Composition of compound calcium sulfonate-based lubricating grease for improving high-temperature performance and preparation method thereof

A composite calcium sulfonate-based lubricating grease with high-temperature performance technology, applied in the field of lubricating grease, can solve problems such as short life, achieve the effects of prolonging retention, saving primary energy, and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

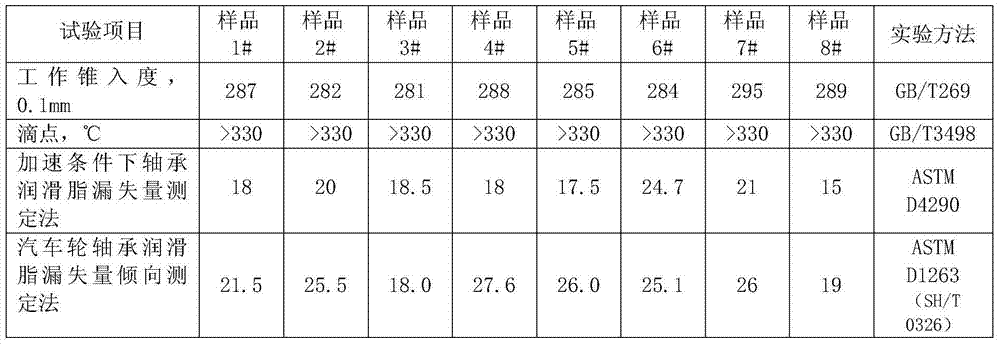

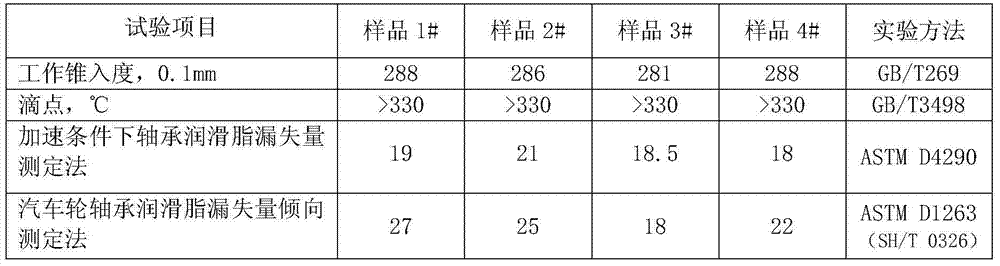

Examples

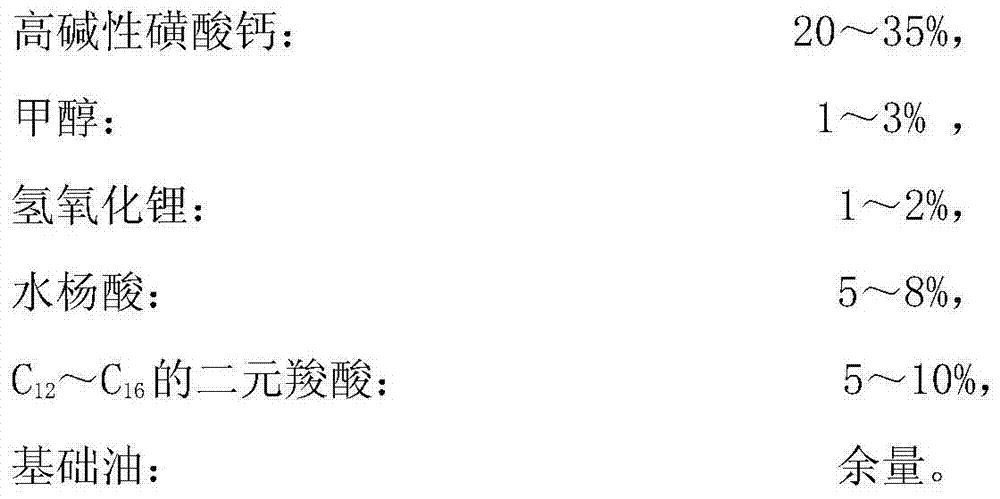

Embodiment 1

[0031] 1) Component: Overbased calcium sulfonate detergent (base value 320mgKOH / g): 200g (20.0%)

[0032]

[0033] 2) Production process: 200g (20.0%) of the overbased calcium sulfonate detergent with a base value of 320mgKOH / g is dropped into a small-sized autoclave, and 10g (1%) of methyl alcohol is added to carry out the production of calcite-structured calcium carbonate, stirring rapidly, Heat up to 90-100°C, keep the temperature until the system material gradually thickens, and gradually add lithium hydroxide powder 10g (1%), salicylic acid 50g (5%), dodecyl Dibasic acid 50g (5%), after constant temperature reaction for 60 minutes, gradually increase the temperature, keep the temperature at 130-135°C for 60 minutes, gradually increase the temperature to 220-222°C for 5-10 minutes, adjust the consistency with polyolefin No. 8, The addition amount is 680g (68%), and finally the finished lubricating grease is 990g (methanol is volatilized during production, not in the com...

Embodiment 2

[0035] 1) Component: Overbased calcium sulfonate detergent (base value 320mgKOH / g): 350g (35%)

[0036]

[0037] 2) production process: 350g (35.0%) of the highly alkaline calcium sulfonate detergent with a base value of 320mgKOH / g is dropped into a small-sized autoclave, and 30g (3%) of methanol is added to carry out the production of calcite structure calcium carbonate, stirring rapidly, Heat up to 90-100°C, keep the temperature constant until the system material gradually thickens, and gradually add 20g (2%) of lithium hydroxide powder, 80g (8%) of salicylic acid, and dodecane to the system at a temperature of 95-100°C Dibasic acid 100g (10%), after constant temperature reaction for 60 minutes, gradually increase the temperature, keep the temperature at 130-135°C for 60 minutes, gradually increase the temperature to 220-222°C, keep the temperature for 5-10 minutes, adjust the consistency with polyolefin No. 8, The addition amount is 420g (42%), and the final product lubr...

Embodiment 3

[0039] 1) Components: overbased calcium sulfonate detergent (base value 320mgKOH / g): 350g (35%)

[0040]

[0041] 2) production process: 350g (35.0%) of the highly alkaline calcium sulfonate detergent with a base value of 320mgKOH / g is dropped into a small-sized autoclave, and 30g (3%) of methanol is added to carry out the production of calcite structure calcium carbonate, stirring rapidly, Heat up to 90-100°C, keep the temperature until the system material gradually thickens, and gradually add lithium hydroxide powder 13g (1.3%), salicylic acid 80g (8%), hexadecyl Dibasic acid 100g (10%), after constant temperature reaction for 60 minutes, gradually increase the temperature, keep the temperature at 130-135°C for 60 minutes, gradually increase the temperature to 220-222°C, keep the temperature for 5-10 minutes, adjust the consistency with polyolefin No. 8, The addition amount is 427g (42.7%), and the final product lubricating grease is 970g (methanol is volatilized during p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com