Method for preparing starch carbon-based Fenton-like catalyst based on EDTA chelation technology

A catalyst and starch technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of low catalytic efficiency, inability to fix uniformly and effectively, and large copper ion dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

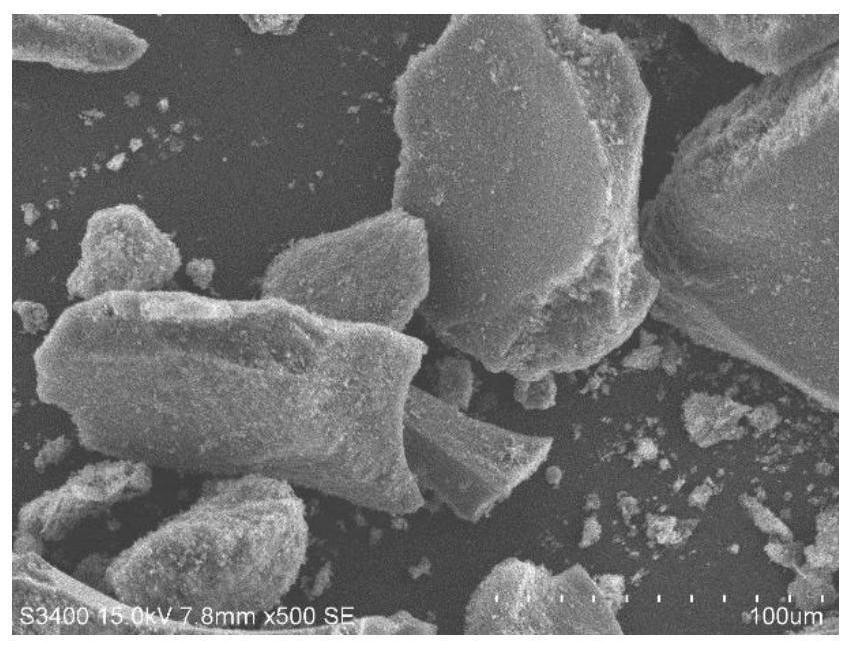

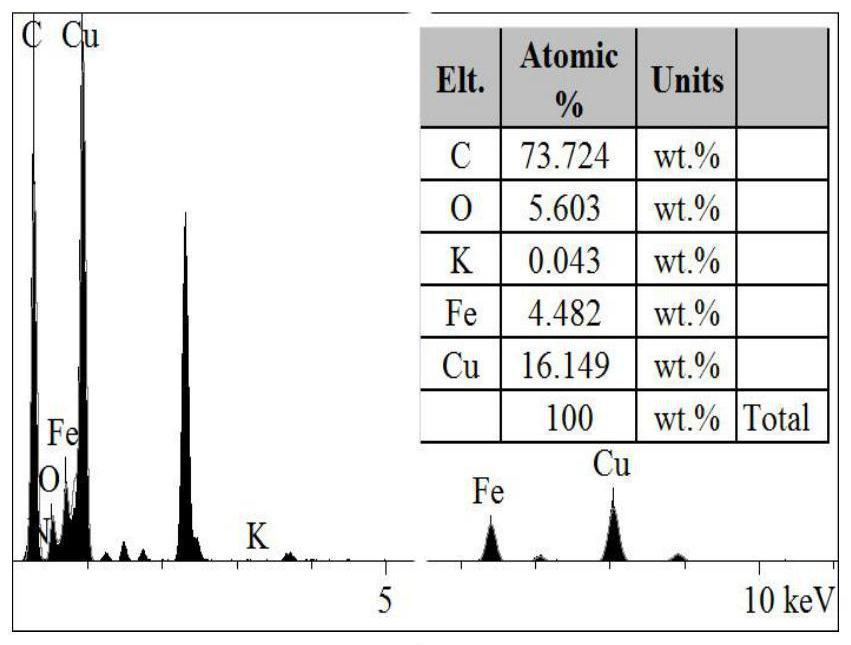

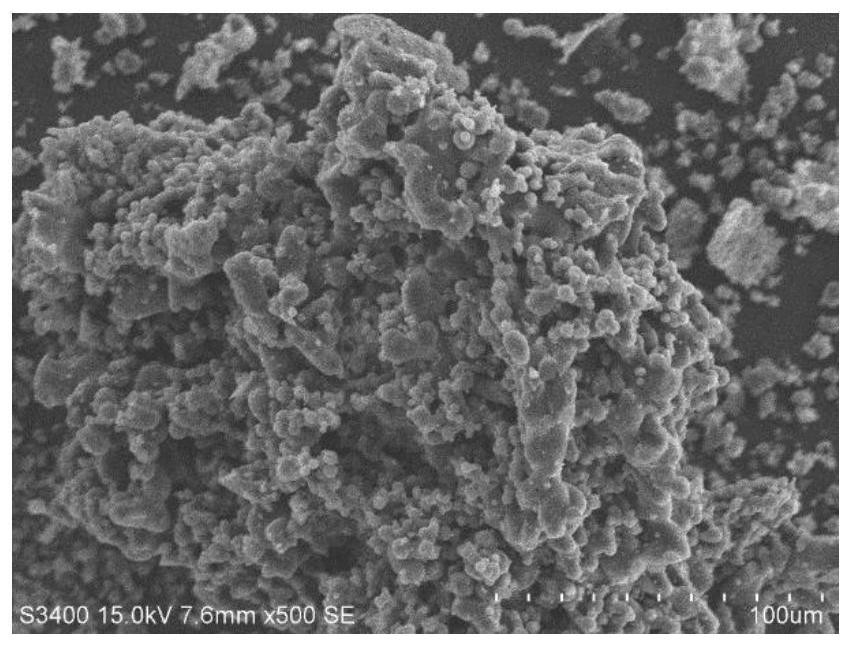

Image

Examples

Embodiment 1

[0055] (1) Add 100 parts of deionized water, 100 parts of cornstarch and 2 parts of NaCl into a three-necked round-bottomed flask, mechanically stir at a speed of 200r / min, adjust the pH value to 10.0, add 5 parts of ethylenediaminetetraacetic acid di Sodium EDTA-2Na, then drop 3 parts of epichlorohydrin, and heat it in a water bath to 55°C for 300 minutes to obtain a cross-linked polymer; among them, deionized water, corn starch, ethylenediaminetetraacetic acid disodium EDTA-2Na and The mass ratio of epichlorohydrin is 100:100:5:3;

[0056] (2) Add 1 part of FeCl dissolved in 20 parts of deionized water to the cross-linked polymer obtained in step (1) 3 ·6H 2 O and 3 parts CuCl 2 2H 2 O, maintain a stirring speed of 200r / min, react at 85°C for 360min, and then cool to room temperature to obtain a catalyst precursor;

[0057] (3) Place the catalyst precursor obtained in step (2) in a polytetrafluoroethylene hydrothermal reaction kettle, and treat it with hot water at 220°C...

Embodiment 2

[0061] (1) Add 100 parts of deionized water, 100 parts of corn starch, and 2 parts of NaCl into a three-necked round-bottomed flask, mechanically stir at a speed of 200r / min, adjust the pH value to 10.0, and then add 5 parts of ethylenediaminetetraacetic acid Disodium EDTA-2Na, then drop 3 parts of epichlorohydrin, heat in a water bath to 55°C and react for 300 minutes to obtain a cross-linked polymer; among them, deionized water, corn starch, ethylenediaminetetraacetic acid disodium EDTA-2Na The mass ratio with epichlorohydrin is 100:100:5:3;

[0062] (2) Add 0.5 parts of FeCl dissolved in 20 parts of deionized water to the cross-linked polymer obtained in step (1) 3 ·6H 2 O and 3 parts CuCl 2 2H 2 O, maintain a stirring speed of 200r / min, react at 85°C for 360min, and then cool to room temperature to obtain a catalyst precursor;

[0063] (3) Place the catalyst precursor obtained in step (2) in a polytetrafluoroethylene hydrothermal reaction kettle, and treat it with hot ...

Embodiment 3

[0065] (1) Add 100 parts of deionized water, 100 parts of potato starch, and 2 parts of NaCl into a three-necked round-bottomed flask, mechanically stir at a speed of 200r / min, adjust the pH value to 10.0, and then add 5 parts of ethylenediaminetetraacetic acid Disodium EDTA-2Na, then drop 3 parts of sodium hexametaphosphate, and heat in a water bath to 55°C for 300 minutes to obtain a cross-linked polymer; among them, deionized water, potato starch, ethylenediaminetetraacetic acid disodium EDTA-2Na The mass ratio with cyclic sodium hexametaphosphate is 100:100:5:3;

[0066] (2) Add 1 part of FeCl dissolved in 20 parts of deionized water to the cross-linked polymer obtained in step (1) 3 ·6H 2 O and 2 parts CuCl 2 2H 2 O, maintain a stirring speed of 200r / min, react at 85°C for 360min, and then cool to room temperature to obtain a catalyst precursor;

[0067] (3) Place the catalyst precursor obtained in step (2) in a polytetrafluoroethylene hydrothermal reaction kettle, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com