Implant for orthopedics department, material for preparing implant and preparation method of implant

An orthopaedic implant and implant technology, applied in the field of implants, can solve the problems of weak interface between glass fiber and resin matrix, unsatisfactory uniform dispersion effect, poor compatibility, etc., and achieve good fracture healing effect. The effect of improving dispersion uniformity and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

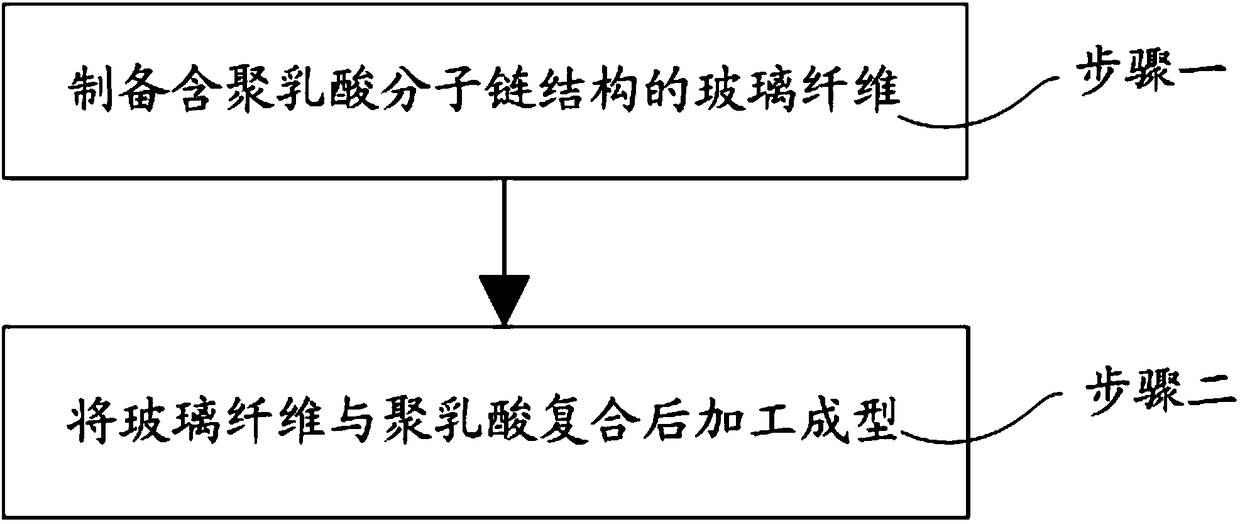

[0053] like figure 1 Shown, the preparation method of the implant of the present embodiment comprises the following steps:

[0054] Step 1: Prepare glass fibers containing polylactic acid molecular chain structure.

[0055] Step 2: Composite the glass fibers and polylactic acid and then process them into shapes.

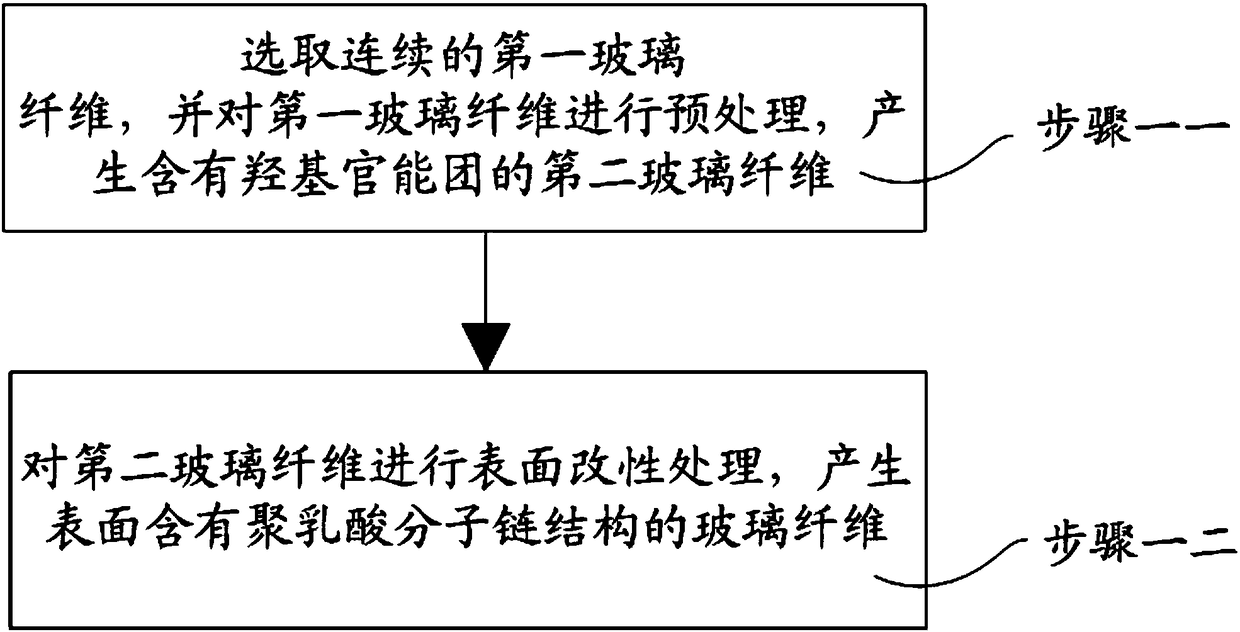

[0056] like figure 2 As shown, preferably, the glass fiber containing the polylactic acid molecular chain structure in the step 1 is made by the following method:

[0057] Step 11: selecting continuous first glass fibers and pretreating the first glass fibers to produce second glass fibers containing hydroxyl functional groups.

[0058] Step 1 and 2: Perform surface modification treatment on the second glass fiber to produce glass fiber with polylactic acid molecular chain structure on the surface. Herein, for the sake of clarity, the glass fiber with polylactic acid molecular chain structure on the surface is defined as the third glass fiber, the same below.

...

Embodiment 1

[0087] In this embodiment, the material used to prepare orthopedic implants is obtained in the following manner:

[0088] First of all, select high-purity and continuous first glass fiber, and its compound mass fractions are respectively:

[0089] SiO 2 : 54~56%; Na 2 O: 7.5-8%; CaO: 20-21%; K 2 O: 12-14%; MgO: 2-3%; P 2 o 5 : 1.5%; the impurity content is not more than 1%, and the tensile strength of the first glass fiber is greater than 3000MPa, and the flexural modulus is greater than 70GPa.

[0090] Secondly, the first glass fiber is dispersed under the drive of the unwinding roller and the pulling roller, and after infrared heating, it is repeatedly passed through a mixed solution with a volume concentration of 0.8% (tetramethylammonium hydroxide and methanol) for about 45 minute.

[0091] Afterwards, the pretreated first glass fiber is washed with deionized water, and dried to obtain the second glass fiber.

[0092] Subsequently, the second glass fiber is disperse...

Embodiment 2

[0100] Similar to the first embodiment, the reaction environment is set to nitrogen protection, but the resin formula is adjusted to isocyanate-terminated low-molecular-weight polylactic acid (molecular weight is selected to be about 2000Da), and at a temperature of 160 ° C, the isocyanate The low-molecular-weight polylactic acid terminated by cyanate group is melted and mixed, and the isocyanate group reacts with the hydroxyl group on the surface of the second glass fiber to obtain the third glass fiber containing the low-molecular-weight polylactic acid terminated by isocyanate group.

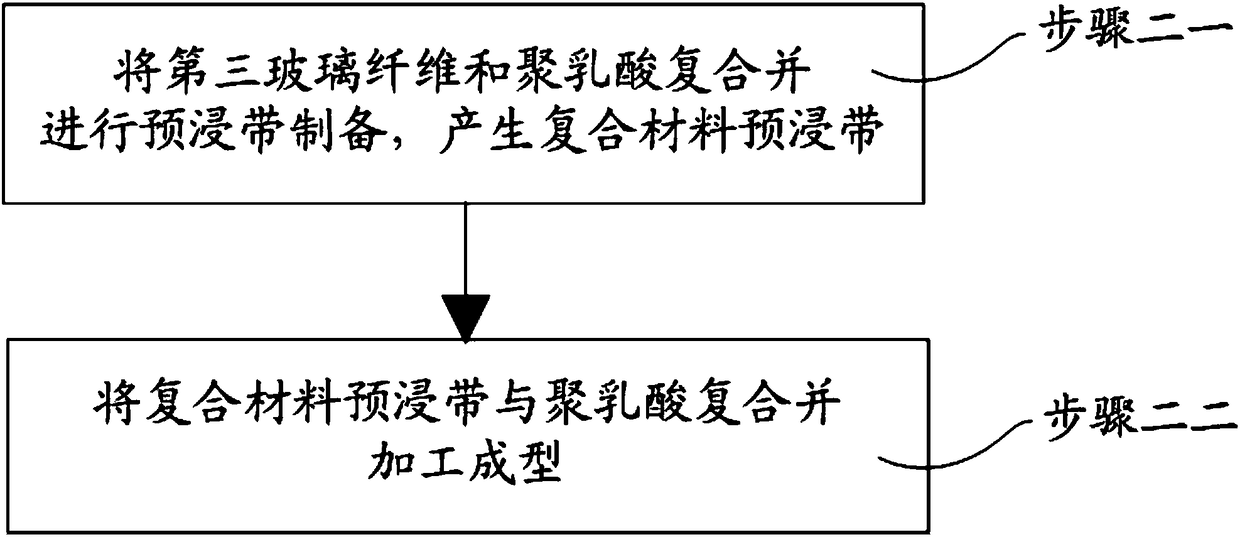

[0101] Afterwards, the third glass fiber is dispersed by the splitting roller, and after being heated by infrared, it is pulled by the pulling shaft into the impregnation mold filled with melt, and melted and impregnated with the polylactic acid in the impregnation mold to form a prepreg tape. Next, the prepreg tape is melted and compounded with polylactic acid and extruded into a cylindrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com