Corrugated plate for architectural shielding

A corrugated plate and corrugated formwork technology, which is used in buildings, building structures, covering/lining, etc., can solve problems such as difficulty in guaranteeing surface flatness, failure to solve leakage problems, and inability to meet test requirements, and achieve excellent surface quality. Shielding effectiveness, the effect of improving shielding effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

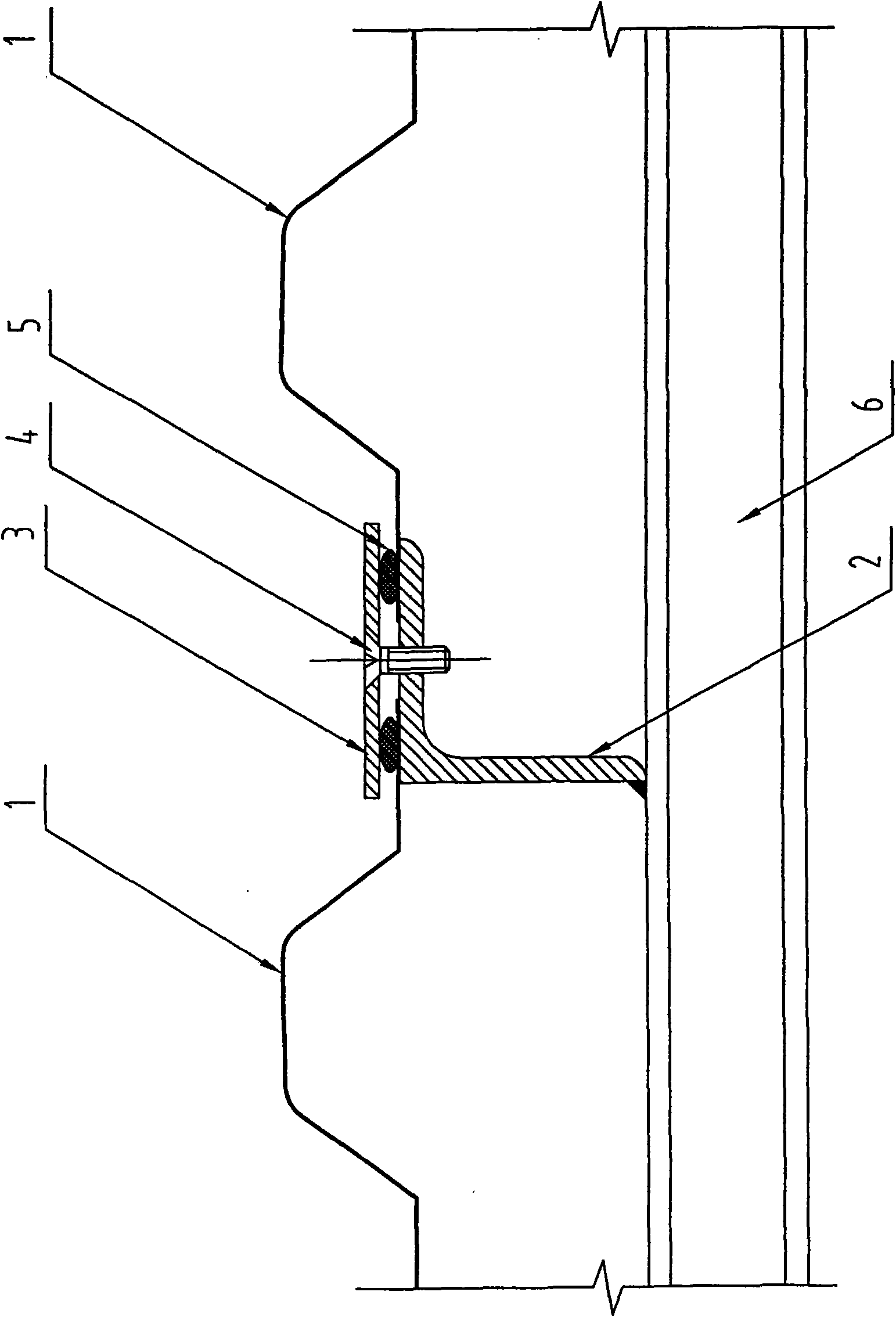

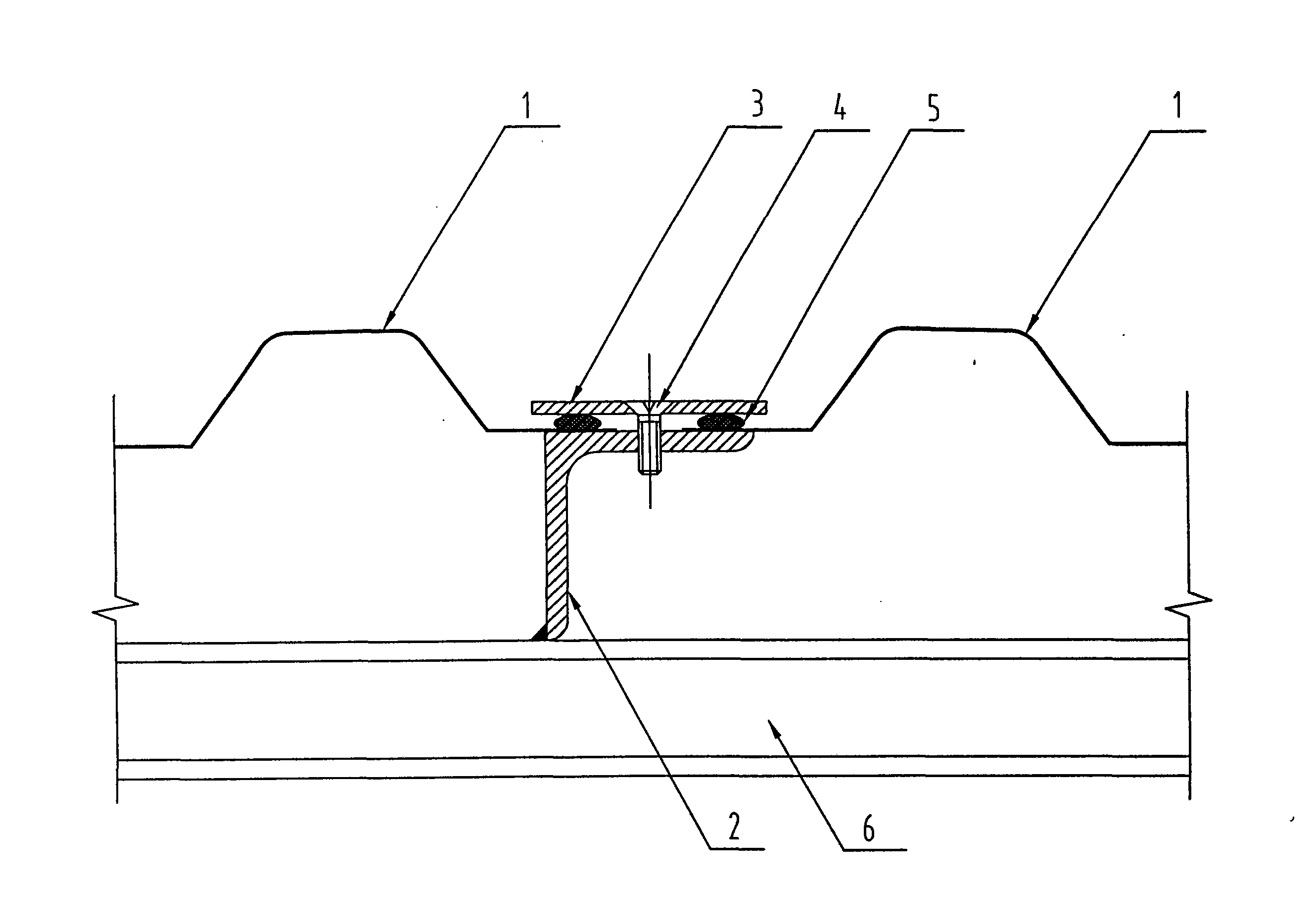

[0031] Such as figure 1 A corrugated plate used for building shielding includes corrugated templates 1 that are shielded and connected to each other, and the corrugated templates 1 are connected through a crimping structure, and adjacent corrugated templates 1 are electrically connected.

[0032] Below the joint of the corrugated formwork 1, there is an angle support connection 2 which is in contact with two adjacent corrugated formworks 1, and a crimping piece 3 is provided above the joint of two adjacent corrugated formworks 1, and the crimping piece 3 is connected to the corner. Type support 2 is connected by screw 4, and screw 4 can be countersunk screw.

[0033] A strip-shaped shielding gasket 5 is provided between the waveform template 1 and the crimping piece 3, which improves the shielding effectiveness of the gap and satisfies the shielding effectiveness of each frequency band.

[0034] The corner support connection 2 is welded and connected with the purlin 6 of the ...

Embodiment 2

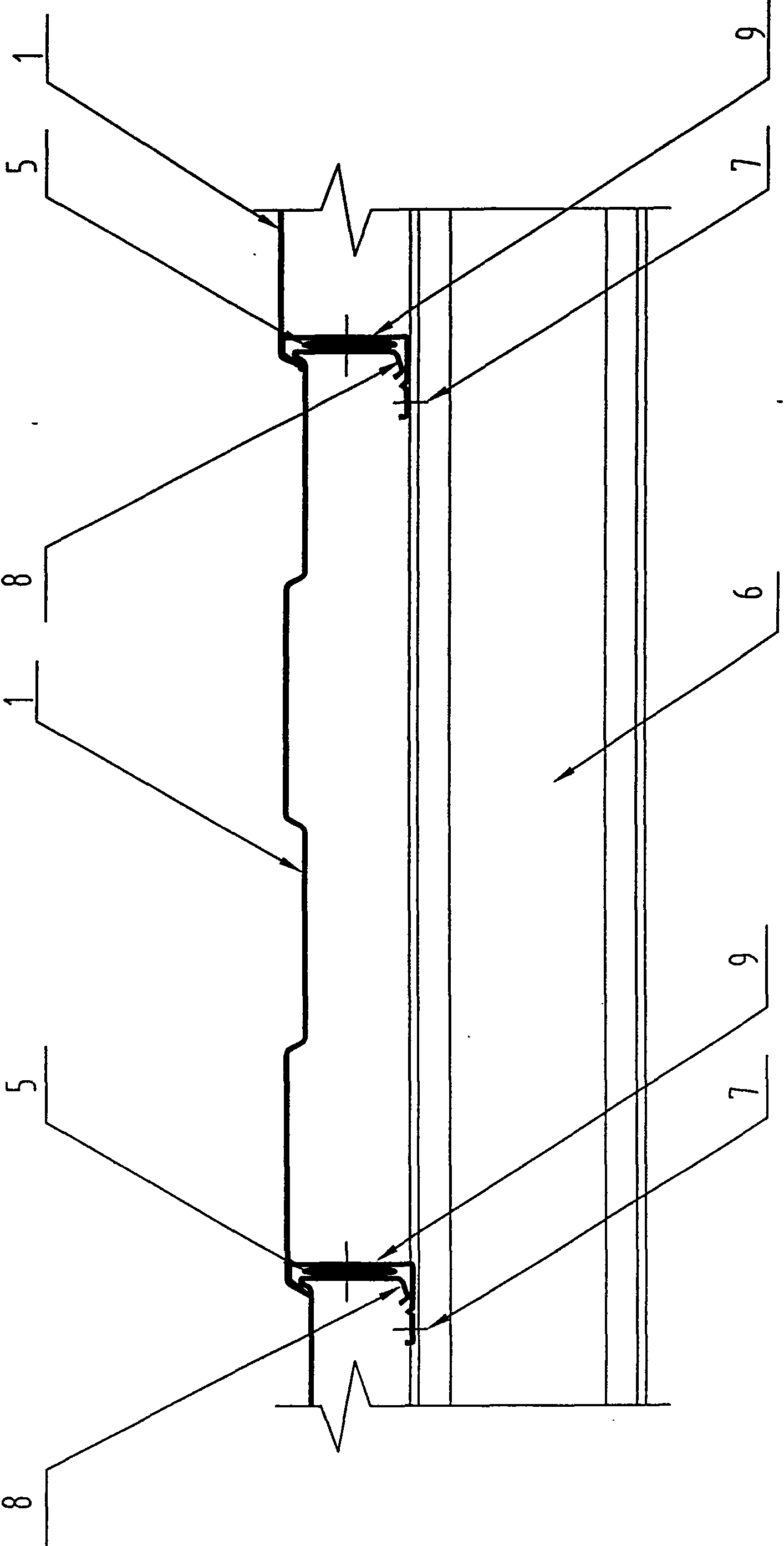

[0036] Such as figure 2 , a corrugated board for building shielding, comprising corrugated templates 1 that are shielded and connected to each other, the corrugated templates 1 are connected through a snap-fit structure, and adjacent corrugated templates 1 are electrically connected.

[0037] One end of the waveform template 1 is provided with a clamping structure 8, and the other end is provided with a clamping groove 9. The waveform templates 1 are connected in turn, and the clamping structure 8 of each waveform template 1 is placed on another adjacent waveform template 1. in the clamping groove 9.

[0038] The clamping structure 8 and the clamping groove 9 are connected by resistance welding at the resistance welding point 7 .

[0039] A shielding gasket 5 is provided between the clamping structure 8 and the clamping groove 9, which improves the shielding effectiveness of the gap and satisfies the shielding effectiveness of each frequency band.

[0040] The corrugated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com