Crimping diffusion welding process of aluminum or aluminum alloy and heterogeneous metal

A technology of dissimilar metals and aluminum alloys, applied in the field of crimping diffusion welding process and its fixtures, can solve the problems of low welding efficiency, high cost, long time, etc., and achieve the effect of satisfying strength and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing, the invention is further described:

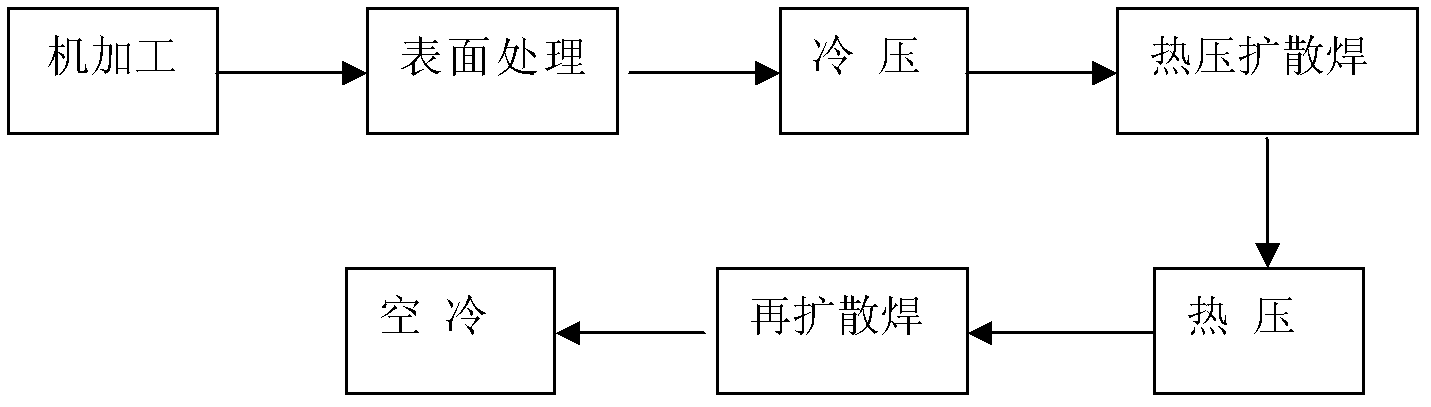

[0032] combine figure 2 , the crimping diffusion welding process of aluminum alloy and stainless steel of the present embodiment, specifically comprises the following steps:

[0033] a. Machining: Use a lathe to process the aluminum alloy and stainless steel into the required size, so that the pre-welded surfaces of the aluminum alloy and stainless steel are as smooth as possible;

[0034] b. Surface treatment: use metallographic sandpaper to polish the pre-welded surface of aluminum alloy and stainless steel to make the surface to be welded as smooth as possible; wash off the grease of aluminum alloy and stainless steel with acetone, rinse with clean water, and soak in distilled water for 15 to 20 minutes to make The surface to be welded is as clean as possible;

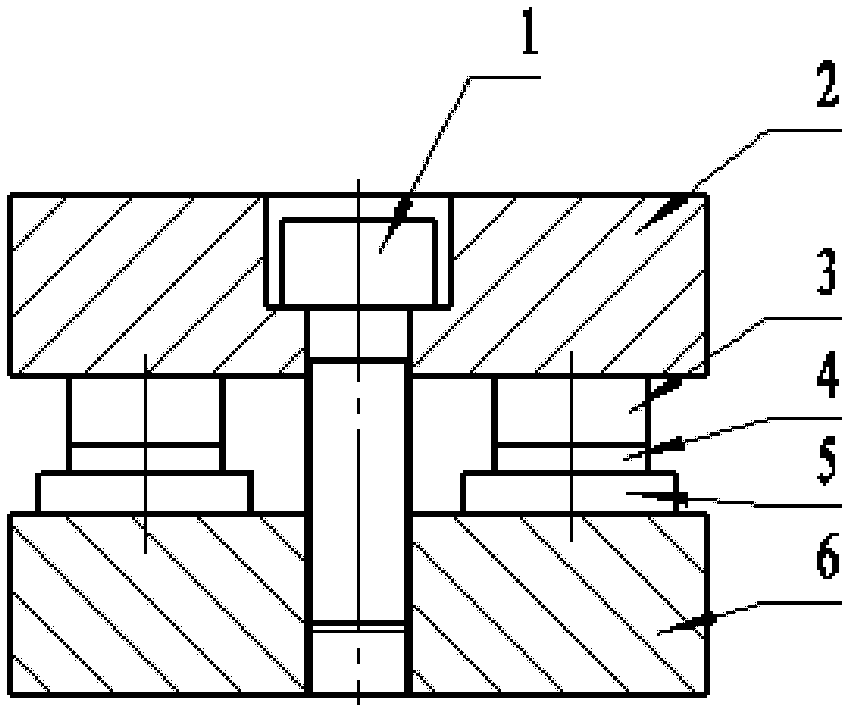

[0035] c, cold pressing: combined figure 1 , stack the aluminum alloy and stainless steel pre-welded face to face and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com