0mm wire rod;

[0040] Step 3. The light ingot in step 2 is prepared in two stages of thick wire hot drawing and room temperature drawing to obtain alloy filaments. The hot drawing method is: put the wire rod in step 1 into the furnace Through graphite milk before, after ten times of high-temperature drawing: Φ8.0mm→Φ7.0mm→Φ6.0mm→Φ5.0mm→Φ4....

Embodiment 2

[0046] A preparation process for titanium alloy wire ropes for ocean engineering, comprising the following specific steps:

[0047] Step 1. According to the formula quantity, select the chemical components of the following weight proportions and mix them evenly. See Table 2 below for the chemical component distribution ratios.

[0048] Table 2 Raw material composition ratio

[0049]

[0050] Step 2. Extrude the mixed material in step 1 to make an electrode, cut off the riser after smelting, and prepare a light ingot by machining. The light ingot is blanked, forged, and rolled at a temperature of 1150°C to obtain a diameter of Φ8. .0mm wire rod;

[0051] Step 3. The light ingot in step 2 is prepared in two stages of thick wire hot drawing and room temperature drawing to obtain →alloy filaments, wherein the hot drawing method is: the wire rod in step 1 is drawn into Graphite milk is passed through the front of the furnace, and after ten times of high temperature drawing Φ8....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

| Breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com