Production process and foaming punching die of automobile inner cowl heat insulation pad

A production process and punching die technology, which are applied to the production process of automobile inner front wall heat insulation pads and the fields of foam punching die, can solve the problems of high production cost, poor product VOC performance, long production cycle, etc., and achieve production cost. The effect of reducing, good bonding stability, and production cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A production process of an automobile inner cowl heat insulation pad, comprising the following two processing steps:

[0031] 1) Blister molding: The EVA material is baked at high temperature. After the EVA material is baked at a high temperature, its surface temperature is 120°C. The baked EVA material is placed on the plastic mold for blister molding to complete the semi-finished product. Production, wherein the temperature of the blister mold is 40°C, and the blister molding time is 30s;

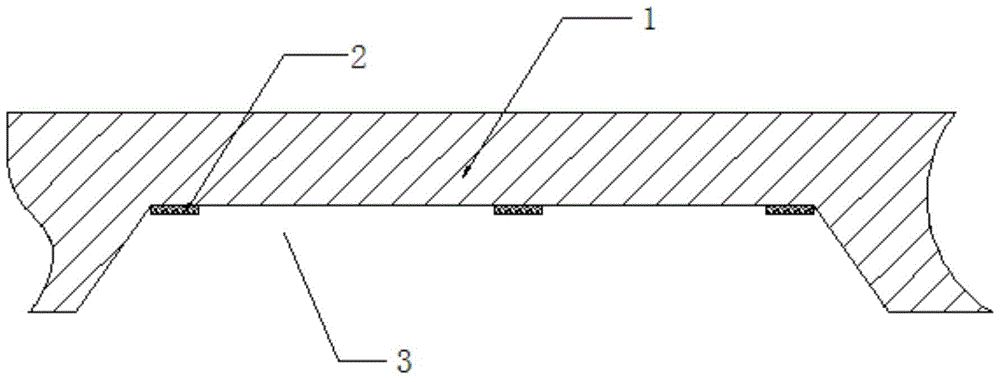

[0032] 2), foam punching: put the semi-finished product obtained in step 1) into the foam punching mold, the upper mold of the foam punching mold is provided with a pre-embedded groove, and place the two-component sound-absorbing cotton In the tank, the semi-finished product is punched during the pressure holding process after the foaming punching mold is closed. The temperature of the foaming punching mold is 65°C. Pouring into the mold cavity for foaming, the pouring speed is 29...

Embodiment 2

[0035] A production process of an automobile inner cowl heat insulation pad, comprising the following two processing steps:

[0036] 1) Blister molding: The EVA material is baked at high temperature. After the EVA material is baked at high temperature, its surface temperature is 140°C. The baked EVA material is placed on the plastic mold for blister molding to complete the semi-finished product. Production, wherein the temperature of the blister mold is 20°C, and the blister molding time is 25s;

[0037] 2), foam punching: put the semi-finished product obtained in step 1) into the foam punching mold, the upper mold of the foam punching mold is provided with a pre-embedded groove, and place the two-component sound-absorbing cotton In the tank, the semi-finished product is punched during the pressure holding process after the foaming punching mold is closed. The temperature of the foaming punching mold is 66°C. Pouring into the mold cavity for foaming, the pouring speed is 310g...

Embodiment 3

[0040] A production process for an automobile inner cowl heat insulation pad, characterized in that it includes the following two processing steps:

[0041] 1) Blister molding: The EVA material is baked at high temperature. After the EVA material is baked at high temperature, its surface temperature is 130°C. The baked EVA material is placed on the plastic mold for blister molding to complete the semi-finished product. Production, wherein the temperature of the blister mold is 30°C, and the blister molding time is 25s;

[0042]2), foam punching: put the semi-finished product obtained in step 1) into the foam punching mold, the upper mold of the foam punching mold is provided with a pre-embedded groove, and place the two-component sound-absorbing cotton In the groove, after the foaming punching mold is closed, the semi-finished product is punched during the pressure holding process. The temperature of the foaming punching mold is 66°C. Pouring into the mold cavity for foaming,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com