Membrane electrode for generating ozone water by tap water and preparation method thereof

A membrane electrode and ozone water technology, applied in the field of environmental electrochemistry, can solve the problems of high ozone concentration, low ozone concentration, and high current efficiency, and achieve the effects of high current efficiency, reduction of by-products, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A method for preparing a membrane electrode utilizing tap water to generate ozone water, comprising the steps of:

[0040] (1) Using boron-carbon diamond heterojunction materials to prepare the anode catalyst layer;

[0041] (2) prepare cation exchange membrane;

[0042] (3) preparing the cathode catalyst layer;

[0043] (4) laminating the anode catalyst layer, the cation exchange membrane and the cathode catalyst layer to obtain a membrane electrode;

[0044] Wherein, the steps (1)-(3) can be carried out simultaneously or in reverse order.

[0045]Further, in the step (1), the preparation method of the anode catalyst layer includes the following steps: decomposing carbon gas and radon gas into carbon, hydrogen atoms and active free radicals at a temperature of 1300-1700 ° C, hydrogen atoms and active radicals The combination of free radicals and carbon matrix first forms a carbide transition layer; carbon atoms deposit diamond nuclei in the carbide transition layer;...

Embodiment 1

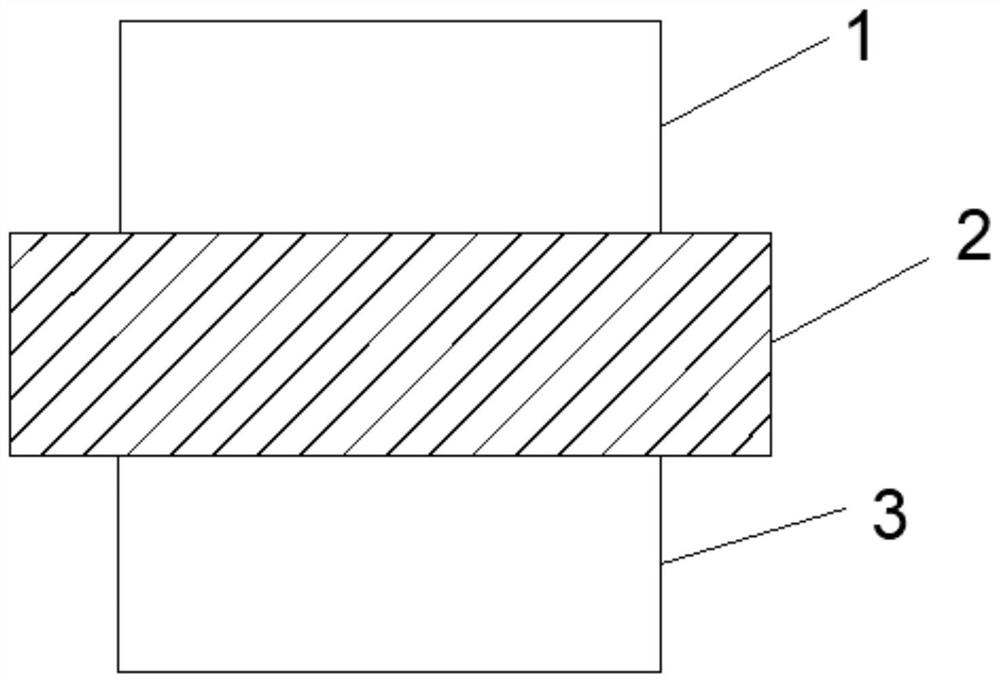

[0056] A membrane electrode that utilizes tap water to generate ozone water includes an ion exchange membrane 2, an anode catalyst layer 1 arranged on one side of the ion exchange membrane 2 and a cathode catalyst layer 3 arranged on the other side of the ion exchange membrane 2, the cation The exchange membrane 2 is a porous ceramic-based solid polymer electrolyte membrane.

[0057] The anode catalyst layer 1 is made of boron carbon diamond heterojunction material, and the cathode catalyst layer 3 is made of graphene composite material.

[0058] A method for preparing a membrane electrode as described above, comprising the steps of:

[0059] (1) Using a boron carbon diamond heterojunction material to prepare the anode catalyst layer 1;

[0060] (2) prepare cation exchange membrane 2;

[0061] (3) preparing the cathode catalyst layer 3;

[0062] (4) Pressing the anode catalyst layer 1, the cation exchange membrane 2 and the cathode catalyst layer 3 to obtain a membrane elec...

Embodiment 2

[0074] A membrane electrode that utilizes tap water to generate ozone water includes an ion exchange membrane 2, an anode catalyst layer 1 arranged on one side of the ion exchange membrane 2 and a cathode catalyst layer 3 arranged on the other side of the ion exchange membrane 2, the cation The exchange membrane 2 is a graphite phase C3N4 / PFSA solid electrolyte composite membrane.

[0075] The anode catalyst layer 1 is made of boron carbon diamond heterojunction material, and the cathode catalyst layer 3 is made of graphene composite material.

[0076] A method for preparing a membrane electrode as described above, comprising the steps of:

[0077] (1) Using a boron carbon diamond heterojunction material to prepare the anode catalyst layer 1;

[0078] (2) prepare cation exchange membrane 2;

[0079] (3) preparing the cathode catalyst layer 3;

[0080] (4) Pressing the anode catalyst layer 1, the cation exchange membrane 2 and the cathode catalyst layer 3 to obtain a membran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com