High-strength anti-cracking anti-deformation plastic window

An anti-cracking and anti-deformation technology, which is applied to the layout of windows/doors, window/door frames, and wing leaves, etc., can solve the problems of deformation of the whole window, cracking of welding corners of plastic windows, and unreliable welding, etc., so as to solve the deformation of the window sash , Conducive to the effect of marketing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

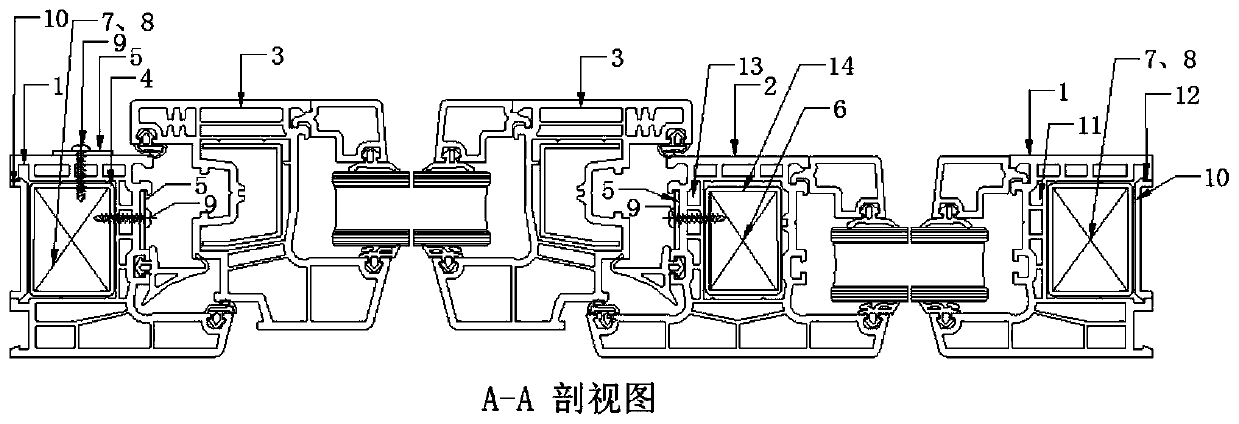

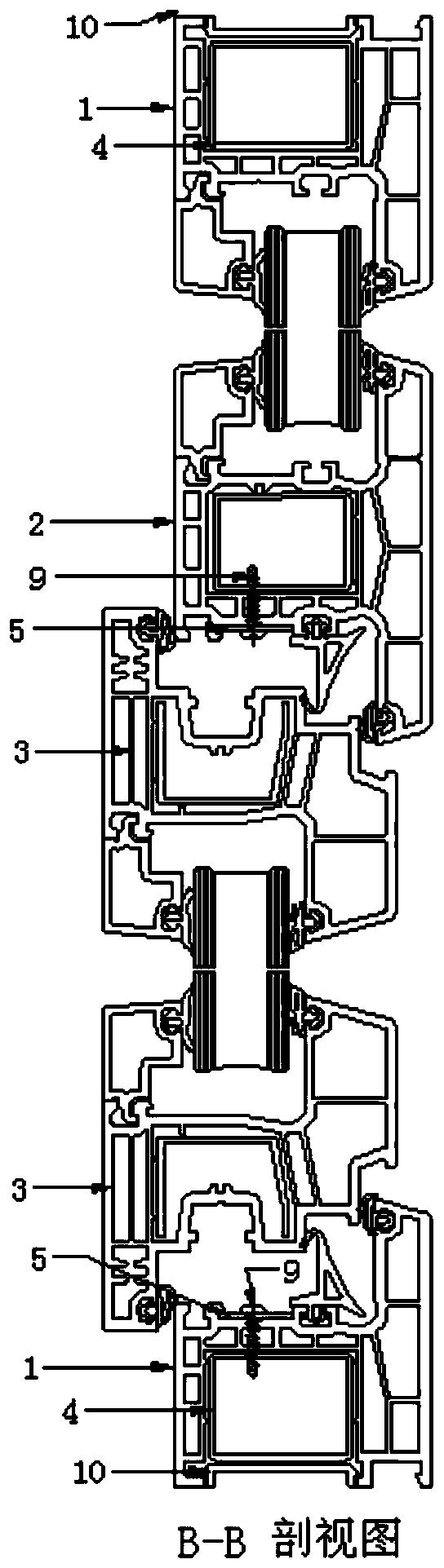

[0018] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0019] The "upper, lower, left, and right" parts described below use the picture as the object of expression. Up is the upper part shown in the picture, down is the lower part shown in the picture, left is the left part shown in the picture, and right This is the part on the right shown in the picture and is for description only.

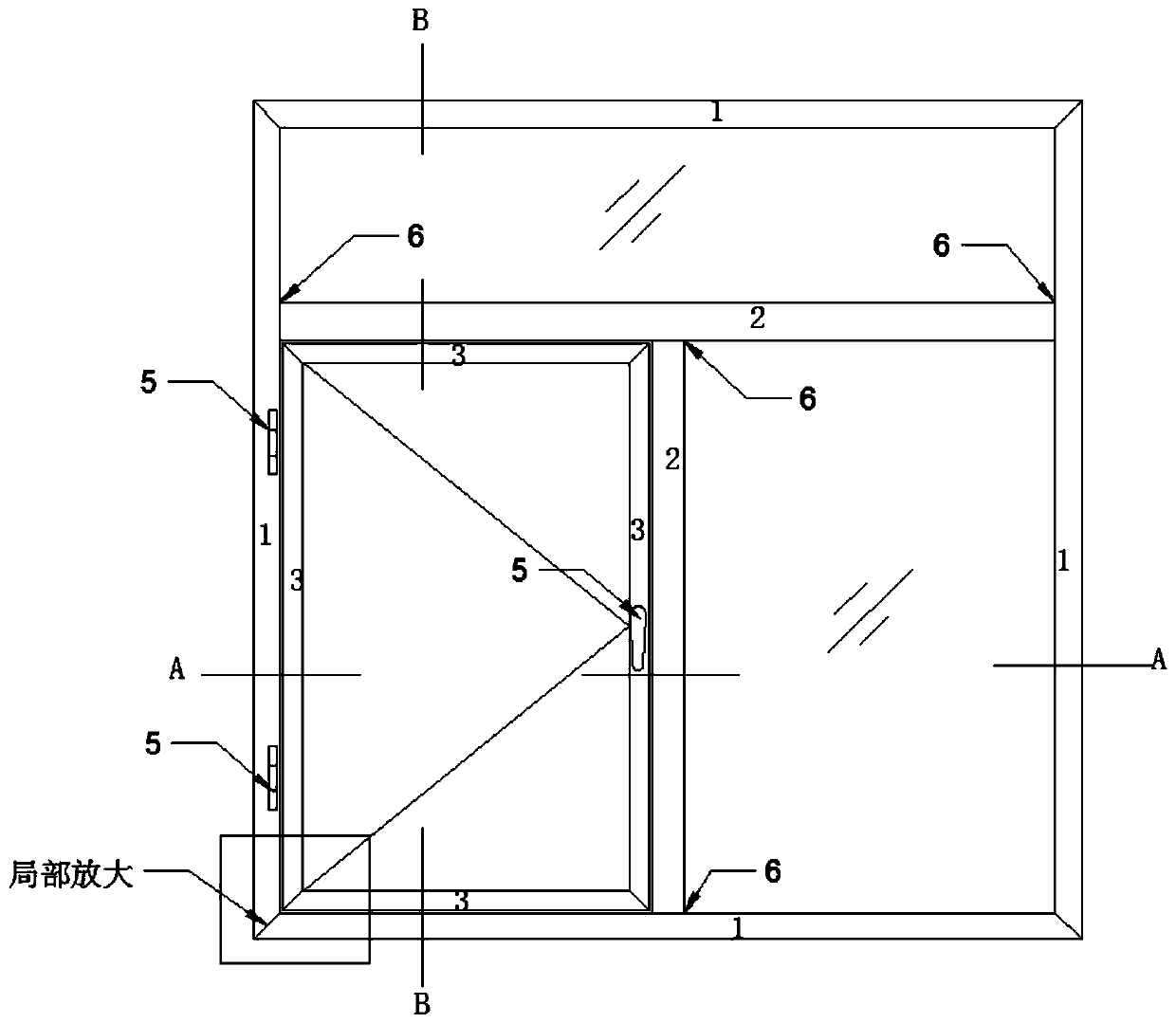

[0020] Such as figure 1 , a high-strength anti-cracking and anti-deformation plastic window, including a window frame 1, a stile 2, an opening fan 3, and hardware parts 5. The outermost layer of the whole window has a window frame 1 connected to the upper, lower, left, and right sides as the outer frame, and the window frame 1. The profile is an L-shaped window frame plastic profile with a multi-cavity structure. The up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com