Method for testing bending strength of fragile wooden cultural relic in micro-damage manner

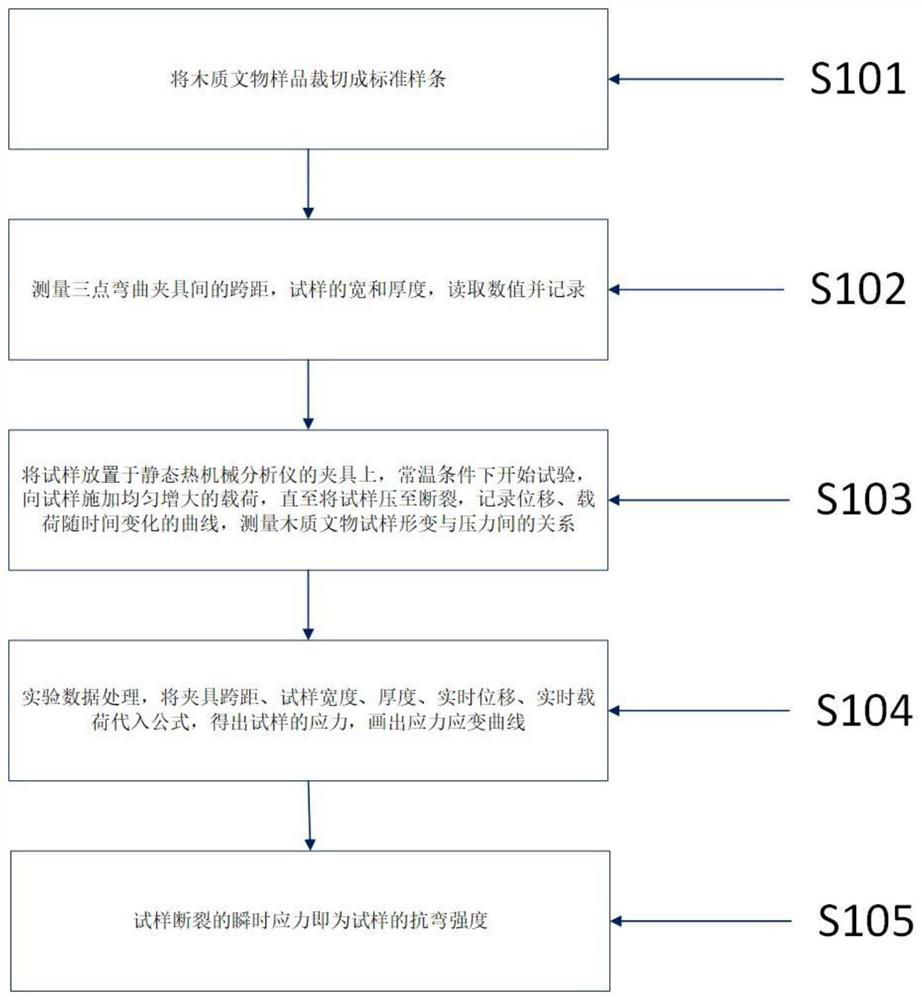

A technology for flexural strength and wood, which is applied in the field of micro-damage testing of the flexural strength of fragile wooden cultural relics, which can solve the problems that it is difficult to apply decayed archaeological wood, the load of the test instrument is large, and the sample volume is large, so as to achieve high sensitivity and accuracy , Simple sample preparation, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

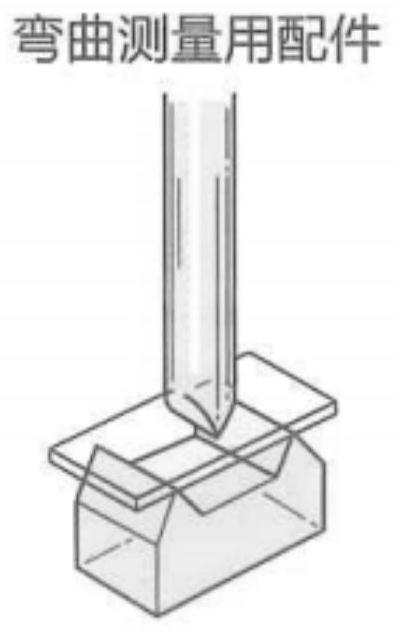

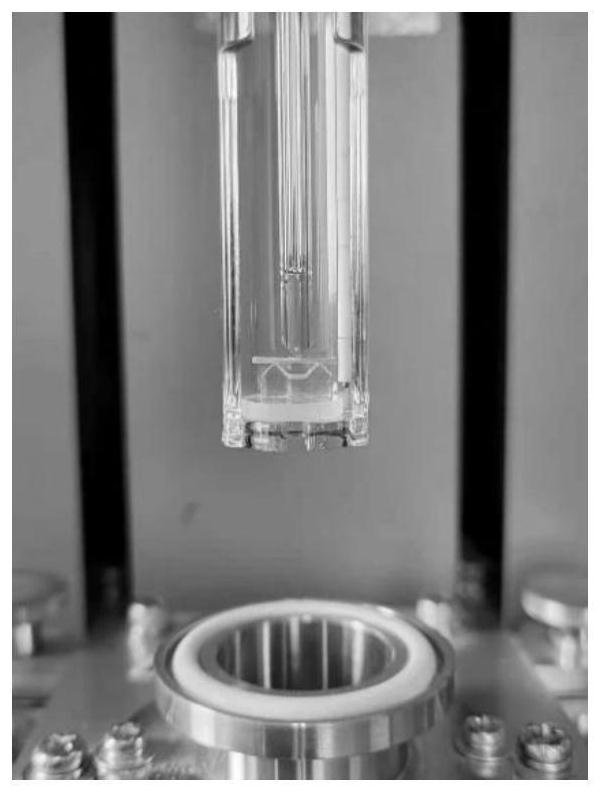

[0052] The flexural strength of the "Nanhai No. 1" shipwreck loose wood samples was tested by bending experiments. The wood species is fir, which is mildly and moderately degraded, and the maximum moisture content is 331%. The samples were cut into standard strips (8mm×2mm×0.3mm) and dried naturally. The span L of the fixture is measured to be 5mm, the width b of the sample is 2.299mm, and the thickness d is 0.244mm; the wooden bar is placed on the three-point bending fixture, and the position is as follows figure 2 shown. Start the test at room temperature, lower the probe, set the initial load to 5mN, and increase it uniformly at 5mN / min. After 30 minutes, the sample breaks, and record the change curve of displacement and load with time; process the data obtained from the experiment, and set the span of the fixture L, sample width b, thickness d, real-time displacement D, real-time load P into the formula The stress σ of the sample is obtained f , Specimen strain ε f...

Embodiment 2

[0054] The flexural strength of the bulkhead of the "Nanhai No. 1" sunken ship was tested by bending experiments. The wood species is hardwood pine, which is moderately degraded and has a moisture content of 452%. Samples were cut into standard strips (8 mm x 2 mm x 0.3 mm) and dried slowly. The span L of the fixture is measured to be 5mm, the width b of the sample is 1.885mm, and the thickness d is 0.172mm; place the wooden bar on the three-point bending fixture, start the test at room temperature, lower the probe, set the initial load 2mN, and Increase uniformly at 5mN / min, the sample breaks after 10min, and record the change curve of displacement and load with time, such as Figure 5 Shown; process the data obtained from the experiment, and substitute the fixture span L, sample width b, thickness d, real-time displacement D, and real-time load P into the formula The stress σ of the sample is obtained f , Specimen strain ε f , to make the stress-strain curve of the sampl...

Embodiment 3

[0056] The flexural strength of the wooden components of the "Nanhai I" shipwreck was tested by bending experiments. The wood species is sweetgum, which is moderately to severely degraded, with a maximum moisture content of 472%. Cut the sample into standard splines (8mm×2mm×0.3mm) and dry them slowly. Measure the clamp span L to be 5mm, sample width b and thickness d; place the strip on the three-point bending fixture, and Start the test under normal temperature conditions, lower the probe, set the initial load of 1mN, and increase it uniformly at 2mN / min. After 12 minutes, the sample breaks, and record the change curve of displacement and load with time; process the data obtained from the experiment, and set the fixture span L , sample width b, thickness d, real-time displacement D, real-time load P into the formula The stress σ of the sample is obtained f , Specimen strain ε f , make a stress-strain curve; the instantaneous stress of the sample fracture is the bending st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com