Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "No shedding problem" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

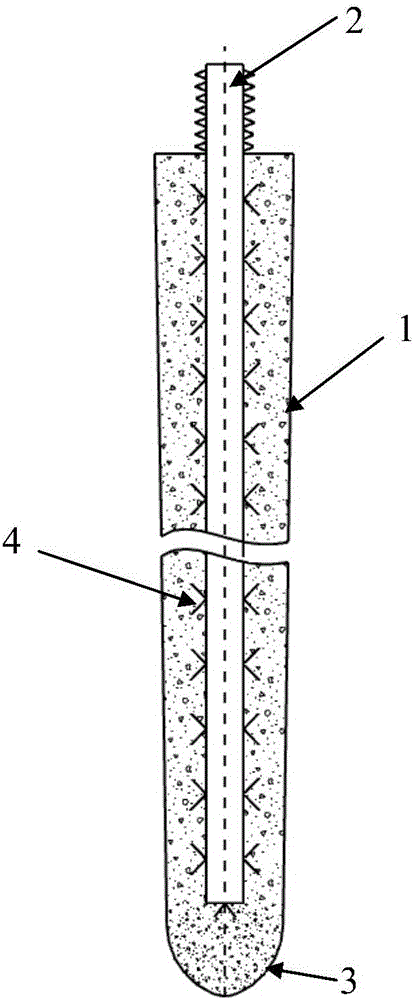

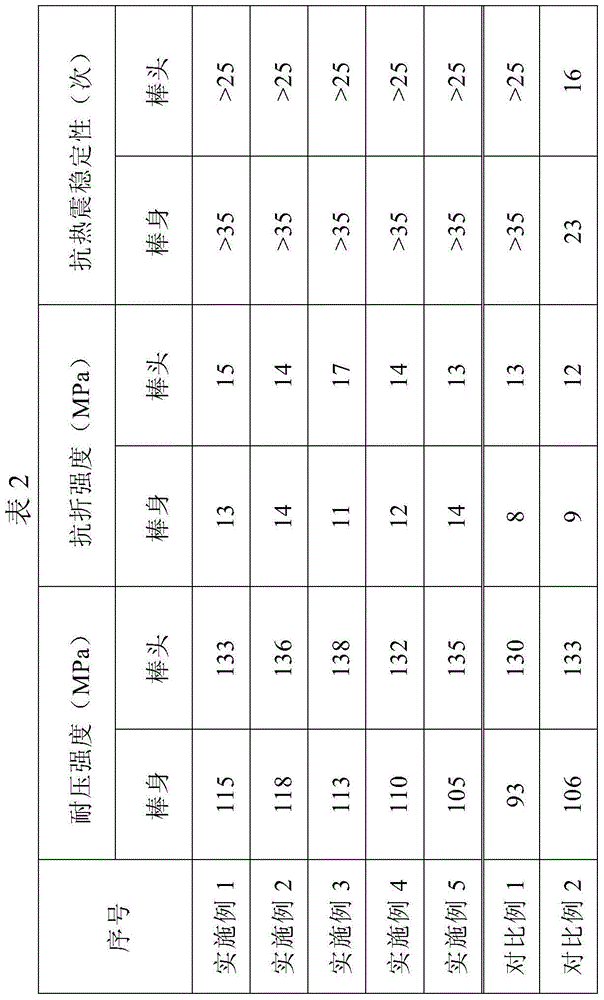

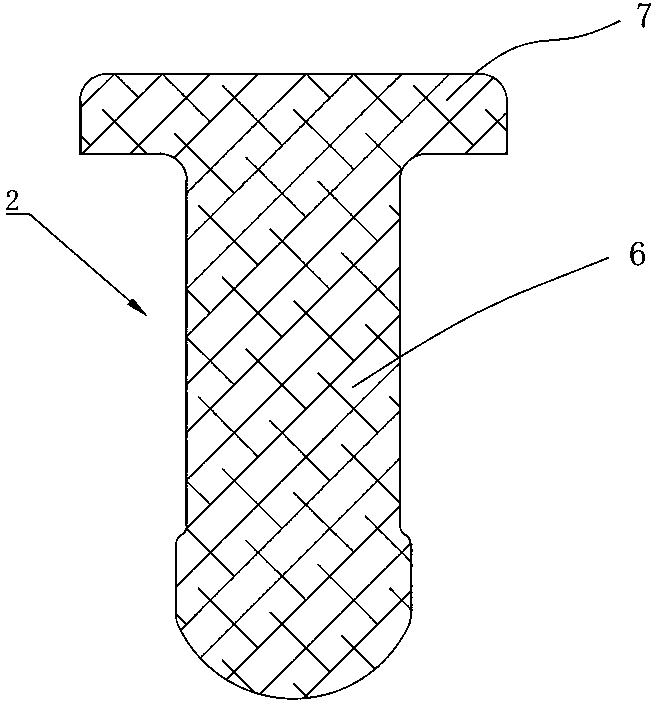

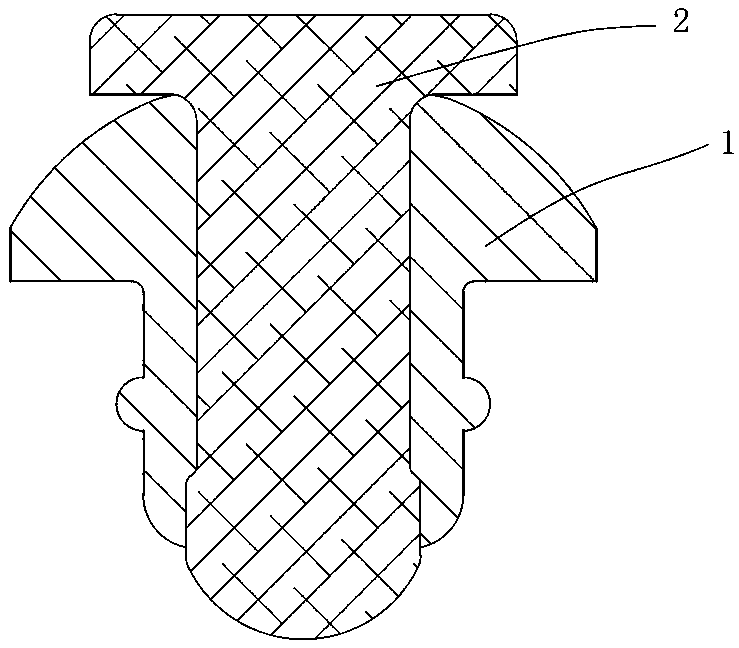

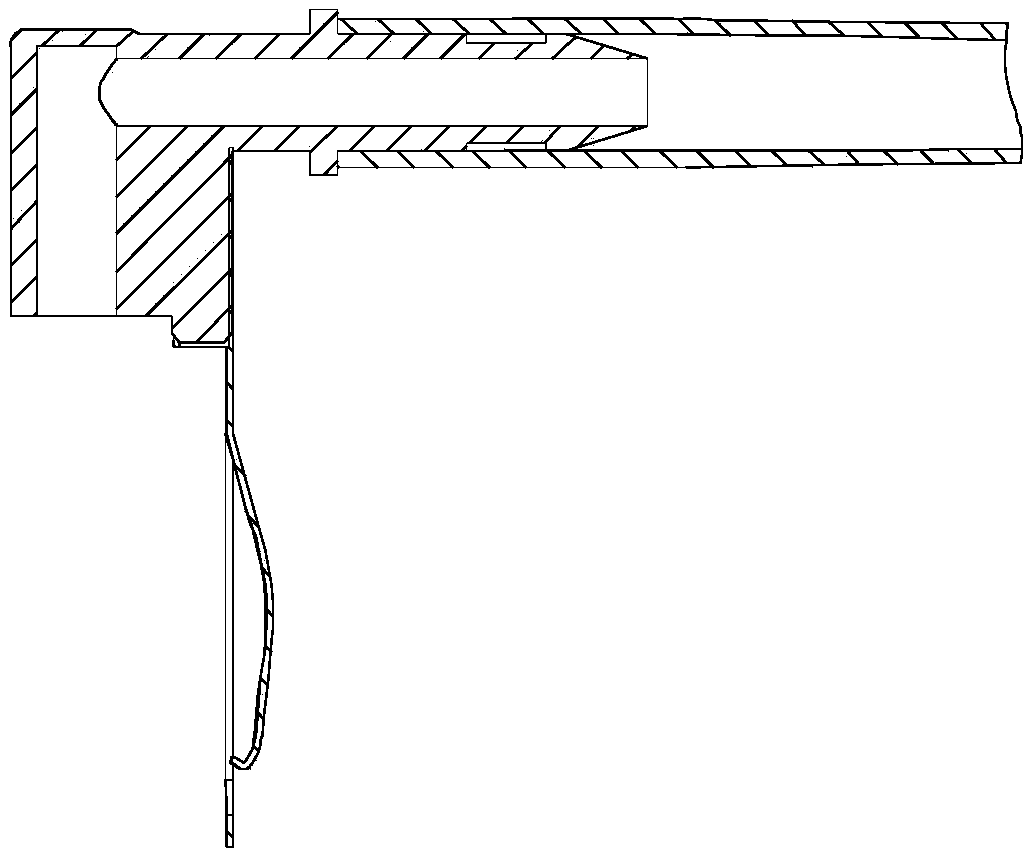

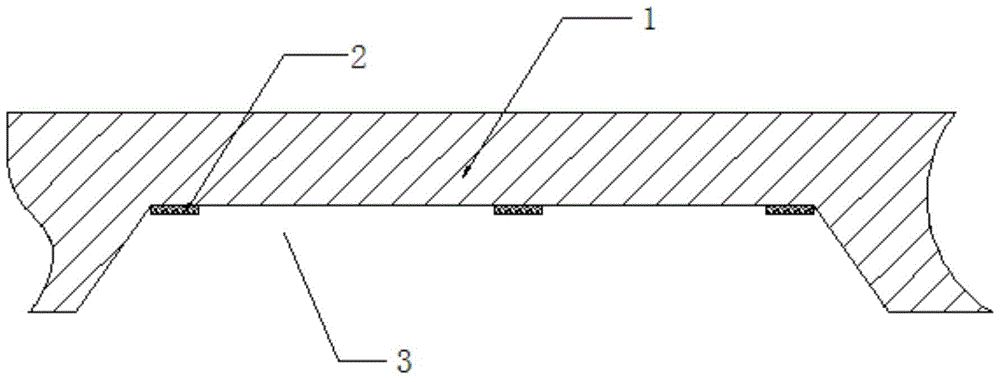

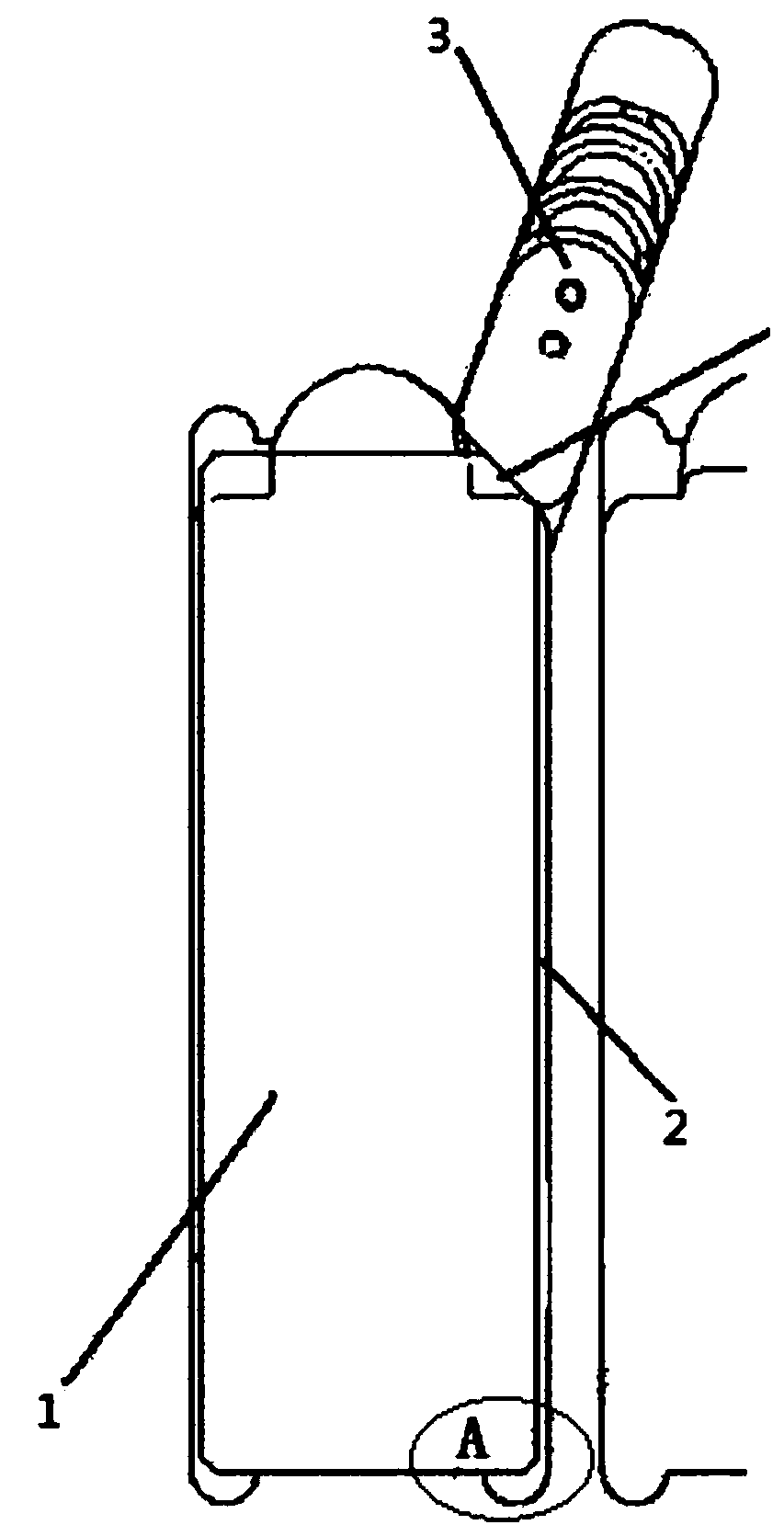

Continuous casting monolithic stopper and method of manufacture thereof

ActiveCN105753489AImprove thermal shock resistanceImprove erosion resistanceMelt-holding vesselsBrickMullite

The invention discloses a continuous casting monolithic stopper and a method of manufacture thereof.The monolithic stopper comprises a stopper body, a steel core inserted into the stopper body and a head connected to the lower end of the stopper body, the surface of the steel core is provided with an anchor, the surface of the monolithic stopper is coated with Al2O3 coating; the stopper body is made by casting castables comprising mullite, the head is made by casting castables comprising corundum and sintered mullite, and the monolithic stopper is manufactured by monolithic casting.The stopper obtained herein is good in monolithicity, is free of brick joint and head shedding problems of sleeve brick stoppers, has good thermal shock resistance, high strength and good resistance to molten steel scour erosion, is simple to manufacture and low in cost, and is suitable for stopping a tundish nozzle under low continuous casting, high-oxygen steel continuous casting and skid flow control.

Owner:BAOSHAN IRON & STEEL CO LTD

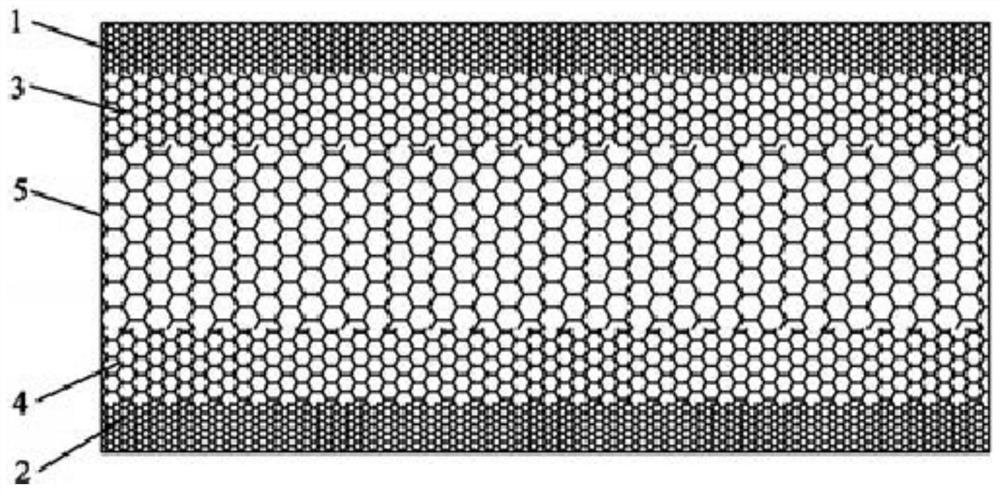

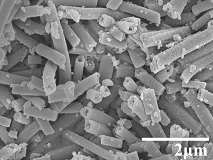

Preparation method of silicon nitride fiber filtration material

The invention belongs to the field of filtration materials, and discloses a preparation method of a silicon nitride fiber filtration material. The preparation method of the silicon nitride fiber filtration material comprises the steps that polyurethane foam is soaked in metal silicon slurry containing nitrogen auxiliaries, the polyurethane foam soaked with the metal silicon slurry is dried and put in a nitrogen furnace to conduct nitridation sintering, metal silicon is converted into a silicon nitride material with an alpha phase fiber structure under the action of the nitrogen auxiliaries, and therefore the silicon nitride fiber filtration material is obtained. The silicon nitride fiber filtration material is high in gas permeability, high in strength, high in corrosion resistance and excellent in thermal shock resistance, and the preparation method of the silicon nitride fiber filtration material has the advantages of being cheap in raw material, simple in technology and low in cost.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Vanadium ion liquid flow accumulator battery

InactiveCN1848506ARenewable energyNo softeningFinal product manufactureRegenerative fuel cellsVanadyl ionPhysical chemistry

The present invention relates to a vanadium ion fluid-flow battery. Said invention is characterized by that on the electrochemical principle it uses liquid vanadium ion as active substance, and makes the vanadium ions with different valences produce oxidation reduction reaction to store or release electric energy.

Owner:フォンリエレクトリックグループカンパニーリミテッド

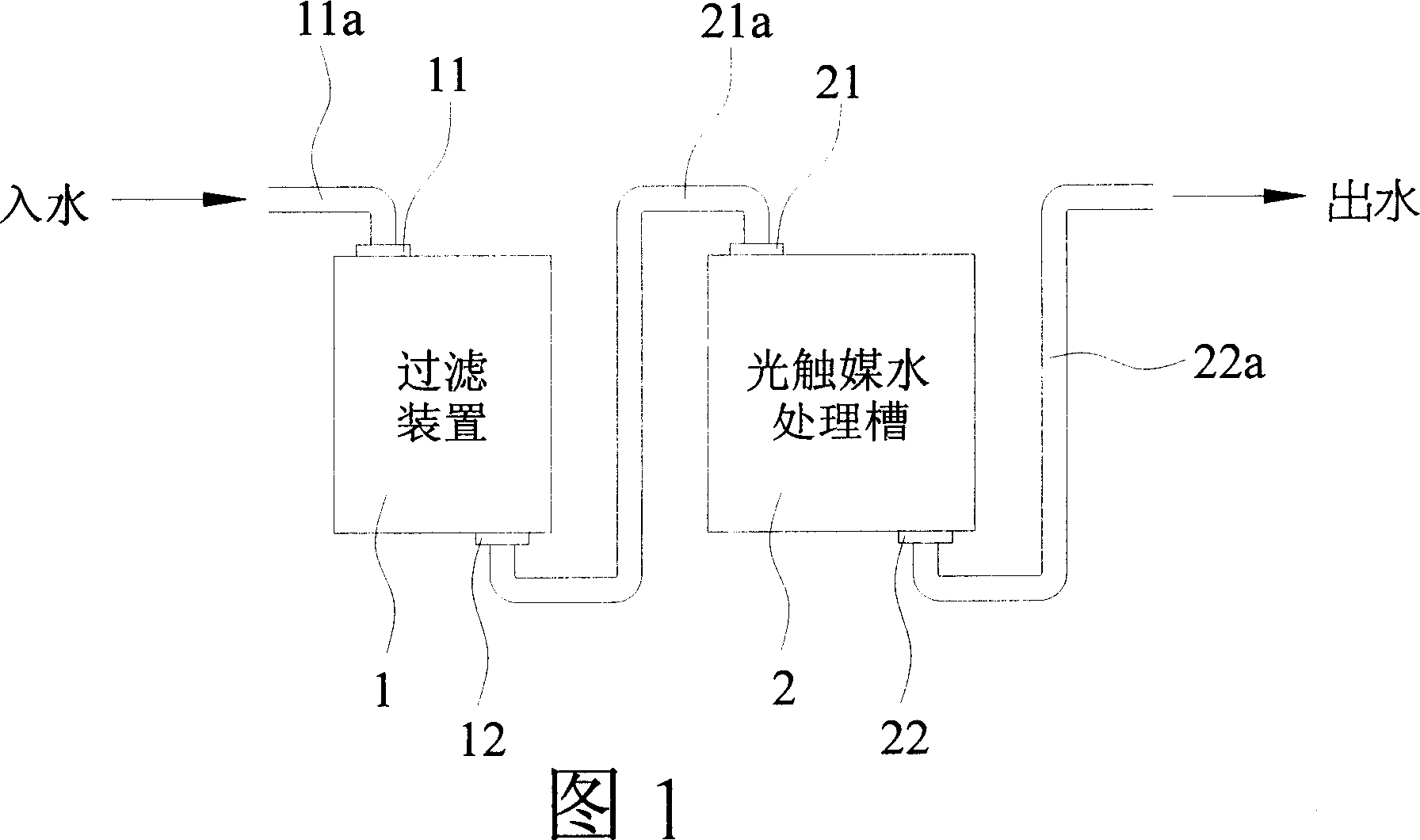

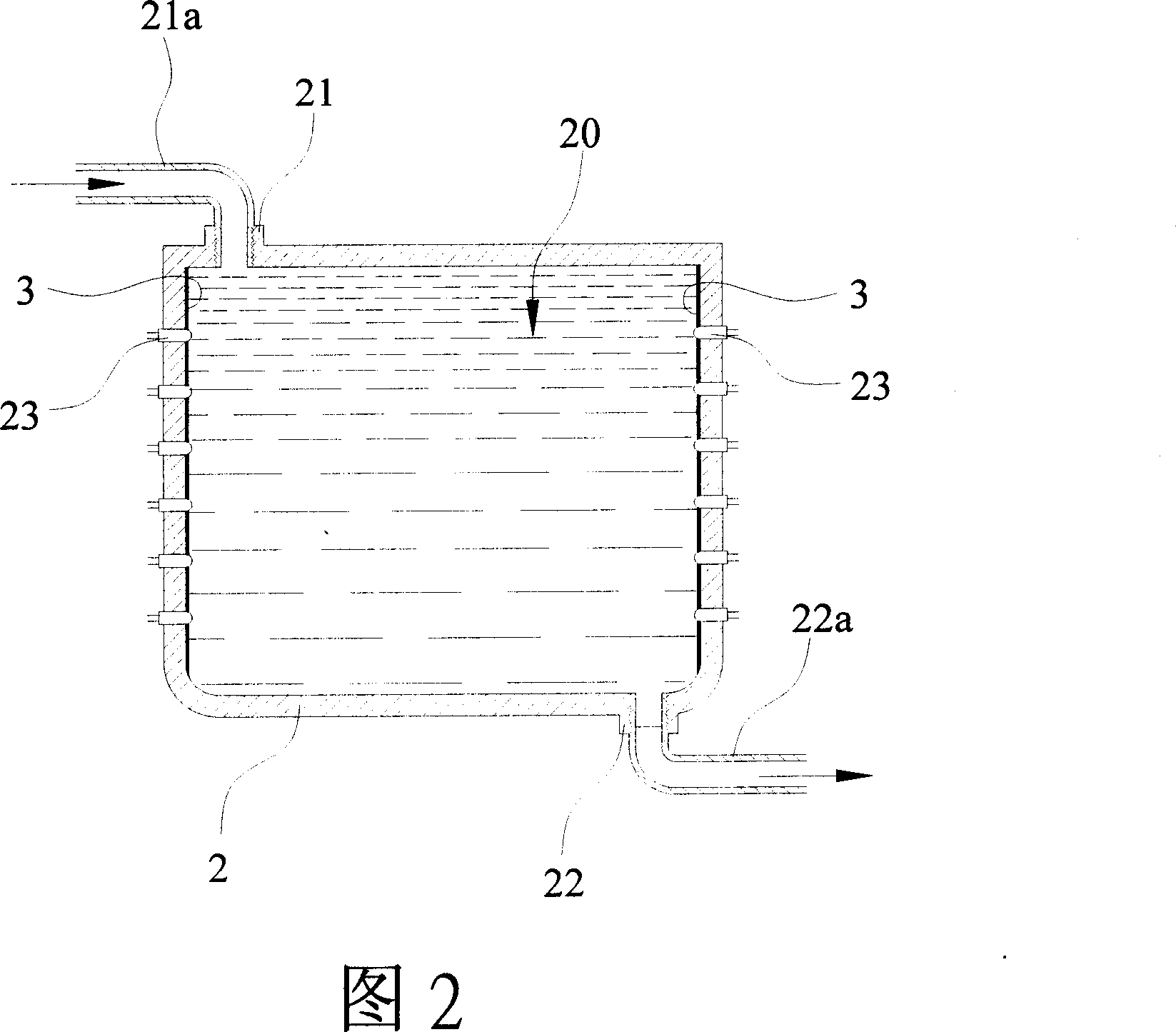

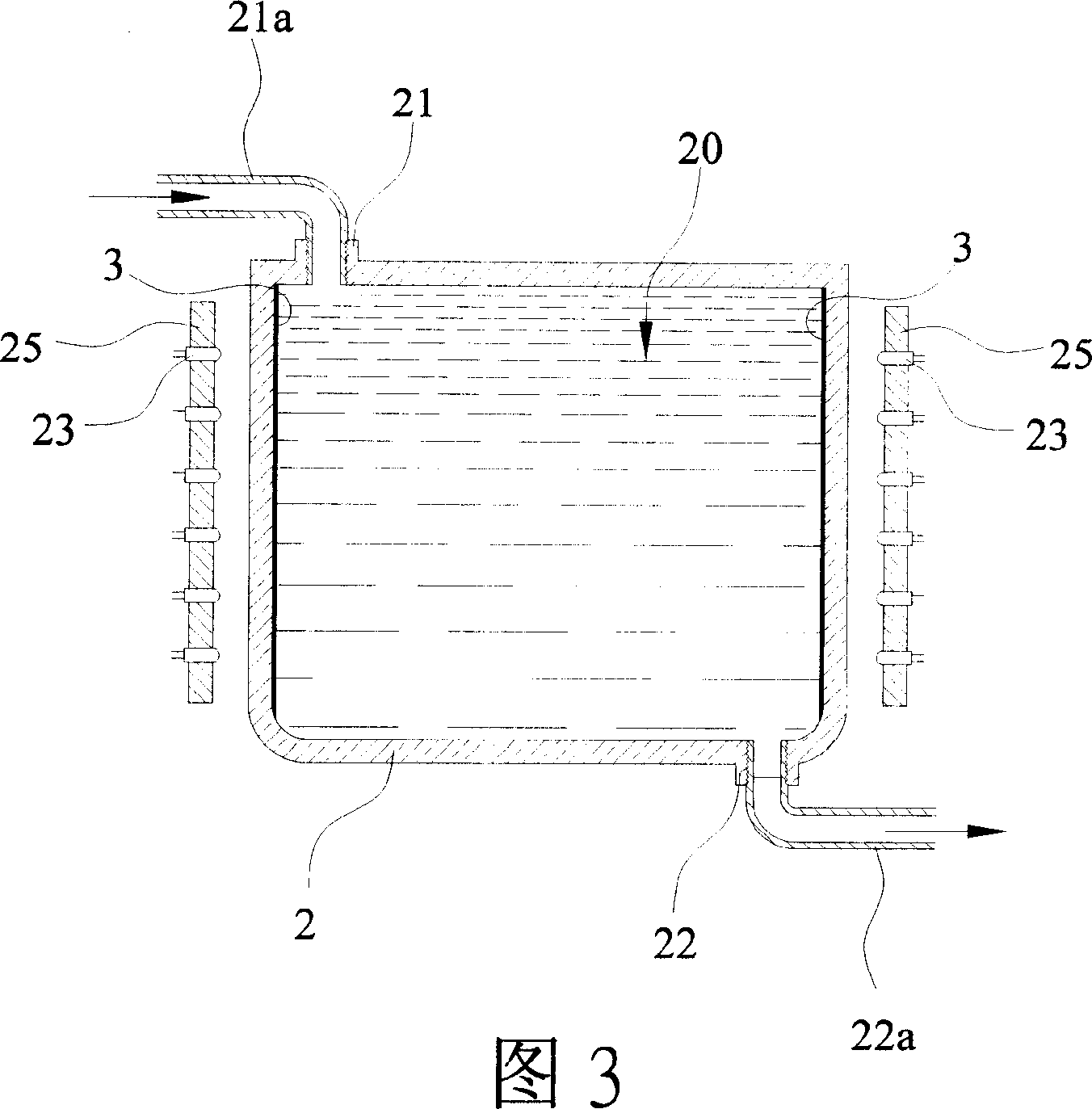

Method and apparatus for sterilizing light catalyst and its cooling water tower

InactiveCN101074122AImprove luminous efficiencyPromote the effect of sterilizationWater/sewage treatment by irradiationEnergy based wastewater treatmentPhotocatalysisLight source

Owner:李幸茹

Polyphenylene sulfide fiber fabric with body membrane and manufacture method thereof

InactiveCN101613953AImprove breathabilityImprove dust removal efficiencySingeingSynthetic resin layered productsFiberInorganic sulfide

The invention provides a polyphenylene sulfide fiber fabric with a body membrane and a manufacture method thereof, aiming to solve the problem that a needled felt with a covering membrane enables micropores of the covering membrane to shrink during a hot pressing process, and contraction of a polyphenylene sulfide micropore can be again caused in use due to a high-temperature work condition so as to seriously affect the ventilation effect, and even affect the normal production of dust-removal enterprises; and the needled felt is subjected to repeated impact of air current and machines when the ash is cleared, and the covering membrane is easy to drop off. The invention adopts the essential that the surface of the polyphenylene sulfide fiber fabric is provided with a layer of the body membrane produced by singeing and hot roller pressing. The invention has the characteristics of no dropping of the body membrane, good ventilation property, high dust-removal efficiency, smooth surface and easy ash clearing.

Owner:辽宁澳源实业发展集团有限公司

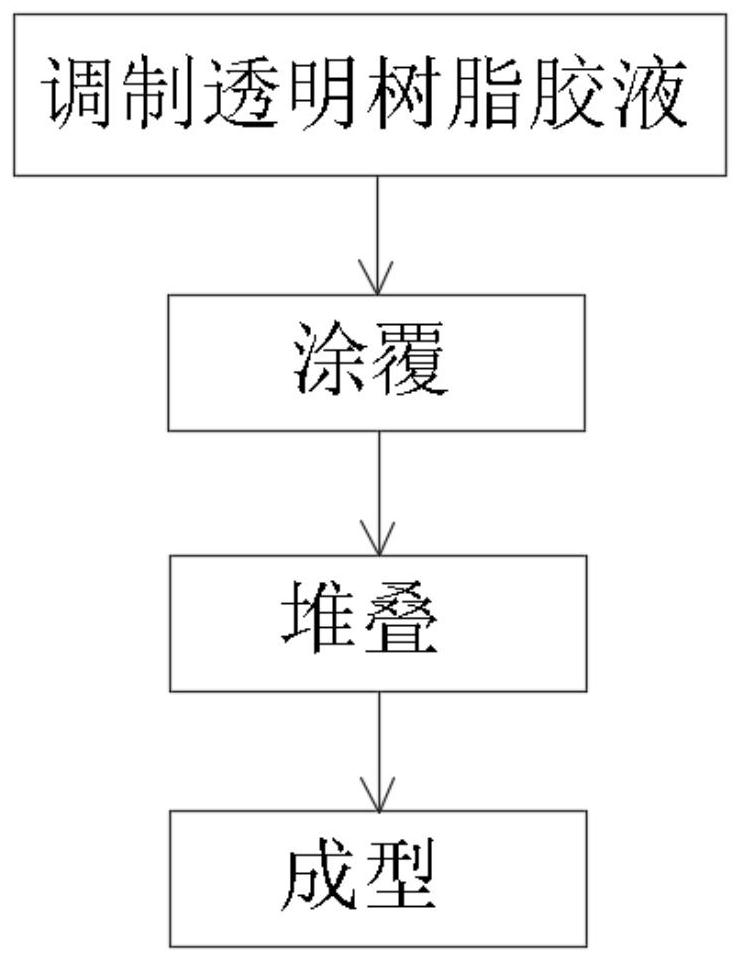

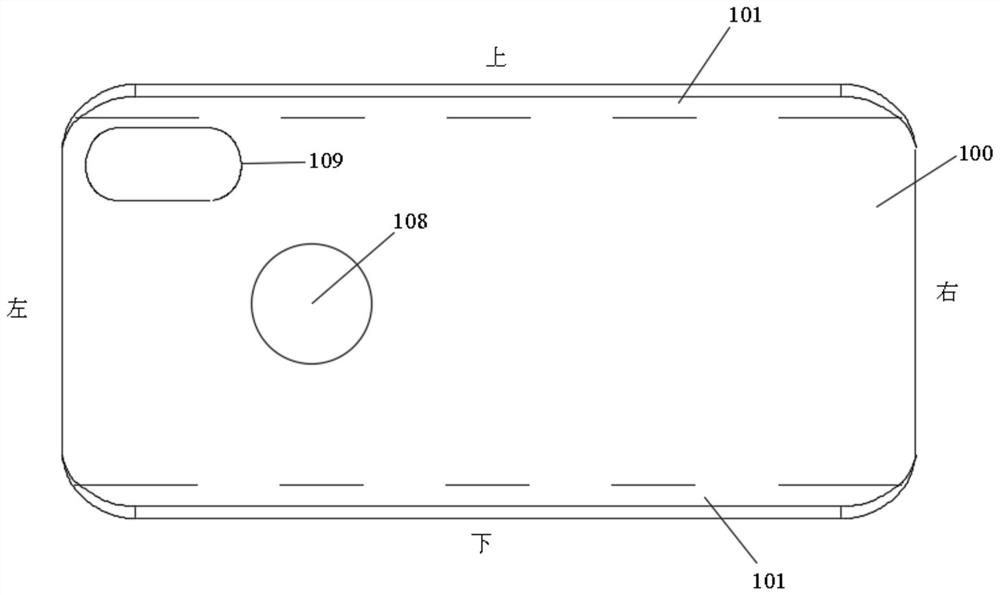

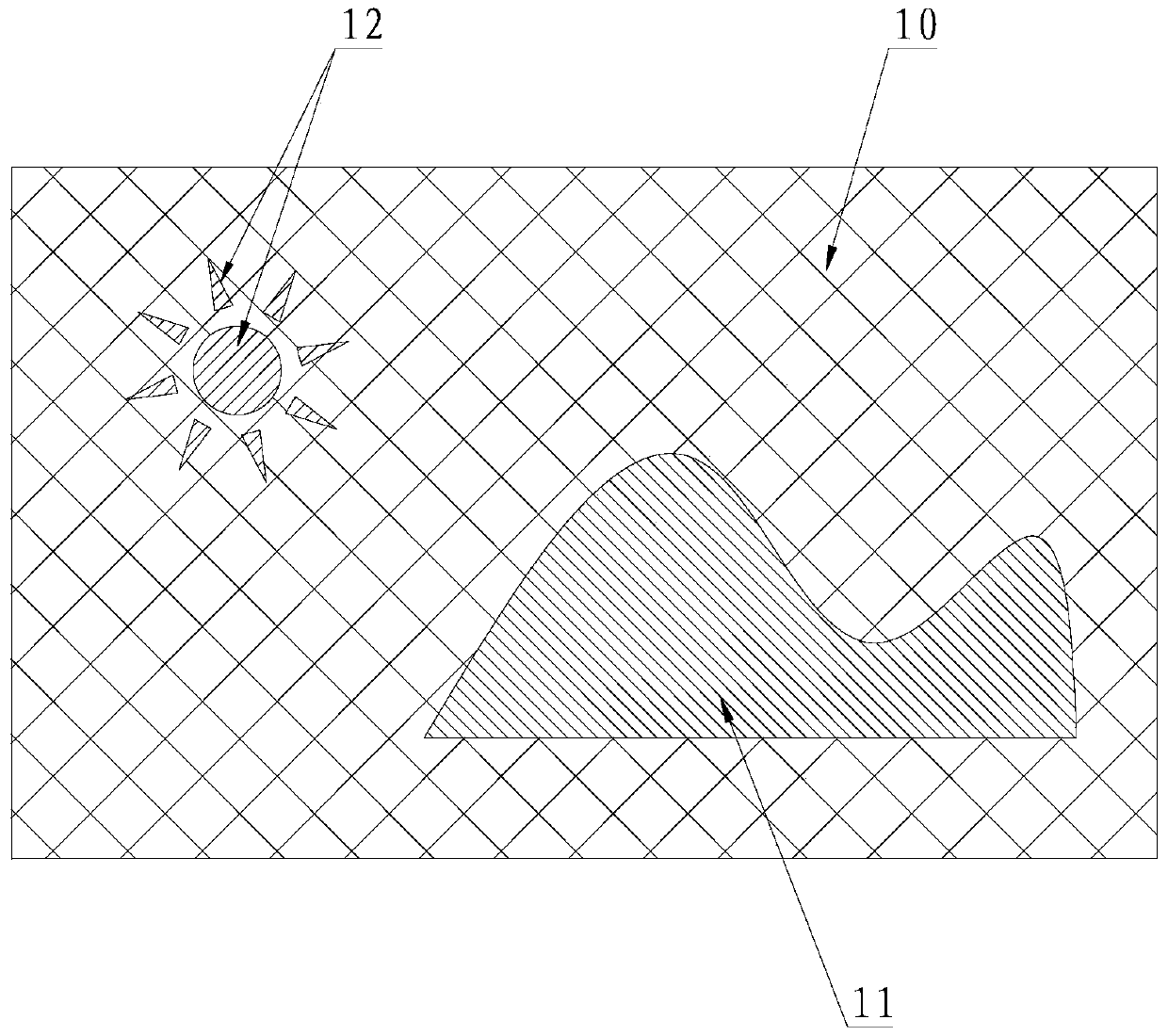

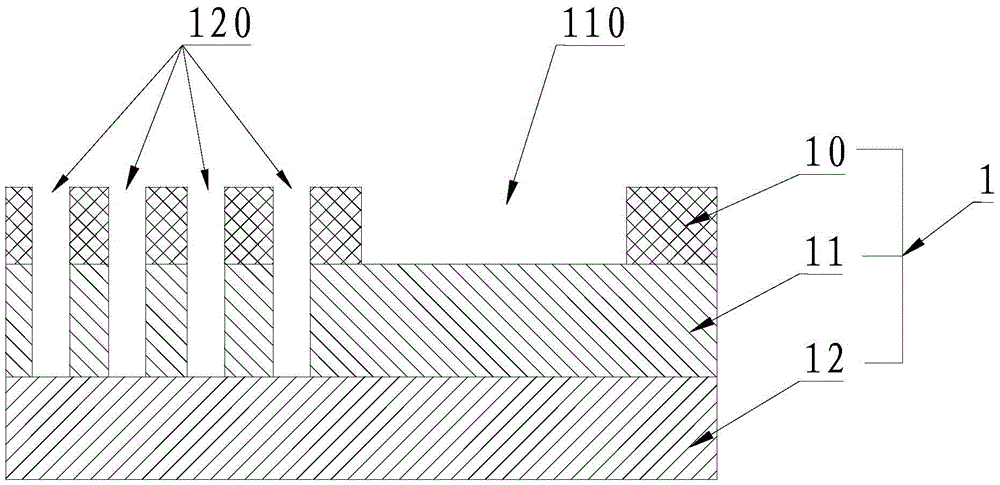

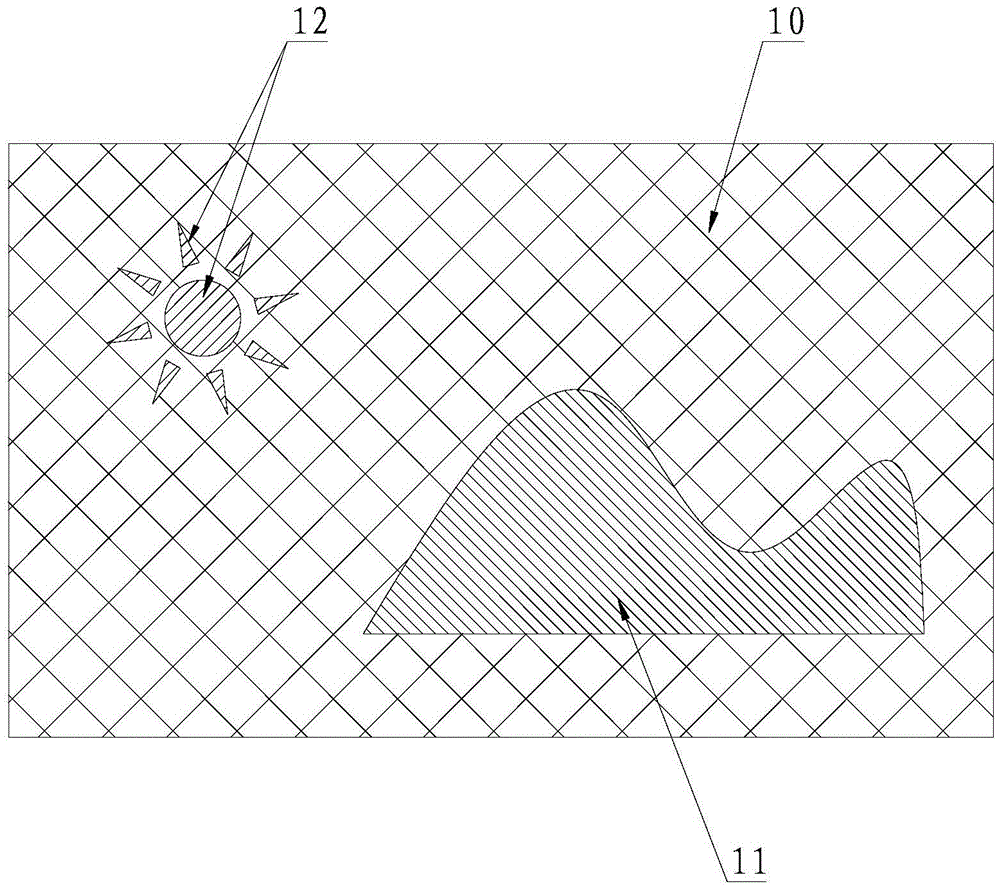

Production process and application of transparent 3D glass fiber board with textures

PendingCN113681935ANo shedding problemGuaranteed flatnessDomestic articlesGlass fiberLight penetration

The invention discloses a production process of a transparent 3D glass fiber board with textures. The production process comprises two production modes, wherein the first production mode comprises the following steps: S1, preparing a transparent resin glue solution; S2, coating to form a prepreg; S3, stacking; and S4, forming. During application, the transparent glass fiber board can be used for manufacturing a 3D mobile phone rear shell, the outer surface of the 3D mobile phone rear shell is a transparent glass fiber board, the inner surface of the 3D mobile phone rear shell is provided with UV glue ink, and the light transmittance of the transparent glass fiber board is 70-90%; and light penetrates through the transparent glass fiber board and is refracted and irradiated on the UV glue ink to form a snowflake effect with light and shade changes. The electronic product shell produced by the process provided by the invention has textures, and has the characteristics of drop resistance, flower texture drop prevention and durability at the same time.

Owner:惠州市众力电子科技有限公司

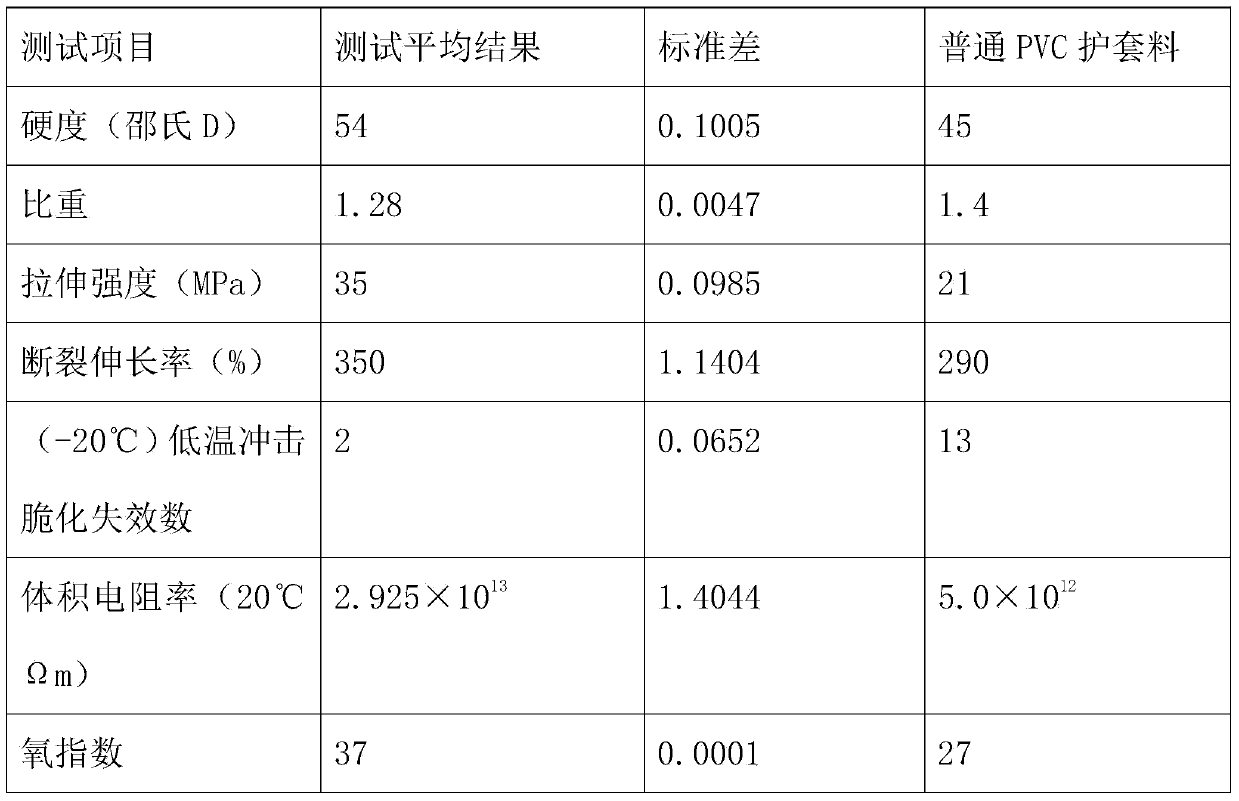

Weather-resistant high-voltage-resistant cable sheath material

InactiveCN103992543AImprove filler compatibilityGood lubricityInsulated cablesInsulatorsEnvironmental resistancePOLYETHYLENE WAX

The invention discloses a weather-resistant high-voltage-resistant cable sheath material, and the preparation method comprises the following steps: putting metallocene polyethylene, ethylene-vinyl acetate resin, 5-8 parts of polymethyl methacrylate, a composite environmental-friendly heat stabilizer, micro encapsulated red phosphorus, expandable graphite, polyethylene wax and a super lubricant into a low speed kneader for mixing evenly; putting phthalate, conductive metal powder, carbon fiber, calcined clay, talcum powder and an antioxidant in the low speed kneader for mixing evenly with the obtained material, then putting the prepared material into a high speed kneader for heating for mixing evenly at a high speed, and cooling; sending the obtained material into a twin-screw granulator for extrusion granulating, and drying to obtain the high-voltage-resistant cable sheath material. The weather-resistant high-voltage-resistant cable sheath material is excellent in high-voltage-resistant performance, free of falling off, higher in hardness and good in thermal stability.

Owner:ANHUI ELECTRIC GRP SHARES

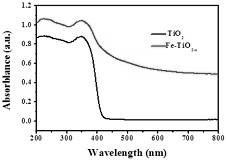

Electrostatically spun defect-state TiO2/Fe3O4 composite nanofiber material and preparation method thereof

PendingCN113546625AEfficient compositeNo shedding problemMaterial nanotechnologyWater/sewage treatment by irradiationFiberSpinning

The invention relates to a defect-state TiO2 / Fe3O4 composite nanofiber material and a preparation method thereof, and belongs to the technical field of materials. The preparation method of the material comprises the following steps: firstly, dispersing a titanium source, an iron source and a high-molecular polymer in a solvent to prepare a stable and uniform solution; then preparing the solution into a nanofiber membrane through an electrostatic spinning technology; and calcining the nanofiber membrane, grinding the calcined material and sodium borohydride, and reducing in a nitrogen atmosphere to obtain the defect-state TiO2 / Fe3O4 composite nanofiber material. The method is simple to operate, easy to control, environment-friendly and capable of realizing continuous production, and the obtained defect-state TiO2 / Fe3O4 composite nanofiber material has good crystallinity and photoresponsiveness and has excellent degradation performance on organic pollutants in a water environment.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

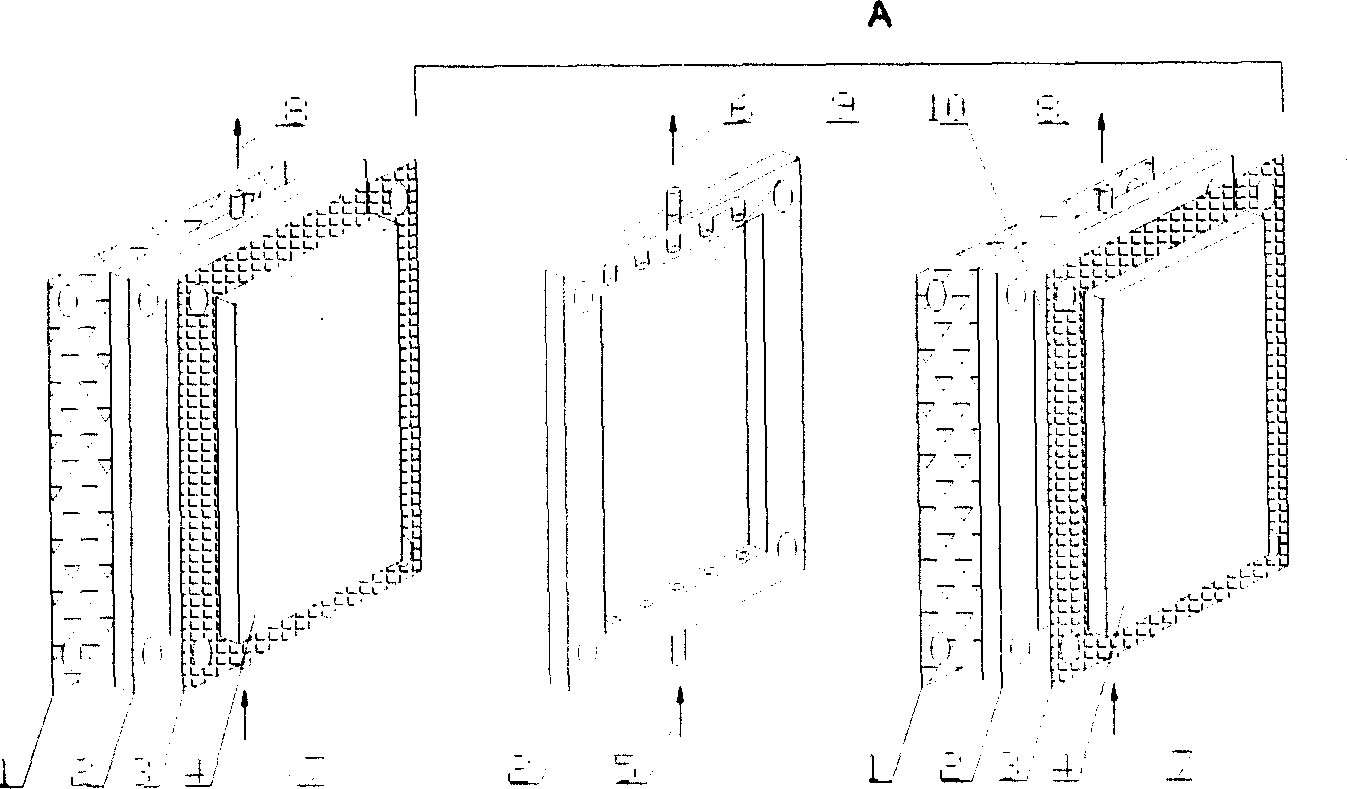

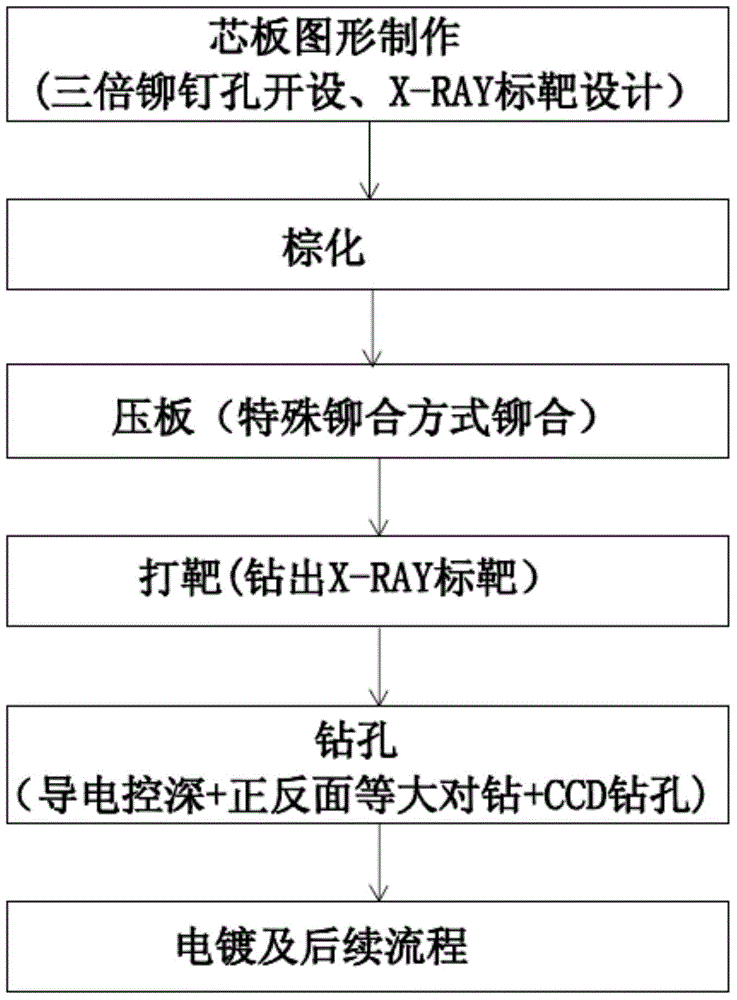

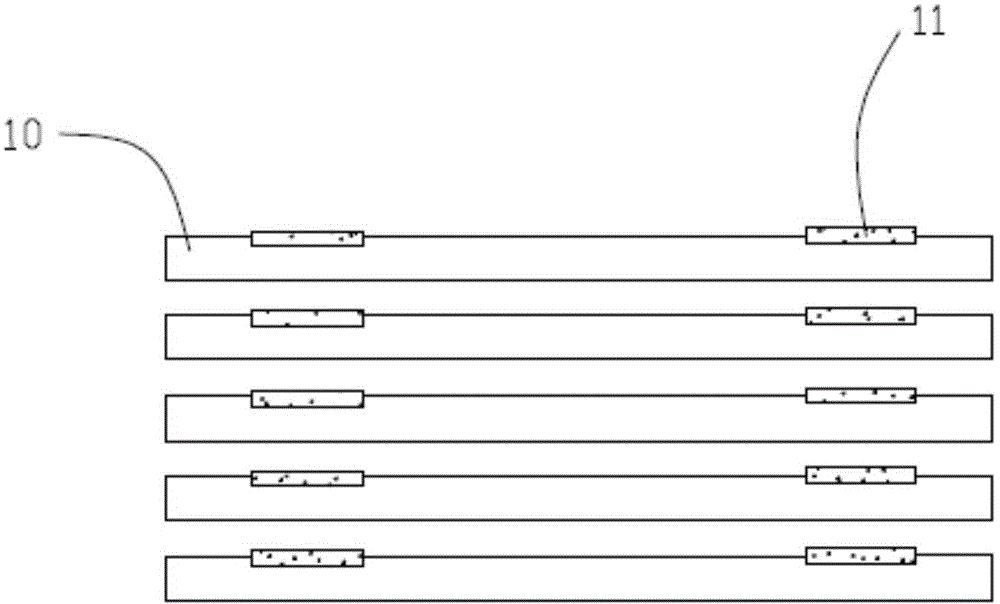

Backboard processing method, adopted die and backboard manufactured by use of processing method

ActiveCN106332473AIncreased rivet fixationBloom evenlyMultilayer circuit manufactureEqual sizeMultiple target

The invention provides a backboard processing method and an adopted die. The backboard processing method comprises following steps of: 1) manufacturing multiple sets of rivet holes and multiple target graphs in / on each sub core board, wherein each set of the rivet holes comprise at least three linearly arranged rivet holes; 2) browning the sub core boards; 3) laminating and riveting the sub core boards to form a backboard, wherein each set of the rivet holes are riveted to two rivet holes; 4) using a target drilling machine to grab target graphs on the backboard and drilling target holes in positions of the target graphs; and 5) using a CCD drilling machine to drill target holes so as to use the target holes as targets, and carrying out front-back face equal-size opposite drilling of functional holes on the backboard in a mode of conductive depth controlling. The method can improve the alignment precision control of the overlapping of all sub core boards in a manufacturing process of the backboard, and improves the machining precision and yield of the backboard.

Owner:DONGGUAN SHENGYI ELECTRONICS

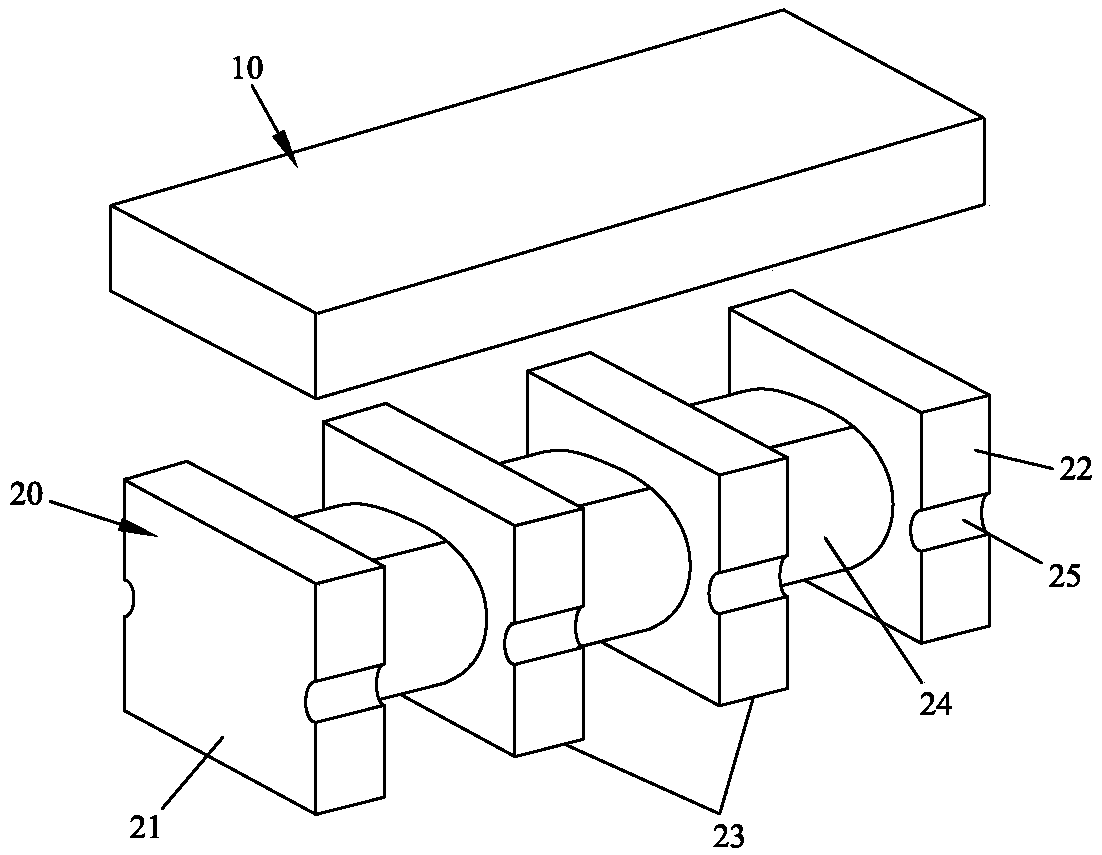

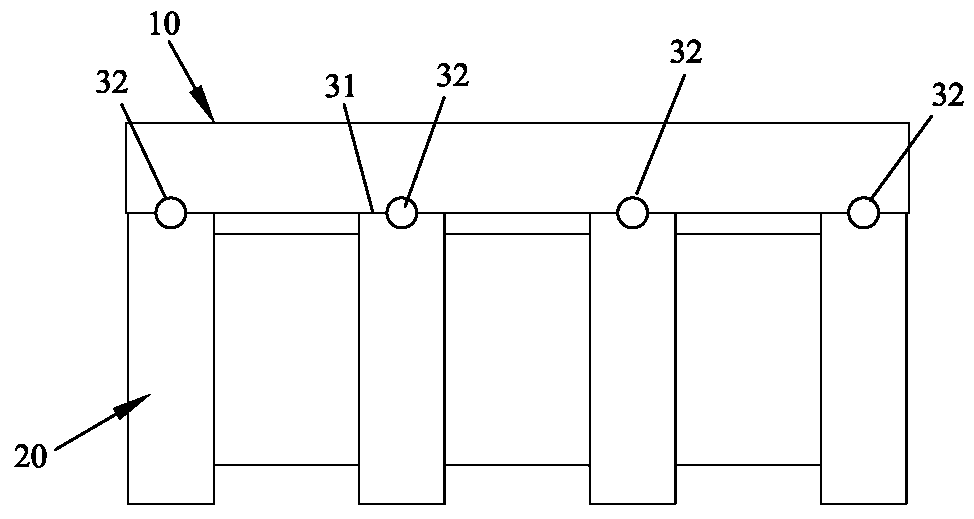

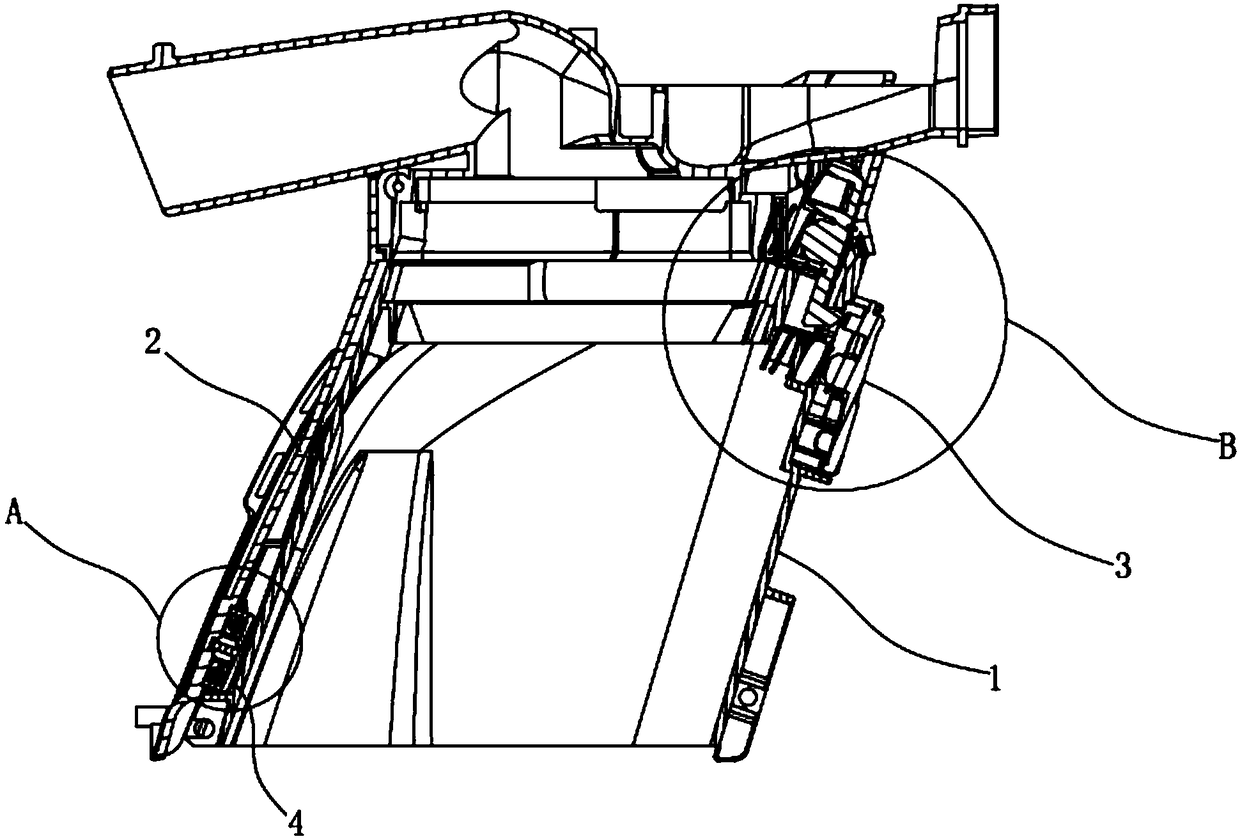

Production technology of automobile front-wall heat-insulation pad and foam punching die

The invention provides a production technology of an automobile front-wall heat-insulation pad, comprising the following two processing steps: 1) plastic uptake shaping; and 2) foam punching. The invention also provides a foam punching die used in the production technology. The invention has advantages and positive effects as follows: 1) production pace is accelerated; 2) consistency of a product is good; 3) VOC performance of the product is improved; and 4) production cost of the product is reduced: two post-procedure operators are saved, there is no superfluous binder, and production cost is controlled effectively.

Owner:GREAT WALL MOTOR CO LTD

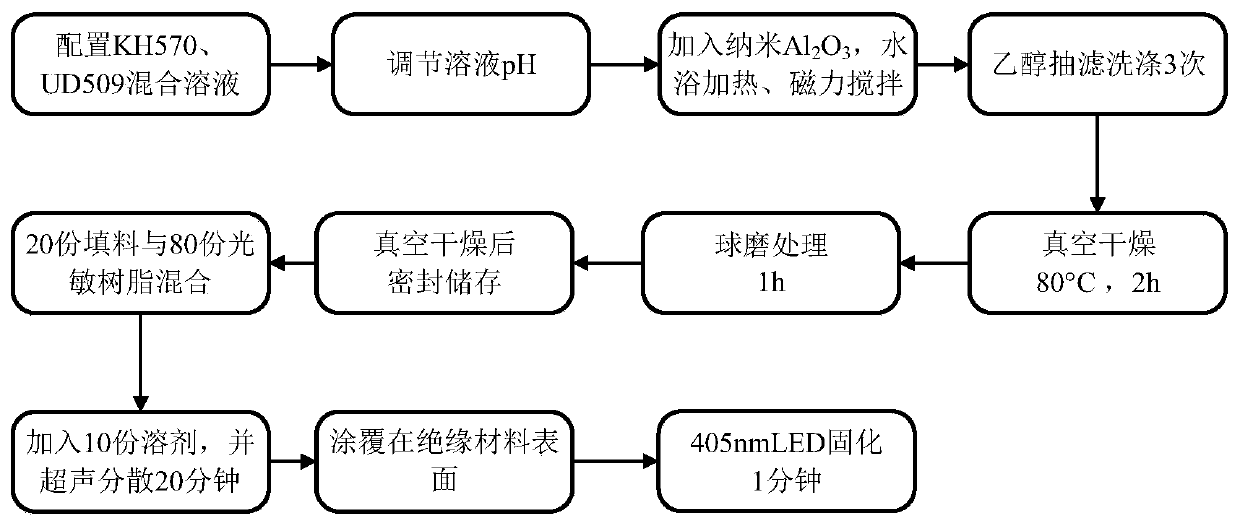

Preparation method of nano-modified film material capable of improving surface electrical resistance of polymer insulating material

ActiveCN109913055AImproved electrical resistance along the surfaceImprove controllabilityCoatingsSilanesFiltration

The invention discloses a preparation method of a nano-modified film material capable of improving surface electrical resistance of a polymer insulating material. Silane modified perfluoropolyether and KH570 are grafted to the surface of a nanoparticle material by ultrasonic, suction filtration and drying steps in a silane coupling mode, and modified nano powder is prepared; the modified nano powder is added to light-cured resin, the resin is uniformly applied to the surface of an insulating material after being subjected to ultrasonic, stirring and solution dispersion treatment, the resin israpidly cured by ultraviolet source irradiation, and the nano-modified film material is obtained. Through combination with the advantages of photocuring, rapid coating of the surface of the insulatingmaterial is realized, the demand of improving the electrical resistance is met, and the problems of low timeliness and high cost of a traditional fluorination method are solved while the treatment speed is increased; the photocuring technology has huge potential in the aspect of fluorination modification of the surface of the insulating material, and the surface electrical resistance of the insulating material is expected to be improved stably.

Owner:XI AN JIAOTONG UNIV

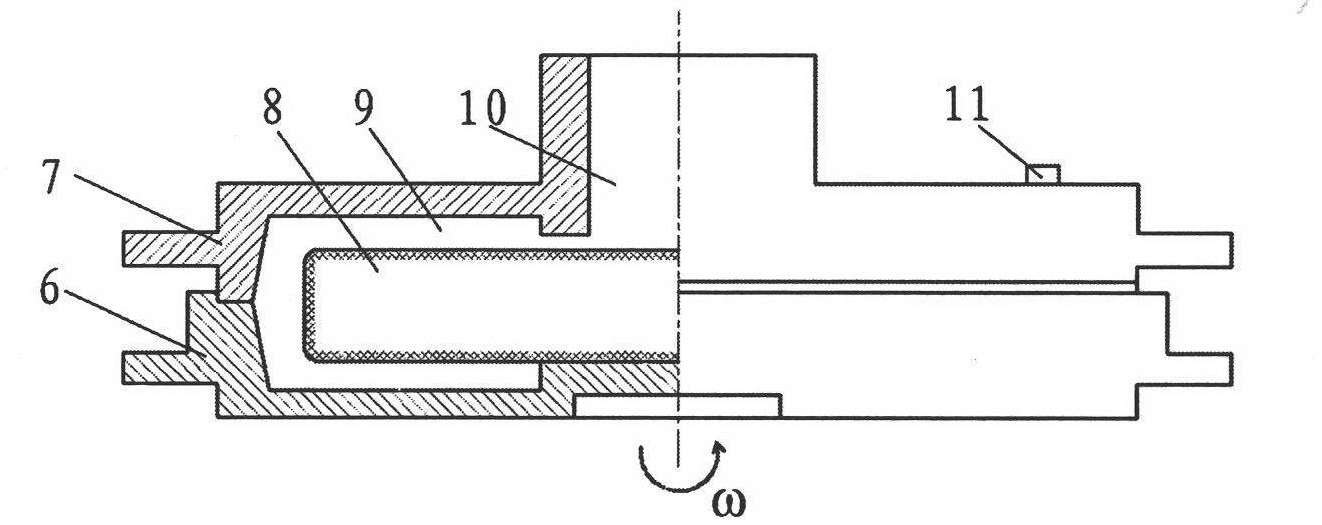

Novel target furnace equipment and target bonding method

InactiveCN106766869AImprove bonding efficiencyFixed efficiencyMuffle furnacesCharge supportsTemperature controlIndium

The invention discloses novel target furnace equipment, and belongs to the technical field of target bonding. A furnace door is arranged on one side of a furnace body of the novel target furnace equipment; the furnace body is internally provided with a heating base station; the heating base station is internally provided with a heating device and a temperature detector that are used for temperature control; a target substrate for the placement of a target is connected with the heating base station; a pressurization plate is arranged over the target substrate; the upper end of the pressurization plate is connected with a hydraulic pump located outside the furnace body; and the interior of the furnace body communicates with an external vacuum pump. The novel target furnace equipment is simple in manual procedures and high in target bonding efficiency; through calculating a welded area and the mass of indium spheres, a situation that a utilization ratio of an indium material is above 98% can be guaranteed; air and water steam in the target and the target substrate can be reduced effectively through vacuumizing, and a situation that the welded area is above 97% can be guaranteed; the binding force between the target and the target substrate can be increased effectively through pressure control, and no falling problem occurs in the post sputtering process; and a yield of target bonding by a skilled worker can reach 100%.

Owner:QINGDAO BLUE LIGHT NEW MATERIAL CO LTD

A kind of artificial leather with three-dimensional pattern and its production method

ActiveCN105568698BDoes not affect leather textureNo shedding problemTextiles and paperSurface layerPulp and paper industry

The invention relates to artificial leather with a three-dimensional pattern and a manufacturing method of the artificial leather. The artificial leather comprises a surface layer, wherein the surface layer is formed by overlaying more than two secondary surface layers with different body colors in sequence from top to bottom; and more than one groove, which directly reaches the surface of each secondary surface layer, is formed in the secondary surface layer which corresponds to the lower side of the uppermost layer. The manufacturing method comprises the following steps: preparing paste of each secondary surface layer; coating the prepared paste of the secondary surface layer of the uppermost layer on release paper; drying the release paper to form the secondary surface layer of the uppermost layer; on the secondary surface layer of the uppermost layer, sequentially coating other prepared secondary surface layer paste according to a layer sequence, and drying to form the surface layer; and after other layers of the artificial leather are synthesized on the surface layer, machining the grooves or machining the grooves in the surface layer, and then synthesizing the other layers. The artificial leather is easy to produce and the formed three-dimensional pattern does not influence leather grains of the artificial leather and does not fall off.

Owner:YANGZHOU XIANE EIDER DOWN PROD CO LTD

Artificial leather with three-dimensional pattern and manufacturing method of artificial leather

ActiveCN105568698ADoes not affect leather textureNo shedding problemTextiles and paperSurface layerPulp and paper industry

The invention relates to artificial leather with a three-dimensional pattern and a manufacturing method of the artificial leather. The artificial leather comprises a surface layer, wherein the surface layer is formed by overlaying more than two secondary surface layers with different body colors in sequence from top to bottom; and more than one groove, which directly reaches the surface of each secondary surface layer, is formed in the secondary surface layer which corresponds to the lower side of the uppermost layer. The manufacturing method comprises the following steps: preparing paste of each secondary surface layer; coating the prepared paste of the secondary surface layer of the uppermost layer on release paper; drying the release paper to form the secondary surface layer of the uppermost layer; on the secondary surface layer of the uppermost layer, sequentially coating other prepared secondary surface layer paste according to a layer sequence, and drying to form the surface layer; and after other layers of the artificial leather are synthesized on the surface layer, machining the grooves or machining the grooves in the surface layer, and then synthesizing the other layers. The artificial leather is easy to produce and the formed three-dimensional pattern does not influence leather grains of the artificial leather and does not fall off.

Owner:YANGZHOU XIANE EIDER DOWN PROD CO LTD

Steady dustproof cloth bag provided with vibrating mechanism

InactiveCN106474838AImprove ash removal efficiencyAvoid cloggingDispersed particle filtrationEngineeringPower flow

The invention discloses a steady dustproof cloth bag provided with a vibrating mechanism. The steady dustproof cloth bag comprises a cloth bag bone shell, a strong gas flush spray pipe is vertically arranged at the position of the middle of the net body of a current blocking net plate, an even backflush nozzle is mounted at the position of the top of the pipe body of the strong gas flush spray pipe, a small vibrating machine is arranged in the upper middle of the plate body of a horizontal mounting plate, manual lifting handles are arranged on left and right sides of the peripheral side wall of the top of the cloth bag bone shell, screw installation blocks are arranged on lower side walls of the manual lifting handles, and circular fastening clamp rings are arranged on the middle and lower peripheral walls of the cloth bag bone shell in a sleeved manner. By the arrangement, the shortcoming of frequent plugging due to too much accumulation in small holes of a traditional cloth bag is overcome, a small amount of dust attached to the bottom wall of the cloth bag is vibrated to float due to constant vibration of the small vibrating machine, and any falling of the cloth bag during long time use is assuredly avoided.

Owner:广西金邦泰科技有限公司

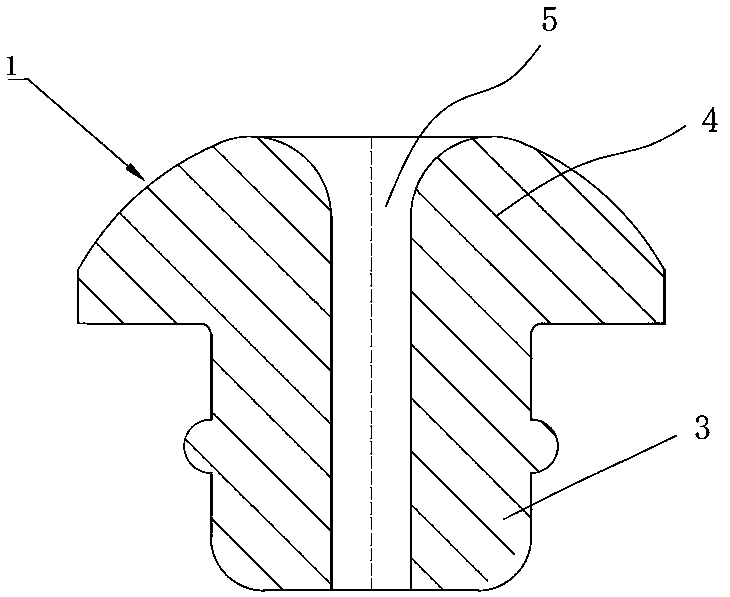

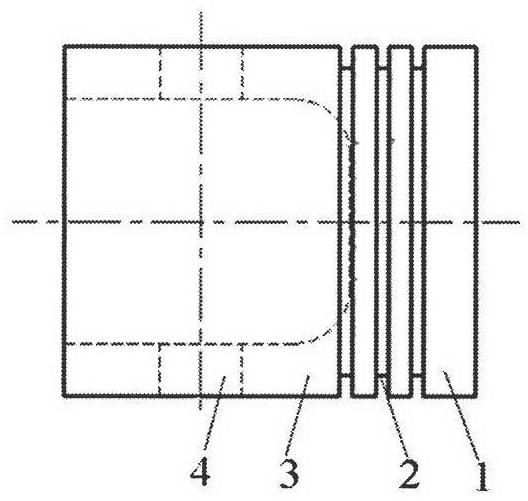

Safety valve structure for lithium battery

PendingCN111192990AAchieve sealingSimple structureCell component detailsInterference fitSafety valve

The invention discloses a safety valve structure for lithium battery. The safety valve structure is characterized in that the safety valve structure is composed of a rubber plug and a dowel, the rubber plug is composed of a plug body part matched with a battery blast hole and a head part with the diameter larger than that of the plug body part, and a through hole is formed in the center of the rubber plug in the symmetry axis direction of the rubber plug; the dowel is composed of a dowel body and a limiting head at the upper end, the diameter of the dowel body is larger than the inner diameterof the through hole, and the dowel body is clamped in the through hole and presses the wall of the through hole of the plug body, so that the periphery of the plug body is in interference fit with the battery blast hole; and a limiting head at the upper end of the dowel is limited by the head of the rubber plug and located outside the through hole. The safety valve structure is simple in overallstructure, low in precision requirement and convenient to install, online installation can be completed in the battery production process, and protection parts do not need to be additionally arranged.

Owner:SUZHOU PHYLION BATTERY

Network transformer and laser welding method thereof

InactiveCN109637785AImprove product qualityImprove reliabilityTransformers/inductances coils/windings/connectionsInductances/transformers/magnets manufactureOxide ceramicPeak value

The invention discloses a network transformer and a laser welding method thereof. The network transformer comprises a linear ceramic flat plate and a ceramic skeleton which are both made of oxide ceramic matrix composite materials. The attaching positions of the linear ceramic flat plate and the ceramic skeleton are welded into a whole through laser. The method comprises the following laser steps:S1, grinding and polishing an area where the ceramic flat plate and the ceramic skeleton are about to be combined together, and grinding the area into a smooth welding crystal face; S2, positioning the ceramic flat plate and the ceramic skeleton in a laser beam irradiation area, adopting the pulse oscillation mode of a laser device with a large output power peak value, irradiating a non-focused laser beam on the above combination area for preheating purpose, utilizing the focused laser with high energy density for irradiation purpose, fusing and welding together the combination area of the ceramic flat plate and the ceramic skeleton; S3, naturally cooling the ceramic flat plate and the ceramic skeleton to form a whole piece. According to the invention, the high-temperature fusion weldingof the laser is utilized, so that the skeleton of the transformer is permanently combined without the problem of falling off. Meanwhile, additional structural parts are omitted, and the structure is simplified.

Owner:DONGUAN PULSE ELECTRONICS CO LTD

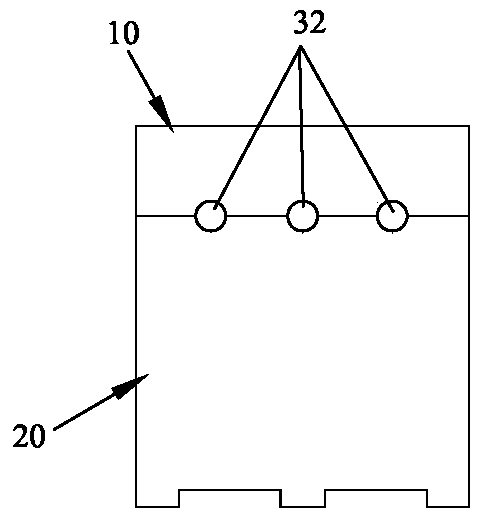

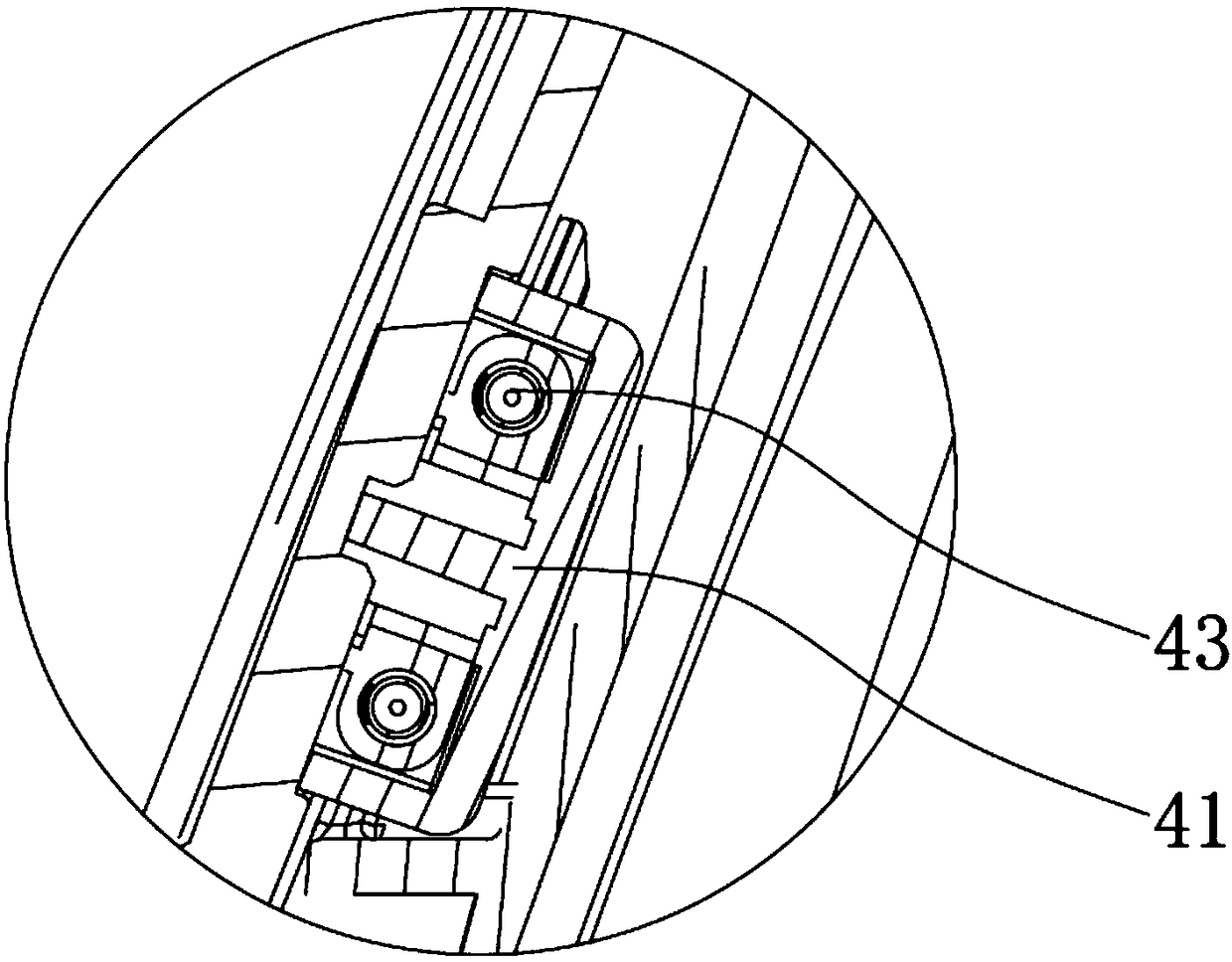

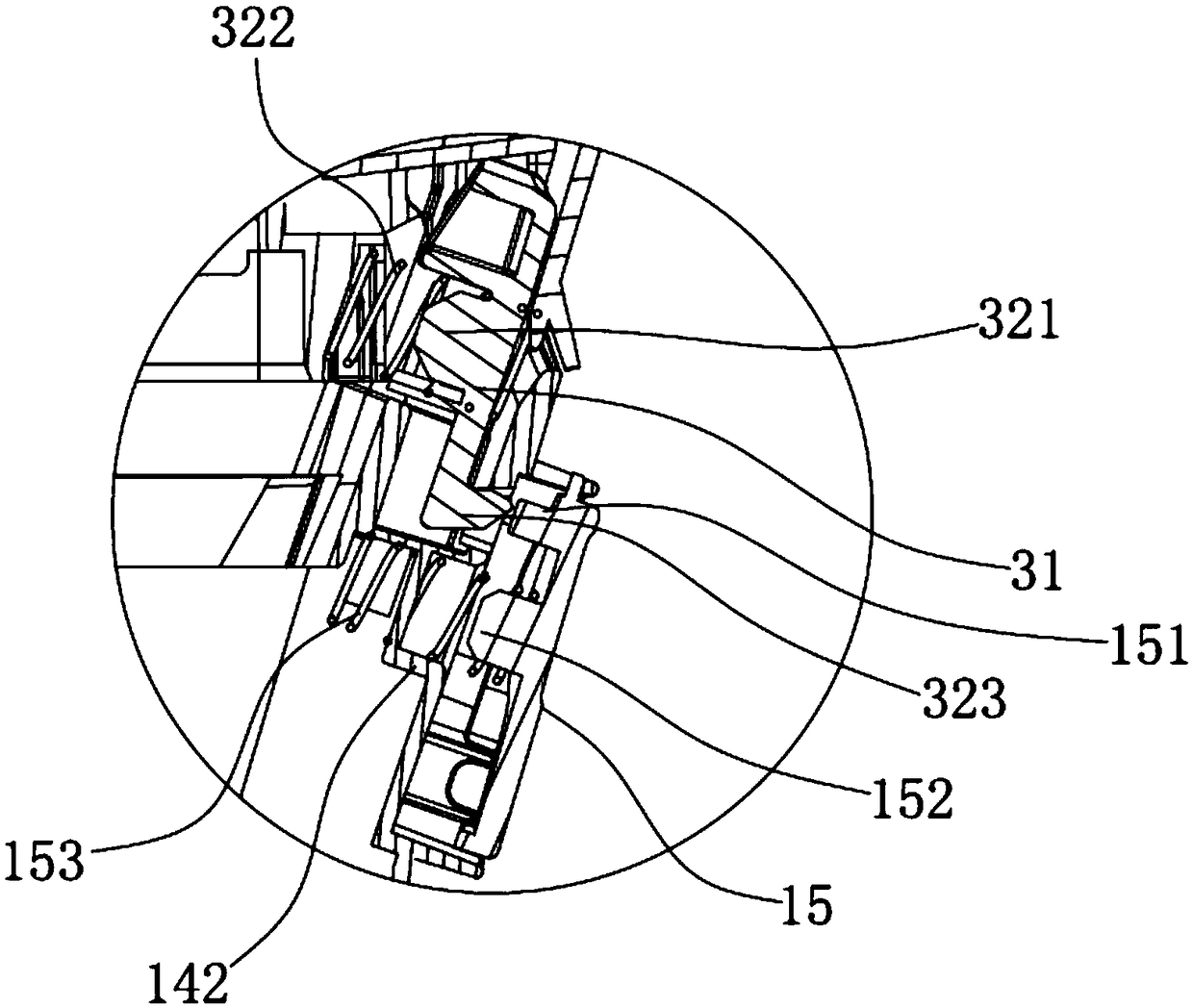

Novel elevator landing door plate assembly

PendingCN112850440AGood corrosion resistance such as acid, alkali and saltGood environmental aging resistanceElevatorsBuilding liftsCorrosive substanceAerospace engineering

The invention belongs to the technical field of elevator equipment, and particularly relates to a novel elevator landing door plate assembly which comprises a landing door plate assembly body. The landing door plate assembly body comprises a landing door plate, reinforcing ribs and guide shoe plates. The multiple sets of reinforcing ribs are fixedly connected to the landing door plate. The reinforcing ribs are arranged on the landing door plate in a latticed manner. The multiple sets of guide shoe plates are fixedly connected to the bottom of the landing door plate. By using a non-metal high polymer material, an anti-rust coating does not need to be additionally sprayed after the landing door plate assembly body is formed, and the material has very good corrosion resistance such as acid, alkali and salt resistance and meanwhile has very good environmental aging resistance; the surface color of the landing door plate assembly body can be changed by mixing colors of the material; and various colors can be mixed according to the requirements of customers, and selectable diversity is achieved.

Owner:陈觉

Preparation method of high-voltage-resistant high hardness cable sheath material

InactiveCN103992578AGood filler compatibilityImprove the lubrication effectPlastic/resin/waxes insulatorsInsulated cablesEpoxyPolymer science

The invention discloses a preparation method of a high-voltage-resistant high hardness cable sheath material, and the method comprises the following steps: weighing PVC (polyvinyl chloride) resin, ethylene-vinyl acetate resin with ethylene-vinyl acetate content of 17.5-19.2%, a composite environmental-friendly heat stabilizer comprising an environmental-friendly Ca / Zn composite stabilizer and epoxy soybean oil, micro encapsulated red phosphorus, expandable graphite, polyethylene wax and a super lubricant to put in a low speed kneader for mixing evenly; weighing phthalate, conductive metal powder, conductive carbon black, calcined clay, talcum powder and an antioxidant to put in the low speed kneader for mixing evenly with the obtained material, then putting the prepared material into a high speed kneader for heating for mixing evenly at a high speed, sending into a twin-screw granulator for extrusion granulating, and drying to obtain the high-voltage-resistant cable sheath material. The high-voltage-resistant high hardness cable sheath material is excellent in high-voltage-resistant performance, free of falling off, higher in hardness and stable in performance.

Owner:ANHUI ELECTRIC GRP SHARES

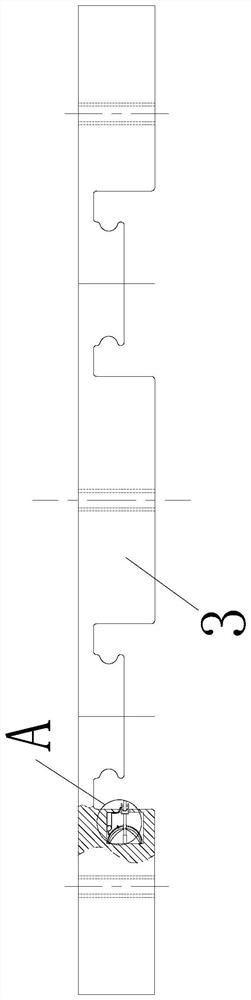

Vacuum cleaner dust cup structure without assembling rail and vacuum cleaner

The invention provides a vacuum cleaner dust cup structure without assembling a rail. The structure comprises a cup body, a front cover, a first locking hook mechanism and a second locking hook mechanism. A first connecting end and a second connecting end are formed at the two opposite ends of the front cover respectively, the first connecting end is connected to a second side part of the cup body, and the second side part is arranged opposite to a first side part and connected to the first side part; the first locking hook mechanism includes a first button, one end of the first button is hinged to the first connecting end, and the other end of the first button is provided with a first clamping hook which is clamped to the second side part; the second locking hook mechanism includes a locking hook base which is fixedly mounted on the first side part, second clamping hooks are disposed on the locking hook base and clamped to third clamping hooks, and the third clamping hooks are connected to the second connecting end. The invention also provides a vacuum cleaner. Compared with the prior art, the structure and the vacuum cleaner have the advantages that user can comfortably assemblea dust cup in a pressing mode and the user experience is improved.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

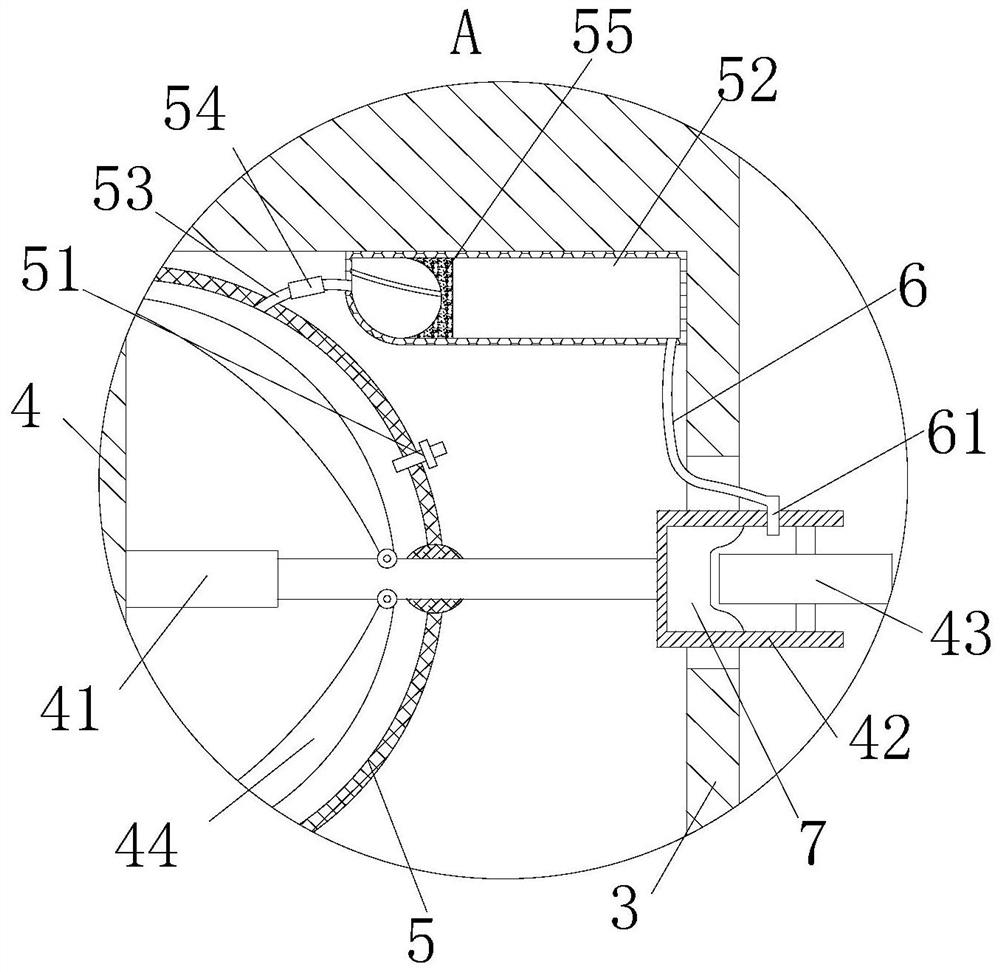

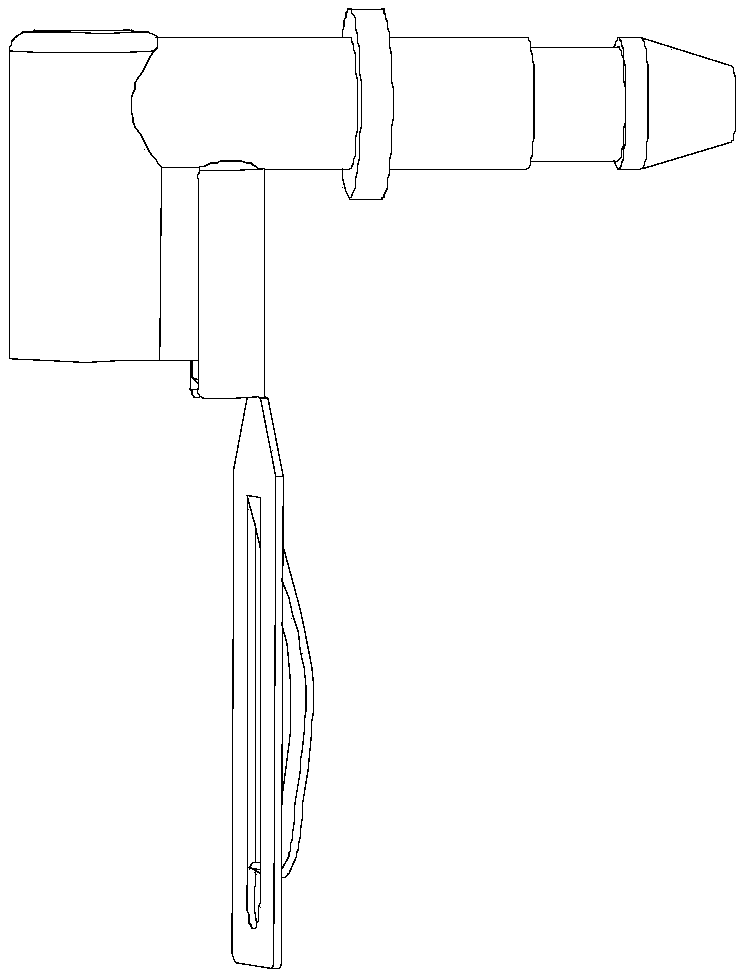

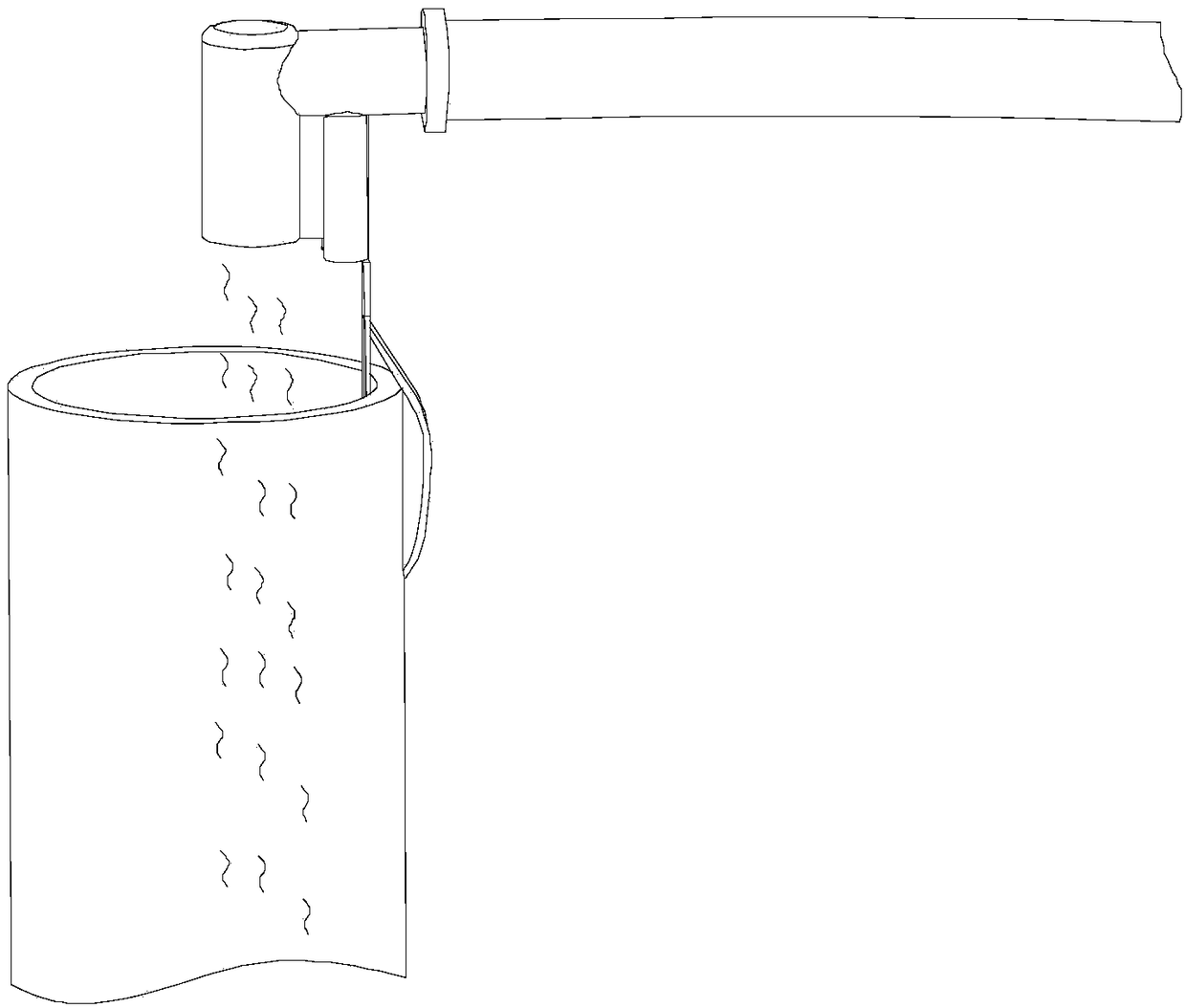

Water replenishing cap which can be quickly installed and is capable of improving overflow capacity and lowering water replenishing sound

The invention relates to the field of toilet water replenishing structures, in particular to a water replenishing cap which can be quickly installed and is capable of improving the overflow capacity and lowering the water replenishing sound. The water replenishing cap comprises a water replenishing cap body, the water replenishing cap body sleeves an overflow pipe, and the angle above the water replenishing cap body can be freely adjusted. The structure is simple, the water replenishing cap is easy to operate, no falling problem occurs, and the problem of deformation of a water replenishing pipe can be avoided, so that normal water replenishment is ensured. A vent hole is formed in the side wall of the water replenishing cap body, so that the formation of eddy current above a pipe openingof the overflow pipe is prevented, a large amount of air is prevented from entering the overflow pipe, normal drainage of the overflow pipe is ensured, and the overflow speed is increased. A connecting pipe is communicated with the upper end face of the water replenishing cap body, the water replenishing pipe is in interference fit connection with the connecting pipe through a reinforcing rib, a drainage baffle is arranged at an opening of the lower end of the connecting pipe, so that the noise generated by water replenishment is effectively lowered.

Owner:HUIDA SANITARY WARE

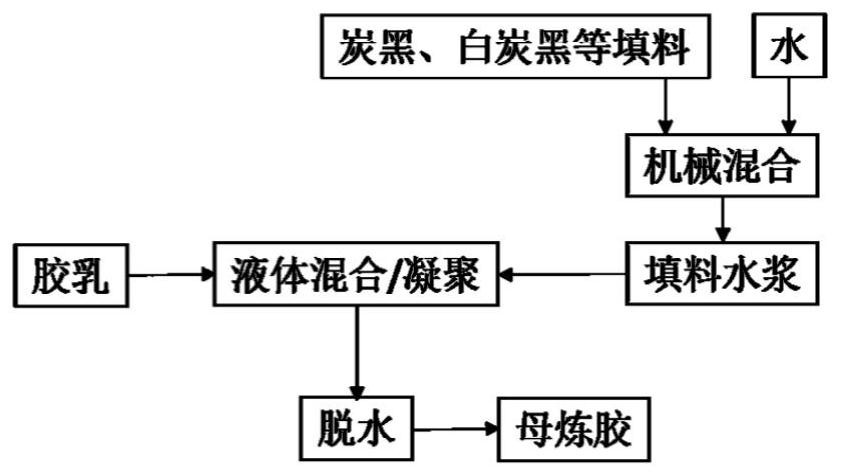

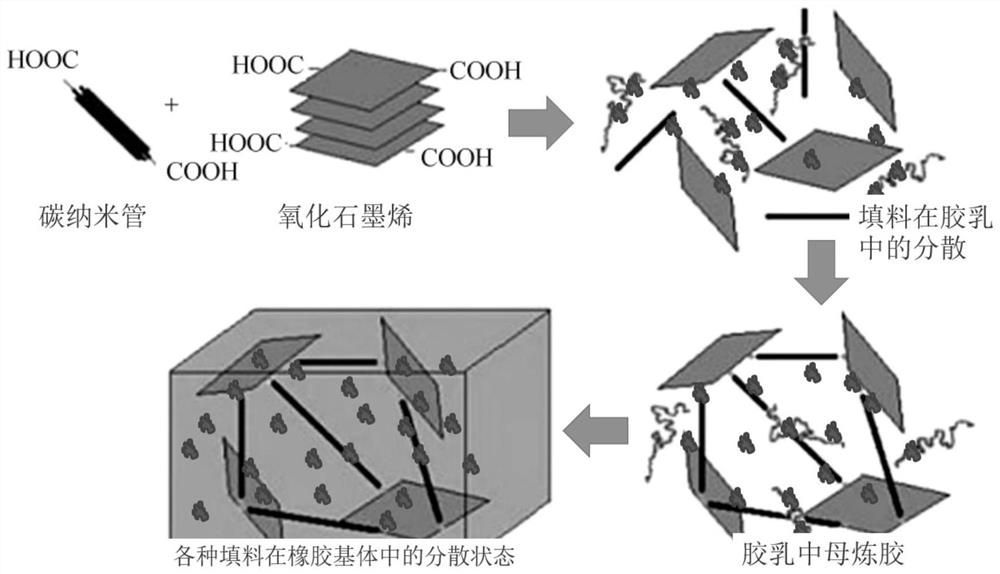

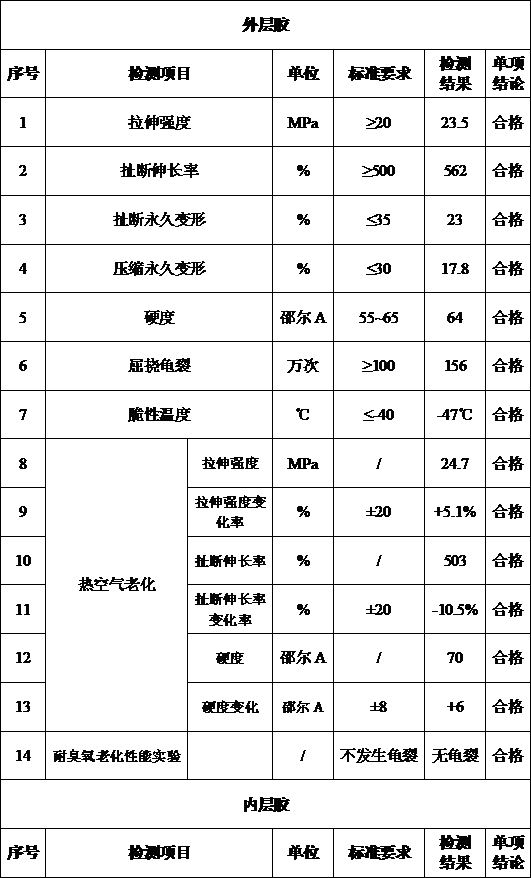

High-damping anti-aging rubber product and preparation method thereof

InactiveCN114621513AHigh strengthExtended service lifeRubber layered productsPolymer scienceVulcanization

The invention relates to a high-damping anti-aging rubber product which is formed by compounding at least two layers of rubber, and the rubber is prepared from the following raw materials in parts by weight: 60-80 parts of synthetic rubber, 30-60 parts of a reinforcing filling system, 2-5 parts of a plasticizing system, 2-4 parts of an anti-aging system, 1-3 parts of an activating system and 1-3 parts of a vulcanizing system. Compared with the prior art, a reinforcing filling system such as natural rubber grafted white carbon black is adopted, so that the problem of dispersion of a reinforcing filling material is thoroughly solved, the bonding effect of a bonding system is further greatly improved, bonding between layers is firmer, and the bonding strength even exceeds the strength of a rubber body; and the problem of falling between layers cannot occur under most damping use conditions.

Owner:南京盛前材料科技有限公司

Environment-friendly transmission line sheath

The invention discloses an environment-friendly transmission line sheath, which belongs to the field of cable sheaths and is used for transmission line protection. The environment-friendly transmission line sheath comprises the following components in parts by weight: 35-40 parts of metallocene polyethylene, 30-40 parts of ethylene propylene diene monomer rubber, 20-30 parts of chlorinated polyvinyl chloride resin, 2-5 parts of maleic anhydride graft EVA (ethylene-vinyl acetate), 2-3 parts of aluminum hydroxide micropowder, 0.5-1 part of barium stearate and 2-4 parts of antioxidant PS802. According to the technical scheme, the environment-friendly transmission line sheath can overcome the defect of toxic and harmful gas generated in the PVC (polyvinyl chloride) material combustion process, and can avoid the problems of damage and shedding of the graphite layer on the high-tension transmission line.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Membrane electrode for generating ozone water by tap water and preparation method thereof

InactiveCN112376072AReduce generationImprove conductivityCellsElectrode shape/formsPtru catalystElectrolysis

The invention relates to the technical field of environmental electrochemistry, in particular to a membrane electrode for generating ozone water by using tap water and a preparation method thereof. The membrane electrode comprises an ion exchange membrane, an anode catalyst layer arranged on one side of the ion exchange membrane and a cathode catalyst layer arranged on the other side of the ion exchange membrane, wherein the cation exchange membrane is a porous ceramic-based solid polymer electrolyte membrane or a graphite-phase C3N4 / PFSA solid electrolyte composite membrane. The method is widely applied to drinking water disinfection, municipal sewage treatment, medical industry disinfection and the like. According to the membrane electrode, only water is needed as a raw material for producing ozone water from tap water, so that the energy consumption is low; an air pump is not needed, and noise generated in use is low; high-purity ozone is generated, no other by-product is generated,no nitrogen oxide is generated, and no secondary pollution is generated to the environment; the membrane electrode can work for a long time, is stable in electrolysis efficiency, and does not need additional oxygen-containing electrolyte.

Owner:东莞市南柏电子科技有限公司

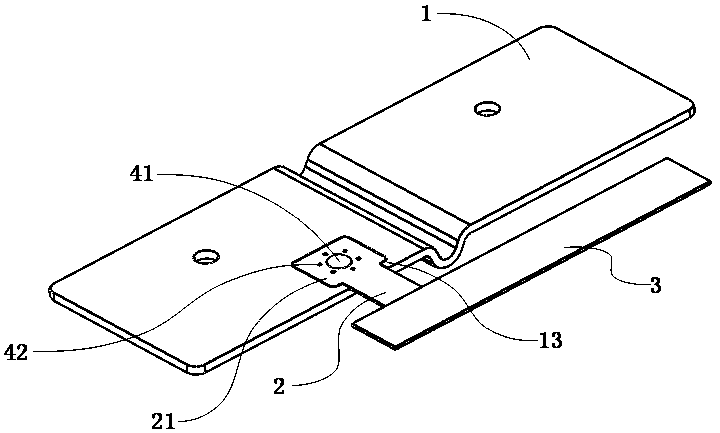

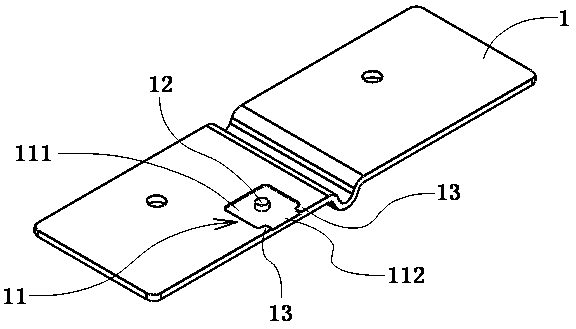

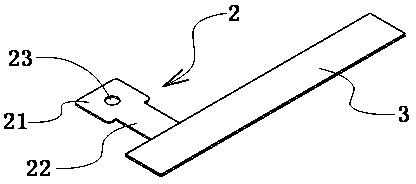

Processing method of acquisition sheet and busbar connecting structure, and connecting structure

The invention discloses a processing method of an acquisition sheet and a busbar connecting structure, and the connecting structure. The connecting structure comprises a busbar and the acquisition sheet. And the busbar is provided with a sheet groove. And a head of the acquisition sheet is clamped in the sheet groove to form a clamping structure between the busbar and the acquisition sheet. And the busbar and the acquisition sheet are connected and fixed in the sheet groove through a riveting portion and a laser welding spot. And the riveting portion is formed in a way that a riveting column arranged in the sheet groove penetrates through a riveting hole arranged in the head of the acquisition sheet and then the riveting column is processed by adopting a hot riveting processing technology.And the laser welding spot is formed after laser welding is performed around a periphery of the riveting portion. Compared with the prior art, by using the method and the structure of the invention,the connecting structure is firm and the acquisition sheet is not easy to fall off.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Production process and foaming punching die of automobile inner cowl heat insulation pad

The invention provides a production technology of an automobile front-wall heat-insulation pad, comprising the following two processing steps: 1) plastic uptake shaping; and 2) foam punching. The invention also provides a foam punching die used in the production technology. The invention has advantages and positive effects as follows: 1) production pace is accelerated; 2) consistency of a product is good; 3) VOC performance of the product is improved; and 4) production cost of the product is reduced: two post-procedure operators are saved, there is no superfluous binder, and production cost is controlled effectively.

Owner:GREAT WALL MOTOR CO LTD

Method for preparing low-wetting and anti-corrosion multihole oxidation film

InactiveCN107641829AThe preparation process is environmentally friendlyNo shedding problemAnodisationHigh humidityWater contact

The invention relates to an anti-corrosion oxidation film, in particular to a method for preparing a low-wetting and anti-corrosion multihole oxidation film on an aluminum surface. The method comprises the following steps: carrying out ultrasonic cleaning and electrochemical polishing in sequence on a matrix aluminum plate, then carrying out anodic oxidation on the matrix aluminum plate in an acidic solution, and drying the matrix aluminum plate, thereby forming the multihole oxidation film on the surface of the matrix aluminum plate, wherein the water contact angle of the multihole oxidationfilm exceeds 95 degrees, so that the multihole oxidation film is high in hydrophobicity; furthermore, no corrosion phenomenon occurs in a test of simulating seawater immersion corrosion resistance, sothat the multihole oxidation film is extremely high in corrosion resistance. According to the method, by the adoption of one-step heating and cooling treatment, the preparation process is simple andenvironmentally friendly; a prepared aluminum oxide film is stable and free of falling, has a practical value, and is expected to be industrially applied; the aluminum oxide film can be applied to a high-humidity and high-salinity ocean environment.

Owner:INST OF OCEANOLOGY - CHINESE ACAD OF SCI

A slice fixing device for preventing slices from falling off

Owner:KONFOONG BIOTECH INT

Al-Si-Ti composite local reinforcement piston and preparation method thereof

InactiveCN102678376AReduce or eliminate failure sheddingReduce or eliminate the chance of failure and sheddingMachines/enginesPistonsCondensation processEngineering

The invention relates to an Al-Si-Ti composite local reinforcement piston and a preparation method thereof, and is characterized in that the top of the piston and a ring groove part are reinforced regions formed by self-separated wild phase primary aluminum-silicon-titanium and primary Si in a condensation process of an alloy, and volume fractions of primary wild phases in the reinforced regions are gradually reduced from the top of the piston to the ring groove part; a piston skirt part and a pinhole are non-reinforced regions without wild phases. According to the piston provided by the invention, a continuous transition of tissue structures and performances of the reinforced regions and non-reinforced regions is realized, and the top of the piston and the ring groove part have excellent wear resistance and high temperature resistance to meet requirements of a high-power engine on the piston. According to the invention, the primary wild phases in a smelted homogenous aluminum-based composite are gathered on the top of the piston and the ring groove part by a centrifugal casting method; and the piston has the advantages of simple process and long service life.

Owner:CHONGQING UNIV

Color function road surface

ActiveCN100362166CGood water permeabilityNot easy to fall off and fadeIn situ pavingsCalcium silicateFiber

The color functional road surface features that it is porous polymer concrete layer comprising white cement 200-500 weight portions, stone material 500-2000 weight portions, vinyl acetate copolymer 10-200 weight portions, inorganic pigment 0.5-20 weight portions, dibutyl phthalate 0.5-90 weight portions, aluminum silicate or fine silica powder 10-100 weight portions, antiageing fiber 0.5-10 weight portions and water 70-200 weight portions. The color functional road surface has good water permeability and is color fast.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com