Novel clamping bus duct

A busway and a new type of technology, applied in the direction of fully enclosed busbar devices, can solve the problems of low connection efficiency, complexity, inconvenient installation and maintenance of the busway, and achieve the effects of easy installation and disassembly, enhanced connection strength, and simplified connection methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

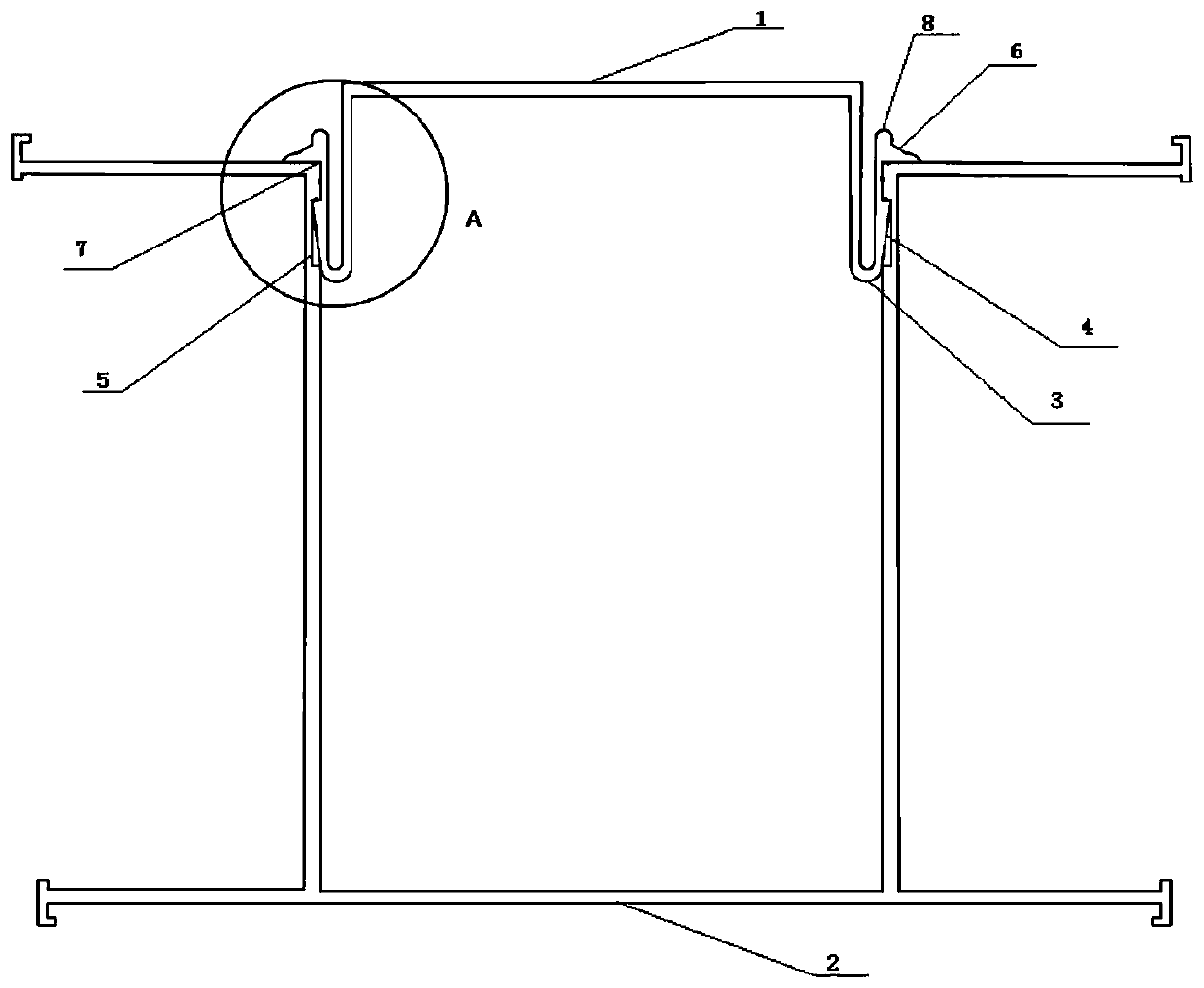

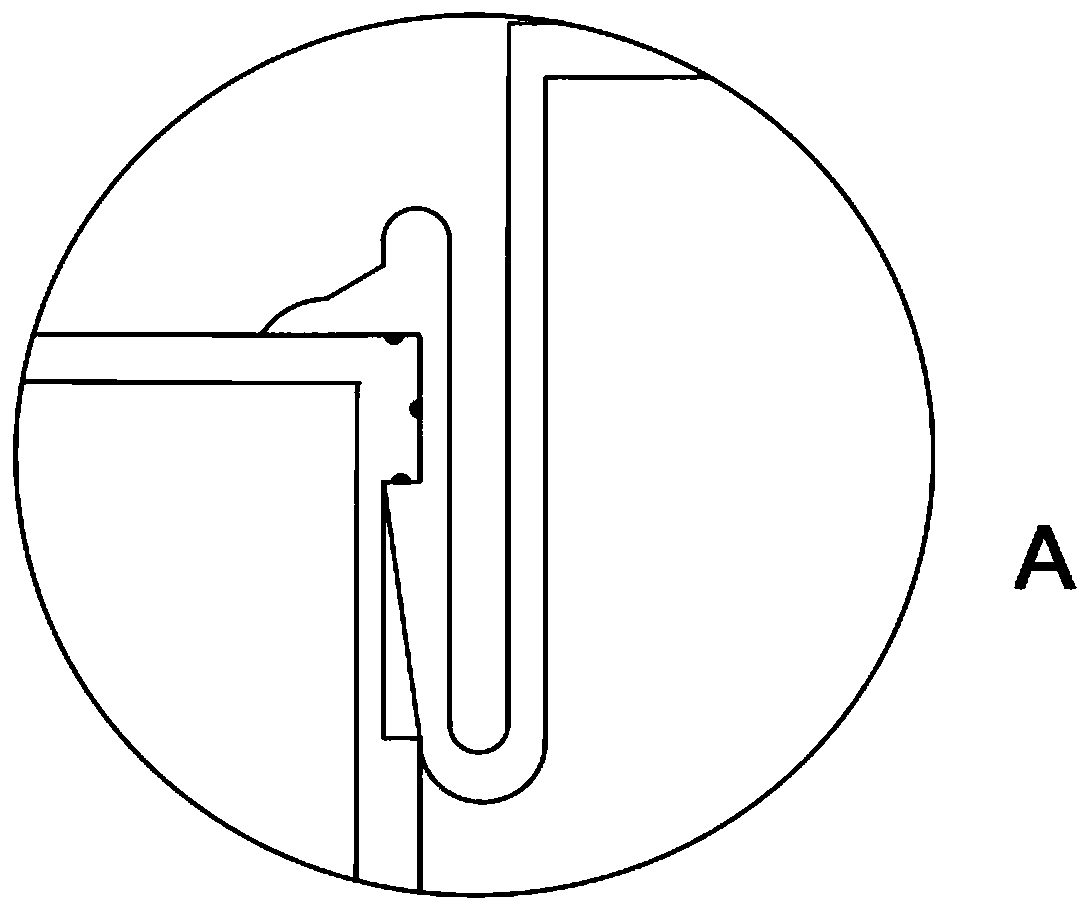

[0015] Such as figure 1 As shown, a new snap-fit bus duct includes a bus bar and a bus duct housing, the bus bar is fixed in the bus duct housing, and the bus duct housing includes upper and lower cover plates and connecting The side plate between the two cover plates, the lower cover plate 2 and the side plates are made of aluminum alloy profiles with integral structure, the upper inner wall of the side plate is provided with a card slot 5, and the upper cover plate 1 Both ends of the U-shaped cantilever 3 are connected, and the outer surface of the U-shaped cantilever 3 protrudes with a block 4, and the block 4 is inserted into the slot 5; the top of the U-shaped cantilever 3 extends horizontally to both sides to form a The pressing arm 6, the upper surface of the pressing arm 6 and the block is formed with a concave notch matching the top end of the side plate, and the top end of the side plate is embedded in the concave notch. The lower part of the clamping block 4 is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com