Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Improve skeleton strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

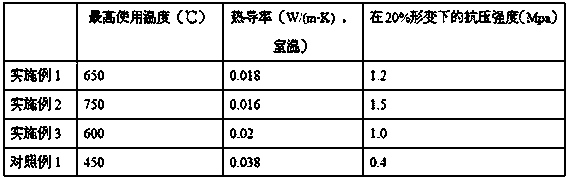

Organic/inorganic phenolic resin hybrid aerogel and preparation method thereof

ActiveCN105838022AImprove high temperature resistanceImprove antioxidant capacityAmbient pressureOxidation resistant

The invention relates to organic / inorganic phenolic resin hybrid aerogel and a preparation method thereof, in particular to porous hybrid phenolic resin aerogel and a preparation method thereof, and is mainly applied to the technical field of light heat shielding / insulation heat protection systems. The hybrid aerogel takes cheap and available commercial phenolic resin and tetraethl orthosilicate as raw materials, and the organic / inorganic phenolic resin hybrid aerogel can be obtained through a mild reaction route and an ambient pressure drying method; the hybrid aerogel is good in high temperature resistance and oxidation resistance and high in carbonated structural strength; the hybrid aerogel is good in heat insulation efficiency, low in heat conductivity and good in high-temperature scour resistance; the hybrid aerogel has a great application value in the field of advanced heat protection materials.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

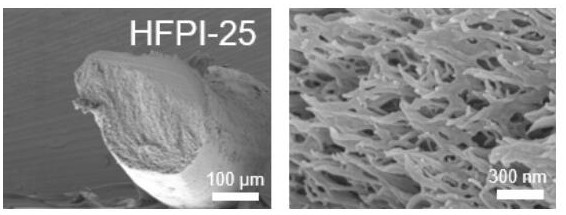

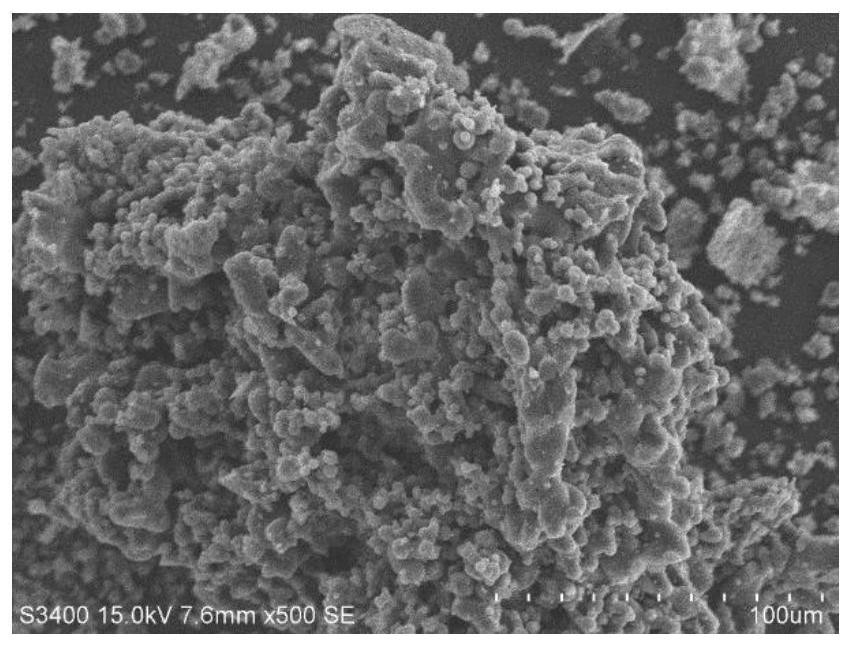

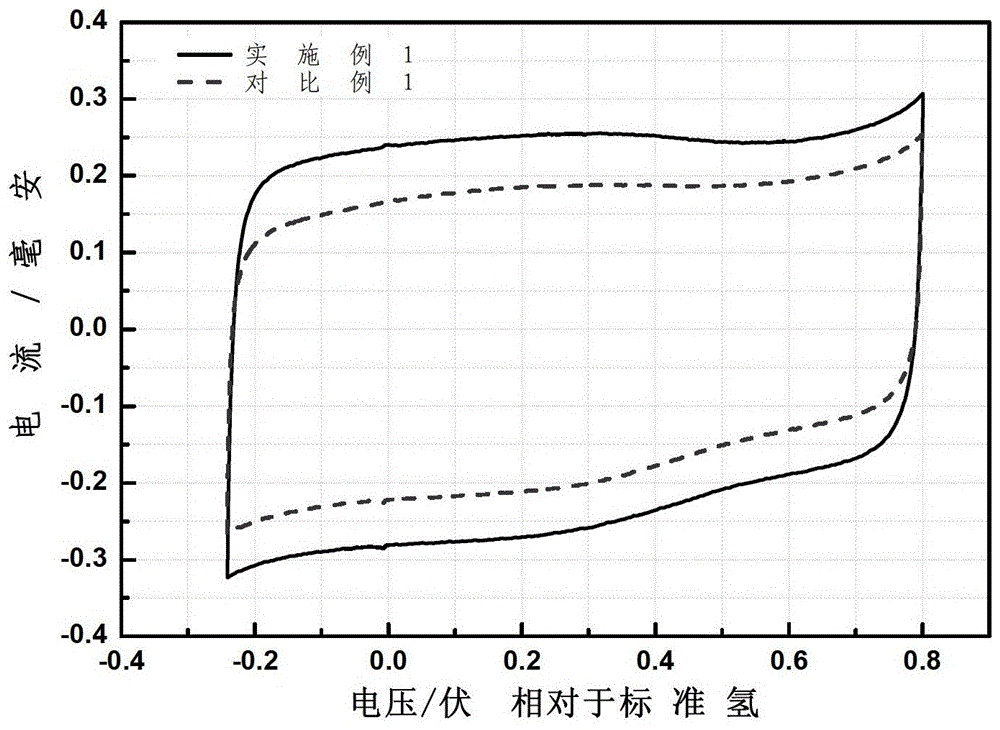

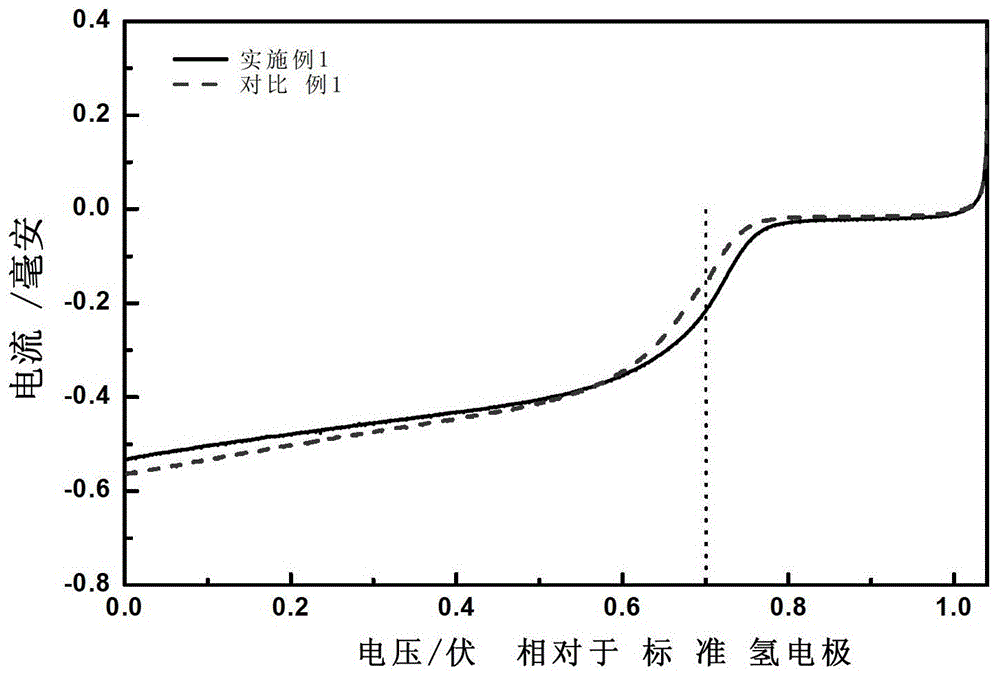

Metal-doped nitrogen-containing carbon-based catalyst of fuel cell and application thereof

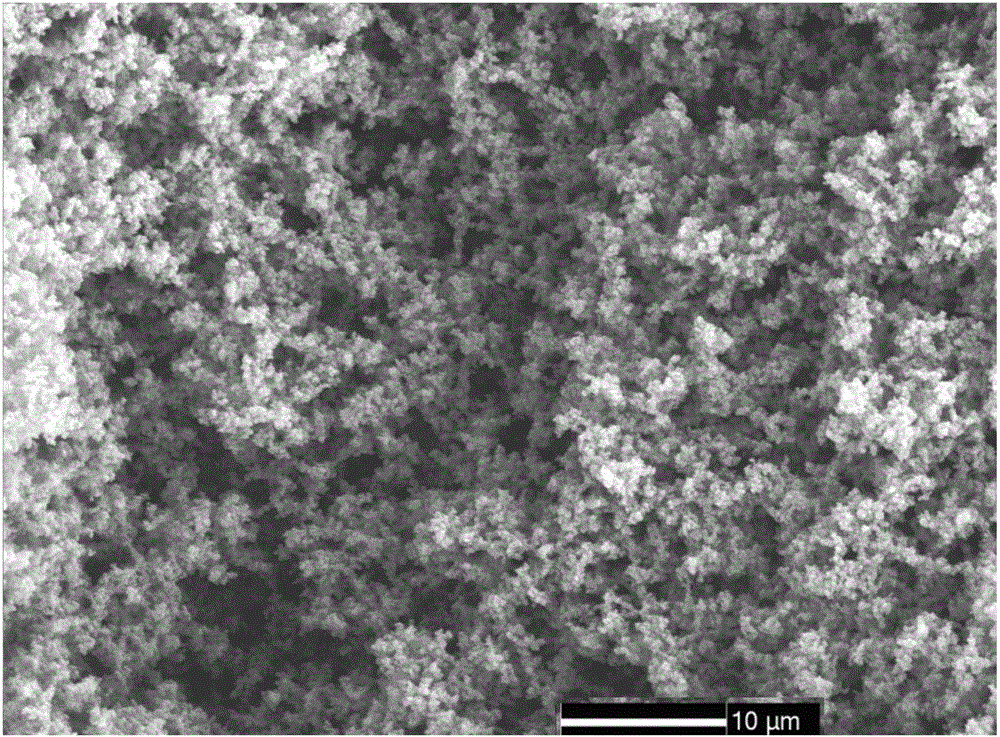

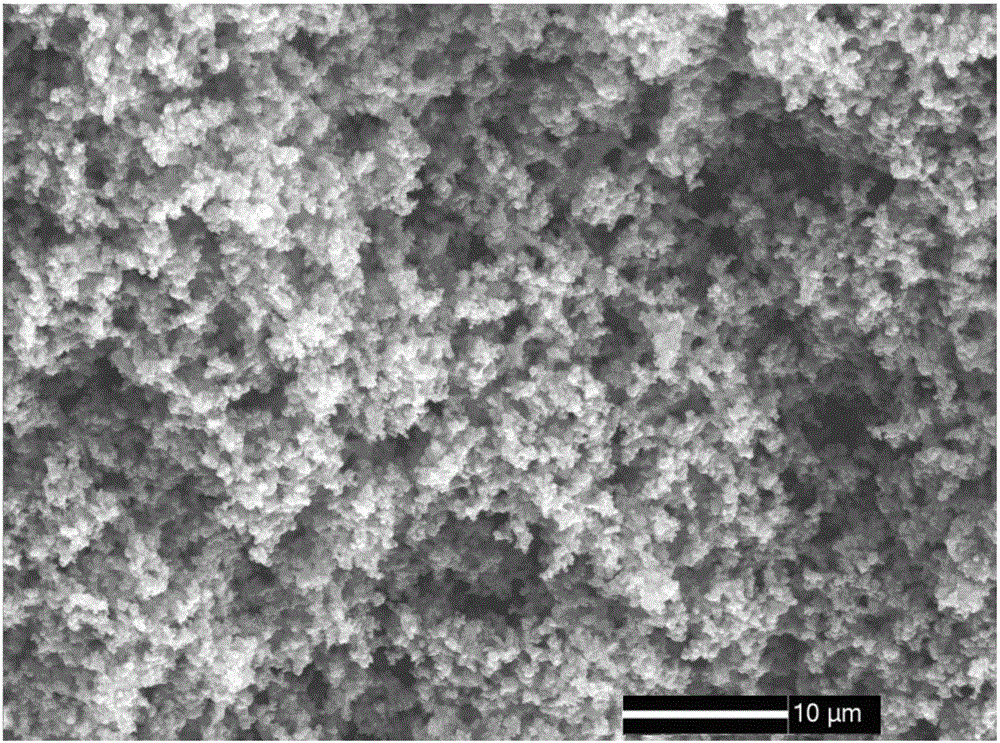

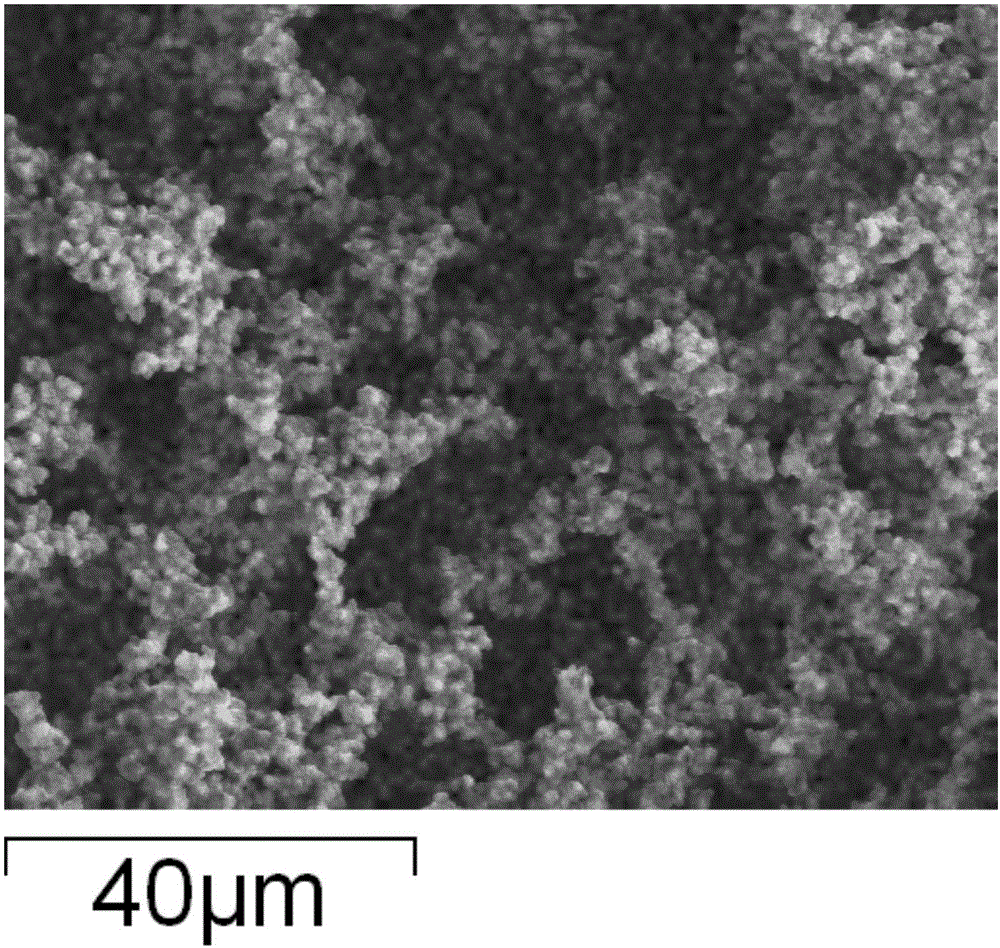

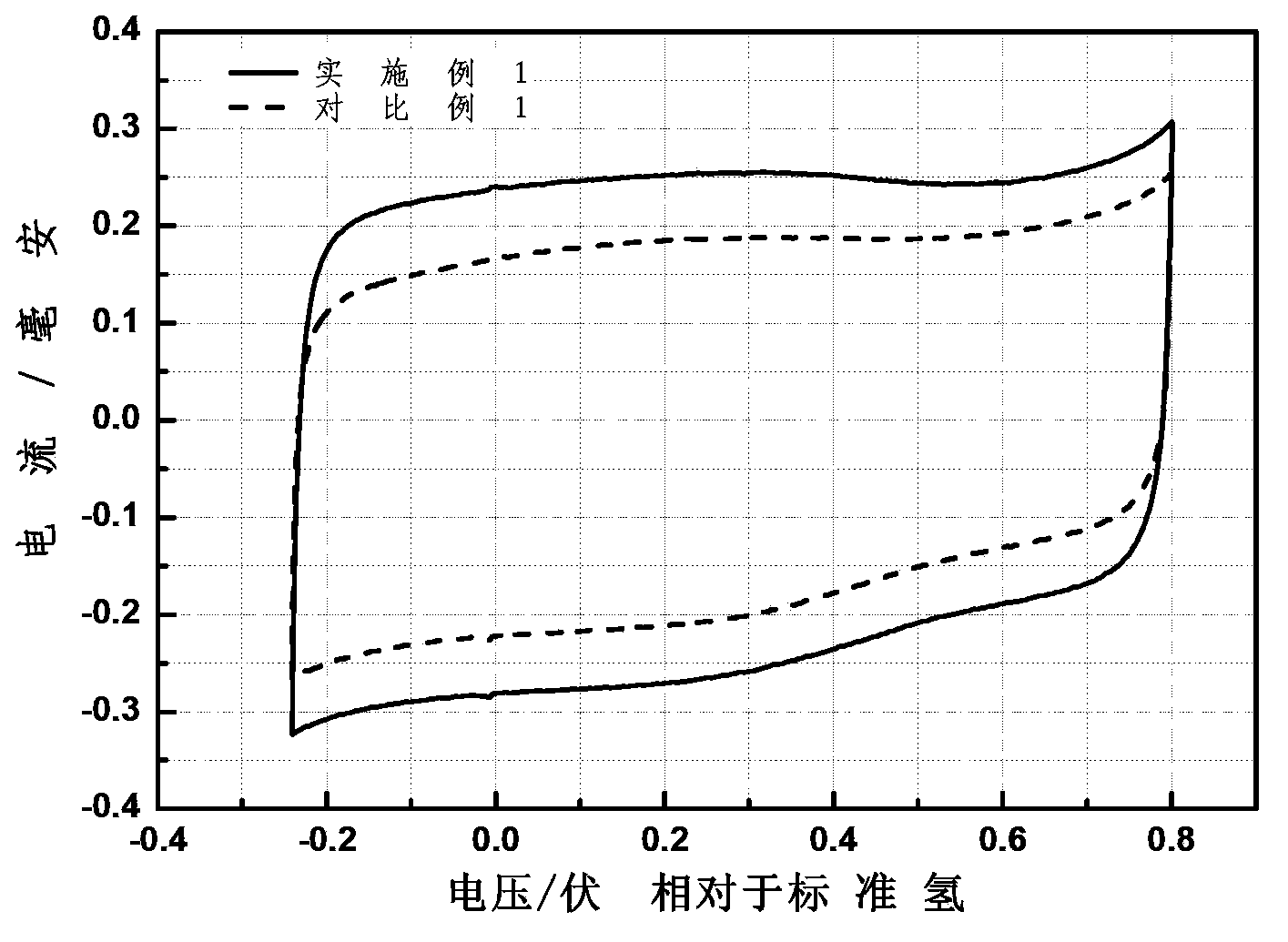

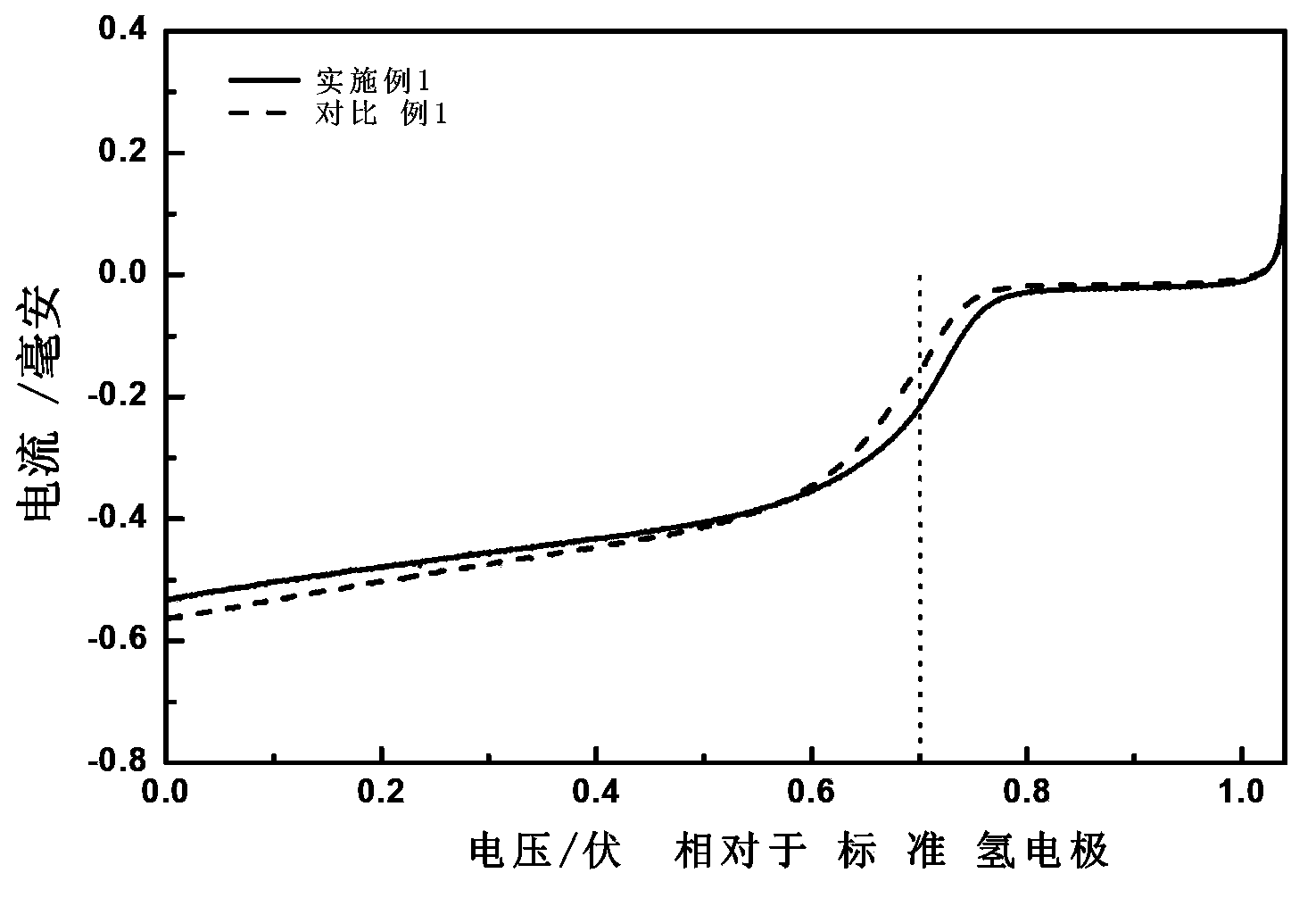

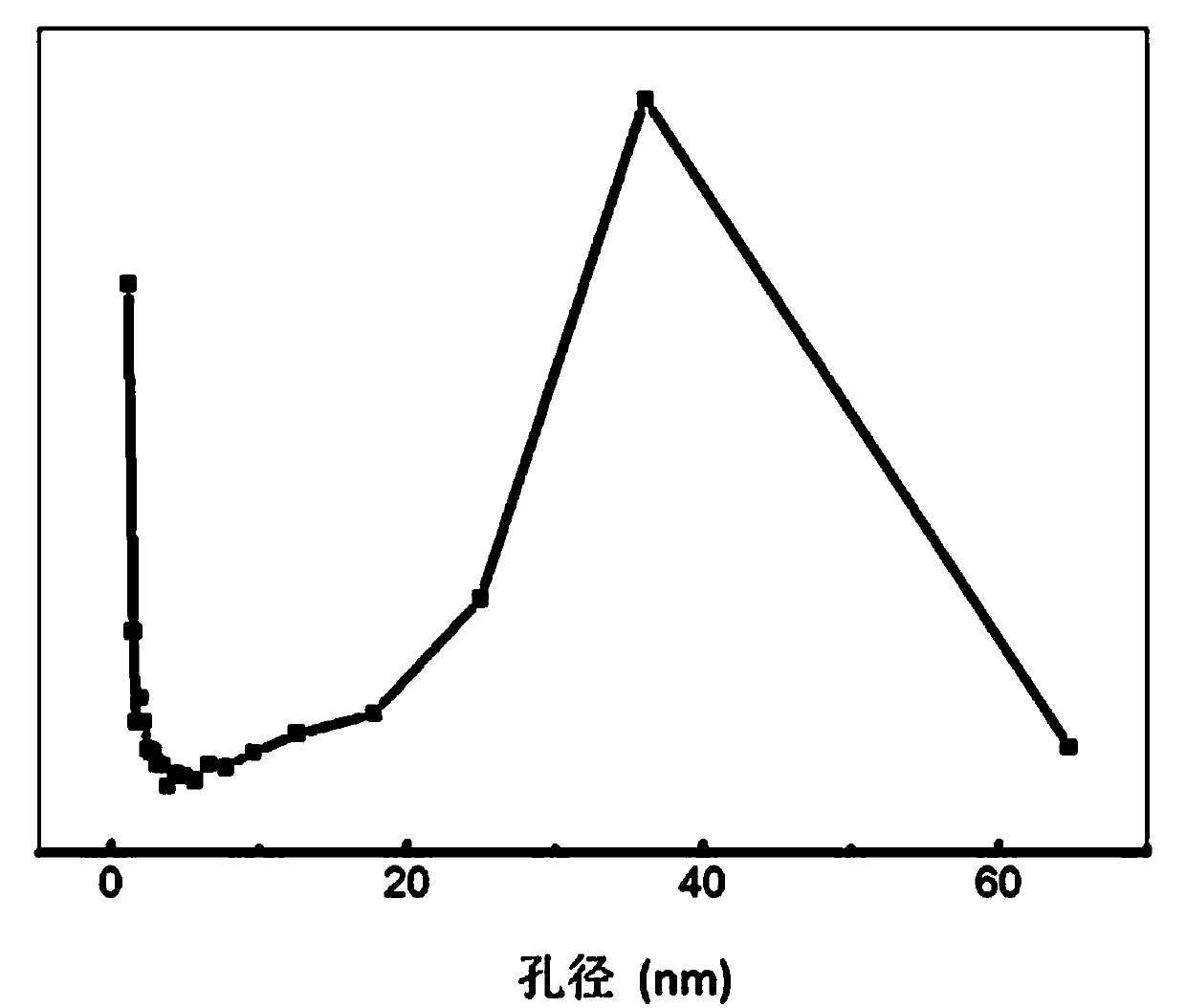

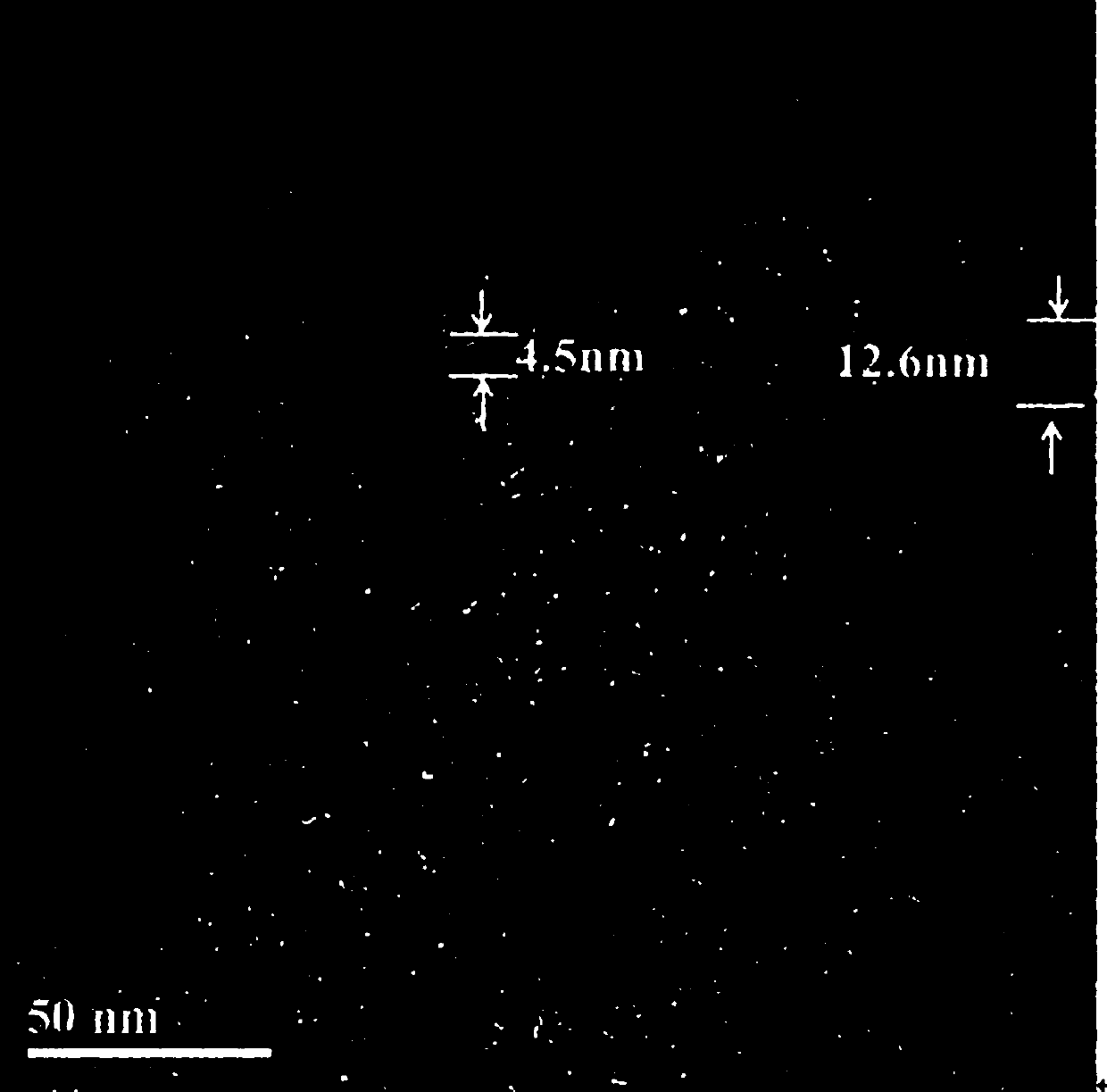

ActiveCN103682379AStructurally effective regulationEffective control of morphologyCell electrodesFuel cellsReduction ActivitySurface-active agents

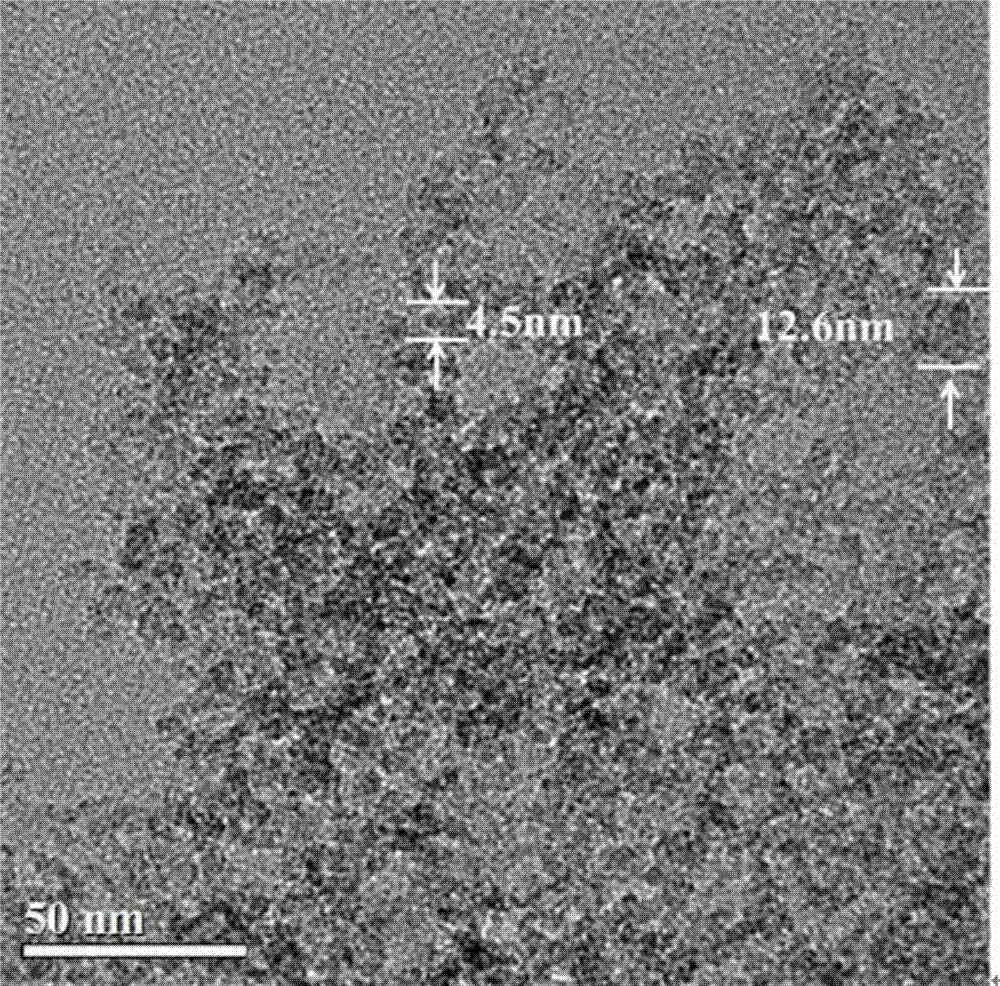

The invention relates to a metal-doped nitrogen-containing carbon-based catalyst of a fuel cell and application of the catalyst. The catalyst adopts organic surface active agents as a protection agent and a structural guide agent and adopts an aromatic compound and aldehyde as reaction monomers, metal elements are added in the reaction process to obtain a polymer-metal compound, and the polymer-metal compound is dried and then is subjected to high-temperature processing with inert gas or / and ammonia gas to finally obtain the metal-doped nitrogen-containing carbon-based catalyst. When the metal-doped nitrogen-containing carbon-based catalyst is used as a cathode catalyst of a proton exchange membrane fuel cell and a direct-methanol fuel cell, the oxide reduction activity, stability and toxicity resistance are excellent; moreover, the catalyst has an environment-friendly effect, is low in cost, controllable in aperture, high in specific surface area and rich in resource and can substitute for platinum to serve as an electric catalyst of the proton exchange membrane fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

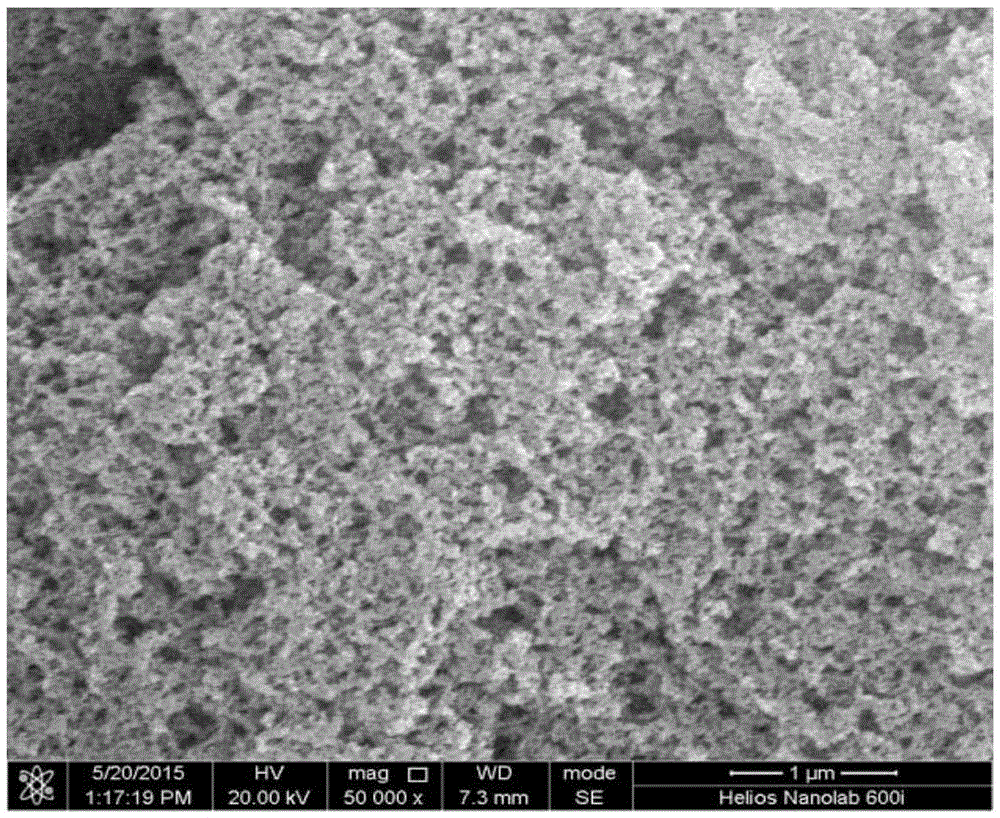

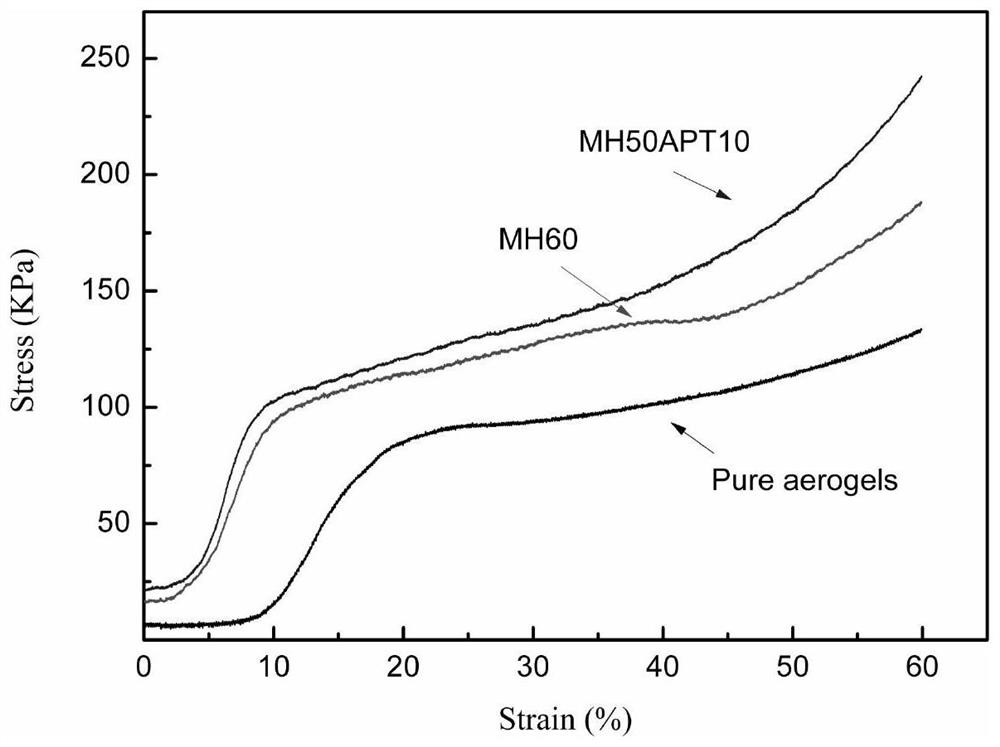

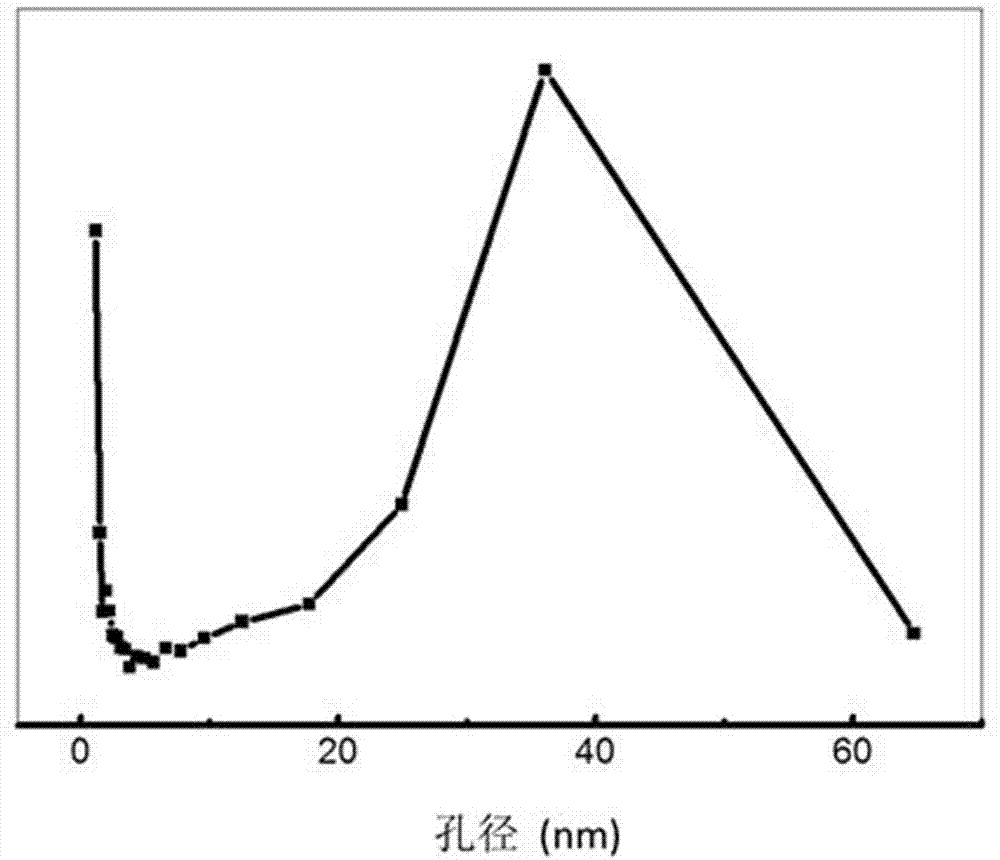

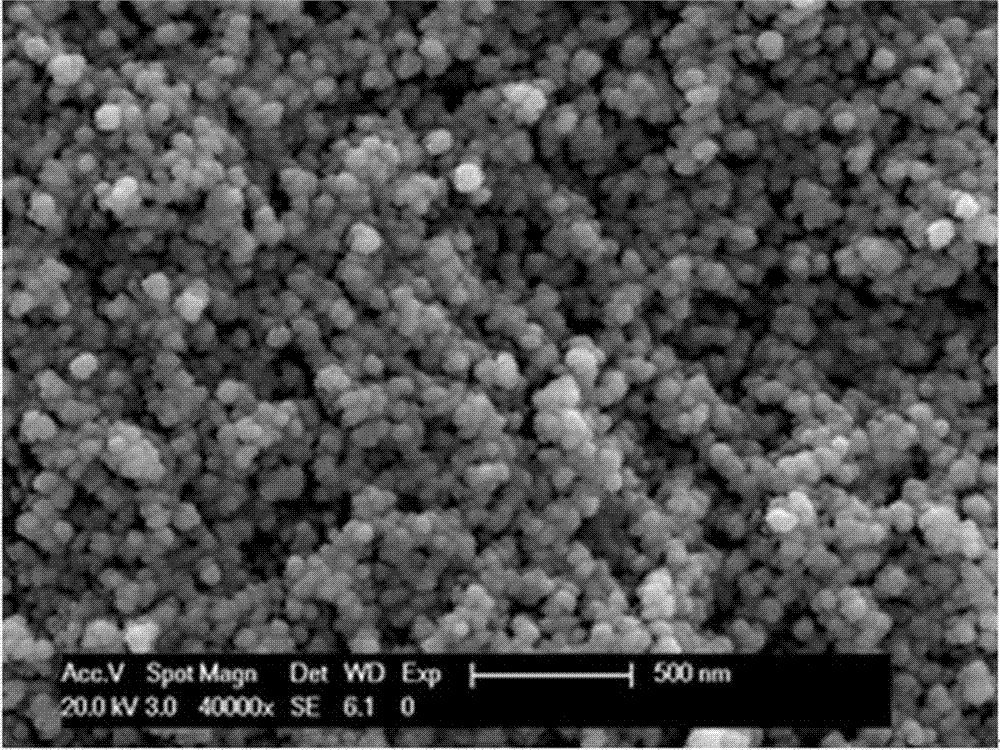

Mechanical-enhanced SiO2 aerogel material and preparation method thereof

The invention relates to a mechanical-enhanced SiO2 aerogel material and a preparation method thereof. According to the method, the mixed SiO2 aerogel with a changed microstructure is successfully prepared by mixing two different concentrations of SiO2 sols via a process (sol coagulation method) capable of performing gelling on the SiO2 sols simultaneously, wherein the elasticity modulus of the mixed SiO2 aerogel is 5.53MPa. Thus, compared with the traditional aerogel, the mechanical property of the mixed SiO2 aerogel provided by the invention is nearly doubled, namely, the mixed SiO2 aerogel has the excellent mechanical property. The specific surface area of the SiO2 aerogel is 882g / cm<3> and the average pore size of the SiO2 aerogel is 28nm due to that the skeleton strength in the network structure of the SiO2 aerogel is further enhanced at the same time when the gel pore structure distribution of the SiO2 aerogel is changed by the sol coagulation method. Thus, the SiO2 aerogel prepared by using the synthesis method has the special porous nanostructure and the excellent mechanical property. As a result, the application value and the application potential of the SiO2 aerogel in the fields of photoelectric devices, gas sensitive sensors, heat insulation and the like are greatly improved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Flame-retardant enhanced-type polypropylene composite material and preparing method thereof

Disclosed are an flame-retardant enhanced-type polypropylene composite material and a preparing method thereof. The flame-retardant enhanced-type polypropylene composite material is prepared from a polypropylene matrix, carbon nanotube modified master batch, a potassium titanate crystal whisker, a composite fire retardant, modified filler, a compatilizer and an antioxidant, wherein the carbon nanotube modified master batch is prepared through the mixed melting of the polypropylene matrix and multiwall-carbon nanotube according to a weight ratio of 10-15:1, the composite fire retardant is a nitrogen-phosphorous composite fire retardant, through the interaction of the nitrogen-phosphorous composite fire retardant and the multiwall-carbon nanotube, a combustion decomposition product of the polypropylene composite material can generate a compact, and continuously stable char layer; meanwhile, two-mechanical melt blending of the multi-walled carbon nanotube are adopted so that the multiwall-carbon nanotube can be fully dispersed in the polypropylene matrix, and two-mechanical melt blending of the multi-walled carbon nanotube are adopted. According to the flame-retardant enhanced-type polypropylene composite material and the preparing method thereof, the operation technology is simple, the added filler causes no pollution to the environment, and thus the flame-retardant enhanced-type polypropylene composite material is environmentally friendly.

Owner:DONGGUAN POLYTECHNIC

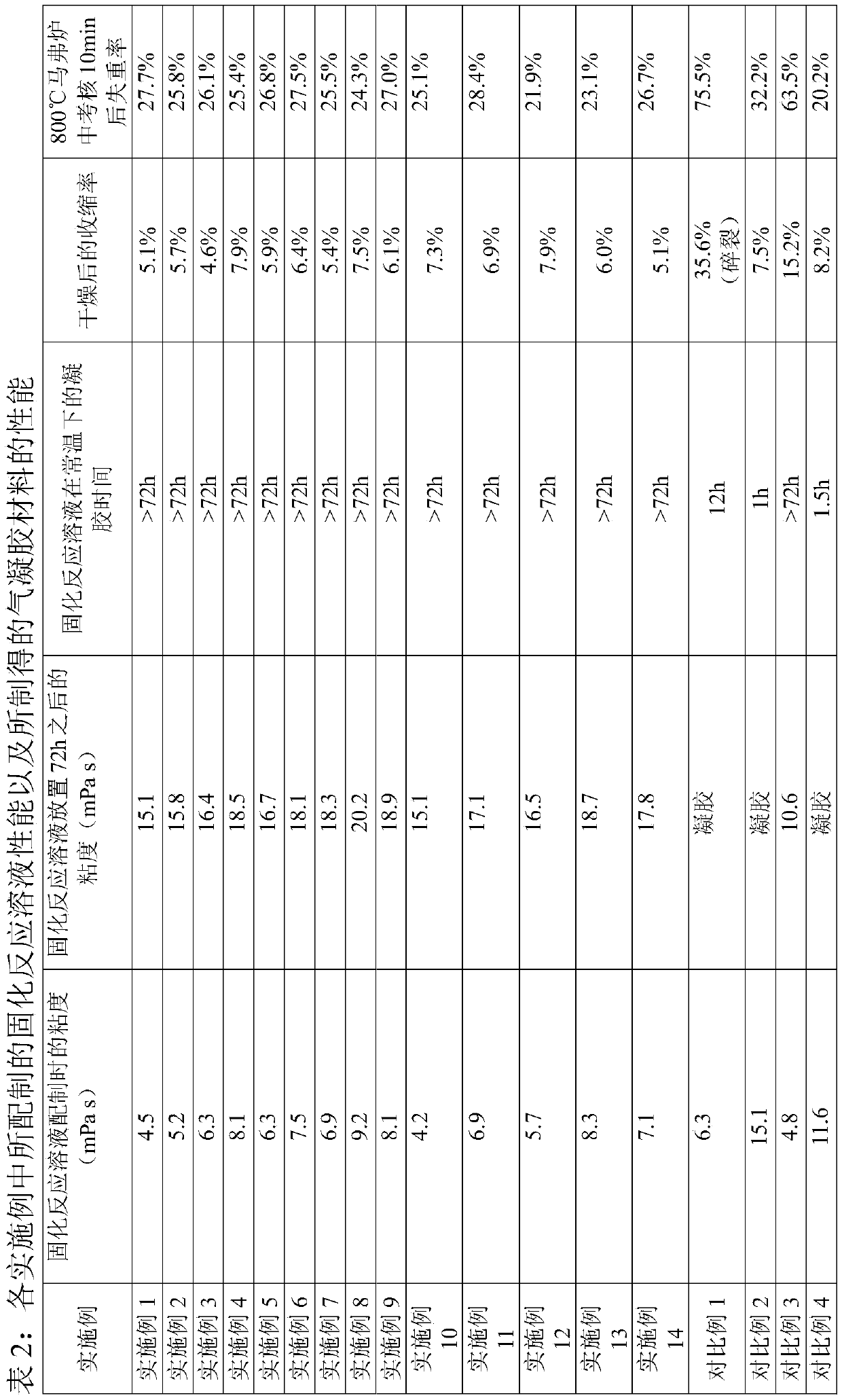

Normal pressure dried phenolic aerogel and preparation method thereof

PendingCN110408071AAtmospheric pressure dryingShorten the overall cycleOrganic solventGraft reaction

The invention provides a method for preparing a phenolic aerogel by normal pressure drying. The method comprises the following steps: preparing a graft reaction solution including a phenolic novolac resin, a silane grafting agent and a first organic solvent, and carrying out a grafting reaction the phenolic novolac resin and the silane grafting agent in the graft reaction solution to obtain a silane-grafted phenolic resin; adding a curing agent and a second organic solvent to form a curing reaction solution, and performing a curing reaction to obtain a phenolic gel; and drying the phenolic gelunder normal pressure to obtain the phenolic aerogel. The invention also provides the phenolic aerogel produced by the method. The method of the invention realizes normal pressure drying, greatly shortens the preparation cycle, reduces the preparation cost, solves the problems of microscopic phase separation and too fast gelling, and leaves sufficient operation time for practical application. Theprepared phenolic aerogel has a significantly improved framework strength, a remarkably reduced shrinkage, good oxidation resistance and good ablation resistance.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Preparation method for high-temperature-resistant thermal-insulation aerogel felt

InactiveCN108689637AImprove structural strengthImprove high temperature resistanceCeramicwareFiberCellulose

The invention belongs to the field of aerogel felts, and discloses a preparation method for a high-temperature-resistant thermal-insulation aerogel felt. The preparation method comprises the followingsteps that SiC whiskers and cellulose are dispersed in a graphene aqueous suspension so as to obtain a suspension A; hollow glass micro-beads are added into the suspension A under the action of stirring so as to obtain a suspension B; n-silicate, ethanol and water are uniformly mixed, then a NH4F solution and ammonia water are sequentially added and uniformly stirred so as to obtain silica sol C;the suspension B is added into the silica sol C under the action of stirring, after uniform stirring is carried out, the mixture is used for soaking a fibrofelt, and immersion treatment is carried out on the fibrofelt under the vibration condition, after the fiber felt is completely soaked, the fibrofelt is taken out, and standing is carried out until a fibrofelt-gel complex is obtained; aging treatment is carried out at room temperature or under heating condition; solvent replacement is carried out for multiple times, and excessive moisture in the fibrofelt-gel complex is removed; and dryingtreatment is carried out so as to obtain the high-temperature-resistant thermal-insulation aerogel felt. According to the preparation method, the mechanical strength of the aerogel felt is improved,and meanwhile, the high temperature resistance and the heat insulation effect are good.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

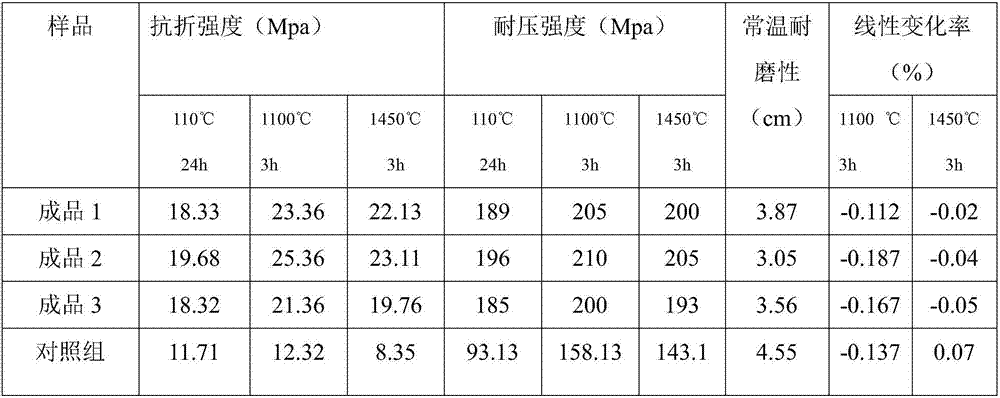

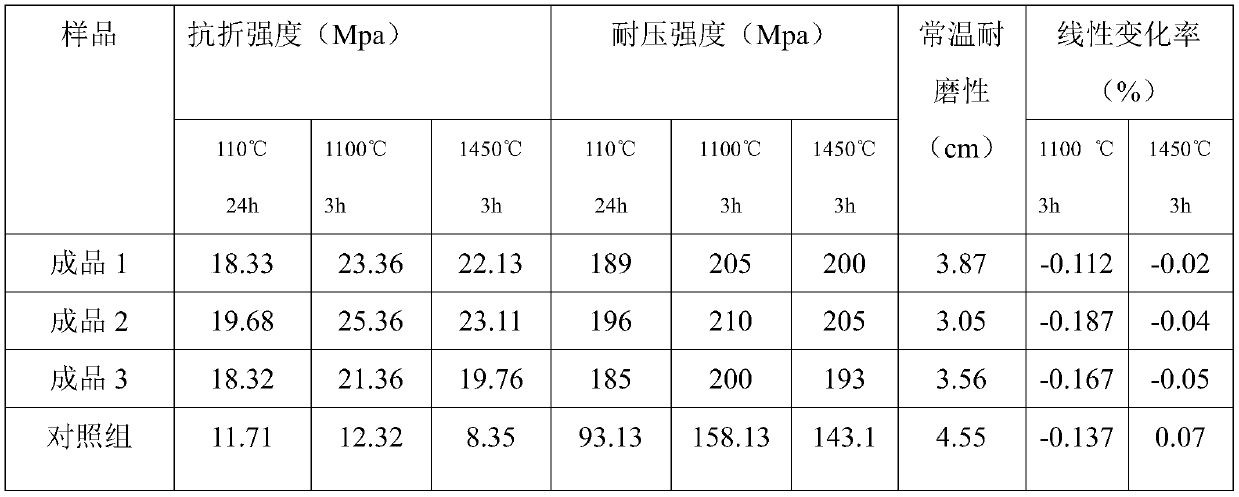

Refractory wear-resistant pouring material and preparation method thereof

The invention discloses a refractory wear-resistant pouring material and a preparation method thereof. The refractory wear-resistant pouring material comprises the following raw material components in percentage by mass: 60-80% of graded ceramic particles, 5-25% of mixed matrix slurry, 4-15% of an adhesive and 6-10% of water, wherein the graded ceramic particles are divided into four granularity grades, and comprise ceramic particles of 8-5mm, ceramic particles of 5-3mm, ceramic particles of 3-1mm and ceramic particles of 1-0mm; and the mixed matrix slurry comprises milled natural river sand, alumina micro powder of 5-10 microns, silica fume, micro steel fibers and a dispersing agent solution. The fire resistance of silicon carbide ceramics is utilized, the cracking phenomenon caused by excessive CaO doping in the traditional cement refractory castable is avoided by adopting a complex adhesive, and steel fibers and boron fibers are introduced, so that the strength and wear resistance of the pouring material are improved on the basis of ensuring the fire resistance.

Owner:宜兴市张泽浇注耐火材料有限公司

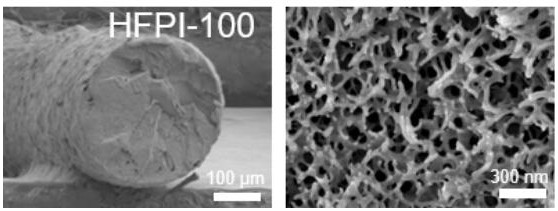

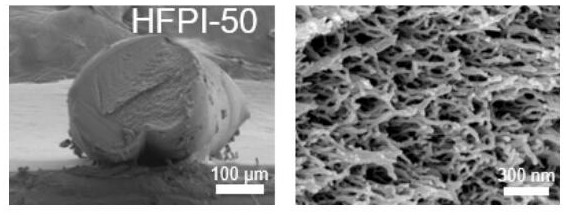

Normal-pressure drying preparation method and application of polyimide aerogel product

ActiveCN113818098AAvoid molecular weight degradationAvoid the problem of macroscopic volume shrinkageMonocomponent synthetic polymer artificial filamentSynthetic polymer filament chemical after-treatmentSupercritical dryingPolymer science

The invention discloses a normal-pressure drying preparation method and application of a polyimide aerogel product. The method comprises the following steps of copolymerizing diamine containing carboxyl or hydroxyl and other diamines with dicarboxylic anhydride, grafting a photosensitive group to obtain photosensitive fluorine-containing polyimide, and taking the photosensitive fluorine-containing polyimide as a precursor solution; carrying out molding means such as casting, blade coating, 3D printing, spinning and the like; and performing ultraviolet irradiation, solvent replacement and normal-pressure drying to obtain the polyimide aerogel product with different macrostructures. According to the normal-pressure drying preparation method and the application of the polyimide aerogel product provided by the invention, the photosensitive group is introduced, and a cross-linked structure is initiated through light, so that the framework strength of wet gel can be effectively improved, and shrinkage caused by surface tension generated in the solvent evaporation process is reduced; and secondly, the fluorine-containing binary anhydride or diamine is selected, so that the surface tension can be effectively reduced, and the shrinkage rate of a product in the normal-pressure drying process is reduced. The method effectively solves the problems of complex process, high cost, low efficiency and incapability of large-scale production in the existing freeze drying and supercritical drying methods for preparing the polyimide aerogel product.

Owner:DONGHUA UNIV

Soft-soil foundation treatment method for expressway engineering

InactiveCN102535291AIncrease connection forceImprove skeleton strengthRoadwaysMaterials scienceUltimate tensile strength

The invention discloses a soft-soil foundation treatment method for expressway engineering, which belongs to the field of foundation treatment. The method includes the following steps: a preparing filler: preparing lime improved soil according to volume ratio of powder lime and soil mass as 4-8%:92-96%; b adopting a method of dot interlace ramming through a hammer to conduct ramming and pore forming on the soft-soil foundation; and c filling the lime improved soil into rammed pores, using the hammer to ram continuously, and performing filling, ramming, refilling and reramming to form a pile to reach the surface of the foundation. The soft-soil foundation treatment method for the expressway engineering has the advantages of treating on site, compacting deeply, using local materials, and being easy in quality controlling, high in pile strength and economical in investment.

Owner:SHIJIAZHUANG TIEDAO UNIV

Method for preparing zirconium oxide aerogel through combination of secondary gelling method and ambient-pressure drying

ActiveCN105271403AOvercoming expensiveProtect the environmentZirconium oxidesSupercritical dryingPolymer science

The invention provides a method for preparing zirconium oxide aerogel through combination of a secondary gelling method and ambient-pressure drying and relates to a preparation method of the zirconium oxide aerogel. The problems that an existing super-critical drying method is high in cost, equipment is expensive, and large-scale production can not be easily achieved are solved. The method includes the steps of 1, preparation of zirconium oxide wet gel; 2, re-gelling and modification of ZrO2 thick-soup-shaped gel; 3, drying of the ZrO2 aerogel. The secondary gelling method is adopted, the stirring speed is controlled, two gelling processes are generated to a system, the frame strength of the aerogel is improved to avoid the influences of capillary force in the following ambient-pressure drying process on the material pore structure, and it is guaranteed that the pore structure of the aerogel is not collapsed. According to the method, ambient-pressure drying is adopted, the problems of high energy consumption and cost existing in the process of preparing zirconium oxide aerogel through super-critical drying are solved, and large-scale production can be easily achieved. The method is used for preparing the zirconium oxide aerogel.

Owner:HARBIN INST OF TECH

Preparation method of enhanced silicon dioxide aerogel composite material

The invention belongs to the field of heat insulation materials, and discloses a preparation method of an enhanced silicon dioxide aerogel composite material. A fiber material is pretreated through a two-step pretreatment method to enable hydroxyl groups and Si-OR groups to be attached to surface of the fiber material, and then an enhanced silicon dioxide aerogel composite material is prepared through sol-gel and drying processes. The prepared silicon dioxide aerogel composite material has a high-strength, more complete and uniform aerogel network framework, the framework strength between fibers and silicon dioxide particles and the framework strength between the silicon dioxide particles are greatly improved, and compared with an existing silicon dioxide aerogel composite material, the silicon dioxide aerogel composite material has excellent compression performance.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

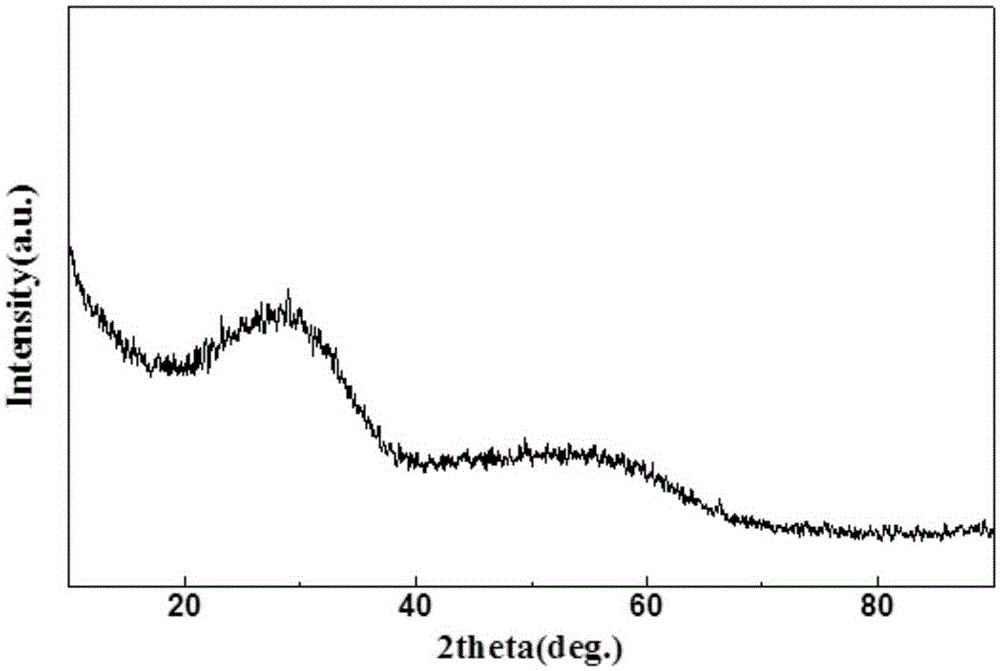

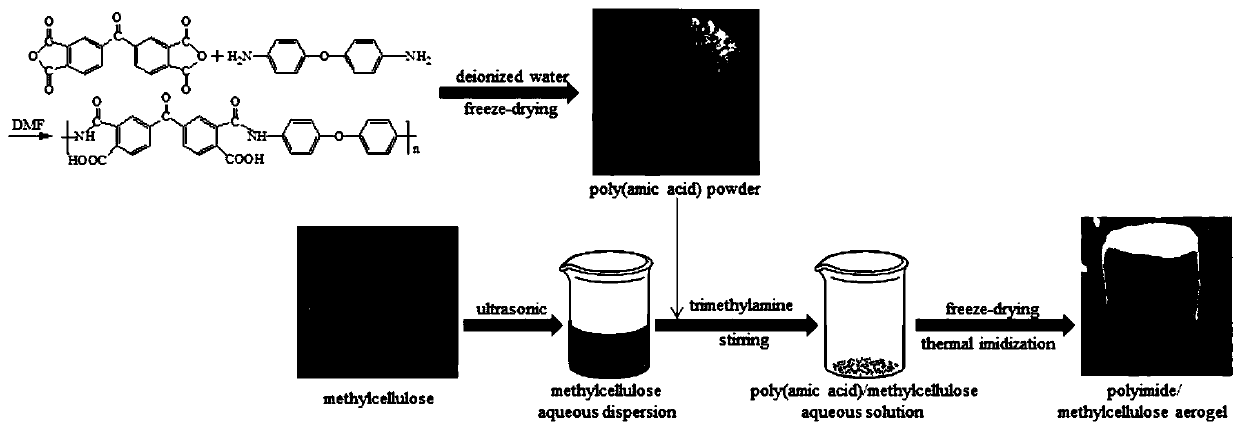

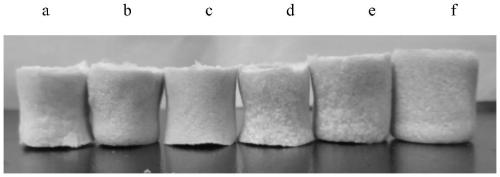

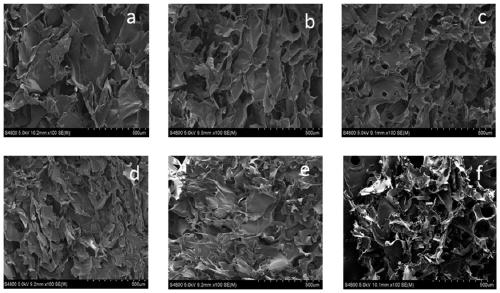

Preparation method cellulose / polyimide composite aerogels

The invention discloses a preparation method cellulose / polyimide composite aerogels, and belongs to the technical field of materials. The preparation method includes the following steps: polyamic acid is dissolved in a cellulose aqueous dispersion through a solubilizer; through freezing, drying, and thermal imidization, the cellulose / polyimide composite aerogels are obtained. The preparation method has the advantages of simpleness, high efficiency, low requirements for equipment, an extensive application scope and friendly environment. The problem that traditional polyimide type high-performance composite aerogels are difficult to prepare is effectively avoided. The obtained composite aerogels can be applied to air adsoprtion, organic substance adsorption, heat insulation materials andthe like and have great potential application value in the field of air pollution treatment, water pollution treatment, heat insulation structured materials and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing carbon aerogel by utilizing normal-pressure drying

InactiveCN111498828AAvoid complex processesLow shrinkageCarbon preparation/purificationAerogel preparationSupercritical dryingPtru catalyst

The invention belongs to the technical field of preparation of carbon aerogel, and specifically relates to a method for preparing carbon aerogel by using normal-pressure drying. The preparation methodcomprises the following steps: introducing a reinforcing agent into a reaction monomer and catalyst system, preparing wet gel by using a sol-gel method, carrying out aging treatment on the wet gel, replacing moisture in the wet gel by using a low-surface-tension solvent, putting the wet gel into air, carrying out normal-pressure drying to obtain organic aerogel, and carbonizing the organic aerogel to obtain carbon aerogel, wherein the reaction monomers are resorcinol and formaldehyde, and the reinforcing agent is high-molecular polymer F127; according to the method disclosed by the invention,complex processes of a conventional supercritical drying method and a freeze drying method are avoided, meanwhile, the shrinkage rate of the carbon aerogel material in a normal-pressure drying process is greatly reduced, and the supercapacitor electrode material with excellent performance can be obtained at a low price.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

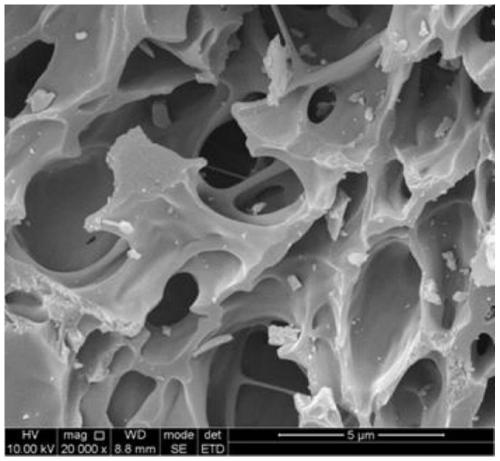

Preparation method of graphene/waste polyurethane composite material

The invention belongs to the technical field of waste polyurethane recovery and reutilization, and particularly relates to a preparation method of a graphene / waste polyurethane composite material. According to the method disclosed by the invention, the waste polyurethane rigid foam subjected to crushing and a polyol, graphene oxide and additive blending system meeting different functional requirements are degraded and recycled according to a certain proportion for reutilization, and the graphene oxide / waste polyurethane composite material with excellent performance is prepared by utilizing a degradation product. The material has good thermal stability, thermal insulation performance and the like, and the apparent density, the compression strength, the water absorption rate and the like are all higher than national standards. In the recovery process, three wastes are not discharged, the method is green and environment-friendly, the recovery utilization rate of the waste polyurethane is close to 100%, and the degradation product can be directly utilized without subsequent treatment, so that the cost of the polyurethane rigid foam product is greatly reduced.

Owner:山东东特环保科技有限公司

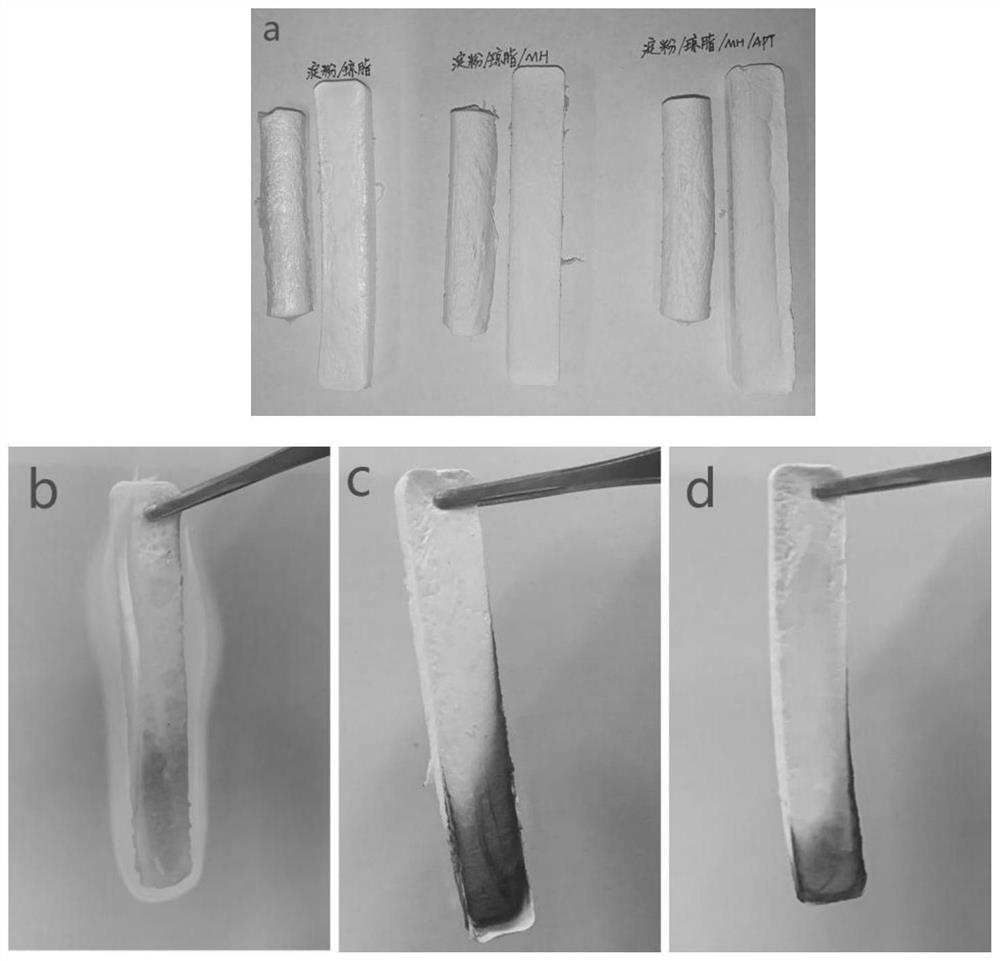

Preparation method of starch/agar composite base flame-retardant aerogel

The invention discloses a preparation method of starch / agar composite base flame-retardant aerogel. The preparation method comprises the following steps of: stirring and heating starch and agar powder in a water bath kettle, and dissolving to obtain starch / agar mixed sol; and carrying out ultrasonic dispersion on a mixed suspension of magnesium oxide powder and attapulgite clay, then adding the mixed suspension into the mixed sol, continuing heating and stirring, cooling and condensing to obtain composite hydrogel, freezing the obtained composite hydrogel in a refrigerator, and then freeze-drying in a vacuum freeze-drying machine. According to the invention, starch / agar composite aerogel is used as a carrier skeleton, and a flame retardant magnesium hydroxide is introduced into polymer aerogel in a simple and economical in-situ generation manner, so that the problem of poor compatibility of magnesium hydroxide and a polymer matrix is solved; and by adding the mineral clay which is rich in reserves and has the flame-retardant characteristic, the high addition of the magnesium hydroxide is reduced, the prepared composite aerogel has a good flame-retardant effect, the mechanical property is also improved, and the composite aerogel has a certain application prospect in the field of building heat preservation.

Owner:LANZHOU JIAOTONG UNIV

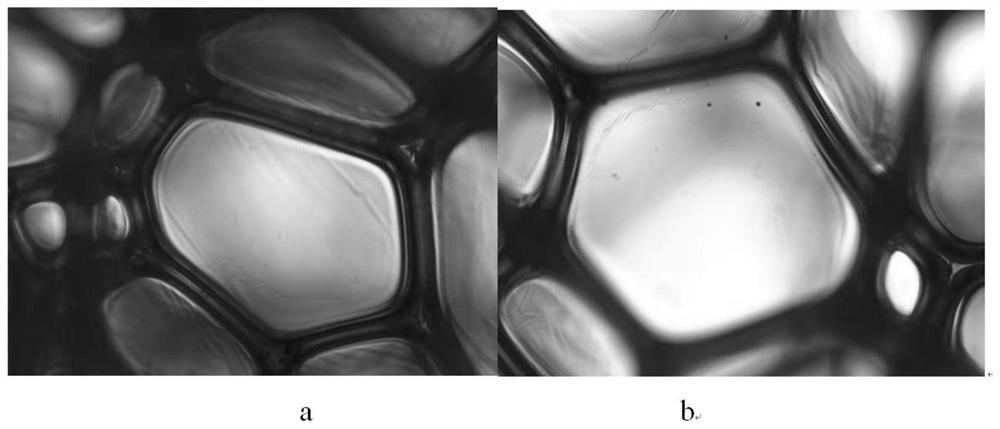

High-strength low-density poly(4-methyl-1-pentene) foam and preparing method thereof

The invention relates to a high-strength low-density poly(4-methyl-1-pentene) foam and belongs to the field of polymer materials. The high-strength low-density poly(4-methyl-1-pentene) foam is prepared from, by mass, 50-99.8% of poly(4-methyl-1-pentene) and 0.2-50% of an enhancer, wherein the enhancer is composed of at least one of a polymer enhancer and an inorganic enhancer. By adding the enhancer into traditional low-density poly(4-methyl-1-pentene) foam, the framework strength of the low-density poly(4-methyl-1-pentene) foam is remarkably improved, and then the processability of the foam and the mechanical property of the foam are improved. The invention further provides a preparing method of the high-strength low-density poly(4-methyl-1-pentene) foam. The preparing method is easy to implement and stable in technology, too complicate equipment is not needed, the high-strength low-density poly(4-methyl-1-pentene) foam can be efficiently obtained with a few of simple steps, and the obtained foam product is stable in parameter and high in repeatability.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Preparation method of polyaniline/straw-based silica aerogel and thermal-insulation anticorrosive coating

ActiveCN113121871AImprove skeleton strengthSuitable for industrial productionAnti-corrosive paintsAcid catalysisPhysical chemistry

The invention belongs to the technical field of coatings, and discloses a preparation method of polyaniline / straw-based silica aerogel and a thermal-insulation anticorrosive coating. The preparation method of the polyaniline / straw-based silica aerogel comprises the following steps of (1) mixing and heating straw ash and a NaOH solution, carrying out suction filtration to obtain straw-based water glass, adding deionized water, and stirring to obtain a straw-based water glass solution, (2) adding hydrochloric acid to adjust the pH value, adding a mixed solution of aniline and hydrochloric acid, dropwise adding an ammonium persulfate solution, and keeping the temperature not higher than 5 DEG C until the polymerization reaction is completed, (3) after the reaction is completed, dropwise adding a NaOH solution until the pH value is 7-9, standing to form hydrogel, aging and standing the hydrogel, and respectively soaking the hydrogel with ethanol and deionized water to obtain straw / polyaniline composite hydrogel, and (4) drying treatment. The polyaniline is prepared through in-situ polymerization in the acid catalysis process of the silicon-based aerogel, and the obtained aerogel is high in compressive strength, small in porosity, low in heat conductivity coefficient and excellent in heat preservation effect.

Owner:吉林省陆柒肆伍贰科技有限公司

Mechanical-enhanced SiO2 aerogel material and preparation method thereof

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

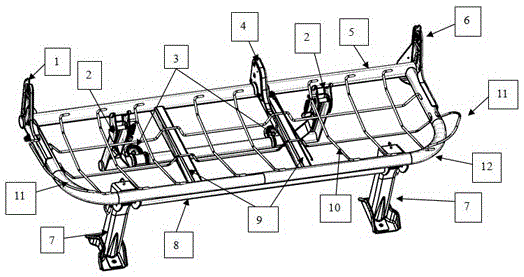

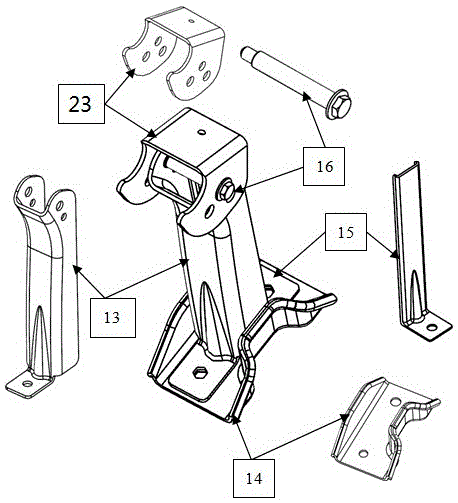

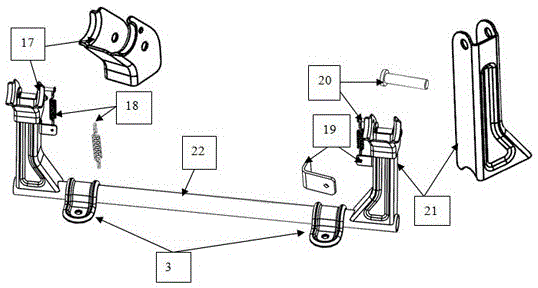

Automobile back-row seat cushion framework assembly

The invention provides an automobile back-row seat cushion framework assembly which comprises a supporting assembly, a cushion frame and a cushion grid assembly. The supporting assembly is connected with the cushion frame. The cushion grid assembly is connected with the cushion frame. The cushion frame comprises a cushion pipe frame, a cushion rear supporting pipe and cushion supporting longitudinal beams. The two ends of the cushion pipe frame are connected with the two ends of the cushion rear supporting pipe respectively. A closed frame is defined by the cushion pipe frame and the cushion rear supporting pipe. One end of each cushion supporting longitudinal beam is connected with the cushion pipe frame, and the other end of each cushion supporting longitudinal beam is connected with the cushion rear supporting pipe. The cushion grid assembly is erected on the cushion supporting longitudinal beam. The automobile back-row seat cushion framework assembly has the advantages that the framework strength is improved, the structure is simplified and precision requirements are lowered.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

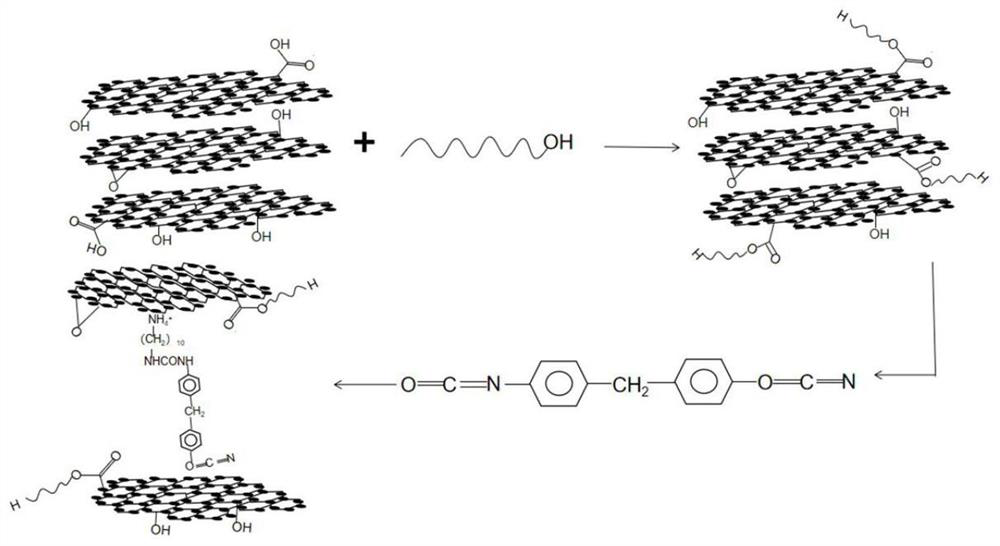

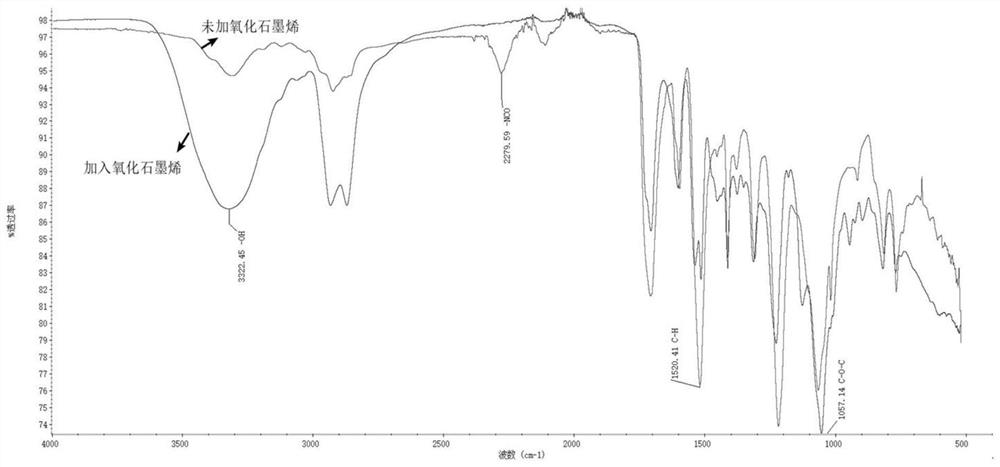

Polylactic acid scarf polyurethane environment-friendly waterproof coating and preparation process thereof

ActiveCN108531067APromote degradationGood compatibilityPolyurea/polyurethane coatingsDibenzoyl PeroxideIsophorone diisocyanate

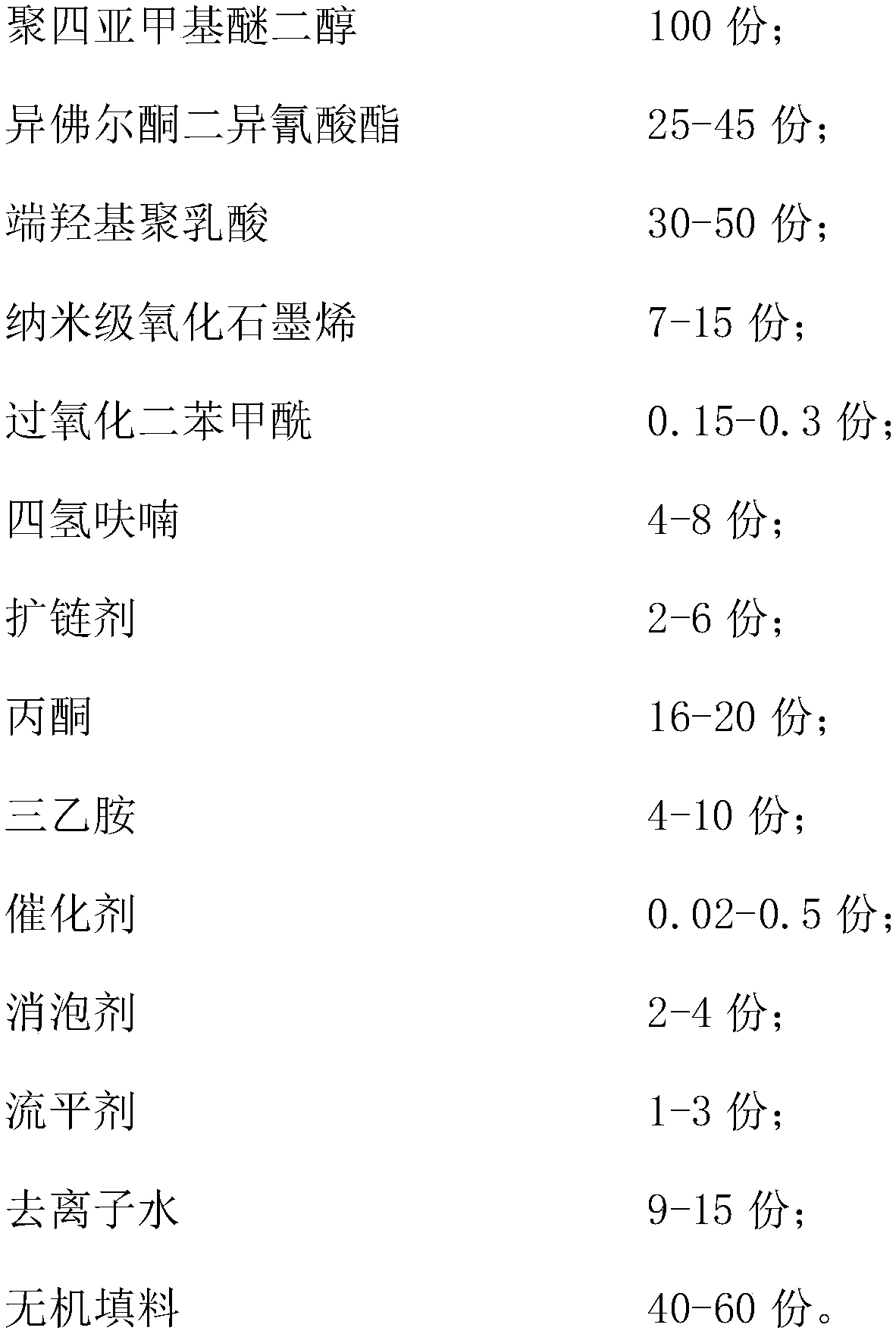

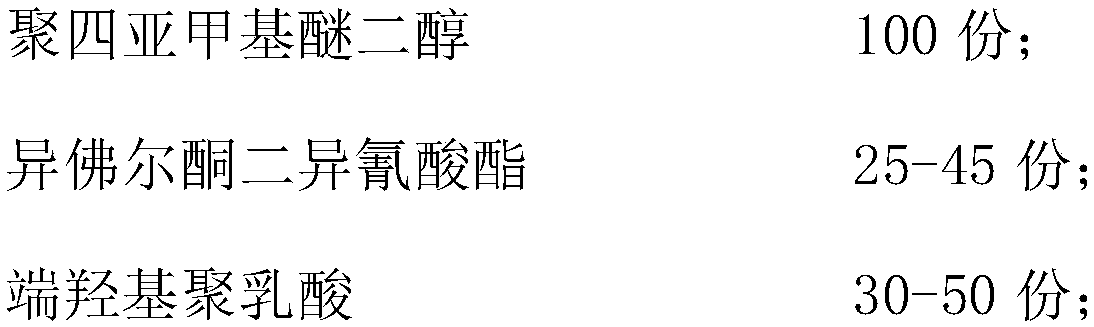

The invention discloses a polylactic acid scarf polyurethane environment-friendly waterproof coating and a preparation process thereof. The waterproof coating comprises, by weight, 100 parts of polytetramethylene ether glycol, 25-45 parts of isophorone diisocyanate, 30-50 parts of hydroxyl-terminated polylactide, 7-15 parts of nano-scale oxidized graphene, 0.15-0.3 part of dibenzoyl peroxide, 4-8parts of tetrahydrofuran, 2-6 parts of chain extenders, 16-20 parts of acetone, 4-10 parts of triethylamine, 0.02-0.5 part of catalysts, 2-4 parts of defoaming agents, 1-3 leveling agents, 9-15 partsof deionized water and 40-60 parts of inorganic fillers. Graphene grafted polylactic acid copolymers are embedded into a polyurethane main chain, active groups such as ester bonds and carboxyl are introduced, the biological degradability and compatibility of the polyurethane coating are improved, and a degradation product is poisonless, harmless, green and environmentally friendly.

Owner:安徽朗凯奇科技股份有限公司

High-strength ceramsite containing sludge ash and preparation method thereof

InactiveCN111517820AEliminate the problem of relatively high organic matter contentIncrease incorporationCeramic materials productionCeramicwareMetallurgySludge

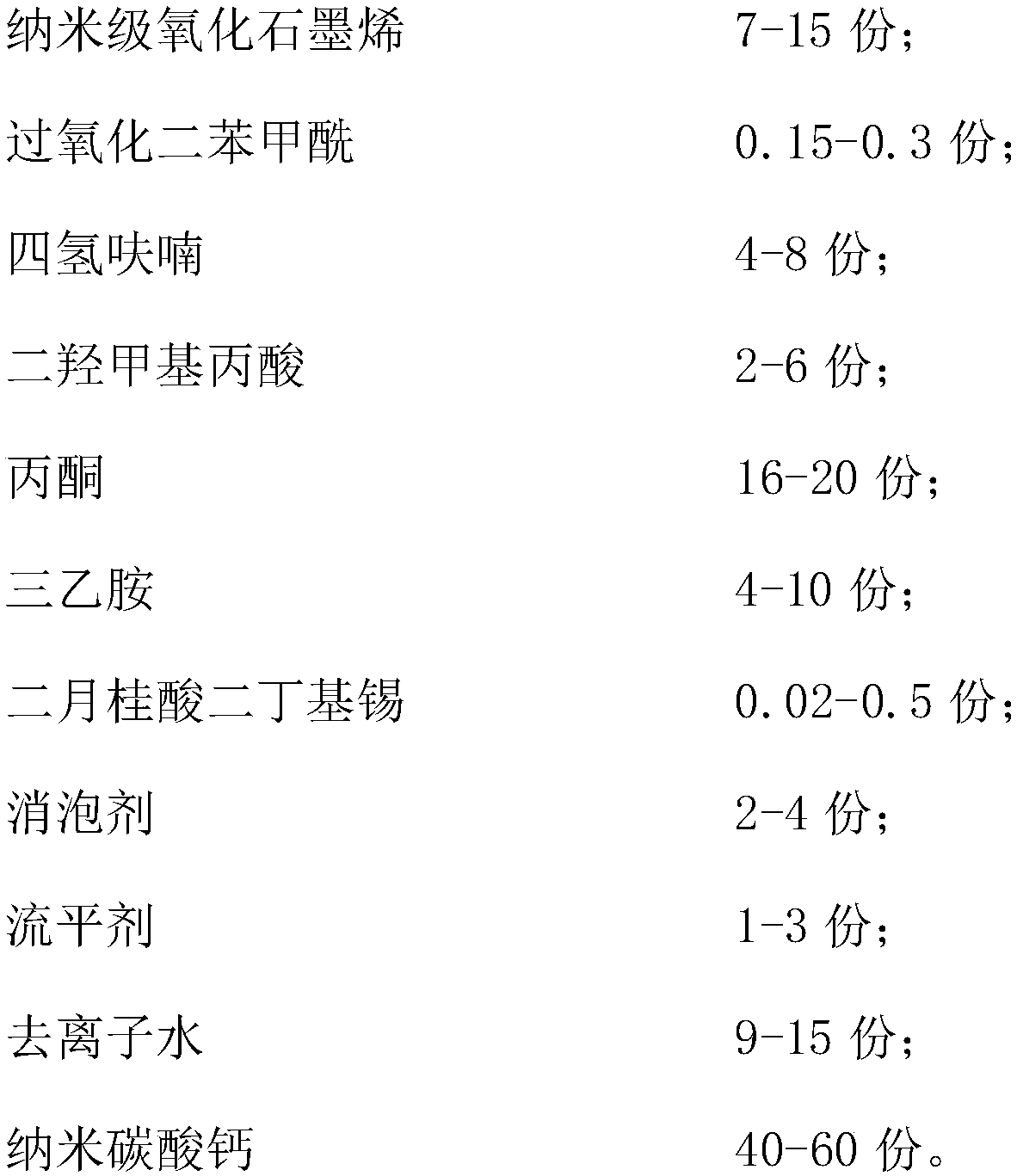

The invention belongs to the technical field of artificial light aggregate, and particularly relates to high-strength ceramsite containing sludge ash and a preparation method of the high-strength ceramsite. The high-strength ceramsite is prepared from the following raw materials in percentage by weight: 10 to 90 percent of sludge ash and 10 to 90 percent of engineering spoil, the preparation method of the ceramsite comprises the following steps: S1, crushing the sludge ash and the engineering spoil according to a ratio, and mixing; S2, grinding an obtained mixture until the screen residue of 80 microns is 15-30%, and preparing raw material spheres with the size of 5-20mm by using a disc granulator; S3, drying the raw material spheres; S4, putting the dried raw material spheres into a muffle furnace, heating from room temperature to 200 DEG C, and keeping the temperature; raising the temperature from 200 DEG C to 600-700 DEG C and then keeping the temperature; and finally, increasing the temperature to 1080-1200 DEG C again, carrying out heat preservation for 20-30 min, and then carrying out natural cooling to the normal temperature. The method solves the problem that high-strengthceramsite cannot be prepared from municipal sludge in a large mixing amount due to high water content and high organic matter content.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

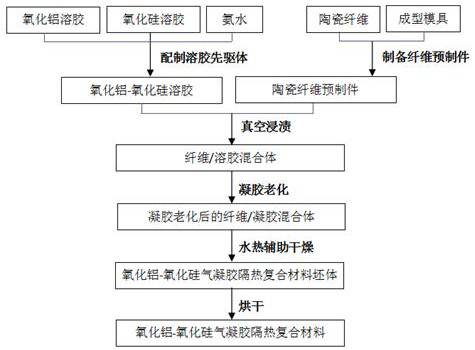

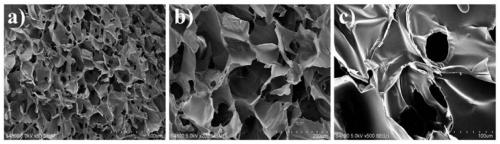

A kind of preparation method of alumina-silica aerogel thermal insulation composite material

Owner:NAT UNIV OF DEFENSE TECH

Coordination crosslinking type polyimide aerogel and preparation method thereof

ActiveCN111574747AImprove skeleton strengthHigh strengthBulk chemical productionPolymer scienceFreeze-drying

The invention discloses coordination crosslinking type polyimide aerogel and a preparation method thereof, and belongs to the technical field of materials. According to the invention, the polyamide acid hydrogel is prepared under the action of the auxiliary agent and the surfactant in an aqueous solution system; the method then includes introducing metal ions to coordinate and crosslink the polyamic acid hydrogel to prepare coordination crosslinking type polyamic acid hydrogel; then carrying out freeze drying and thermal imidization to obtain coordination cross-linking type polyimide aerogel;the method has the advantages of being simple, efficient, low in equipment requirement, wide in application range and environmentally friendly; the problem that traditional polyimide high-performanceaerogel is difficult to prepare can be effectively avoided, and the obtained aerogel can be used for gas adsorption, organic matter adsorption, heat insulation materials and the like and has high potential application value in the fields of air pollution treatment, water pollution treatment, heat insulation structural materials and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing starch carbon-based Fenton-like catalyst based on EDTA chelation technology

ActiveCN113828314AImprove skeleton strengthHigh catalytic efficiencyWater treatment compoundsWater contaminantsEthylene diamine tetra aceticEthylene diamine

The invention belongs to the technical field of catalysts, and provides a method for preparing a starch carbon-based Fenton-like catalyst based on an EDTA chelation technology, the method comprises the following steps: firstly, cross-linking starch and disodium ethylene diamine tetraacetate EDTA-2Na by using a cross-linking agent to form a high polymer; uniformly chelating a large amount of metal ions on a high polymer by using ammonia nitrogen and carboxyl oxygen functional groups with extremely strong coordination ability in disodium ethylene diamine tetraacetate, so that the metal loading capacity of the catalyst is improved, and the prepared Fenton-like catalyst is high in skeleton strength, high in catalytic efficiency and low in metal ion dissolution rate; meanwhile, incomplete carbonization is generated by utilizing low-temperature hydrothermal carbonization so that tar and volatile gas are prevented from being generated, and the yield is as high as 50%. Results of the embodiment show that when the starch carbon-based Fenton-like catalyst prepared by the preparation method is used for degrading rhodamine B, the degradation efficiency can reach 98.9% within 10 minutes, and after five times of circulation, the degradation rate of rhodamine B can still reach 96.5% within 15 minutes.

Owner:GUANGXI ACAD OF SCI

Aluminium alloy material with good forging and pressing property

The invention relates to an aluminium alloy material with good forging and pressing property. The aluminium alloy material comprises the following components in percentage by mass: 4.8-5.0% of copper, 0.3-0.35% of tin, 0.35-0.50% of bismuth, 0.6-0.65% of zinc, 0.03-0.045% of iron, 0.01-0.015% of chromium, 0.01-0.25% of magnesium and the balance of inevitable impurities. The magnesium is added to the aluminium alloy material, so that on the one hand, the skeleton strength of the copper in the aluminium alloy can be improved, and on the other hand, cracks are prevented from occurring by increasing the size of the magnesium, tin, bismuth and zinc compound and reducing the coefficient of thermal deformation.

Owner:黄宣斐

Ceramsites prepared from coal gangue and coal slime, and preparation method for ceramsites

ActiveCN103319192BHigh in ironLower iron levelsSolid waste disposalCeramicwareExpanded clay aggregateMuffle furnace

The invention discloses ceramsites prepared from coal gangue and coal slime and a preparation method for the ceramsites, and belongs to the technical field of artificial light aggregates. The ceramsites are obtained by roasting a mixture comprising the coal gangue, the coal slime, quartz sands and feldspar. The preparation method for the ceramsites comprising steps of porphyrizing and sieving three raw materials to obtain raw materials whose particle sizes are less than 200 meshes, wherein the three raw materials comprise, by weight, 60% to 80% of the coal gangue, 5% to 10% of the quartz sands and 10% to 20% of the feldspar; mixing the raw materials with the coal slime to obtain the mixture, wherein the weight percentage content of the coal slime is 10% to 30%; balling the mixture; carrying out high temperature roasting to spheres in a muffle furnace after the spheres being dried; and carrying out a cooling treatment to obtain products. The ceramsites are characterized by no aperture on the surface, high strength and uniform size, and can widely used in the field of engineering construction, chemical engineering, etc.

Owner:柳州紫荆生态工程科技有限公司

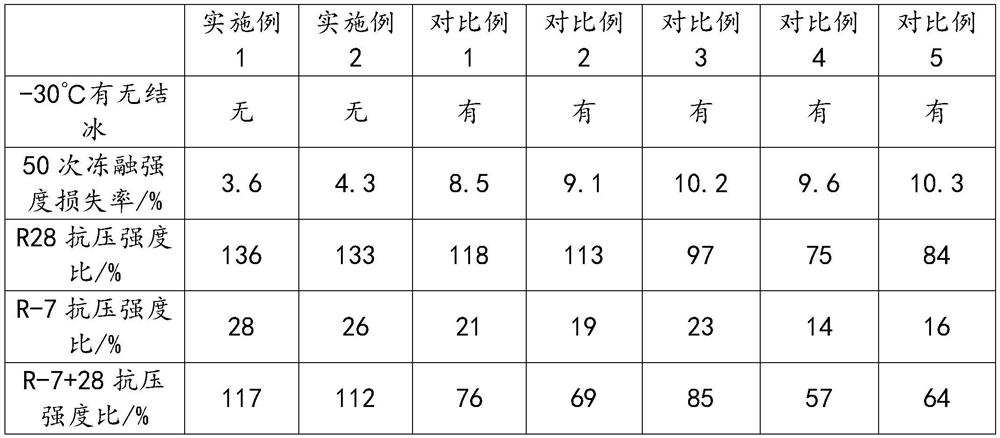

A kind of concrete antifreeze and preparation method thereof

The invention provides a concrete antifreeze and a preparation method thereof. The antifreeze of the present invention comprises 35-50 parts of modified calcium sulfate crystal whiskers, 5-10 parts of calcium formate, 6-12 parts of modified diatomaceous earth, 4-8 parts of urea, and 15-25 parts of sodium lignosulfonate, 8-15 parts of solid alcohol amine, the above parts are by weight. Through the combination, ratio and synergistic ratio of the above substances, a concrete antifreeze agent that can work at ‑30℃ is prepared, which improves the freeze-thaw resistance of concrete. Corrosion, has good durability.

Owner:山东高速集团有限公司创新研究院 +1

A kind of high-strength ceramsite and preparation method thereof

ActiveCN110128109BHigh cylinder compressive strengthHigh bulk densityCeramic materials productionCeramicwareExpanded clay aggregateUltimate tensile strength

The invention belongs to the technical field of artificial lightweight aggregates and discloses a high-strength ceramsite and a preparation method thereof. The high-strength ceramsite comprises the raw materials: decarbonized coal slime, project spoil and iron raw materials; the method comprises the following steps: S1, mixing the decarbonized coal slime, the project spoil and a small deal of ironraw materials according to the mass percentage, and then, grinding the mixture by using a ball mill to obtain 15%-30% of 80-m um sieving residues; and S2, preparing a raw sphere by using a disc pelletizer; raising the temperature from the room temperature to 200 DEG C in a muffle furnace, and keeping the temperature; then, raising the temperature to 600 DEG C, and keeping the temperature; and finally, raising the temperature to 1180-1195 DEG C, keeping the temperature, and carrying out natural cooling to the normal temperature to obtain a finished product of the high-strength ceramsite. The high-strength ceramsite is prepared without adding other additives such as 15-30% of quartz sand and feldspar, and the prepared ceramsite has the advantages such as hard surface texture, relatively light volume weight, high cylinder compressive strength and low water absorption rate.

Owner:TIANJIN CEMENT IND DESIGN & RES INST

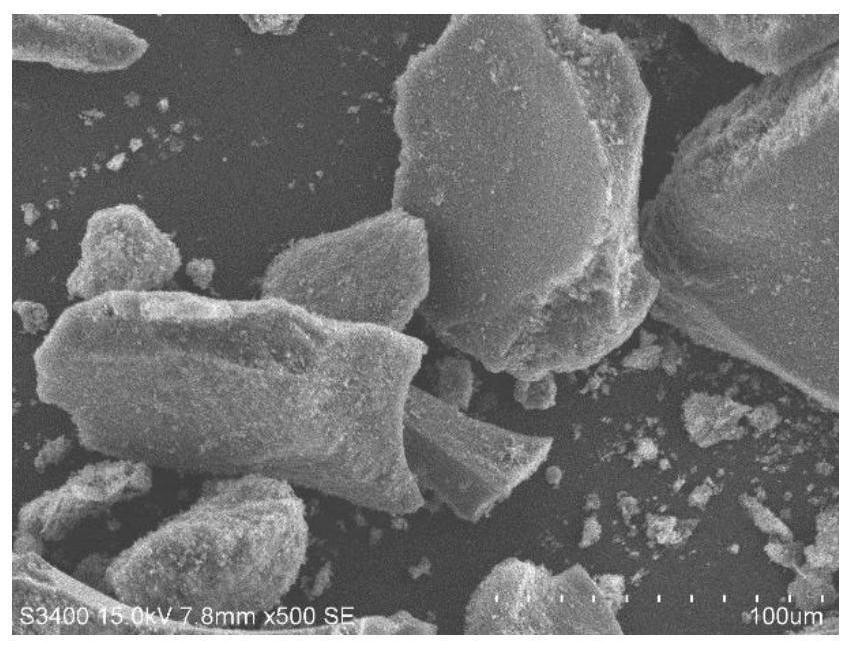

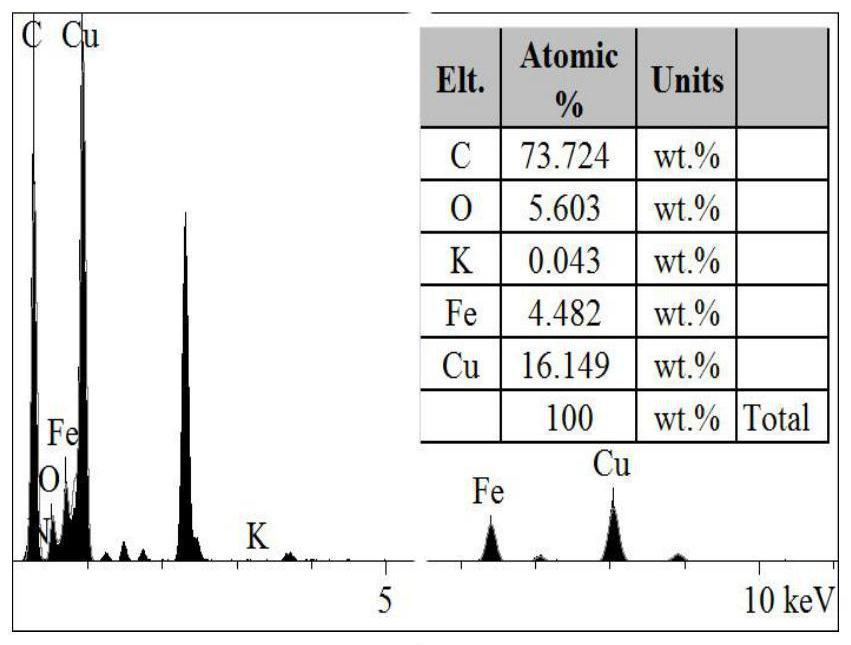

A metal-doped nitrogen-containing carbon-based catalyst for fuel cells and its application

ActiveCN103682379BStructurally effective regulationEffective control of morphologyCell electrodesFuel cellsReduction ActivitySurface-active agents

The invention relates to a metal-doped nitrogen-containing carbon-based catalyst of a fuel cell and application of the catalyst. The catalyst adopts organic surface active agents as a protection agent and a structural guide agent and adopts an aromatic compound and aldehyde as reaction monomers, metal elements are added in the reaction process to obtain a polymer-metal compound, and the polymer-metal compound is dried and then is subjected to high-temperature processing with inert gas or / and ammonia gas to finally obtain the metal-doped nitrogen-containing carbon-based catalyst. When the metal-doped nitrogen-containing carbon-based catalyst is used as a cathode catalyst of a proton exchange membrane fuel cell and a direct-methanol fuel cell, the oxide reduction activity, stability and toxicity resistance are excellent; moreover, the catalyst has an environment-friendly effect, is low in cost, controllable in aperture, high in specific surface area and rich in resource and can substitute for platinum to serve as an electric catalyst of the proton exchange membrane fuel cell.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Refractory wear-resistant pouring material and preparation method thereof

The invention discloses a refractory wear-resistant pouring material and a preparation method thereof. The refractory wear-resistant pouring material comprises the following raw material components in percentage by mass: 60-80% of graded ceramic particles, 5-25% of mixed matrix slurry, 4-15% of an adhesive and 6-10% of water, wherein the graded ceramic particles are divided into four granularity grades, and comprise ceramic particles of 8-5mm, ceramic particles of 5-3mm, ceramic particles of 3-1mm and ceramic particles of 1-0mm; and the mixed matrix slurry comprises milled natural river sand, alumina micro powder of 5-10 microns, silica fume, micro steel fibers and a dispersing agent solution. The fire resistance of silicon carbide ceramics is utilized, the cracking phenomenon caused by excessive CaO doping in the traditional cement refractory castable is avoided by adopting a complex adhesive, and steel fibers and boron fibers are introduced, so that the strength and wear resistance of the pouring material are improved on the basis of ensuring the fire resistance.

Owner:宜兴市张泽浇注耐火材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com