A kind of concrete antifreeze and preparation method thereof

A technology of antifreeze and concrete, which is applied in the field of concrete antifreeze and its preparation, which can solve the problems that the antifreeze performance of concrete cannot be improved, and achieve the effects of reasonable distribution of hydration products, enhanced strength, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

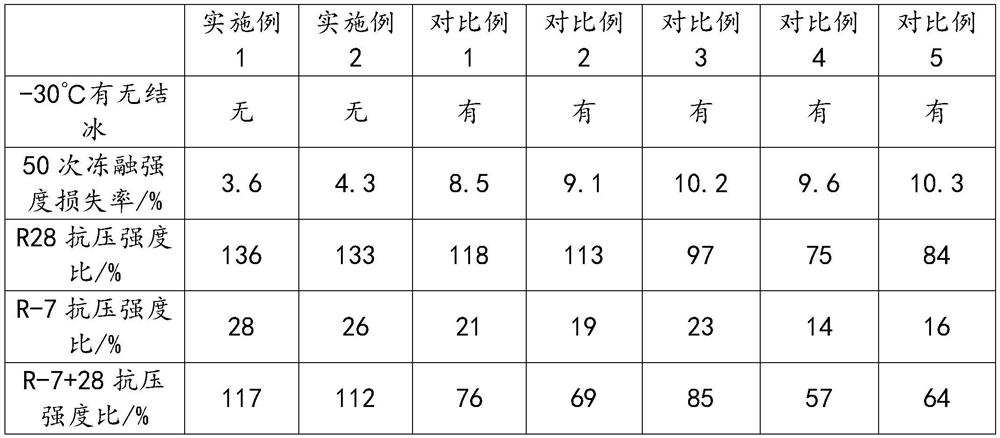

Examples

Embodiment 1

[0016] An antifreeze agent for concrete comprises: 45 parts of modified calcium sulfate crystal whiskers, 8 parts of calcium formate, 10 parts of modified diatomaceous earth, 6 parts of urea, 20 parts of sodium lignosulfonate, and 11 parts of solid alcohol amine.

[0017] The preparation method of the modified calcium sulfate crystal whisker is as follows: the calcium sulfate crystal whisker is weighed and added to the modifier solution, stirred and reacted at 80° C. for 30 minutes, and then separated and dried. Wherein the modifier is sodium dodecylbenzenesulfonate, the mass ratio of calcium sulfate whisker to sodium dodecylbenzenesulfonate is 1:0.01; the stirring speed is 1000r / min.

[0018] The preparation method of the modified diatomite is as follows: weighing the diatomite, adding it into the modifier solution, stirring and reacting at 120° C. for 60 minutes, and then separating it. The modifier is KH570, the mass ratio of diatomite and modifier is 1:0.05, and the stirri...

Embodiment 2

[0021] A concrete antifreeze, comprising: the composition of the concrete antifreeze is: 40 parts of modified calcium sulfate whiskers, 10 parts of calcium formate, 7 parts of modified diatomaceous earth, 8 parts of urea, 25 parts of sodium lignosulfonate, solid 10 parts of alcohol amines.

[0022] The preparation method of the modified calcium sulfate crystal whisker is as follows: the calcium sulfate crystal whisker is weighed and added to the modifier solution, stirred and reacted at 70° C. for 30 minutes, and then separated and dried. Wherein the modifier is sodium dodecylbenzenesulfonate, the mass ratio of calcium sulfate whisker and sodium dodecylbenzenesulfonate is 1:0.03; the stirring speed is 1000r / min.

[0023] The preparation method of the modified diatomite is as follows: weighing the diatomite, adding it into the modifier solution, stirring and reacting at 120° C. for 60 minutes, and then separating it. The modifier is KH570, the mass ratio of diatomite and modif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com