Network transformer and laser welding method thereof

A network transformer and laser welding technology, applied in the field of transformers, can solve the problems of difficult products, easy aging of colloids, and occupying space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

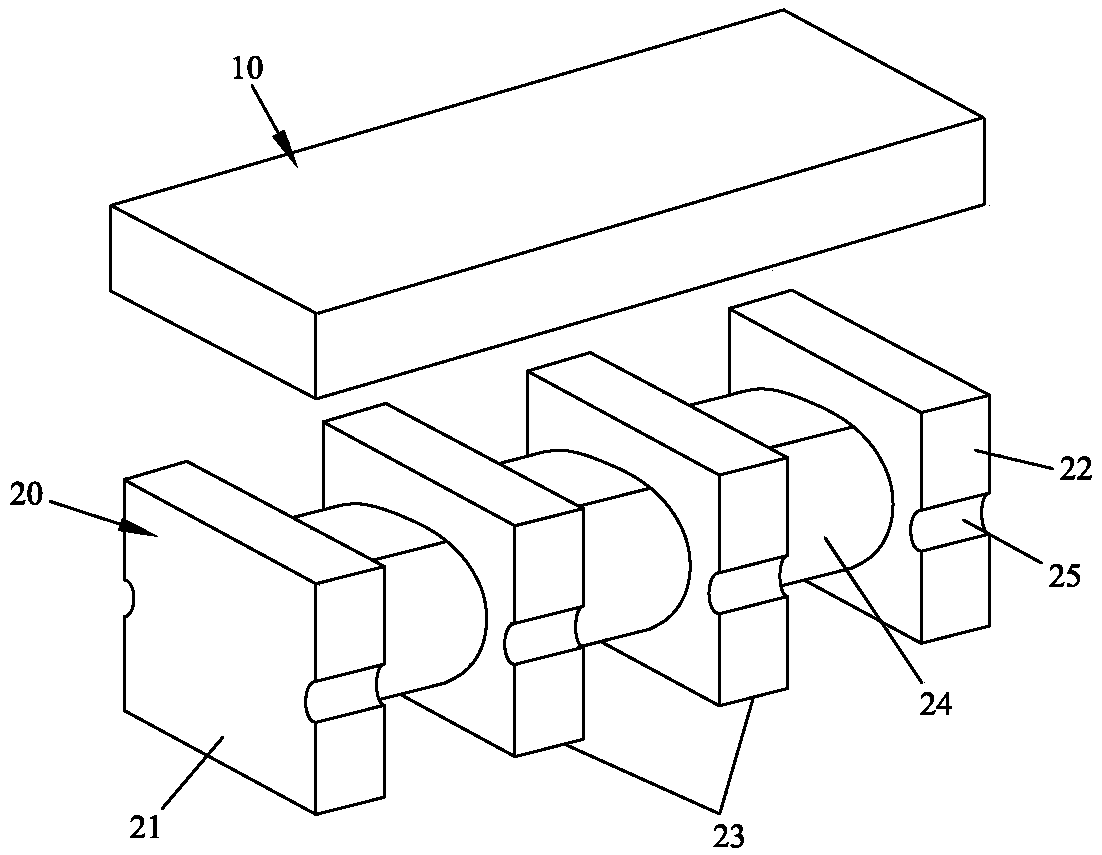

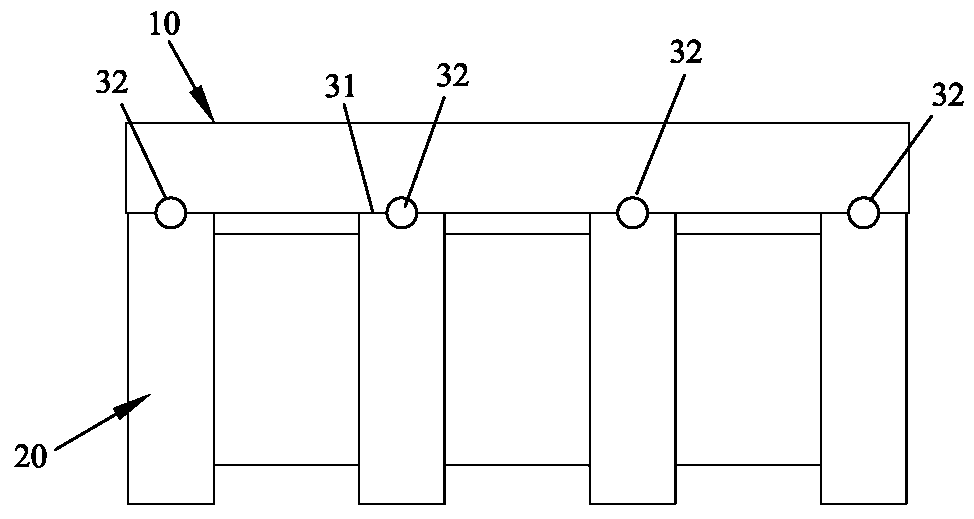

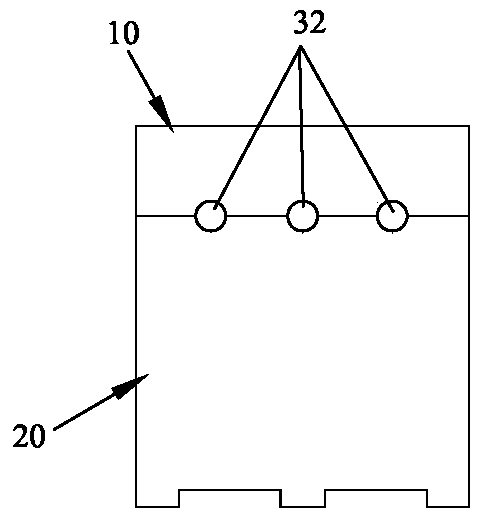

[0028] Please refer to Figure 1 to Figure 3 Shown, it has shown the specific structure of the preferred embodiment of the present invention, is a kind of network transformer, comprises inline ceramic plate 10 and ceramic skeleton 20, and coil is wound on this ceramic skeleton 20, and this ceramic plate 10 and The laminating position of the ceramic skeleton 20 is integrated by laser welding.

[0029] Wherein, both the ceramic plate 10 and the ceramic skeleton 20 are oxide-based ceramic matrix composite materials. In this embodiment, the oxide-based ceramic matrix composite material is a mixture of an oxide ceramic matrix material or a non-oxide ceramic matrix material and iron oxide / zinc / nickel. Among them, the oxide ceramic matrix material refers to MgO, Al 2 o 3 , SiO 2 , ZrO 2 Or mullite and so on. The non-oxide ceramic matrix material refers to Si 3 N 4 , SiC, etc.

[0030] The ceramic frame 20 is a multi-stage I-shaped frame with a three-stage winding section. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com