Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Intensity exceeds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environment-friendly adhesive for quickly adhering aluminum alloy and PVC thin film and preparation and application thereof

InactiveCN101792641AOver tear strengthImprove adhesionOrganic non-macromolecular adhesiveModified epoxy resin adhesivesAdhesiveFirming agent

The invention discloses an environment-friendly adhesive for quickly adhering aluminum alloy and PVC thin film and preparation and application thereof. The environment-friendly adhesive comprises the following components: 10 to 30 parts of urethane acrylate, 5 to 40 parts of epoxy acrylate, 10 to 30 parts of rubber, 5 to 15 parts of viscosifier, 20 to 60 parts of reactive diluent, 2 to 5 parts of glutinous rice flour, 0.2 to 1.5 parts of initiator and 0.2 to 1.0 part of curing agent. The environment-friendly adhesive has excellent adhesion performance on the aluminum alloy and PVC insulating thin film, has the adhesive force of the first level, and can be applied to high-temperature operating environment; and the cured adhesive film has higher softening point of over 80 DEG C. The mean value of the hardness of the cured adhesive film obtained by using the adhesive is between 70 and 75A; and the adhesive film cured has good hardness and toughness. The environment-friendly adhesive for quickly adhering aluminum alloy and PVC thin film and the preparation and application thereof have the advantages of simple preparation method, moderate cost, stable comprehensive performance of the obtained products, and great functions of energy conservation and emission reduction.

Owner:SOUTH CHINA UNIV OF TECH

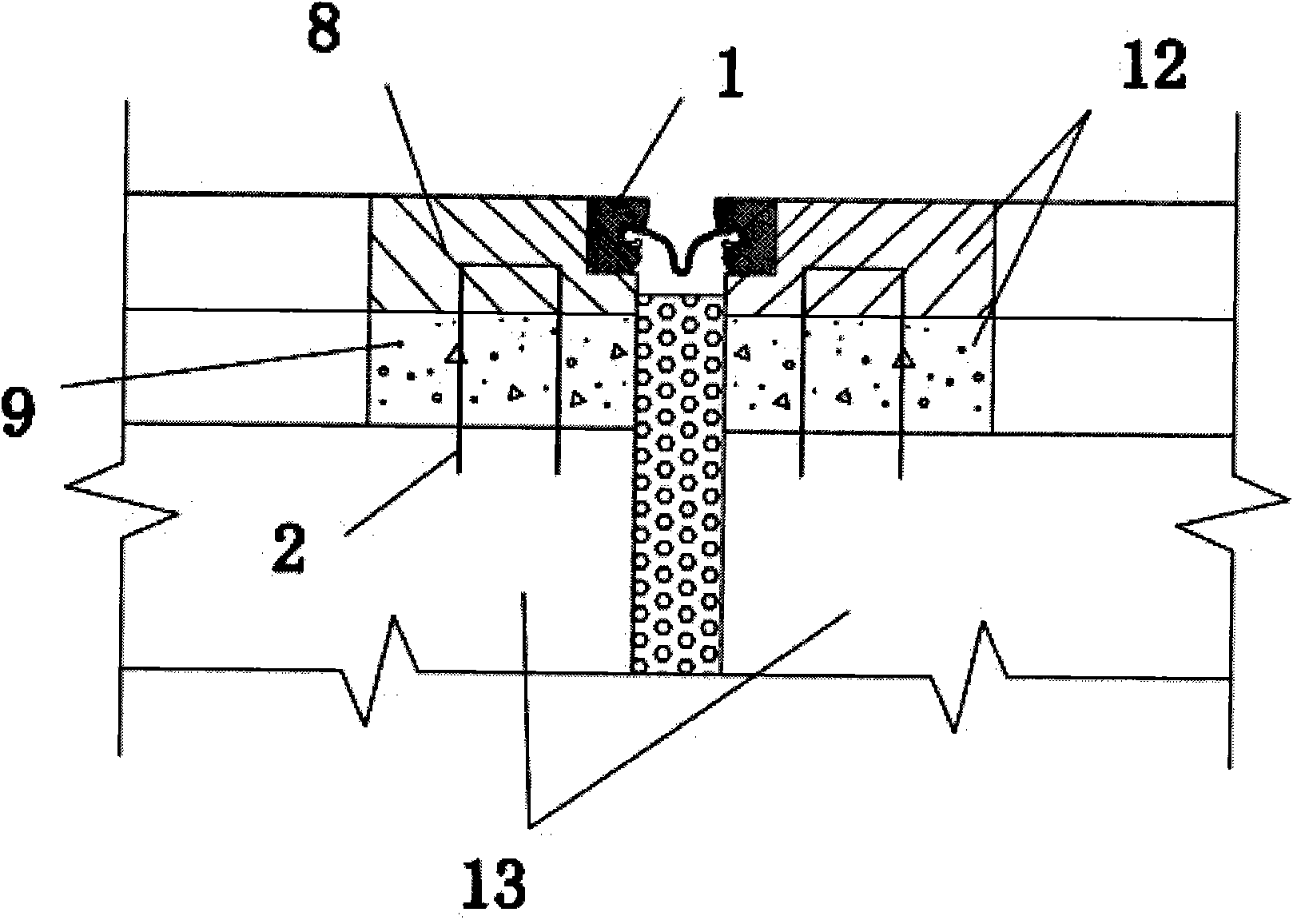

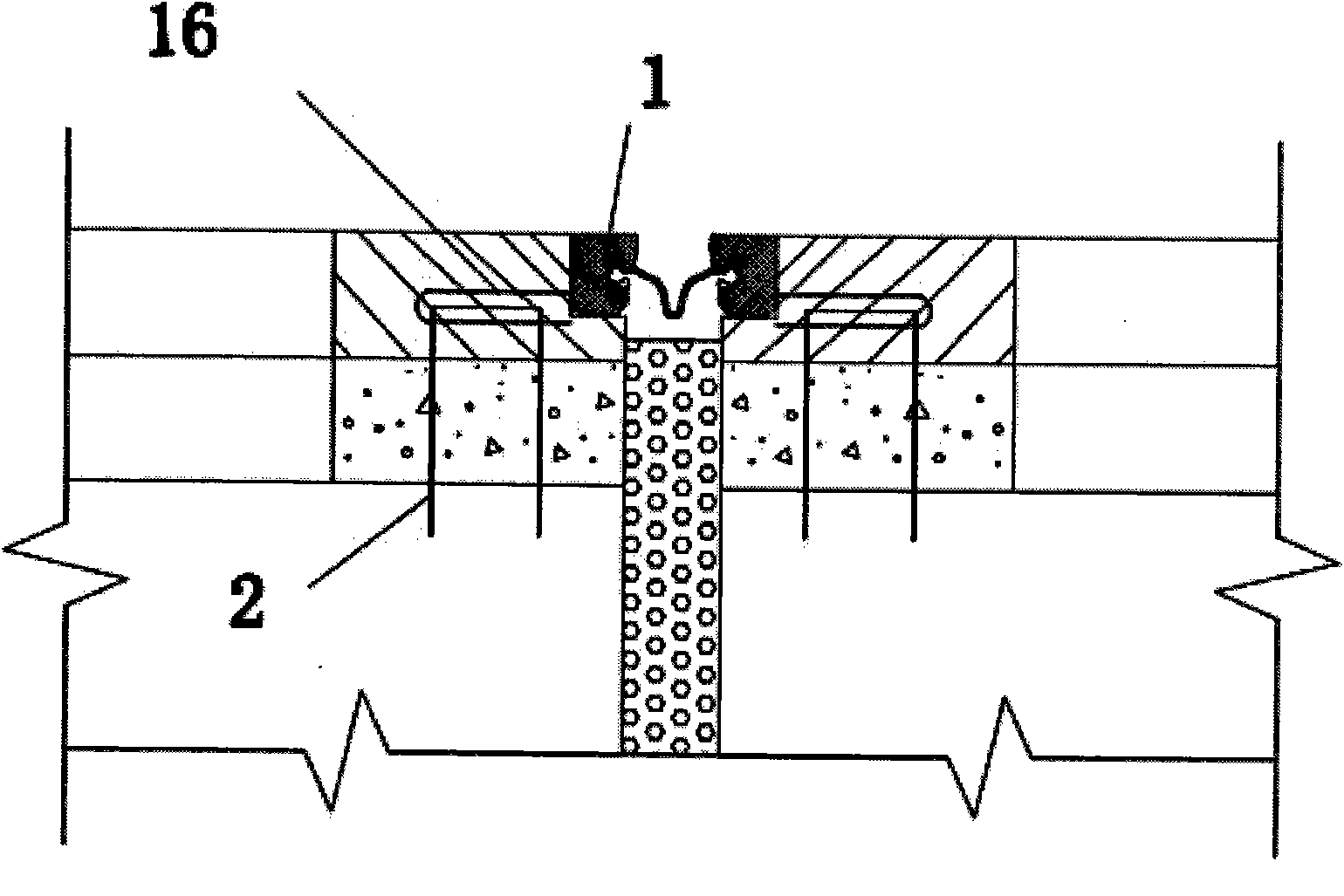

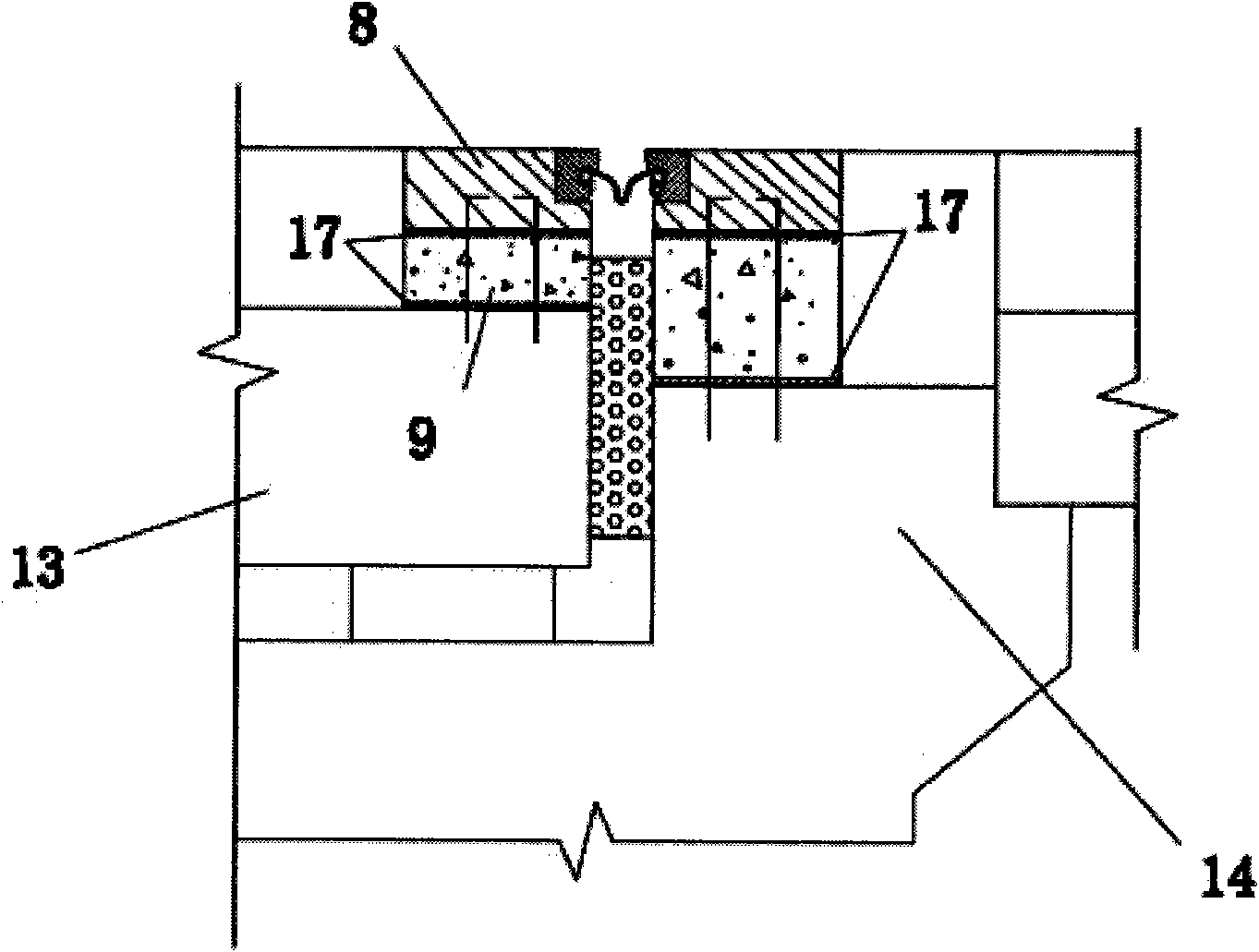

Bridge expansion joint structure and construction technology thereof

InactiveCN101892631ALow costFast constructionBridge structural detailsBridge materialsExpansion jointAbutment

The invention provides a bridge expansion joint structure which comprises a concrete layer, section steel, embedded bars and a packing layer, wherein, the concrete layer mainly comprises an elastic concrete layer and an epoxy resin concrete layer, wherein, the elastic concrete layer is positioned above the epoxy resin concrete layer, and the epoxy resin concrete layer is arranged above adjacent beam slabs or above adjacent beam slabs and abutment coping back walls. The construction technology of the bridge expansion joint structure is to pour concrete on the beam slabs or the abutment coping back walls, and comprises the following specific measures: coating a binder on the beam slabs or the abutment coping back walls; pouring epoxy resin concrete on the binder and curing for 1 hour; painting the binder on the cured epoxy resin concrete; and pouring elastic concrete on the binder painted on the epoxy resin concrete and curing for 2 hours. The bridge expansion joint structure and the construction technology provided by the invention have the beneficial effects of high strength, simple construction technology, short curing time and low construction cost.

Owner:ZHEJIANG KEBO REINFORCEMENT WORKS CO LTD

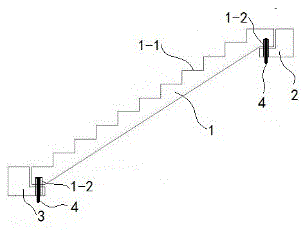

Concrete prefabricated stair

InactiveCN105544895APaste strength exceedsIntensity exceedsTreadsArchitectural engineeringUltimate tensile strength

The invention relates to the field of building components, in particular to a concrete prefabricated stair. The concrete prefabricated stair comprises a prefabricated stair body and stepping surfaces of the prefabricated stair body, and the stepping surfaces are granitic plaster surfaces. According to the concrete prefabricated stair, the bottoms of the two ends of the prefabricated stair body are provided with threaded holes for construction and installation respectively; the concrete prefabricated stair is high in strength after site construction and installation are conducted, an artificial chiseling chip-axe is not needed for the surface of the stair, later-period work can be directly conducted, and the construction period is shortened.

Owner:山东汇富建设集团建筑工业有限公司

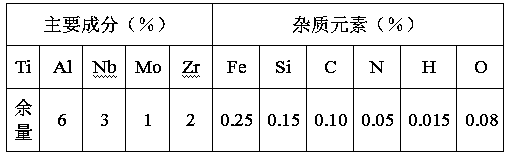

Preparation process of Ti alloy wire rope for marine engineering

InactiveCN110387486AIntensity exceedsStrong corrosion resistanceTextile cablesCorrosion resistantWire rope

The invention provides a preparation process of a Ti alloy wire rope for marine engineering. The preparation process comprises the following steps: step 1, electing sponge Ti, sponge Zr, Al shots, anAl-Mo intermediate alloy and an Al-Nb intermediate alloy according to the composition amount, and uniformly mixing the above raw materials; step 2, preparing an electrode by extruding the mixed materials obtained in step 1, cutting off a riser after smelting, and preparing a polished ingot by the adoption of machining; step 3, carrying out wire material preparation by subjecting the polished ingotprepared in step 2 to two stages: hot drawing of a coarse wire and hot drawing at room temperature, so as to obtain alloy fine wires; and step 4, stranding and braiding the alloy fine wires obtainedin step 3 in the form of point contact, so as to obtain the Ti alloy wire rope finally. According to the preparation process provided by the invention, the Ti alloy wire rope is prepared by adopting the Ti alloy material; the corrosion-resistance performance of the Ti alloy wire rope is relatively strong; compared with a steel wire rope, the Ti alloy wire rope has the advantages that the corrosionproblem is solved and the equipment running safety is guaranteed; meanwhile, the maintenance and replacement cost is greatly reduced; and the Ti alloy wire rope is widely applicable to marine engineering and other corrosion environments.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

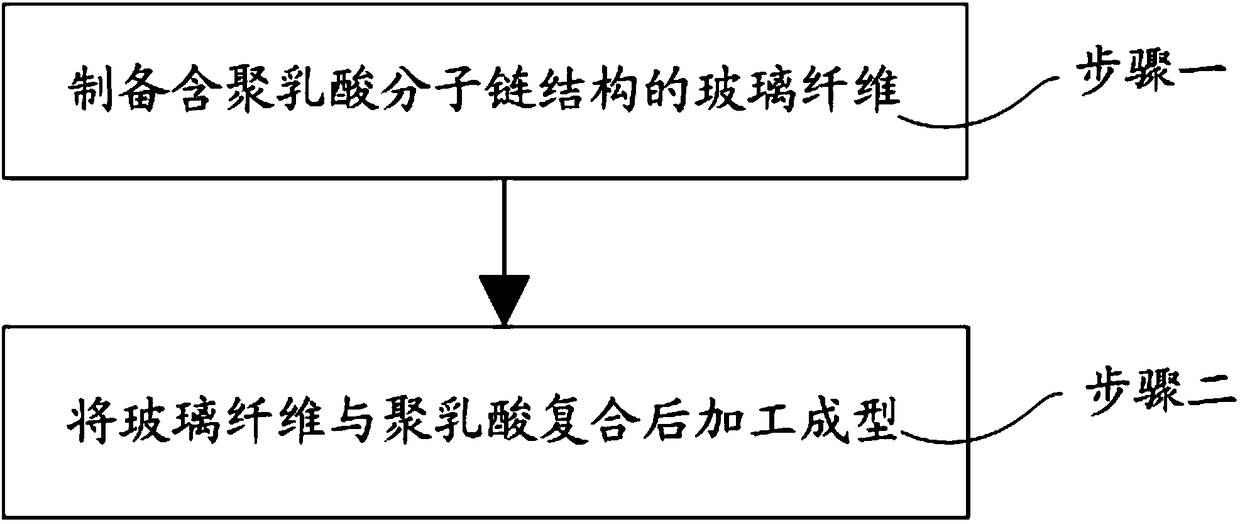

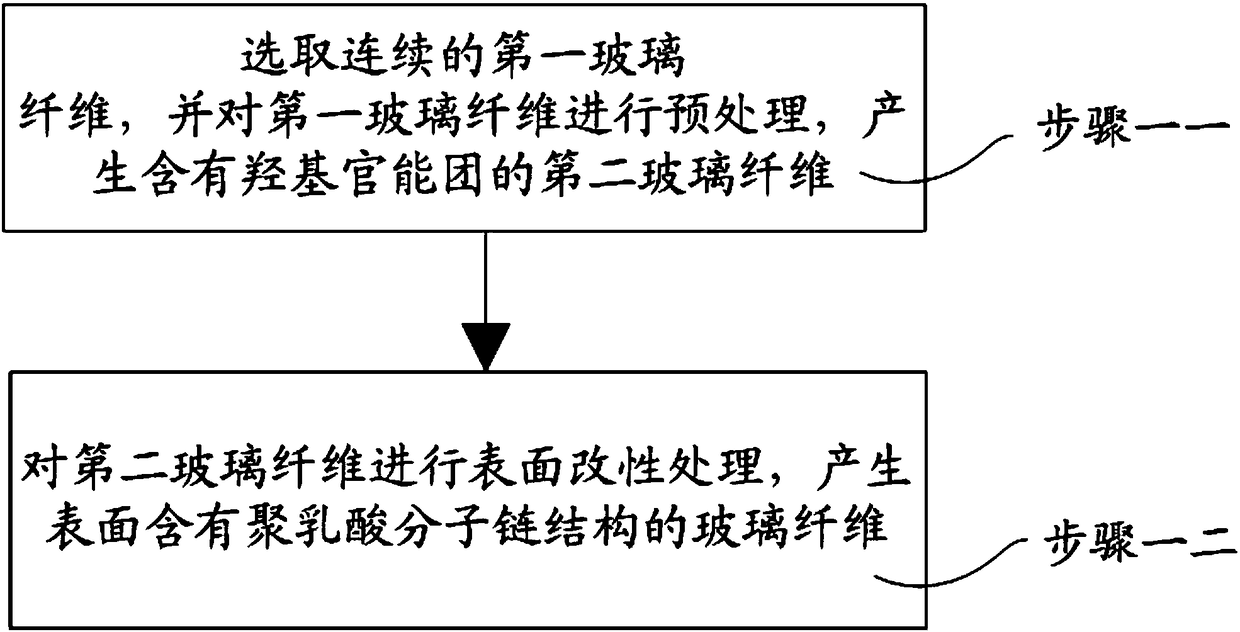

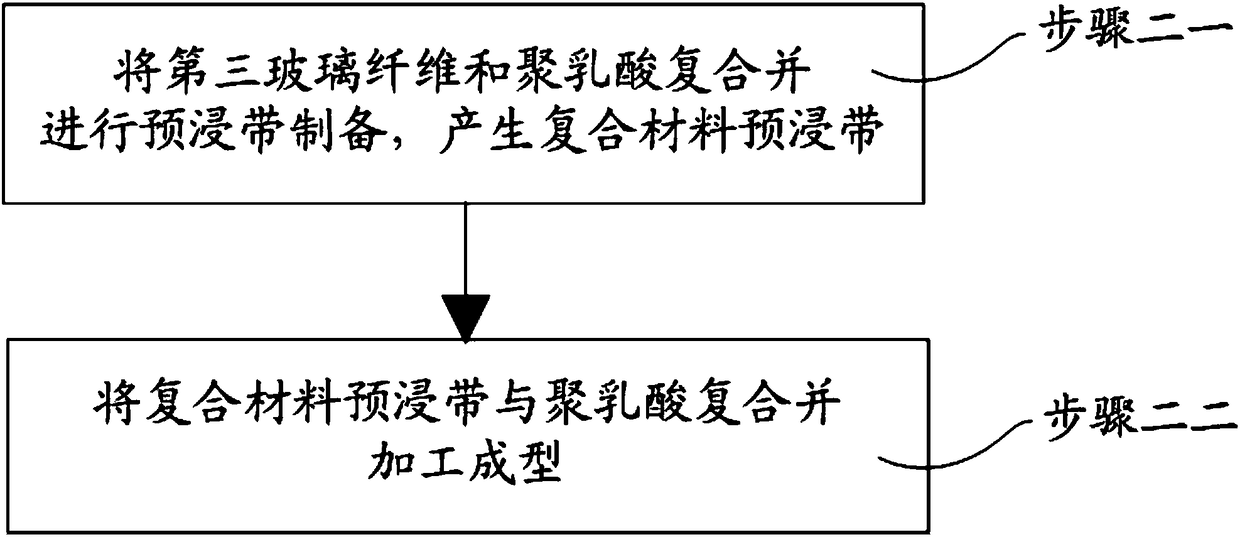

Implant for orthopedics department, material for preparing implant and preparation method of implant

InactiveCN108066822ASolve the problem of mechanical strengthHigh strengthPharmaceutical delivery mechanismTissue regenerationGlass fiberChain structure

The invention provides an implant for the orthopedics department, a material for preparing the implant and a preparation method of the implant. The material for preparing the implant is formed by compositing glass fiber serving as a reinforcing phase and polylactic acid serving as a base phase. The preparation method of the implant comprises the steps as follows: step 1, preparing the glass fibercontaining a polylactic acid molecular chain structure; step 2, compositing the glass fiber and polylactic acid and then performing processing. The compatibility and dispersion uniformity of the glassfiber and the polylactic acid base body are improved, the strength of the polylactic acid implant is improved effectively, the stress shielding effect can be avoided, and the implantation effect is good.

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

Ceramic particle for water treatment and preparation thereof

InactiveCN101348383AAppropriate proportionSmall expansion coefficientSustainable biological treatmentCeramicwareCeramic particleCoal

The invention discloses a ceramic particle for water treatment and a preparation method thereof, belonging to the production field of water treatment filter material. The ceramic particle is made from granite powder, bentonite, coke powder, sawdust and pulverized coal in a certain proportion. Compared with the prior art, the ceramic particle has the characteristics of good water purifying effect, low production cost, little energy consumption, and so on, and can be widely applied to sewage treatment in various fields.

Owner:商士强

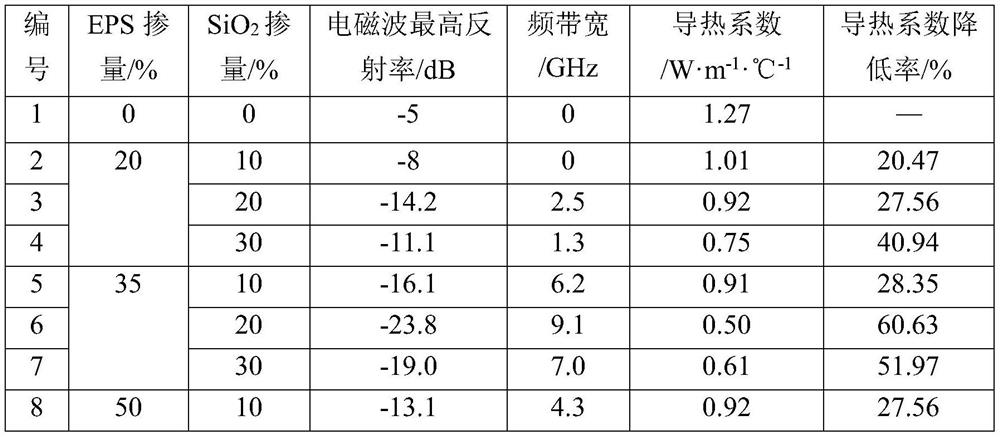

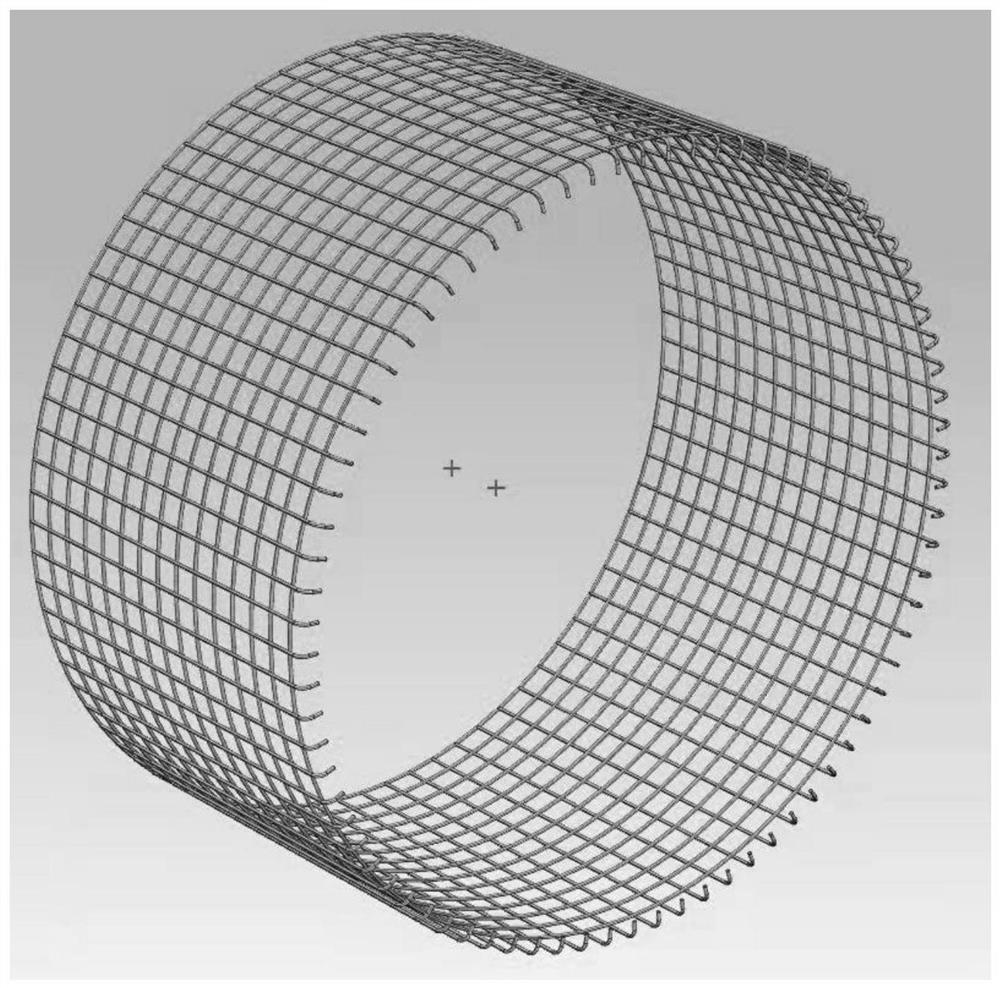

Preparation method for electromagnetic protection phosphate material capable of being subjected to 3D printing

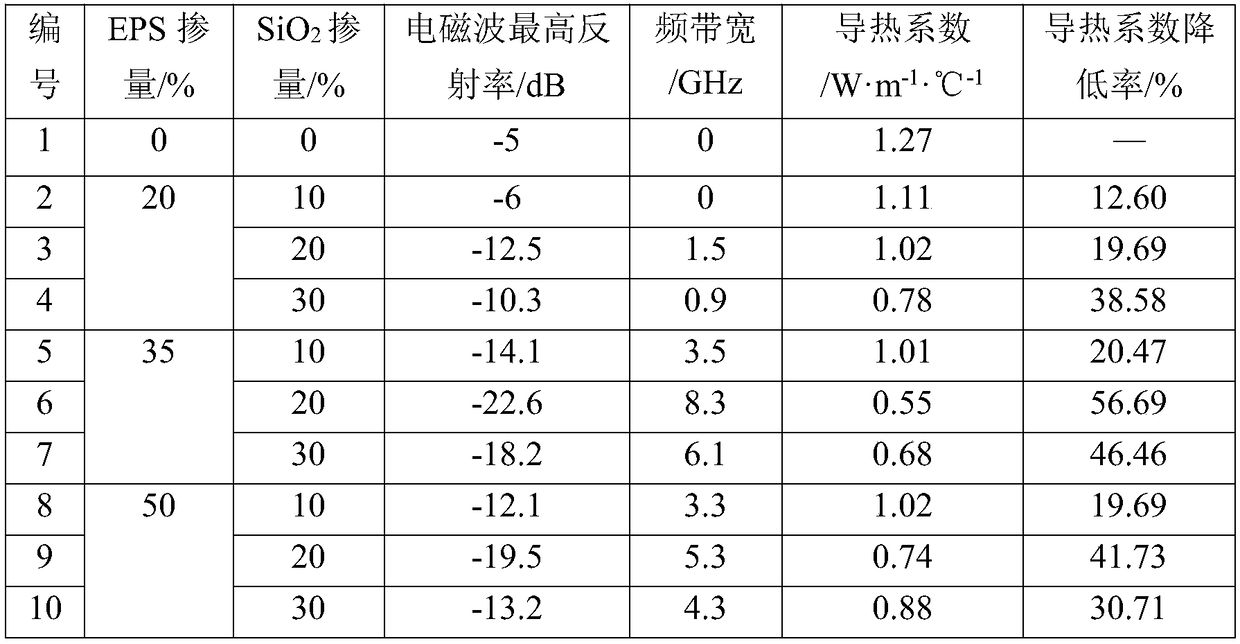

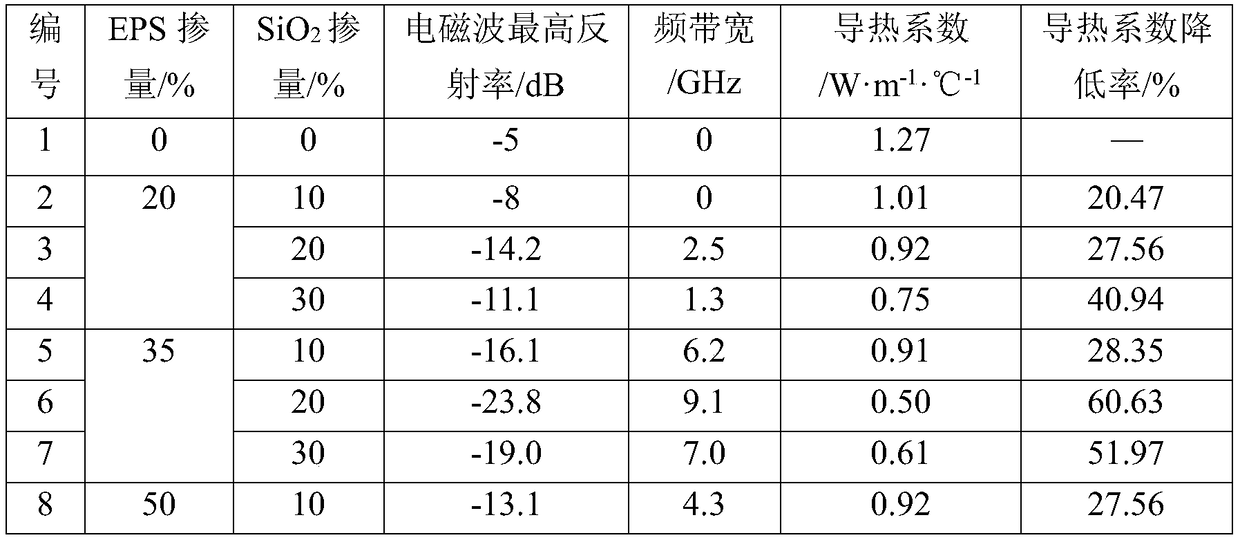

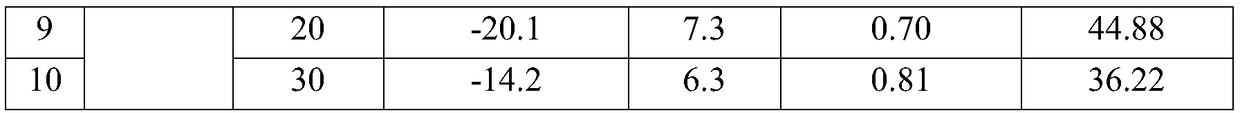

ActiveCN109265128AImprove high temperature resistanceImprove stabilityAdditive manufacturing apparatusBuilding constructionsElectromagnetic electron waveDual effect

The invention discloses a preparation method for an electromagnetic protection phosphate material capable of being subjected to 3D printing. According to the method, phosphate cement and a porous aggregate material are utilized for preparing functional phosphate cement integrating electromagnetic wave absorbing and heat preservation integration, an electromagnetic wave absorbing structure is printed on the surface of a concrete structure by utilizing the performance of intelligence, flexibility, precision and the like of the 3D printing technology, and the porous aggregate material is porous EPS, and the dual effects of achieving electromagnetic wave absorbing and protection on the concrete structure and improving the heat preservation performance of the concrete structure are achieved.

Owner:HEBEI UNIV OF TECH

Recycling technology for manufacturing industrial pallets by utilizing organic solid waste in furniture industry

Provided is a recycling technology for manufacturing industrial pallets by utilizing organic solid waste in the furniture industry. The invention belongs to the field of transforming solid waste into useful articles, and especially belongs to the solid waste recycling field of manufacturing industrial pallets by utilizing wood waste in the furniture industry. The industrial pallets are mainly composed of waste wood material powder, nano-scale calcium carbonate and / or calcium sulfate whiskers, a titanate coupling agent, stearic acid, silicone oil, plastics and / or waste plastics, aluminum hydroxide, chlorinated polyethylene (CPE), maleic anhydride, dicumyl peroxide (DCP) and paraffin wax. The key point of the technology is that the industrial pallets contain the calcium sulfate whiskers. The manufactured industrial pallets are of high strength, can be used repeatedly, have a smooth appearance, and have very high environmental benefit.

Owner:HUNAN BOXIANG NEW MATERIAL RES

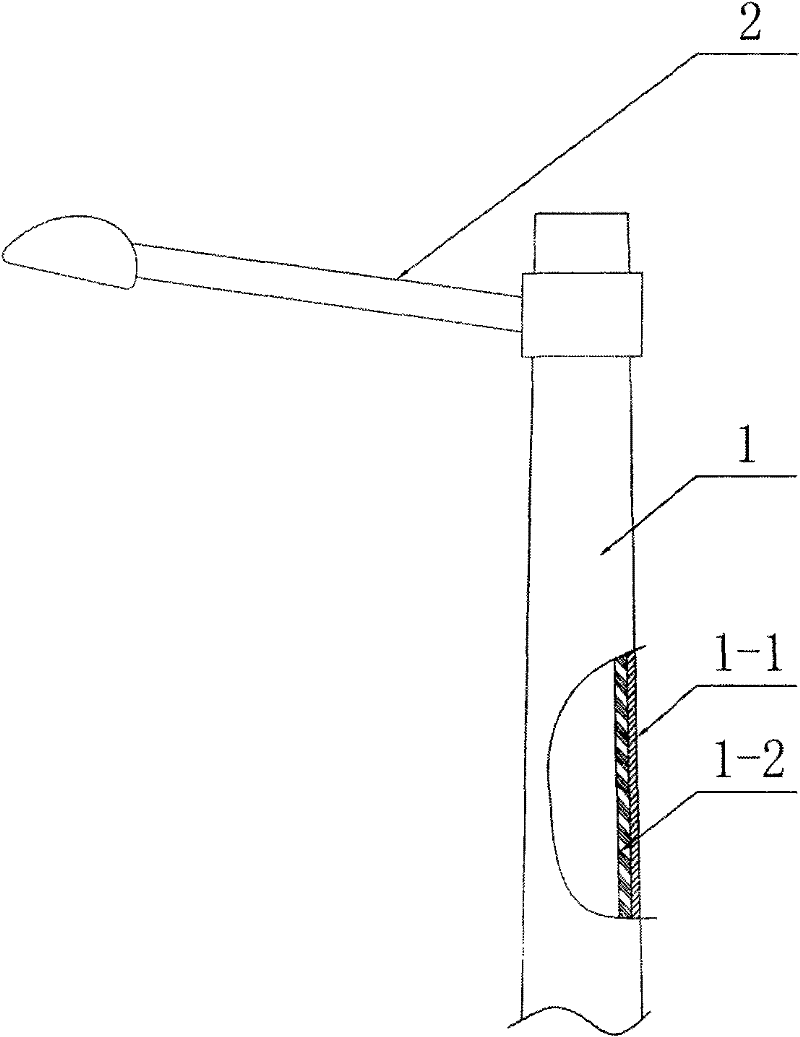

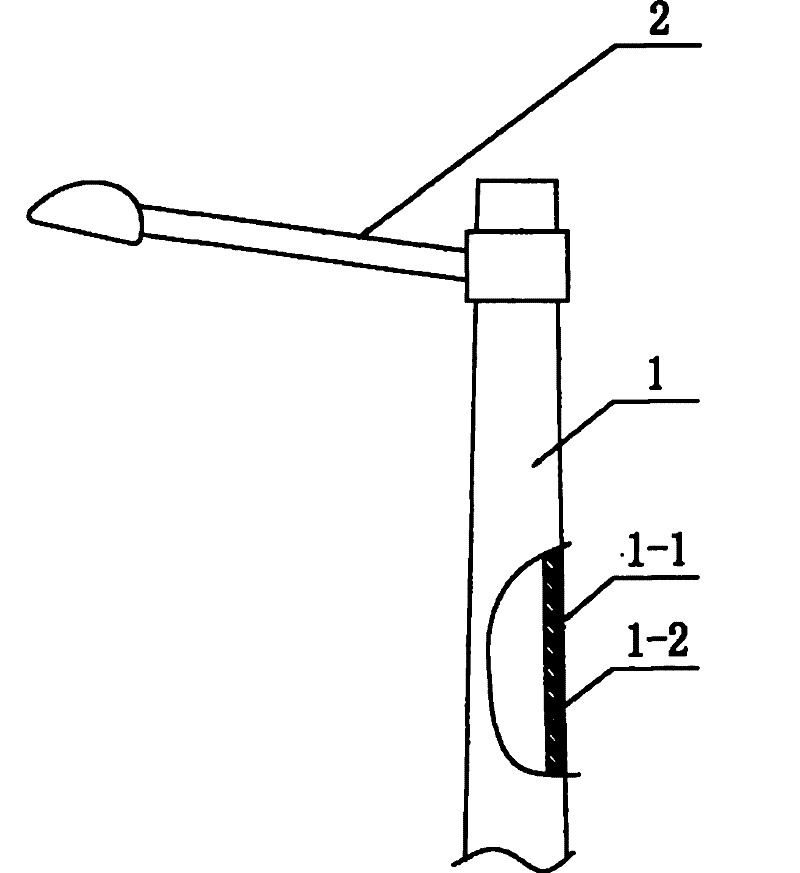

Lamp post made of composite material

The invention relates to a lamp post made of a composite material. The lamp post comprises a post body and a post arm, wherein the lamp body is composed of an outer wall layer and an inner core layer, the outer wall layer is composed of continuous fiber reinforced resin and the inner core layer is composed of resin concrete; the post arm is composed of continuous fiber reinforced resin; the fiber is selected from at least one of glass fiber, carbon fiber or basalt fiber, and 30-95% fibers of the post body is in axial distribution; and the resin is unsaturated polyester resin, vinyl resin or ethoxyline resin, the resin concrete is composed of 15-30% of resins, 0-20% of short glass fibers and 50-80% of 10mu m-4mm inorganic particle paddings. The lamp post made of the composite material provided by the invention has the characteristics of beautiful appearance, never rustiness, long service life, low manufacturing cost, wide popularization value and the like, and can be used for replacing steel resources.

Owner:曾建祥

High-strength and high-performance mineral admixture for concrete and production method thereof

The invention relates to a high-strength and high-performance mineral admixture for high-strength and high-performance concrete and a production method thereof. The particle size of 97% of the total weight of the high-strength and high-performance mineral admixture is smaller than 20 microns. A closed-loop microsphere tube mill with a superfine powder concentrator is used for grinding. The production method has the advantages of industrial feasibility, energy conservation and the like. The high-strength and high-performance mineral admixture not only comprehensively utilizes a large amount of industrial waste residues in the industries of metallurgy, coal mine, thermal power, garbage treatment and the like, but also fundamentally improves the constructability of concrete and multiplies the strength and durability.

Owner:郑州无为粉体科技有限公司

Ceramic particle for water treatment and preparation thereof

InactiveCN101348383BLow costImprove performanceSustainable biological treatmentCeramicwareFilter materialSewage treatment

The invention discloses a ceramic particle for water treatment and a preparation method thereof, belonging to the production field of water treatment filter material. The ceramic particle is made from granite powder, bentonite, coke powder, sawdust and pulverized coal in a certain proportion. Compared with the prior art, the ceramic particle has the characteristics of good water purifying effect,low production cost, little energy consumption, and so on, and can be widely applied to sewage treatment in various fields.

Owner:商士强

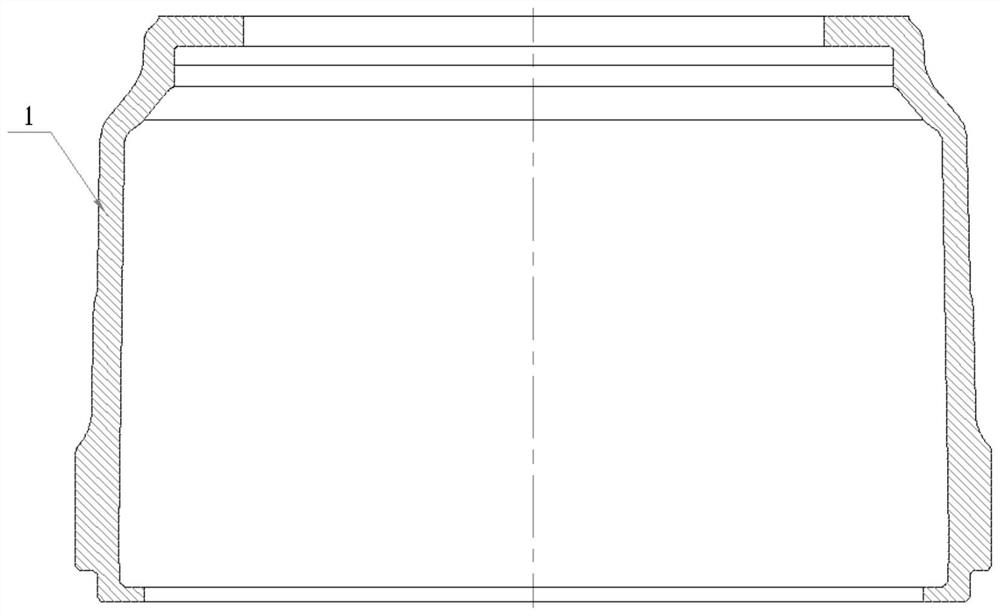

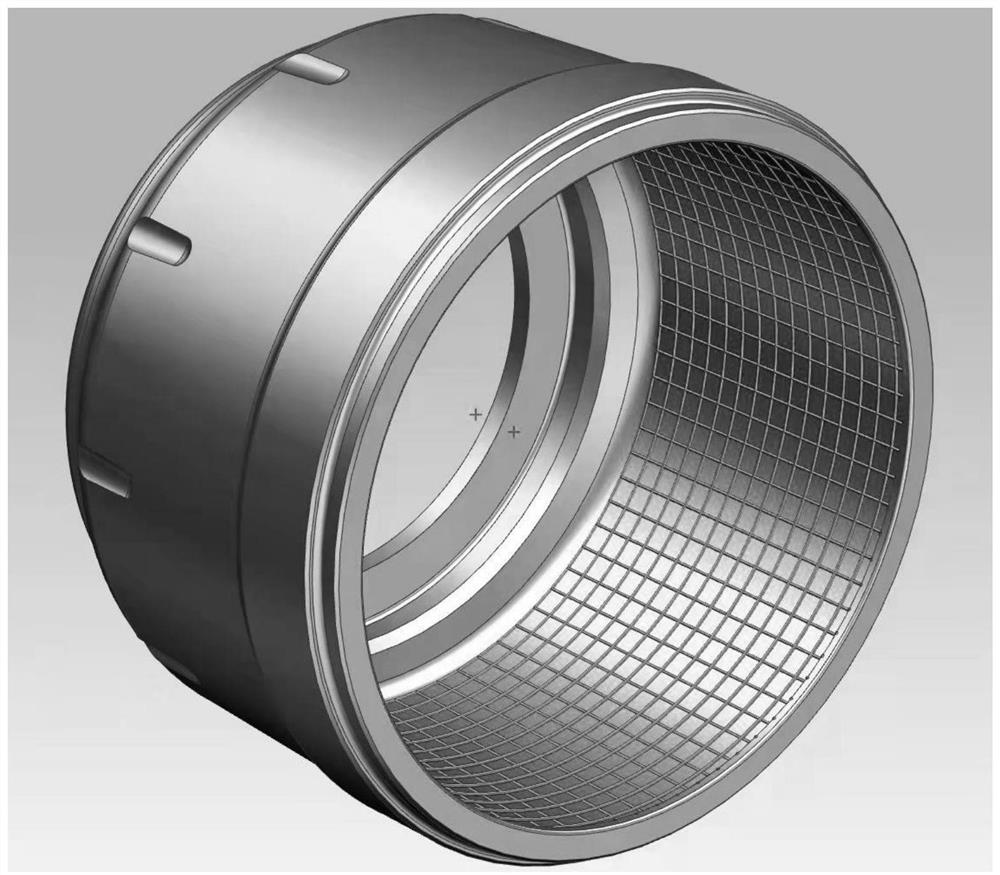

High-strength and high-thermal-conductivity new material solid-liquid composite brake drum and preparation method thereof

The invention discloses a high-strength high-thermal-conductivity new material solid-liquid composite brake drum and a preparation method thereof, and belongs to the technical field of automobile parts. The composite brake drum is integrally cast by outer-layer high-strength ductile iron and inner-layer high-thermal-conductivity gray cast iron through centrifugal solid-liquid composite casting. Firstly, the outer layer of the composite brake drum is poured on an iron particle filling precoated sand shell production line, the iron particle filling precoated sand shell is fast in solidification and cooling, an obtained casting has the characteristics of fine and compact tissue, high strength and high toughness of outer ductile iron are ensured, on the basis, inner gray cast iron is poured under the centrifugal casting condition, and the composite brake drum is obtained. By controlling the centrifugal casting forming process, good metallurgical bonding of the inner layer and the outer layer is achieved, distribution of graphite is remarkably improved, and the composite brake drum has the advantages of being high in strength and heat conductivity. The service life of the composite brake drum is prolonged by more than three times compared with that of a common bimetal composite brake drum, and the composite brake drum has good economic and social benefits in application and popularization.

Owner:山西汤荣机械制造股份有限公司

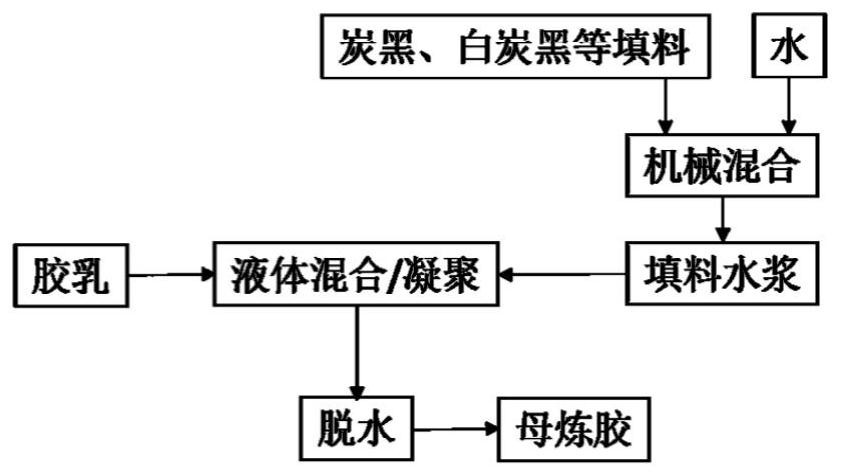

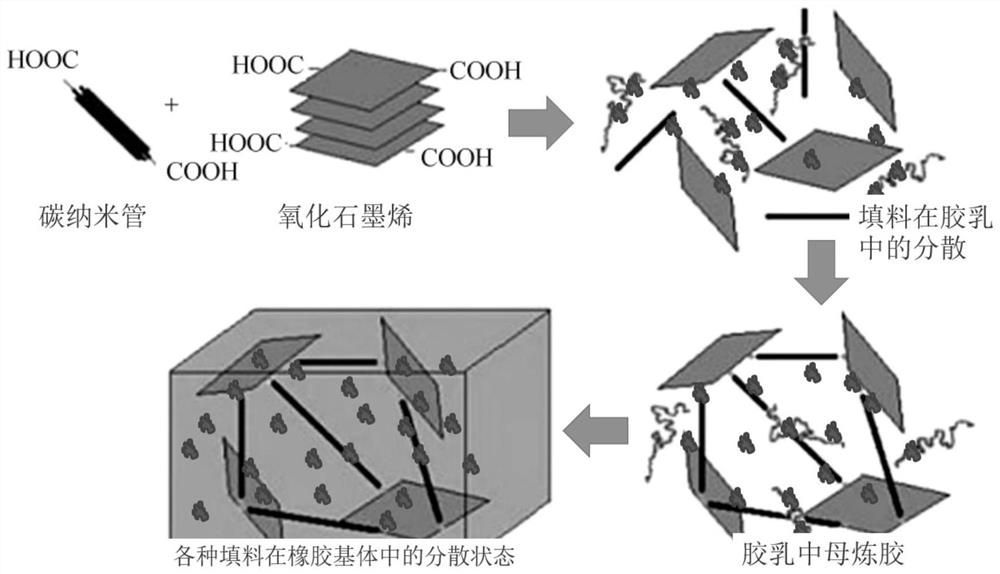

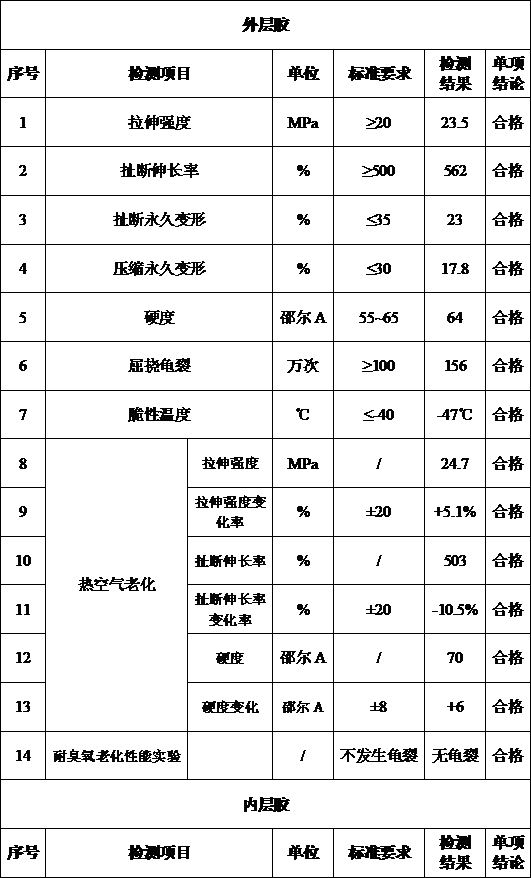

High-damping anti-aging rubber product and preparation method thereof

InactiveCN114621513AHigh strengthExtended service lifeRubber layered productsPolymer scienceVulcanization

The invention relates to a high-damping anti-aging rubber product which is formed by compounding at least two layers of rubber, and the rubber is prepared from the following raw materials in parts by weight: 60-80 parts of synthetic rubber, 30-60 parts of a reinforcing filling system, 2-5 parts of a plasticizing system, 2-4 parts of an anti-aging system, 1-3 parts of an activating system and 1-3 parts of a vulcanizing system. Compared with the prior art, a reinforcing filling system such as natural rubber grafted white carbon black is adopted, so that the problem of dispersion of a reinforcing filling material is thoroughly solved, the bonding effect of a bonding system is further greatly improved, bonding between layers is firmer, and the bonding strength even exceeds the strength of a rubber body; and the problem of falling between layers cannot occur under most damping use conditions.

Owner:南京盛前材料科技有限公司

Integrated joint bicycle frame, electric bicycle frame and electric moped frame

The invention discloses an integrated connector bicycle, electric vehicle and electric moped frame which comprises an upper pipe, a lower pipe, a middle pipe, a bottom fork and a vertical fork and further comprises an integrated head pipe connector, an integrated five-way connector, an integrated middle pipe connector and an integrated rear hook claw. One end of the upper pipe is sleeved with the head pipe joint, and the other end is sleeved with the middle pipe joint; one end of the lower pipe is sleeved with the head pipe joint, and the other end is sleeved with the five-way joint; the middle pipe penetrates through the middle pipe joint, and the lower end is sleeved with the five-way joint; one end of the bottom fork is sleeved with the five-way joint, and the other end is sleeved with the rear hook claw; the upper end of the vertical fork is sleeved with the middle pipe joint, and the lower end is sleeved with the rear claw; the sleeving positions are bonded and fixed through adhesives, and the middle pipe and the middle pipe connector are bonded and fixed through adhesives. Or an upper pipe joint sleeved on the middle pipe is additionally arranged on the middle pipe. The frame is free of welding, high in strength, easy and convenient to assemble, high in production efficiency and low in cost; and meanwhile, a foundation is laid for later automatic production.

Owner:吴志华 +1

Welding process for lightweight aluminum alloy automotive roof

ActiveCN108296662AGuaranteed sizeReduce the amount of weldingOther manufacturing equipments/toolsWelding apparatusEngineeringMachining process

The invention belongs to the technical field of lightweight of automobiles, and relates to a welding process for a lightweight aluminum alloy automotive roof. The welding process of the lightweight aluminum alloy automotive roof comprises the steps that an air duct support of the automotive roof is integrally formed through extrusion by an extrusion die, and the air duct support integrally formedthrough extrusion is cut at equal intervals; a corner weld structure is formed between an automotive crossbeam and a bent plate; after the two sides of a weld are polished, the automotive crossbeam and the bent plate are welded, wherein the welding current is 155-165 A, the voltage is 21.2-22.5 V, and the welding speed is 9-11 mm / s; and a butt weld structure is formed between the air duct supportand the automotive crossbeam, the bevel angle is 55 degrees, and after the two sides of a weld are polished, the air duct support and the automotive crossbeam are welded, wherein the welding current is 155-165 A, the voltage is 21.2-22.5 V, and the welding speed is 12-14 mm. By adoption of the welding process of the lightweight aluminum alloy automotive roof, the problems that in the machining process of the automotive roof, the welding workload is large, and operation is complex are solved.

Owner:辽宁忠旺铝合金精深加工有限公司

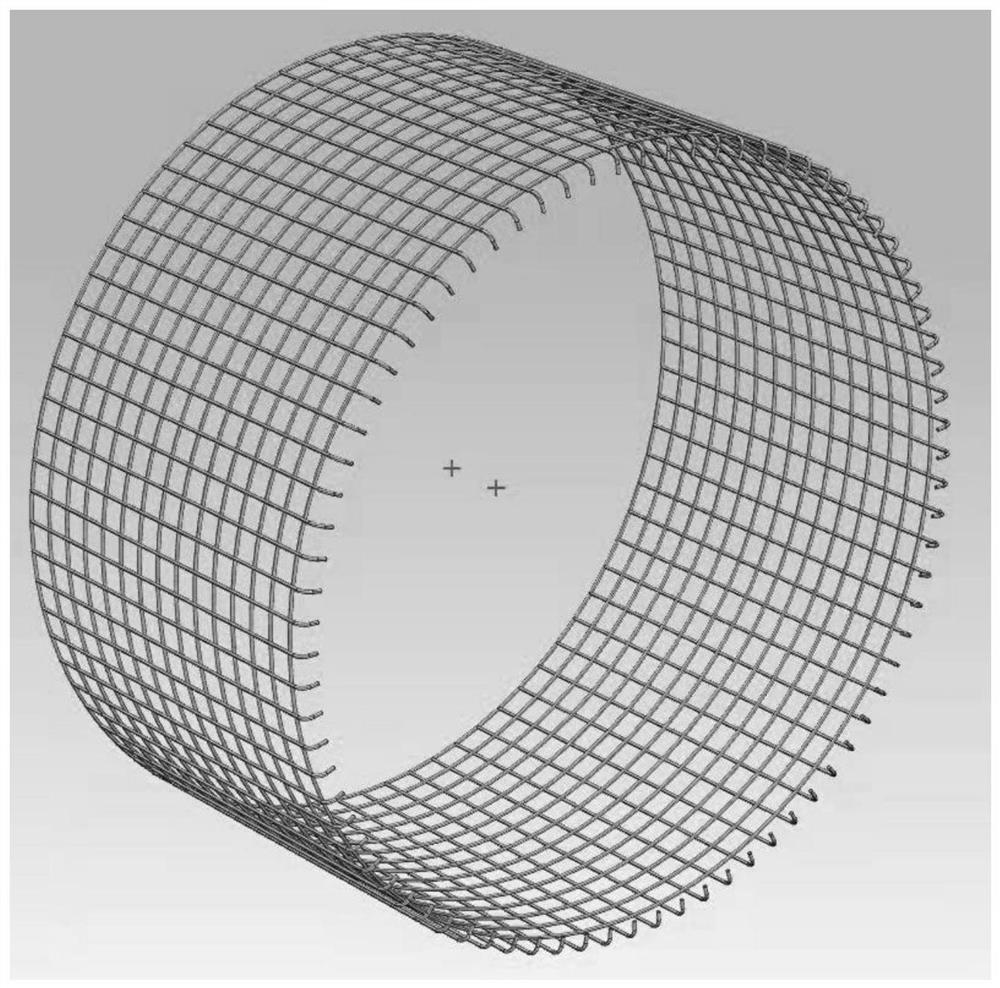

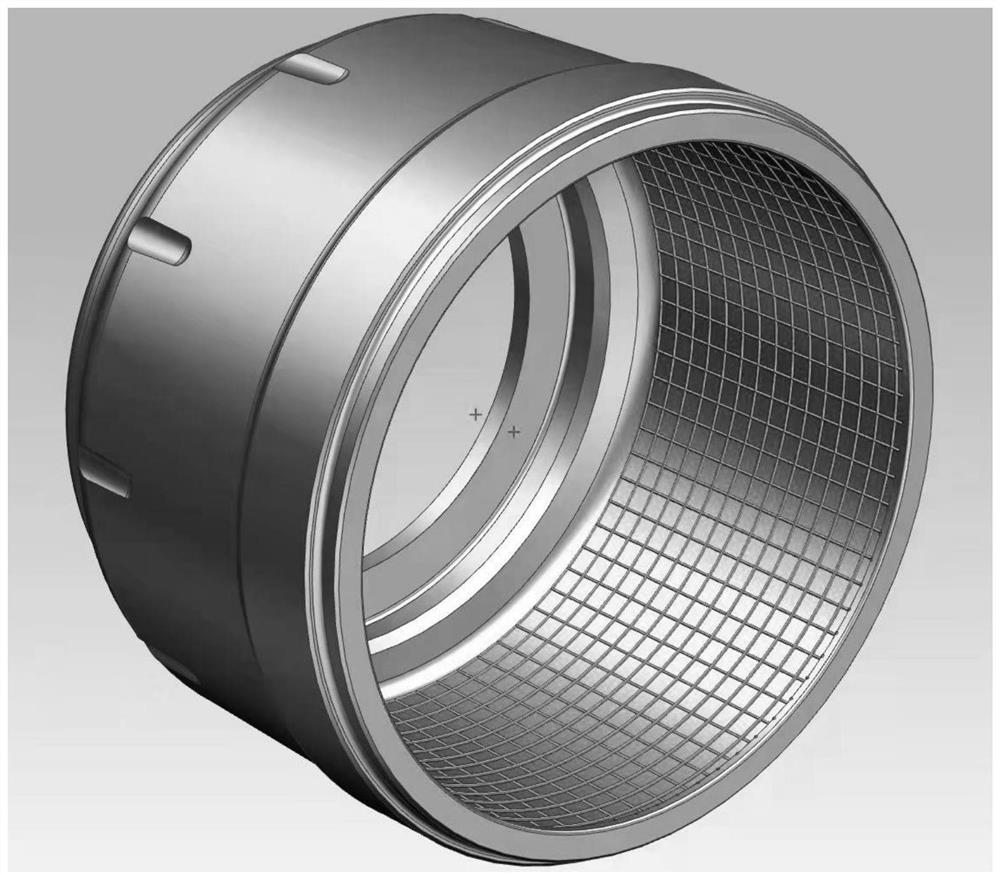

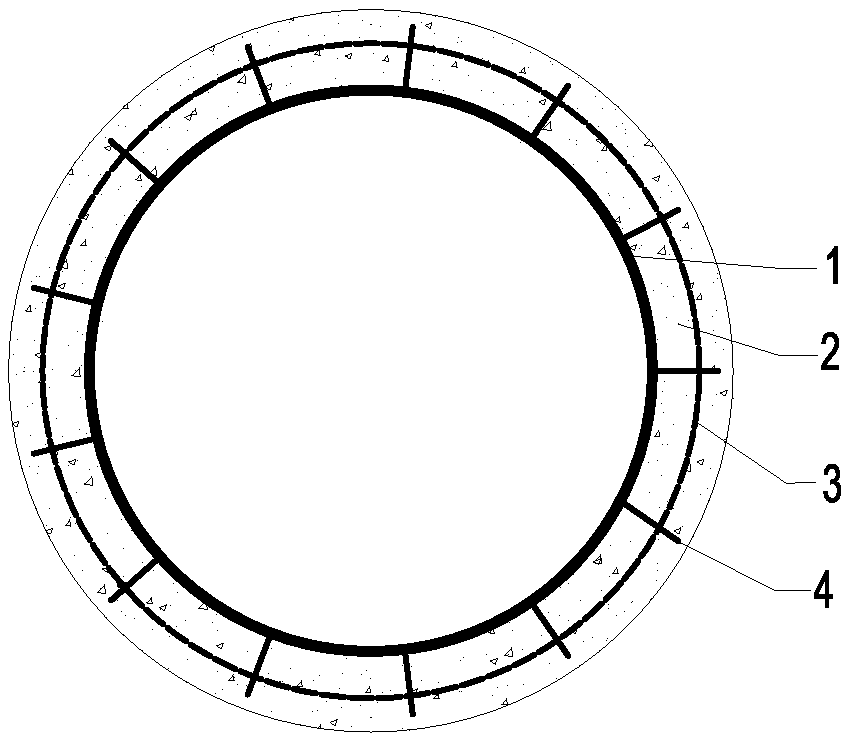

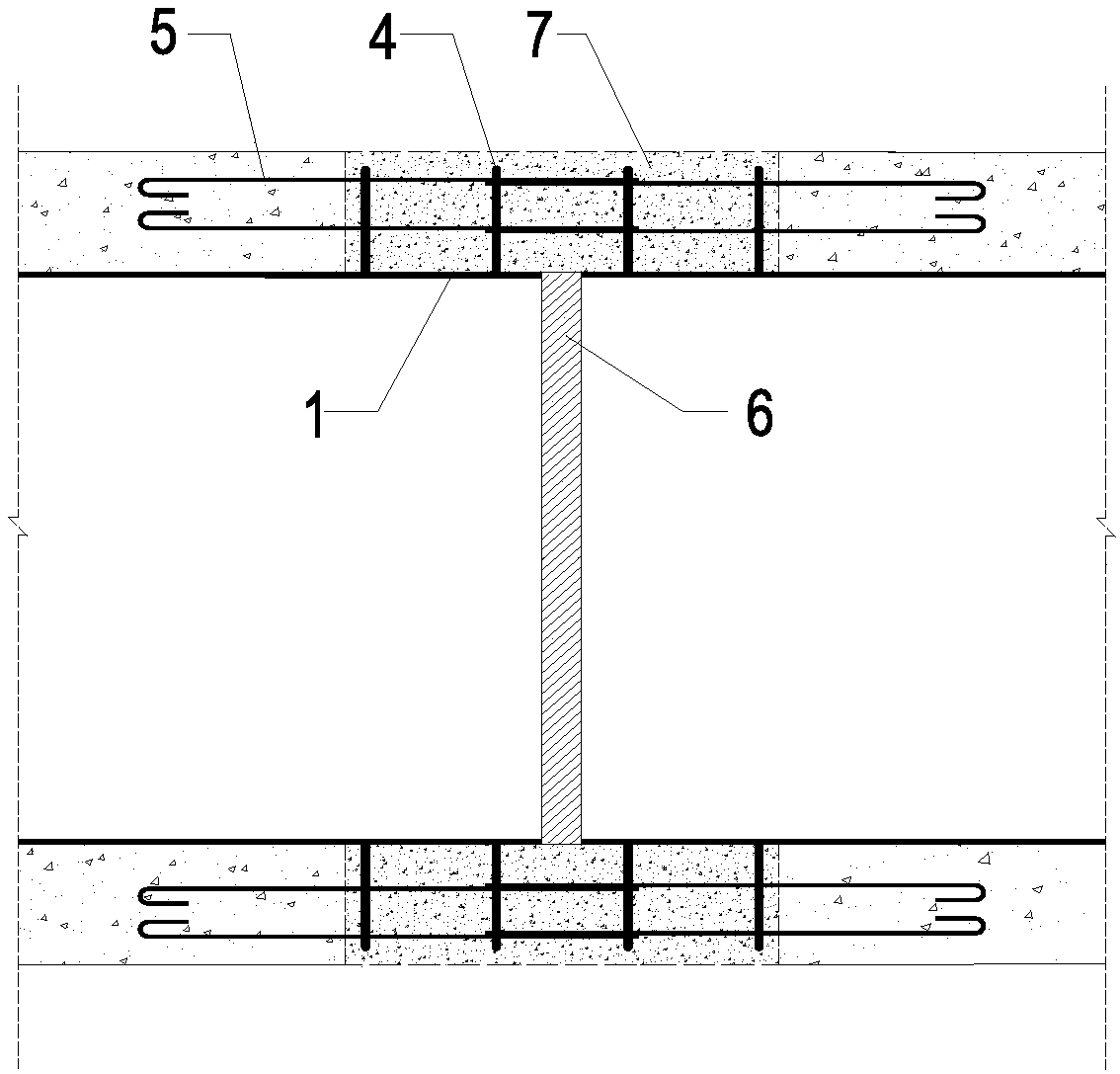

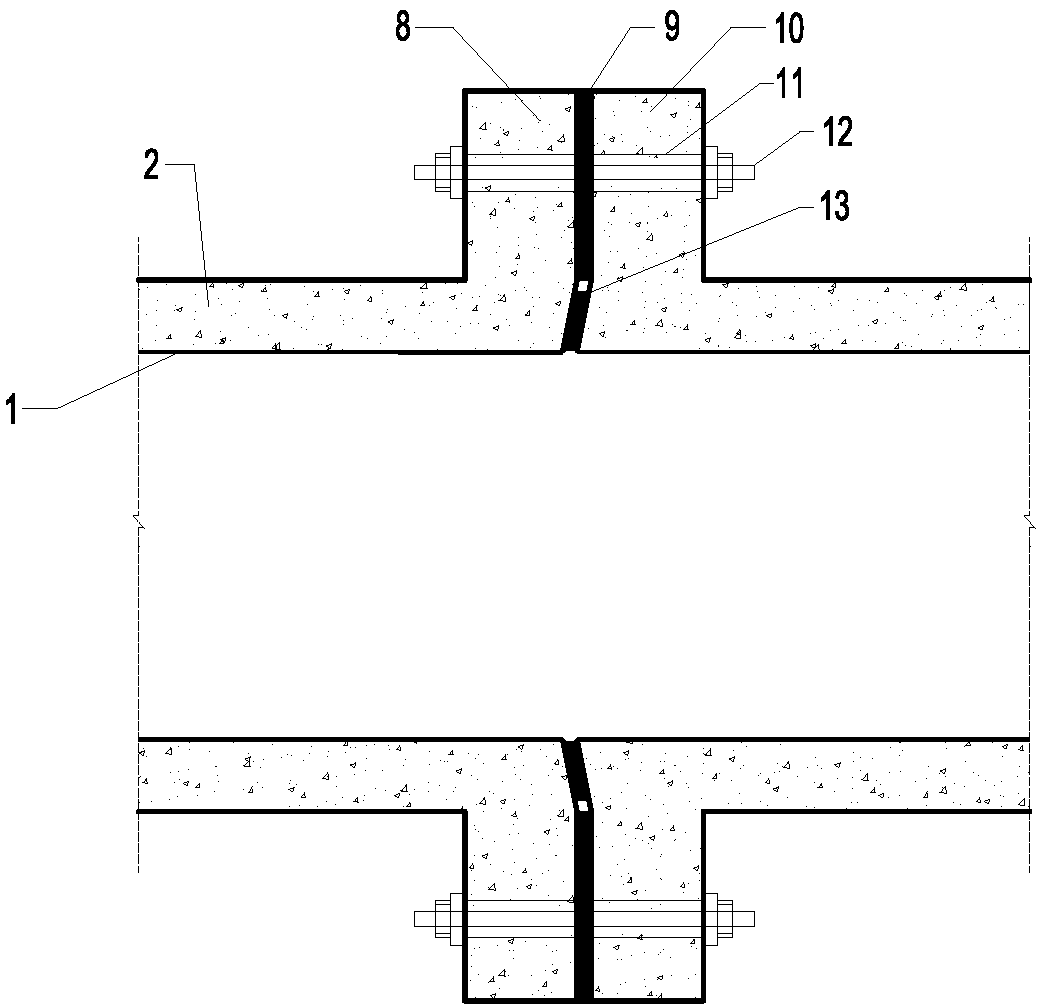

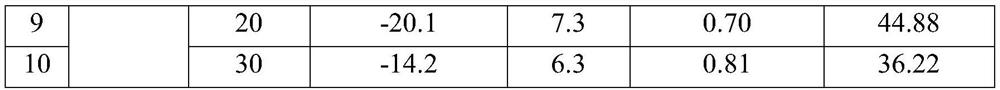

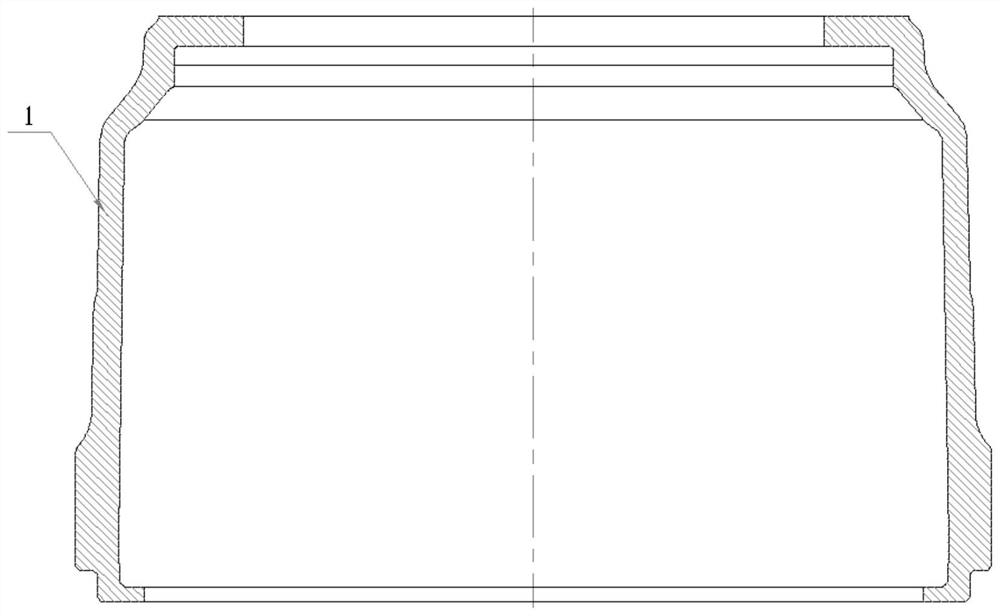

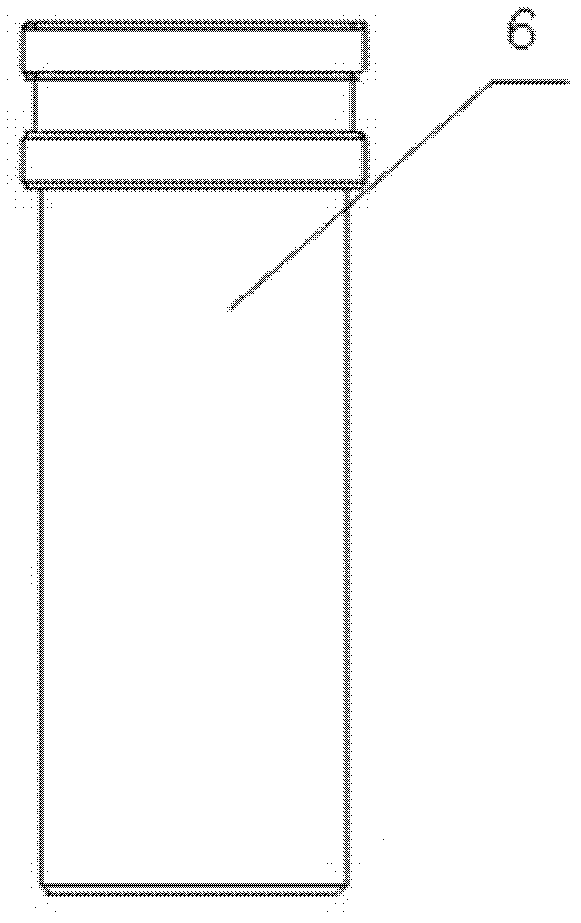

UHPC-SS (Ultra High Performance Concrete) composite pipeline and manufacturing method thereof

PendingCN108426103AIncrease stiffnessImprove thermal insulation performanceThermal insulationGeneral water supply conservationFiberFrost

The invention discloses an UHPC-SS (Ultra High Performance Concrete) composite pipeline and a manufacturing method thereof. The UHPC-SS composite pipeline consists of a stainless steel tube, wherein casting the outer side of the stainless steel with an UHPC concrete layer; a reinforced steel network is arranged in the UHPC concrete layer; the UHPC concrete layer is prepared from the following rawmaterials in percentage by mass: 25 to 30 percent of cement, 5 to 15 percent of silicon powder, 3.5 to 13.5 percent of quartz powder, 30 to 50 percent of fine sand being 1.6 to 3.7mm in particle size,3 to 9 percent of steel fiber being 8mm in length and 3.4 to 9.4 percent of water; the raw materials are stirred and cast on the outer surface of a stainless steel inner tube; compaction is performedby adopting a compaction platform after casting; then, hot water maintenance is performed on the UHPC-SS composite pipeline in water of 80 DEG C for 3 days. Three connection manners are adopted for pipeline joints. The inner tube is made of stainless steel, and the outer tube is made of UHPC, so that the problems concerned with tendency to corrosion, poor frost resistance, poor durability and high manufacturing cost in the existing pipelines for transporting crude oil, natural gas and dangerous chemicals are solved.

Owner:周敉

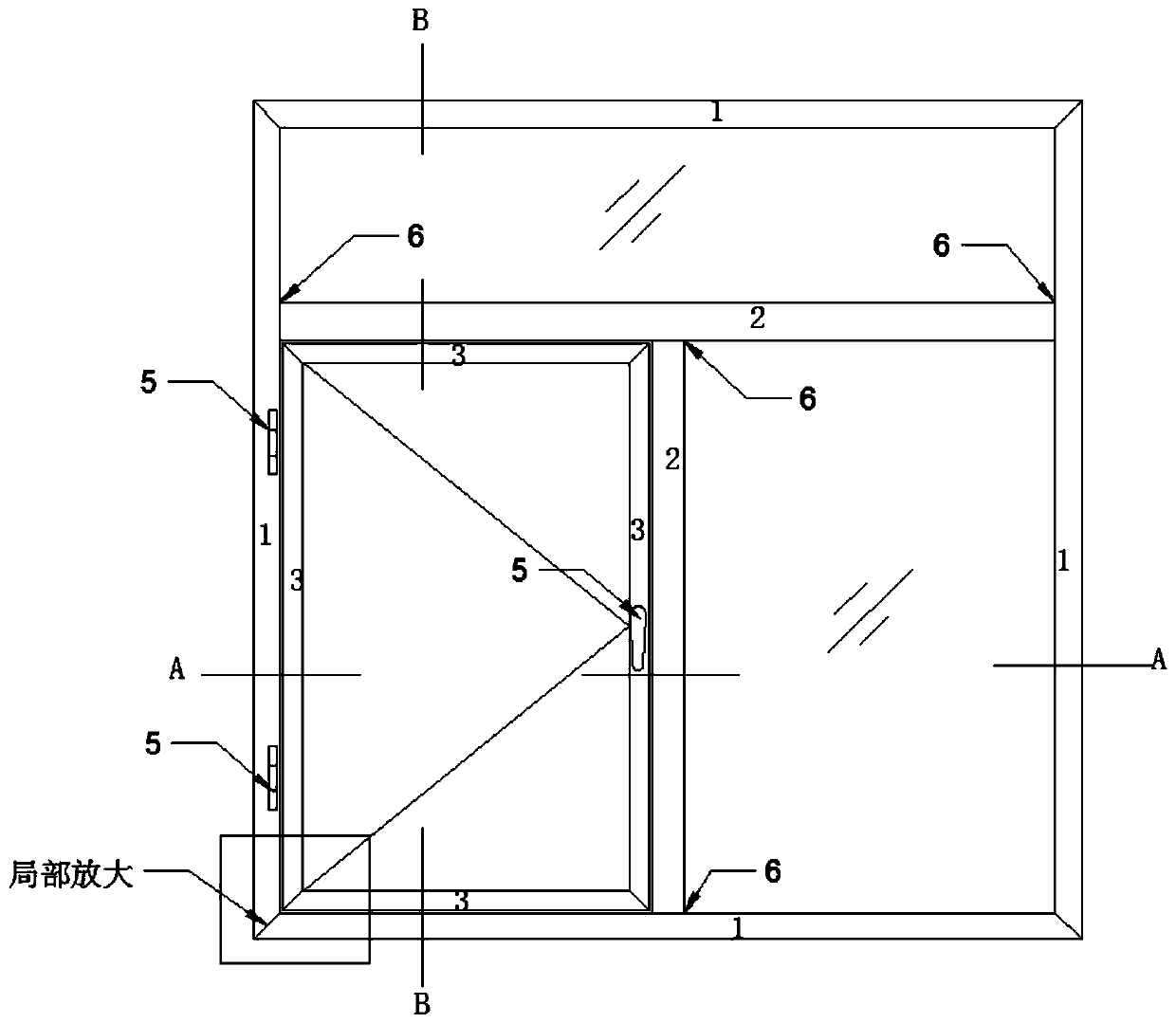

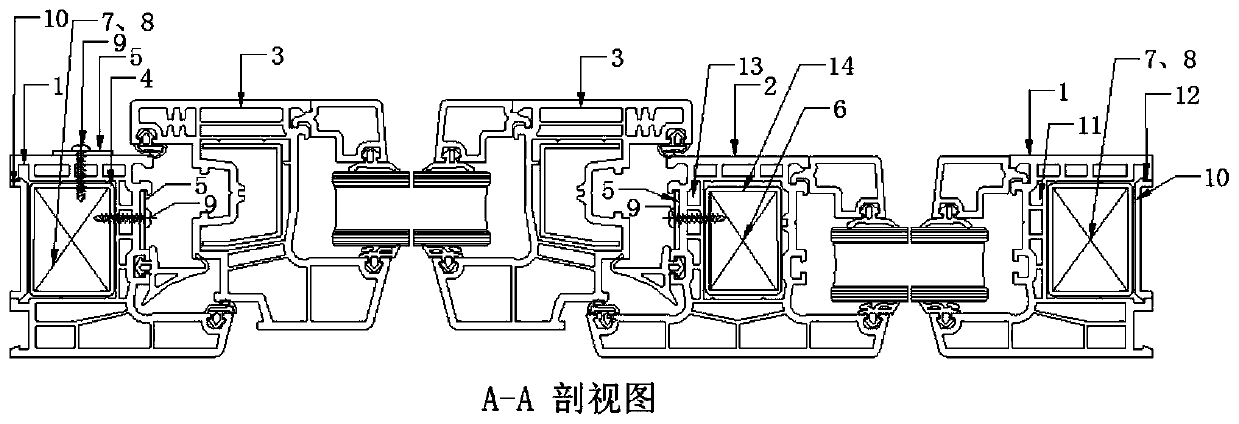

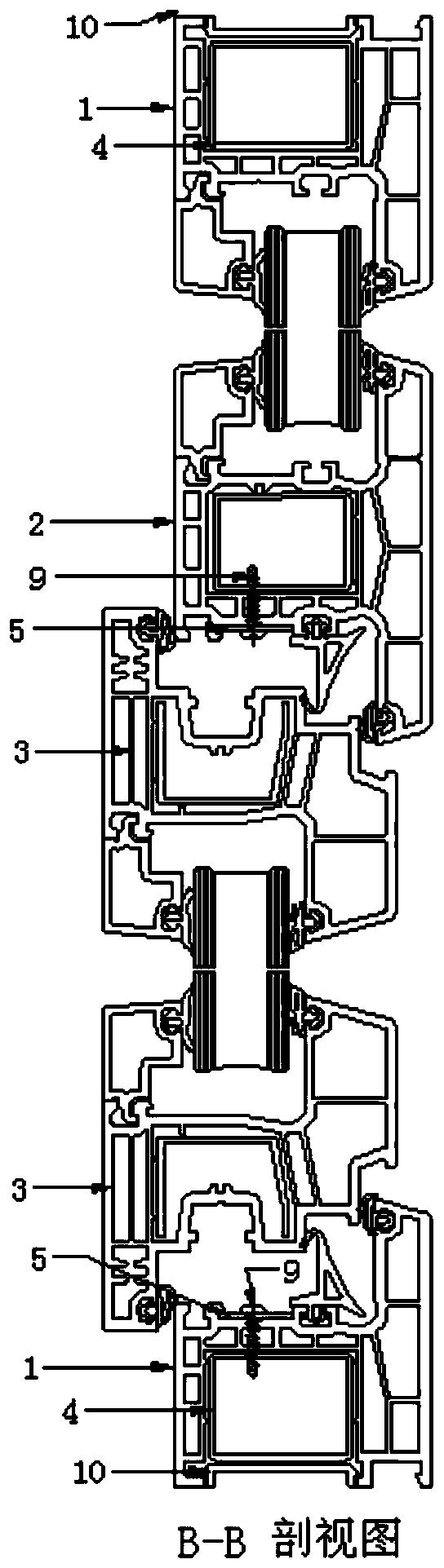

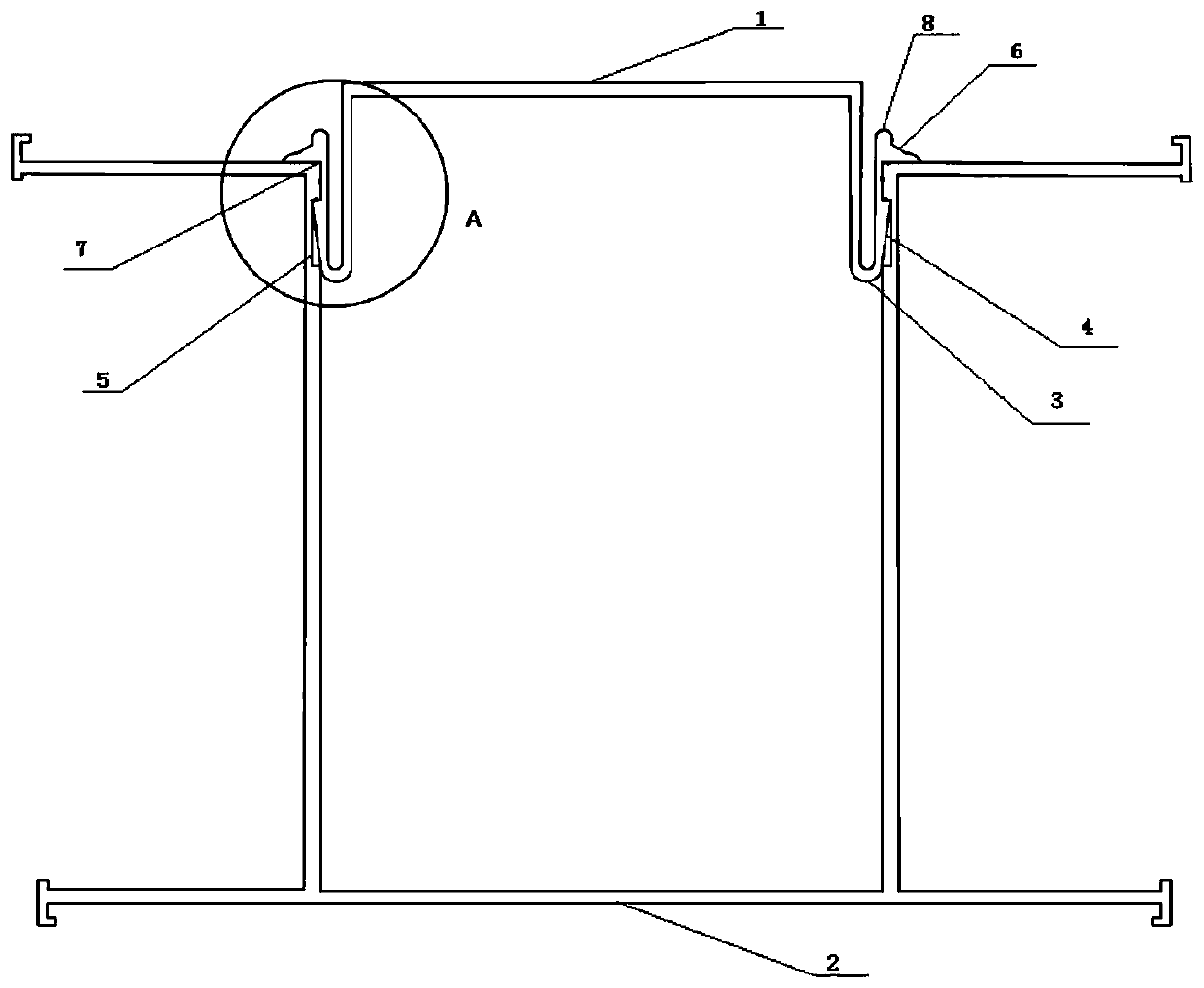

High-strength anti-cracking anti-deformation plastic window

PendingCN110656847ASolve the deformationSolve the problem of not being able to open and close normallyWindow/door framesWing arrangementsEngineeringMechanical engineering

The invention relates to a high-strength anti-cracking anti-deformation plastic window. The plastic window comprises window frames, mullions, an opening fan and hardwares, The upper side, lower side,left side and right side of the outermost layer of the whole window are respectively provided with a window frame and the window frames are connected into an outer frame; the mullions are arranged inthe transverse middle part and the vertical middle part of the outer frame; the window frames, the mullions, the transverse middle part and the vertical middle part of the outer frame are connected into a whole through mullion connecting pieces; the opening fan is formed through plastic special profiles which are arranged in the upper sides, lower sides, left sides and right sides of the window frames and the mullions; and the opening fan is connected with the window frames through the hardwares. The plastic window has the beneficial effects that the existing machining device is not changed, the ingenious design is adopted, the problems that the plastic window fillet is cracked, the mullion connection is not firm and the whole window is deformed are thoroughly solved, the entrance steel lining inspection of the door and window products is realized, and the market promotion is facilitated.

Owner:高科建材(咸阳)铝材科技有限公司

Novel clamping bus duct

PendingCN109936101AAvoid connectionAvoid pinchingTotally enclosed bus-bar installationsEngineeringAlloy

The invention discloses a novel clamping bus duct. The bus duct comprises a bus bar and a bus duct shell, and the bus bar is fixed in the bus duct shell. The bus duct shell comprises an upper side plate, a lower side plate and a side plate which is connected between the upper and lower side plates. The lower cover plate and the two side plates are made of aluminum alloy sections of an integral structure, and clamping grooves are formed in the inner walls of the upper portions of the side plates. U-shaped cantilevers are connected to the two ends of the upper cover plate, and clamping blocks extend out of the outer side faces of the U-shaped cantilevers in a protruding mode. The clamping blocks are clamped into the clamping grooves. The top ends of the U-shaped cantilevers horizontally extend towards the two sides to form pressing arms, and concave notches matched with the top ends of the side plates are formed in the upper surfaces of the pressing arms and the upper surfaces of the clamping blocks. The top ends of the side plates are embedded into the concave notches. By adopting the clamping mode that the clamping blocks are matched with the clamping grooves, other connection modes such as threaded connection, clamping and pasting are avoided, the connection mode between the bottom plate and the cover plate can be simplified, and the mounting and dismounting are facilitated.

Owner:镇江市美盛母线有限公司

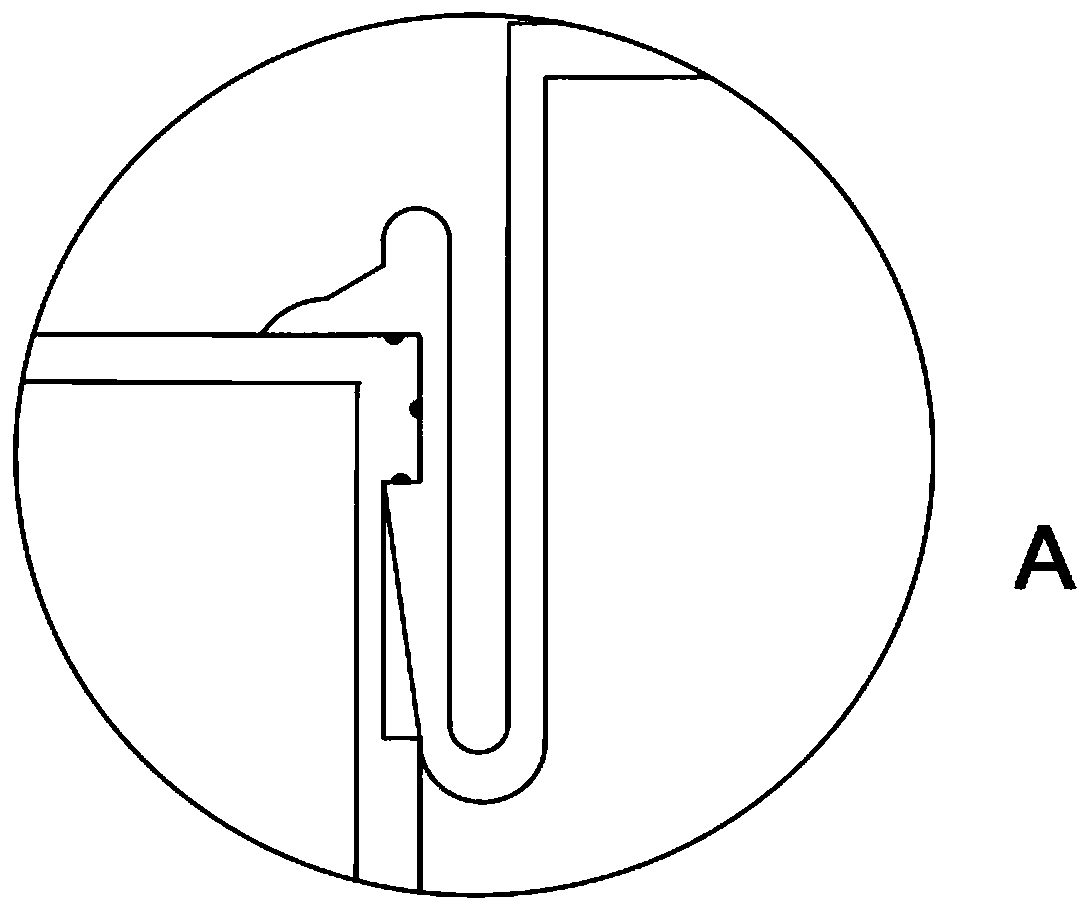

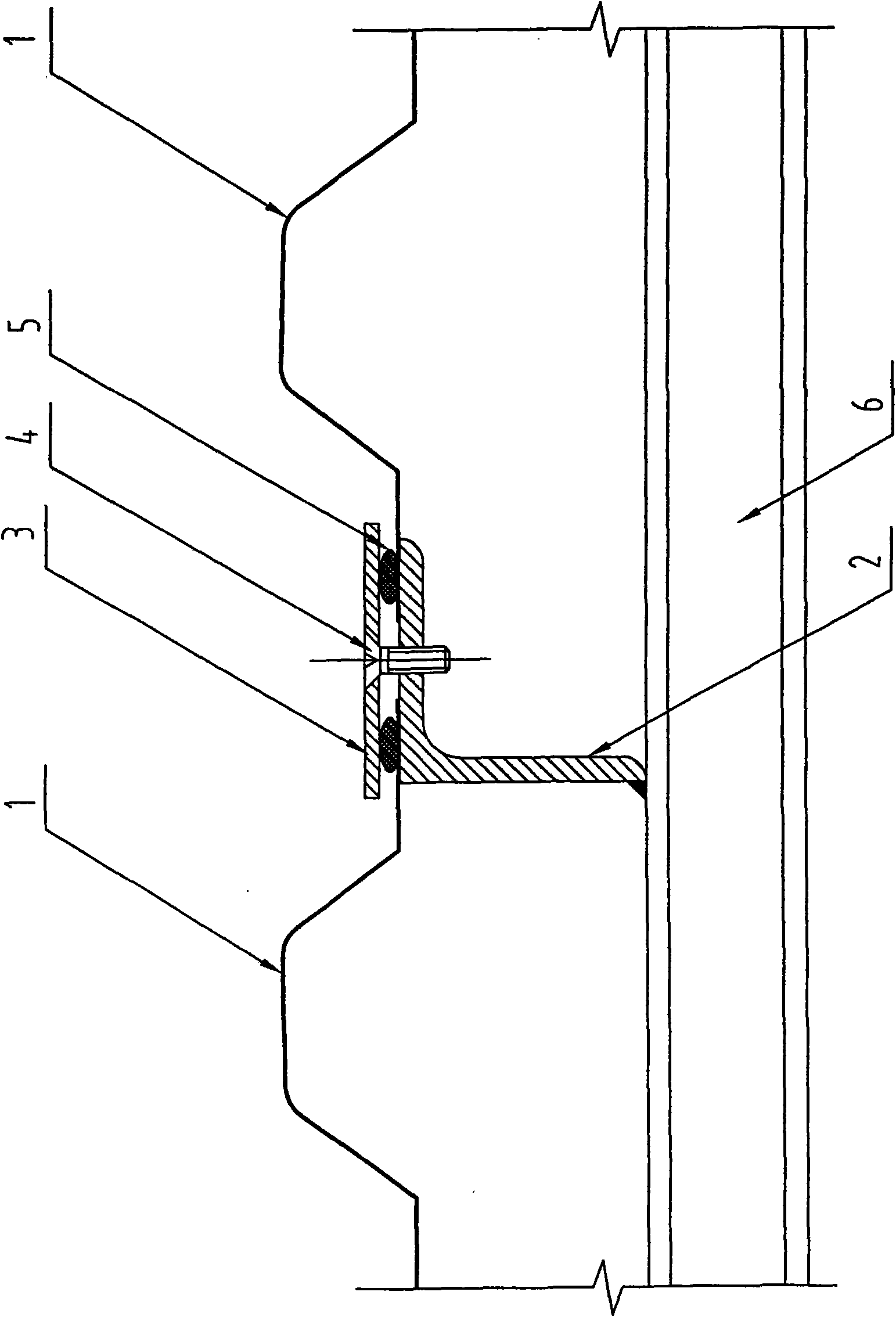

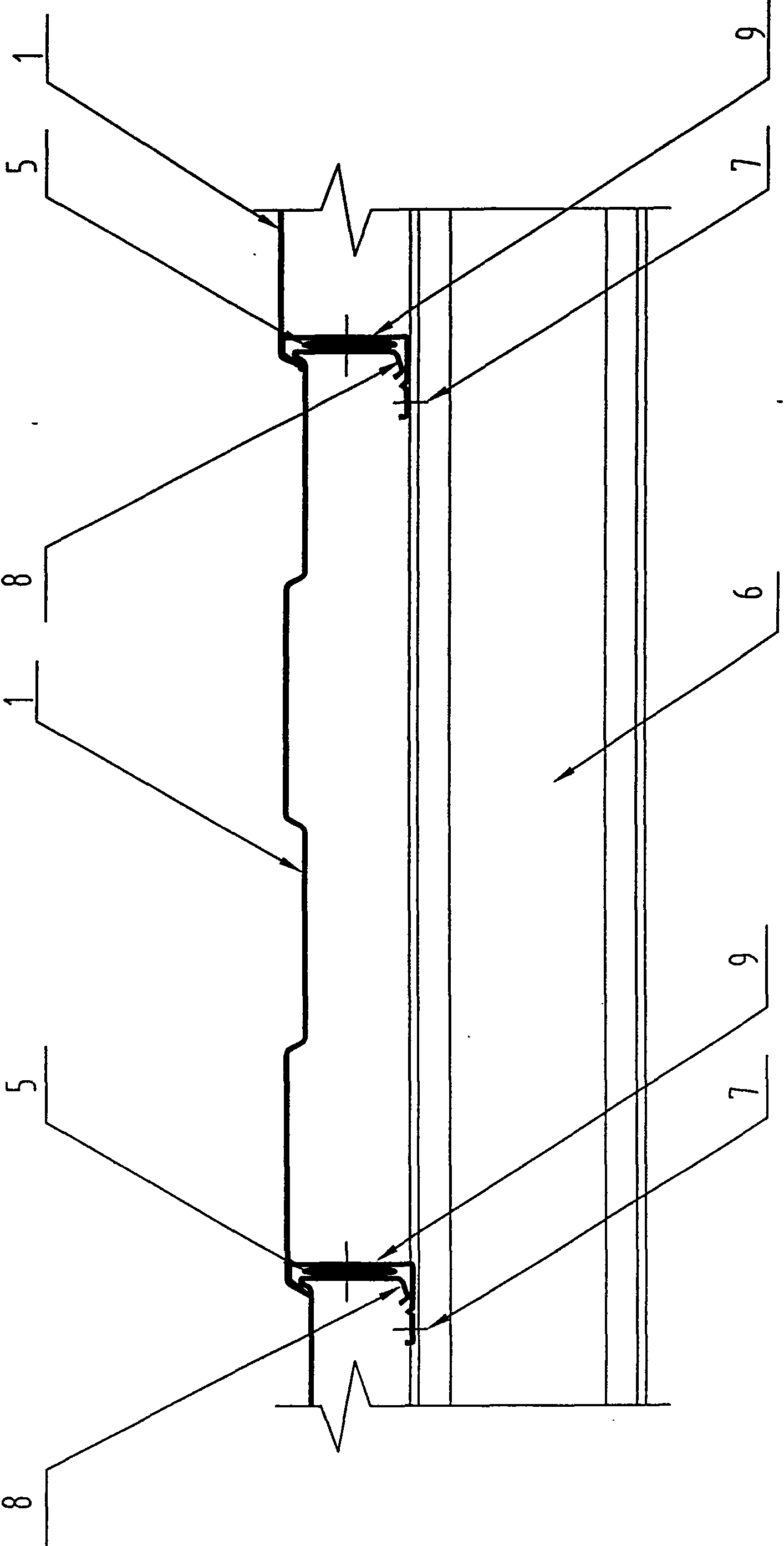

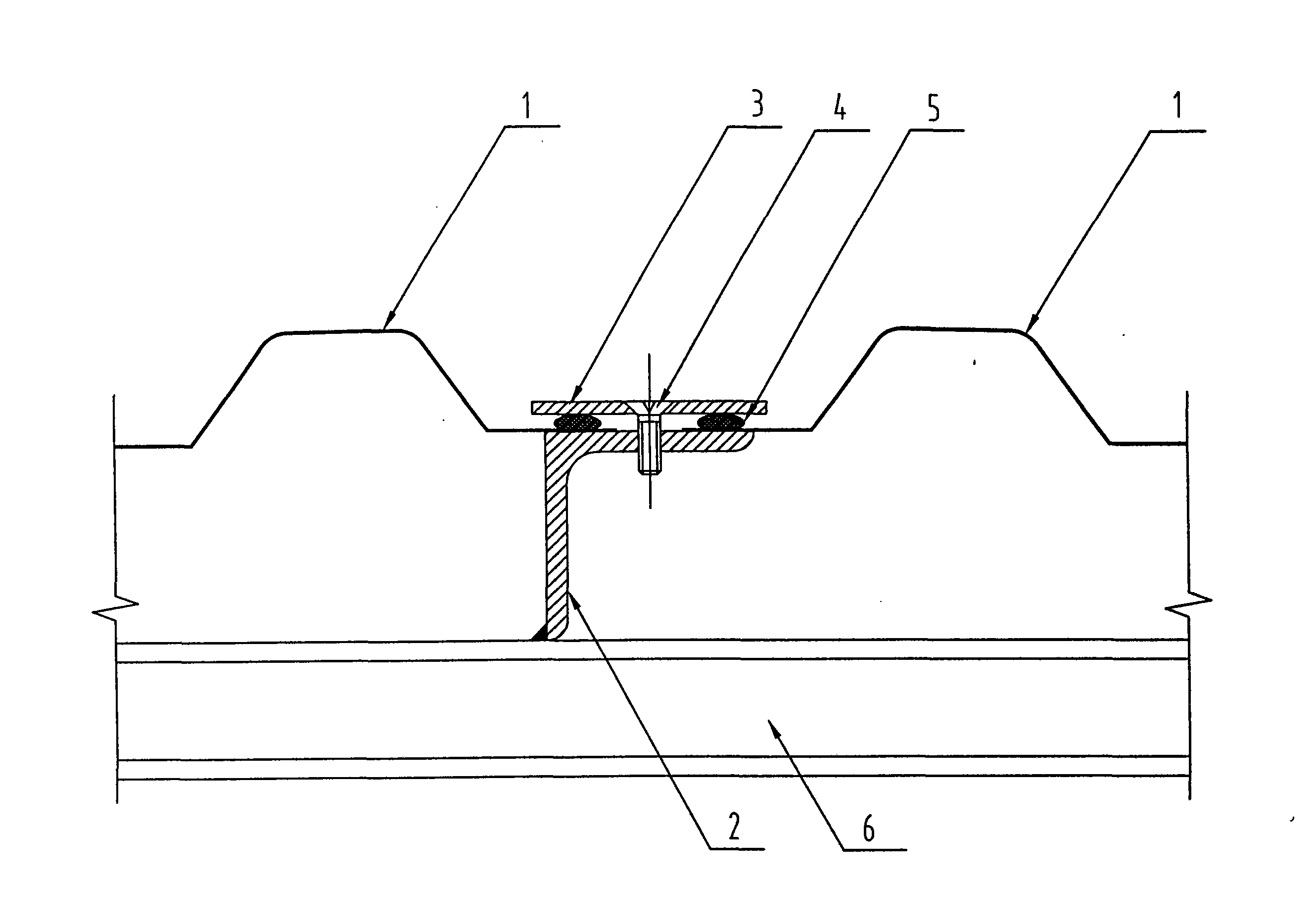

Corrugated plate for architectural shielding

ActiveCN101586386BReduce manufacturing costReduce installation costsCovering/liningsElectrical resistance and conductanceWave shape

A corrugated plate for architectural shielding and connection structure thereof, including waveshaped templates (1) shielding connected with each other, among the waveshaped templates (1) are connected by crimping structure or clamping structure, and the adjacent waveshaped templates (1) are electrically connected. In addition to conventional crimping, spiro union, riveting, welding and other programs, the invention provided seams shielding connection structure specifically utilizes resistance welding process, the seams are shielding connected by forcipated spot welding, the connection surfacehas small contact resistance, the surface has no damage and conquers defects of screw and riveting, both reducing shielding efficiency of seams caused by oxidation corrosion and conquering defects ofcontinuous welding, that are defects of large internal stress, surface irregularity and pollution in construction process. The process is provided with reliable connection, high efficiency, low costand good construction adaptability.

Owner:常州新区金利达电子有限公司

A preparation method of 3D-printable electromagnetic protection phosphate material

ActiveCN109265128BImprove high temperature resistanceImprove stabilityAdditive manufacturing apparatusBuilding constructionsCement MaterialElectromagnetic wave absorption

The invention discloses a preparation method for an electromagnetic protection phosphate material capable of being subjected to 3D printing. According to the method, phosphate cement and a porous aggregate material are utilized for preparing functional phosphate cement integrating electromagnetic wave absorbing and heat preservation integration, an electromagnetic wave absorbing structure is printed on the surface of a concrete structure by utilizing the performance of intelligence, flexibility, precision and the like of the 3D printing technology, and the porous aggregate material is porous EPS, and the dual effects of achieving electromagnetic wave absorbing and protection on the concrete structure and improving the heat preservation performance of the concrete structure are achieved.

Owner:HEBEI UNIV OF TECH

High-strength and high-thermal conductivity material solid-liquid composite brake drum and preparation method thereof

The invention relates to a high-strength and high-thermal conductivity new material solid-liquid composite brake drum and a preparation method thereof, belonging to the technical field of auto parts. The composite brake drum is made of high-strength nodular iron in the outer layer and gray cast iron with high thermal conductivity in the inner layer, which are cast into one body through centrifugal solid-liquid composite casting. Firstly, the outer layer of the composite brake drum is poured on the iron particle-filled coated sand shell production line, and the iron particle-filled coated sand shell is used to solidify and cool quickly. High strength and high toughness, on this basis, under the conditions of centrifugal casting, the gray cast iron of the inner layer is poured, and by controlling the centrifugal casting forming process, good metallurgical bonding of the inner and outer layers is achieved, and the distribution of graphite is significantly improved, so that the composite system of the present invention The dynamic drum has the characteristics of high strength and high thermal conductivity. The service life of the composite brake drum of the invention is more than three times higher than that of the common bimetallic composite brake drum, and the popularization and application has good economic and social benefits.

Owner:山西汤荣机械制造股份有限公司

High-conductivity copper-magnesium alloy material

InactiveCN105220005AReduce raw material costsGood economic and social benefitsHigh conductivityCopper

The invention discloses a high-conductivity copper-magnesium alloy material. The high-conductivity copper-magnesium alloy material comprises, by weight percentage, 0.05-0.15% of Mg, 0.005-0.01% of P, 0.01-0.15% of CuY15 alloy, 0.09-0.15% of Ge, 0.32-0.37% of Sc, smaller than or equal to 0.06% of the sum of other elements serving as impurities, and the balance Cu. The high-conductivity copper-magnesium alloy material reaches the level of a copper-based silver alloy in the aspects of appearance, conductivity, softening-resisting temperature and the like, is superior to the copper-based silver alloy in the aspects of strength and elongation and has the beneficial effect that the cost of raw materials is obviously reduced.

Owner:无棣向上机械设计服务有限公司

Environment-friendly adhesive for quickly adhering aluminum alloy and PVC thin film, preparation and application thereof

InactiveCN101792641BOver tear strengthImprove adhesionOrganic non-macromolecular adhesiveModified epoxy resin adhesivesAdhesiveHardness

The invention discloses an environment-friendly adhesive for quickly adhering aluminum alloy and PVC thin film and preparation and application thereof. The environment-friendly adhesive comprises the following components: 10 to 30 parts of urethane acrylate, 5 to 40 parts of epoxy acrylate, 10 to 30 parts of rubber, 5 to 15 parts of viscosifier, 20 to 60 parts of reactive diluent, 2 to 5 parts ofglutinous rice flour, 0.2 to 1.5 parts of initiator and 0.2 to 1.0 part of curing agent. The environment-friendly adhesive has excellent adhesion performance on the aluminum alloy and PVC insulating thin film, has the adhesive force of the first level, and can be applied to high-temperature operating environment; and the cured adhesive film has higher softening point of over 80 DEG C. The mean value of the hardness of the cured adhesive film obtained by using the adhesive is between 70 and 75A; and the adhesive film cured has good hardness and toughness. The environment-friendly adhesive for quickly adhering aluminum alloy and PVC thin film and the preparation and application thereof have the advantages of simple preparation method, moderate cost, stable comprehensive performance of the obtained products, and great functions of energy conservation and emission reduction.

Owner:SOUTH CHINA UNIV OF TECH

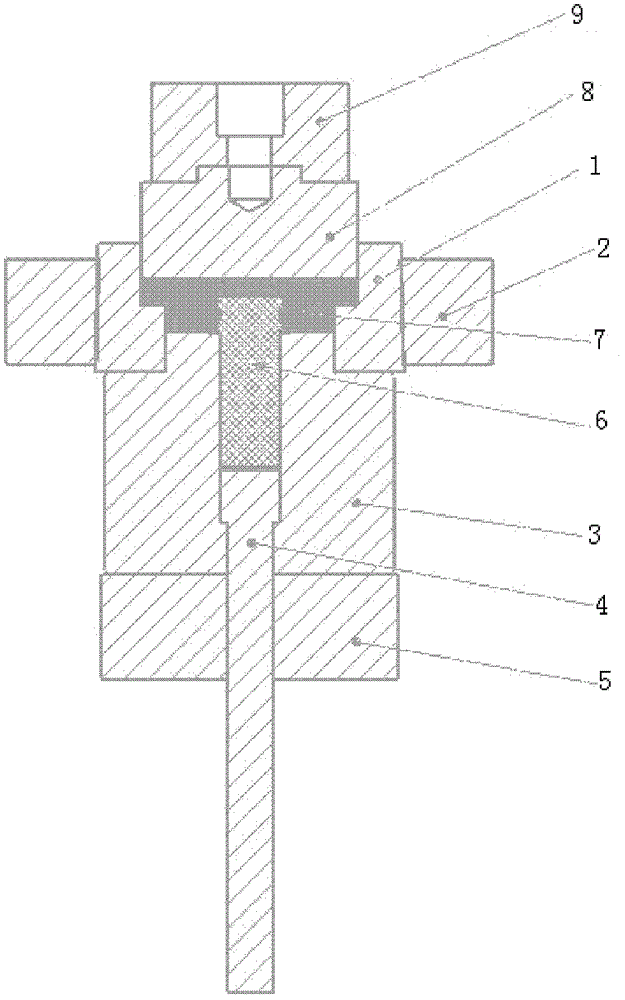

A Dissimilar Metal Composite Piston Forging Technology

ActiveCN102397968BEnsure finishing precision requirementsImprove work efficiencyPlungersForging/hammering/pressing machinesInternal pressureHigh pressure

The invention discloses a dissimilar metal composite piston forging process, which relates to the technical field of solid-state thermal die forging. Dissimilar metals are cut according to their respective required lengths and weights; the piston rod is processed into a piston by leaving a surplus of metal material The shape of the rod, and the processed piston rod material is placed in the die on the press table; the heated piston head is placed on the piston rod material in the die with metal material, and the press is operated to squeeze the punch. Forming of dissimilar metals in the concave die; the press ejects the forged composite piston, takes the forged composite piston out of the concave die and air-cools, and completes the forging process; according to the use requirements of different parts of the piston, different metal materials are used , and the performance and reliability of the composite piston after forging can meet the operating requirements of high-voltage switch electrical components. Also disclosed is a mold used for extrusion forging when implementing the dissimilar metal composite piston forging process.

Owner:QINHAN PRECISION IND CO LTD

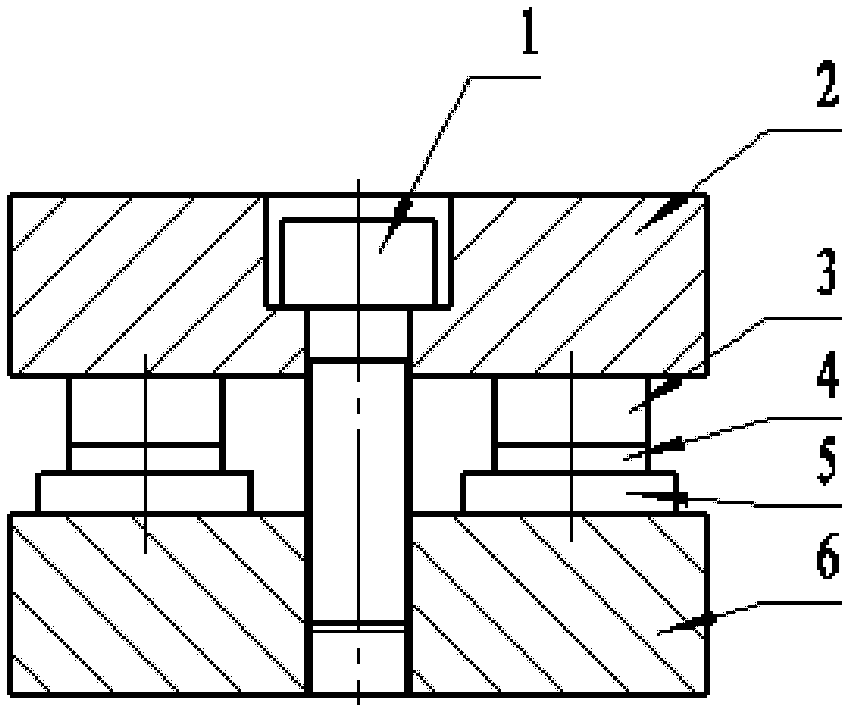

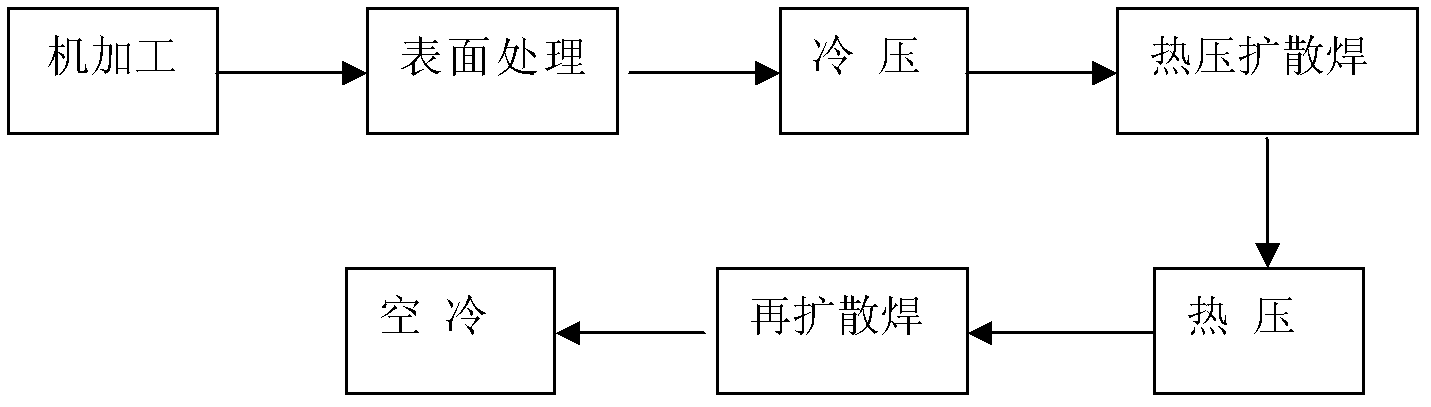

Crimping diffusion welding process of aluminum or aluminum alloy and heterogeneous metal

InactiveCN102328153BImprove conductivityIntensity exceedsNon-electric welding apparatusMaterials scienceMetal

The invention discloses a crimping diffusion welding process and clamp of aluminum or aluminum alloy and heterogeneous metal, relating to the technical field of solid-state welding. The process comprises the following steps of: carrying out surface treatment on prewelded surfaces: overlapping the prewelded surfaces of a piece to be welded face to face together, then putting between an upper pressing plate and a lower pressing plate of the clamp, and carrying out cold pressing; putting the piece to be welded, which is tightly pressed and protected, and the whole clamp into a box-type electric furnace, heating, preserving the heat and prewelding; after diffusion welding is finished, taking the whole clamp out, and carrying out hot pressing on a hydraulic machine once; and then carrying out diffusion welding. The invention provides the process which is used for carrying out crimping diffusion welding of aluminum or aluminum alloy and heterogeneous metal under the non-vacuum condition by using the common hydraulic machine, the common box-type electric heating furnace and the clamp; meanwhile, a workpiece with large feature size and larger thickness is not limited by the traditional vacuum diffusion welding process.

Owner:HENAN UNIV OF SCI & TECH

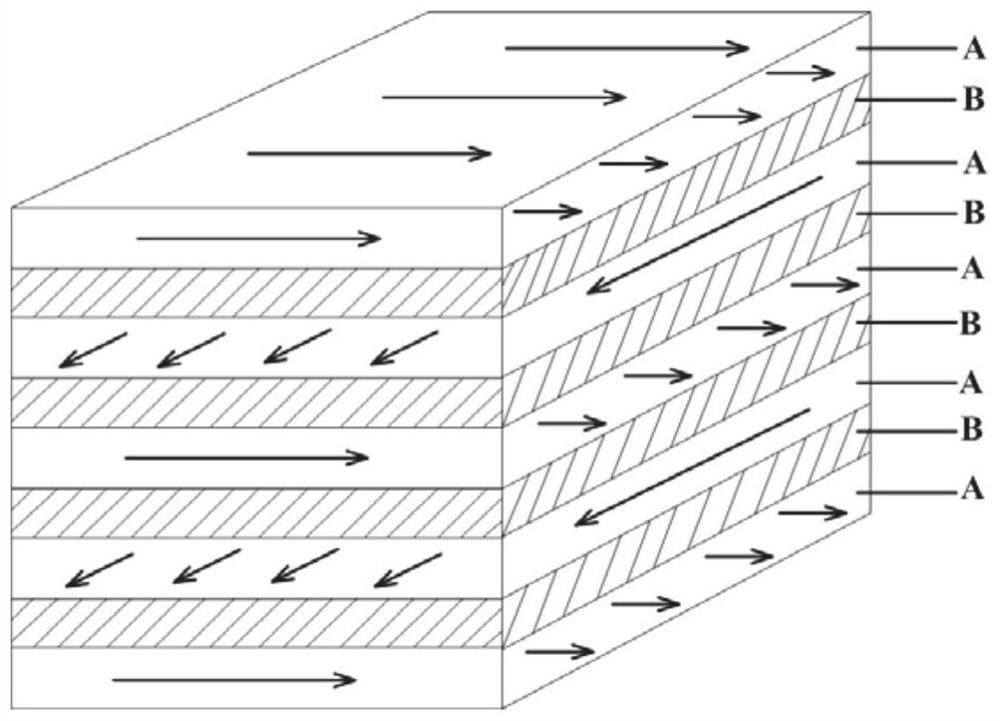

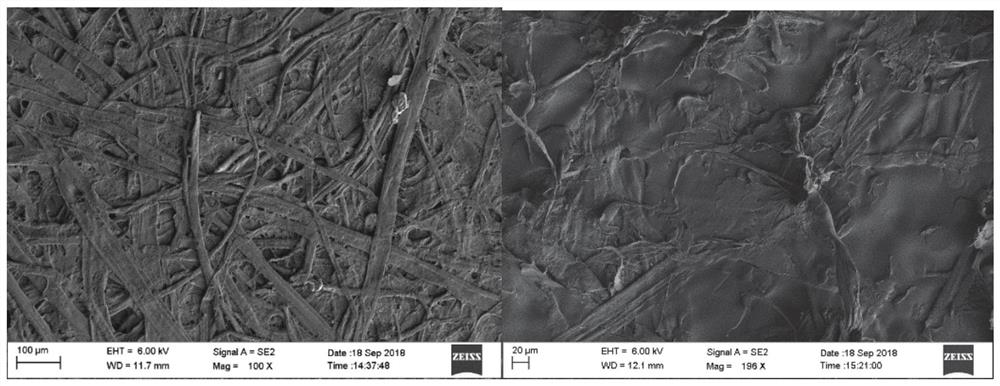

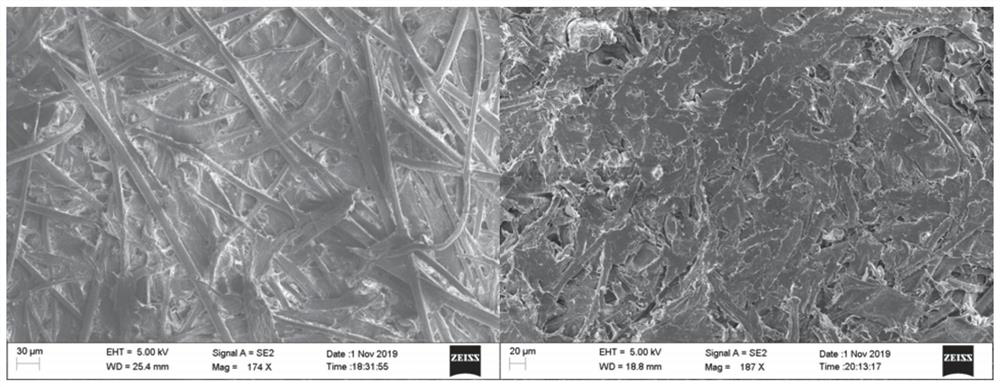

Composite material taking two-dimensional bio-based material as skeleton unit and processing technology of composite material

PendingCN112776446AHigh strengthImprove performanceLamination ancillary operationsLaminationPlastic fiberUltimate tensile strength

The invention relates to a composite material taking a two-dimensional bio-based material as a framework unit and a processing technology of the composite material. The simple and efficient method for producing a novel material with high strength and high cost performance through hot pressing by using kraft paper and the like as a two-dimensional basic structure unit and a framework material for the first time, and by using natural lignin and a synthetic viscous polymer as binding materials, and the invention also a product thereof, the novel low-cost and high-performance composite material which takes a bio-based material as a main body and greatly reduces the use amount of resin or plastic is realized; the strength, the toughness and the internal binding force of the material greatly exceed those of natural materials, plastics, plastic fiber composite materials and high-density fiberboards, and a series of problems that fibers in plastic resin are difficult to disperse, the adding amount is small, and the strength reduction amplitude is large are solved.

Owner:XIAMEN UNIV +2

Method for processing wall space cracking

The invention relates to a new method for processing wall space cracking. An electric drill is adopted to punch holes, and filling and repairing are carried out by adopting glass fiber reinforced plastics resin and glass fiber silk floss. The new method for processing the wall space cracking has the advantages that the connection strength is high, the method is economical and practical; the purchase of materials is convenient; the repairing method is simple, and common workers conveniently perform conventional construction; the waterproof function of wall space is enhanced; the surface layer seam is small, and the subsequent putty and wallpaper construction are not affected.

Owner:曹颖

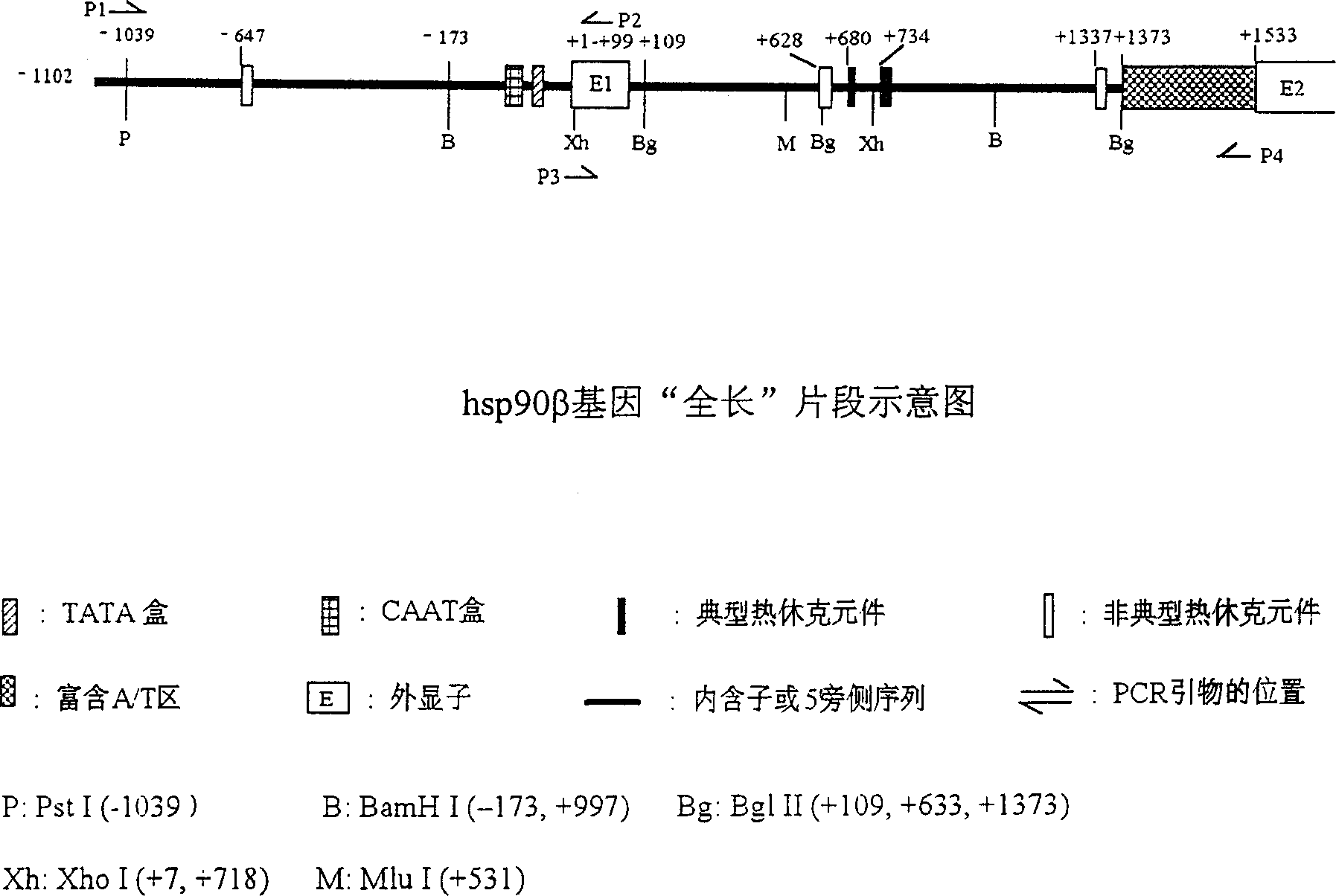

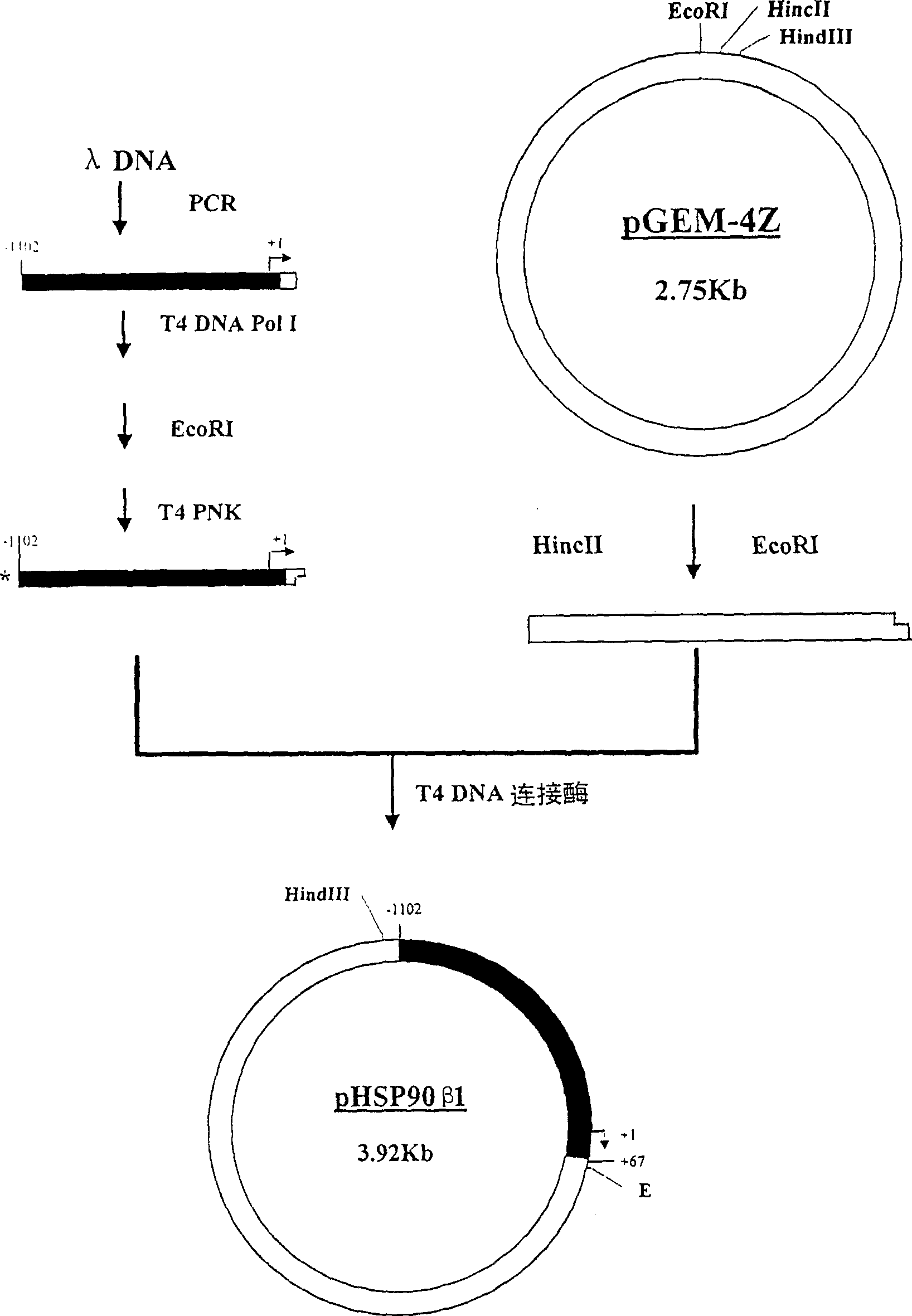

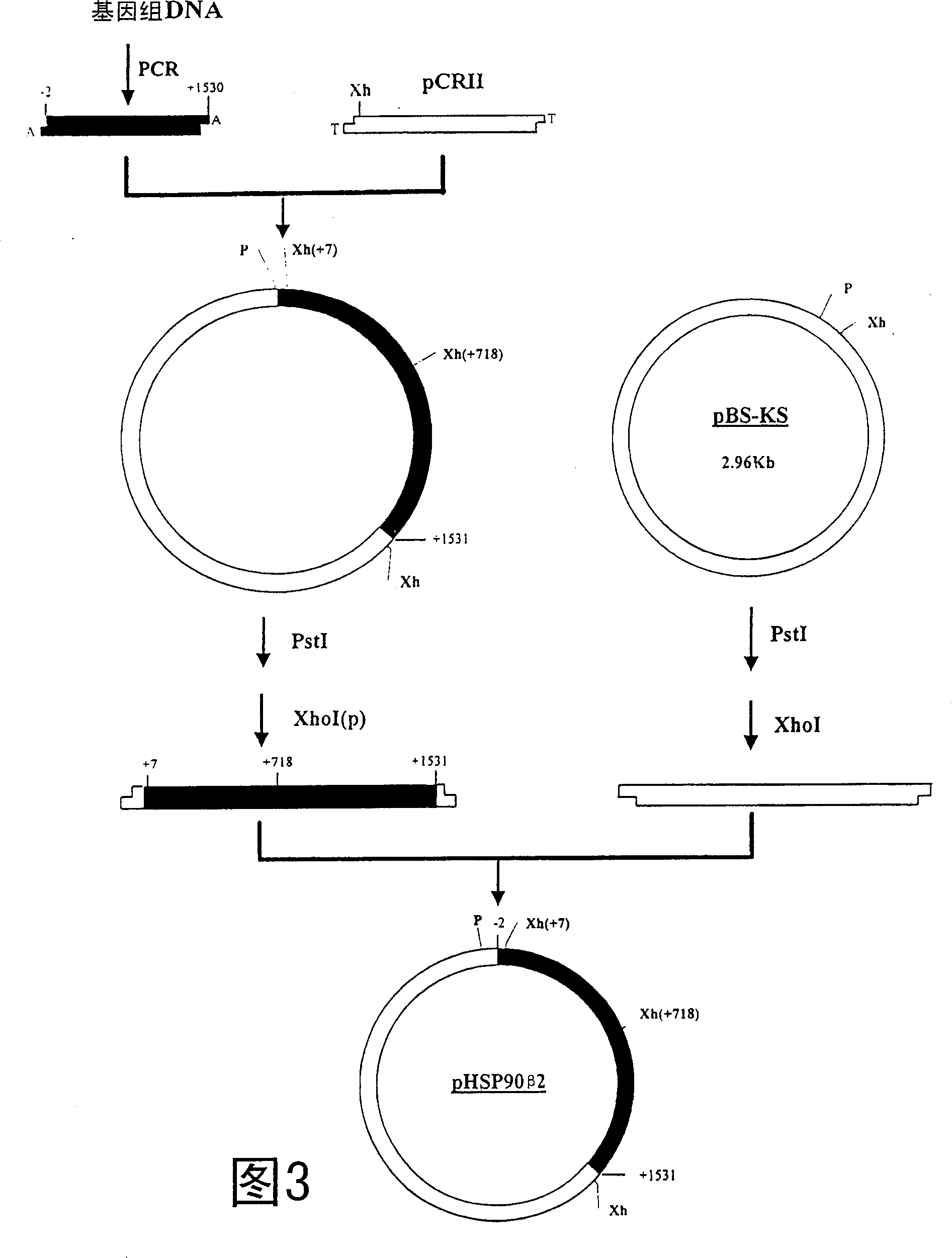

Human originating promoter for human body cell to express exogenous gene efficiently

InactiveCN1143894CIntensity exceedsFermentationVector-based foreign material introductionThermal shockHuman body

The present invention relates to a humanized promotor for human body cell to high-effectively express exogenous gene. In the concrete the invented promotor is from human thermal shock protein gene hsp 90 beta.

Owner:THE INST OF BASIC MEDICAL SCI OF CHINESE ACAD OF MEDICAL SCI

A lightweight aluminum alloy automobile roof welding process

ActiveCN108296662BGuaranteed sizeReduce the amount of weldingOther manufacturing equipments/toolsWelding apparatusEngineeringMachining process

The invention belongs to the technical field of lightweight of automobiles, and relates to a welding process for a lightweight aluminum alloy automotive roof. The welding process of the lightweight aluminum alloy automotive roof comprises the steps that an air duct support of the automotive roof is integrally formed through extrusion by an extrusion die, and the air duct support integrally formedthrough extrusion is cut at equal intervals; a corner weld structure is formed between an automotive crossbeam and a bent plate; after the two sides of a weld are polished, the automotive crossbeam and the bent plate are welded, wherein the welding current is 155-165 A, the voltage is 21.2-22.5 V, and the welding speed is 9-11 mm / s; and a butt weld structure is formed between the air duct supportand the automotive crossbeam, the bevel angle is 55 degrees, and after the two sides of a weld are polished, the air duct support and the automotive crossbeam are welded, wherein the welding current is 155-165 A, the voltage is 21.2-22.5 V, and the welding speed is 12-14 mm. By adoption of the welding process of the lightweight aluminum alloy automotive roof, the problems that in the machining process of the automotive roof, the welding workload is large, and operation is complex are solved.

Owner:辽宁忠旺铝合金精深加工有限公司

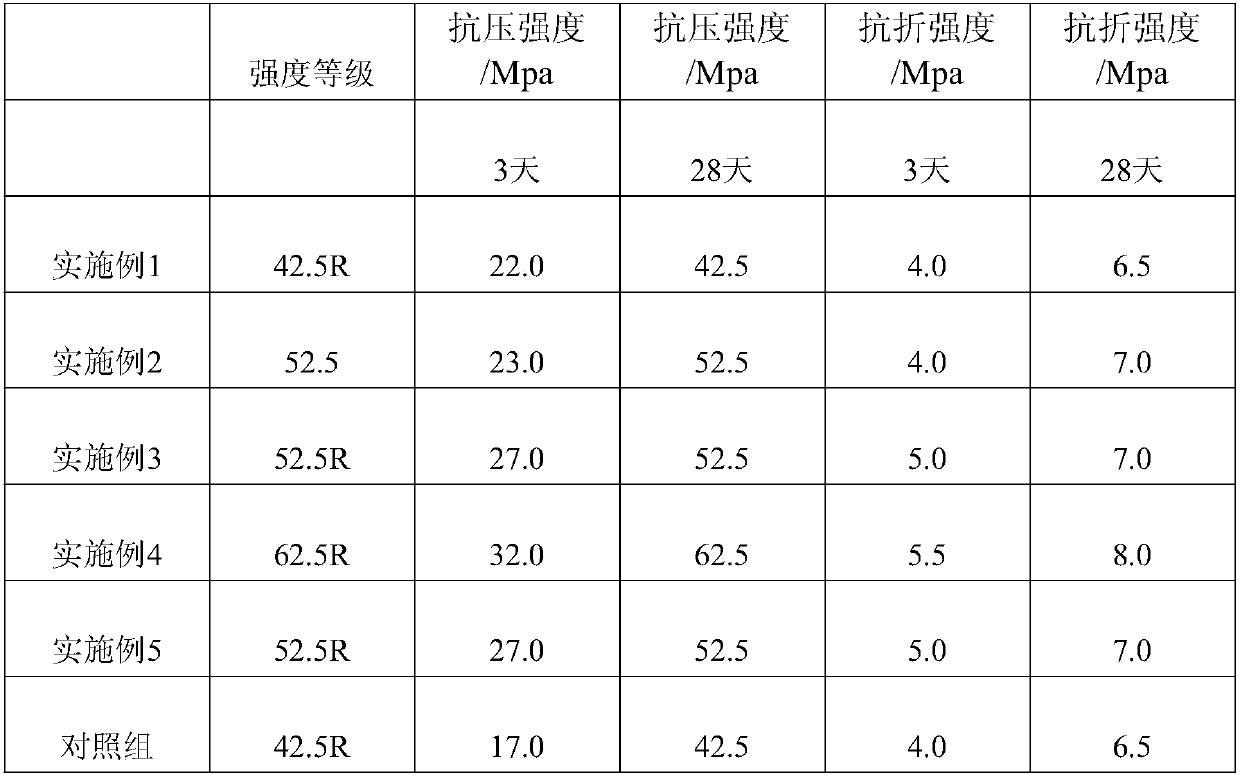

Calcium magnesium silico-phosphate cement and processing method of same

The invention belongs to the field of building materials, and relates to calcium magnesium silico-phosphate cement and a processing method of same. The calcium magnesium silico-phosphate cement includes the following raw materials: diammonium phosphate, magnesium oxide, fly ash, borax, potassium dihydrogen phosphate, and sodium hexametaphosphate. The maximum strength of the calcium magnesium silico-phosphate cement is 62.5R; due to addition of fly ash accounting for 26-29%, cost is reduced by 120-150 Yuan, coal is saved by 270-3200 kg and CO2 emission is reduced by 1960-2300 kg in production of 1 ton of the composite calcium magnesium silico-phosphate cement.

Owner:GUIZHOU PHOSPHORUS MAGNESIUM MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com