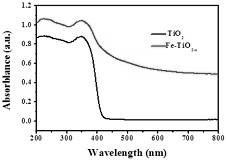

Electrostatically spun defect-state TiO2/Fe3O4 composite nanofiber material and preparation method thereof

A technology of composite nanofibers and nanofiber membranes, applied in the field of materials, can solve the problems that limit the development of the Fenton method, achieve the effects of optimizing the electronic energy level structure, saving costs, and improving photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

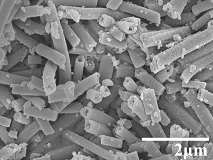

Embodiment 1

[0026] Add 1.6 g of polyvinylpyrrolidone and 3.2 g of polymethyl methacrylate solid powder into 20 mL of dimethylformamide, and form a homogeneous solution by magnetic stirring at room temperature, then add 2 ml of acetic acid and 4 ml of tetra-n-butyl titanate Esters and 0.095 g of anhydrous ferric chloride were stirred for 2 h to obtain a homogeneous spinning solution, in which the atomic ratio of Ti and Fe was 20:1. Transfer the prepared spinning solution into a 20 ml syringe for high-voltage electrospinning. The electrospinning control voltage was 18kV, the drum speed was 400 r / min, the distance between the spinning head tip and the drum receiver was 15 cm, and the flow rate of the spinning solution was 1 mL h -1 , received by aluminum foil, and prepared nanofiber membrane; the obtained nanofiber membrane was calcined in a tube furnace with a heating rate of 10 °C min -1 , the temperature was set at 700 °C, and the calcination time was 2h; the calcined material was mixed ...

Embodiment 2

[0028]Add 1.0 g of polyvinylpyrrolidone and 2.0 g of polymethyl methacrylate solid powder into 20 mL of dimethylformamide, and form a homogeneous solution by magnetic stirring at room temperature, then add 2 ml of acetic acid and 4 ml of tetra-n-butyl titanate Esters and 0.095 g of anhydrous ferric chloride were stirred for 2 h to obtain a homogeneous spinning solution, in which the atomic ratio of Ti and Fe was 20:1. Transfer the prepared spinning solution into a 20 ml syringe for high-voltage electrospinning. The electrospinning control voltage was 15kV, the drum speed was 400 r / min, the distance between the spinning head tip and the drum receiver was 15 cm, and the flow rate of the spinning solution was 1 mL h -1 , received by aluminum foil, and prepared nanofiber membrane; the obtained nanofiber membrane was calcined in a tube furnace with a heating rate of 10 °C min -1 , the temperature was set at 350 °C, and the calcination time was 3h; the calcined material was mixed w...

Embodiment 3

[0030] Add 1.6 g of polyvinylpyrrolidone and 3.2 g of polymethyl methacrylate solid powder into 20 mL of dimethylacetamide, and form a homogeneous solution by magnetic stirring at room temperature, then add 2 ml of acetic acid and 4 ml of tetraethyl titanate and 0.04 g of anhydrous ferric chloride, and continued to stir for 0.5 h to obtain a uniform spinning solution, in which the atomic ratio of Ti and Fe was 50:1. Transfer the prepared spinning solution into a 20 ml syringe for high-voltage electrospinning. The electrospinning control voltage was 18 kV, the drum speed was 400 r / min, the distance between the spinning head tip and the drum receiver was 20 cm, and the flow rate of the spinning solution was 1 mL h -1 , received by aluminum foil, and prepared nanofiber membrane; the obtained nanofiber membrane was calcined in a tube furnace with a heating rate of 10 °C min -1 , the temperature was set at 600 °C, and the calcination time was 2.5 h; the calcined material was mixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com