High-damping anti-aging rubber product and preparation method thereof

A rubber product, anti-aging technology, applied in the direction of rubber layered products, chemical instruments and methods, layered products, etc., can solve the problems of weather aging and poor oil resistance of vibration damping products, so as to improve the service life, solve the problems of poor weather resistance and Poor oil resistance and strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

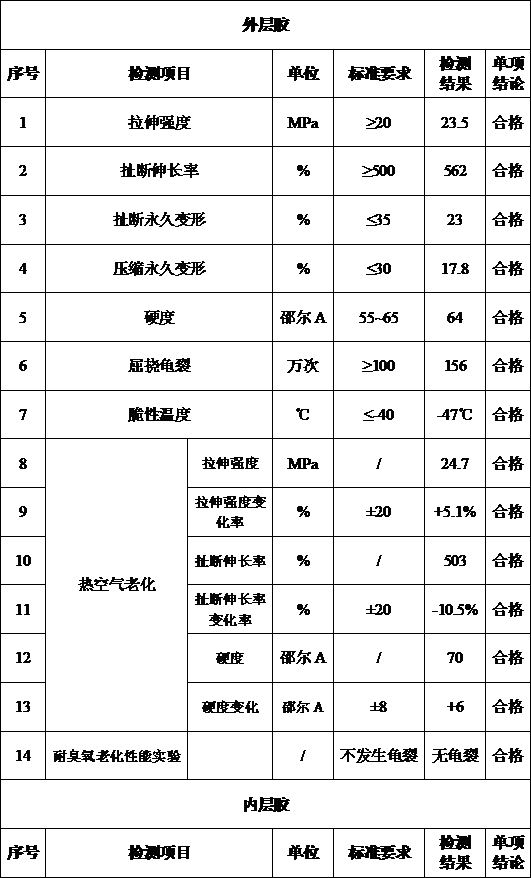

[0030]A high damping and anti-aging rubber product is composed of three layers of different rubbers, such as outer layer rubber, middle layer rubber and inner layer rubber, wherein the outer layer rubber is composed of the following raw materials by weight: 60 parts of ethylene acrylate rubber, chlorine 40 parts of butadiene rubber, 30 parts of carbon black (reinforcing and filling system), 20 parts of white carbon black (reinforcing and filling system), 3 parts of paraffin oil (plasticizing system), 1 part of polyethylene wax (plasticizing system), anti-aging 1 part of agent RD, 2 parts of antioxidant 4010NA, 5 parts of zinc oxide (activation system), 4 parts of magnesium oxide (activation system), 1 part of stearic acid (activation system), 1 part of sulfur (vulcanization system), peroxide ( vulcanization system) 2 parts; the inner rubber layer is composed of the following raw materials by weight: 70 parts of butyl rubber, 30 parts of styrene-butadiene rubber, 30 parts of car...

Embodiment 2

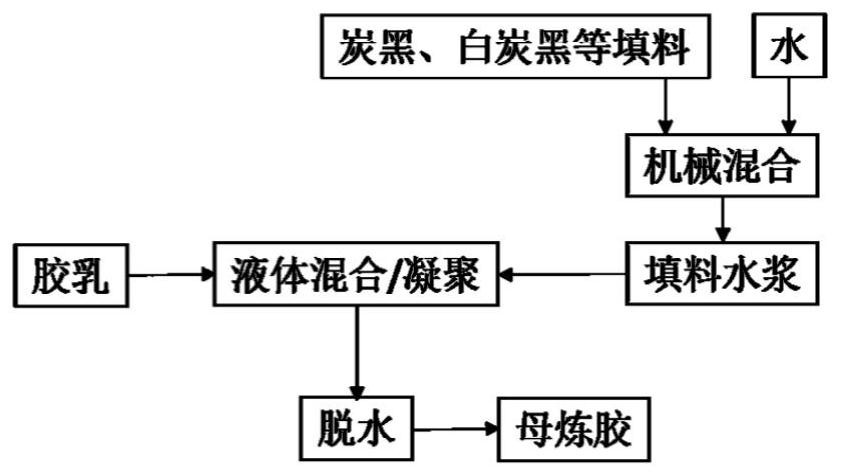

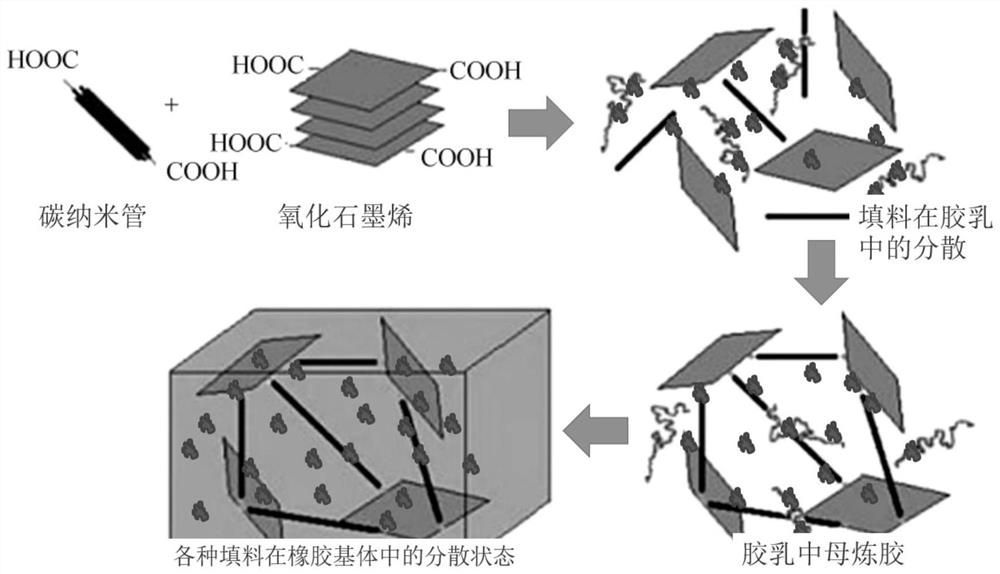

[0040] In the rubber mixing process, an appropriate amount of masterbatch and adhesive systems such as resorcinol and hexamethoxymethyl melamine are added as needed. The masterbatch is an indispensable part of the preparation of composite rubber materials. The reinforcing and filling system in each layer of rubber formulation is included, and the reinforcing and filling system is wet-mixed with the natural rubber latex grafted with silica to obtain the masterbatch. like figure 1 As shown, the masterbatch preparation process is as follows:

[0041] The filler water slurry is obtained by mechanically stirring fillers such as silica and carbon black in water. The filler water slurry is mixed with the natural rubber latex grafted with silica and then coagulated and dehydrated to obtain a masterbatch with high filler content. The quality of filler and water The ratio is 1:1, and the mass ratio of latex to water slurry is 1:1.

[0042] The adhesive system consists of the following...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com