Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Comply with industrial production requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

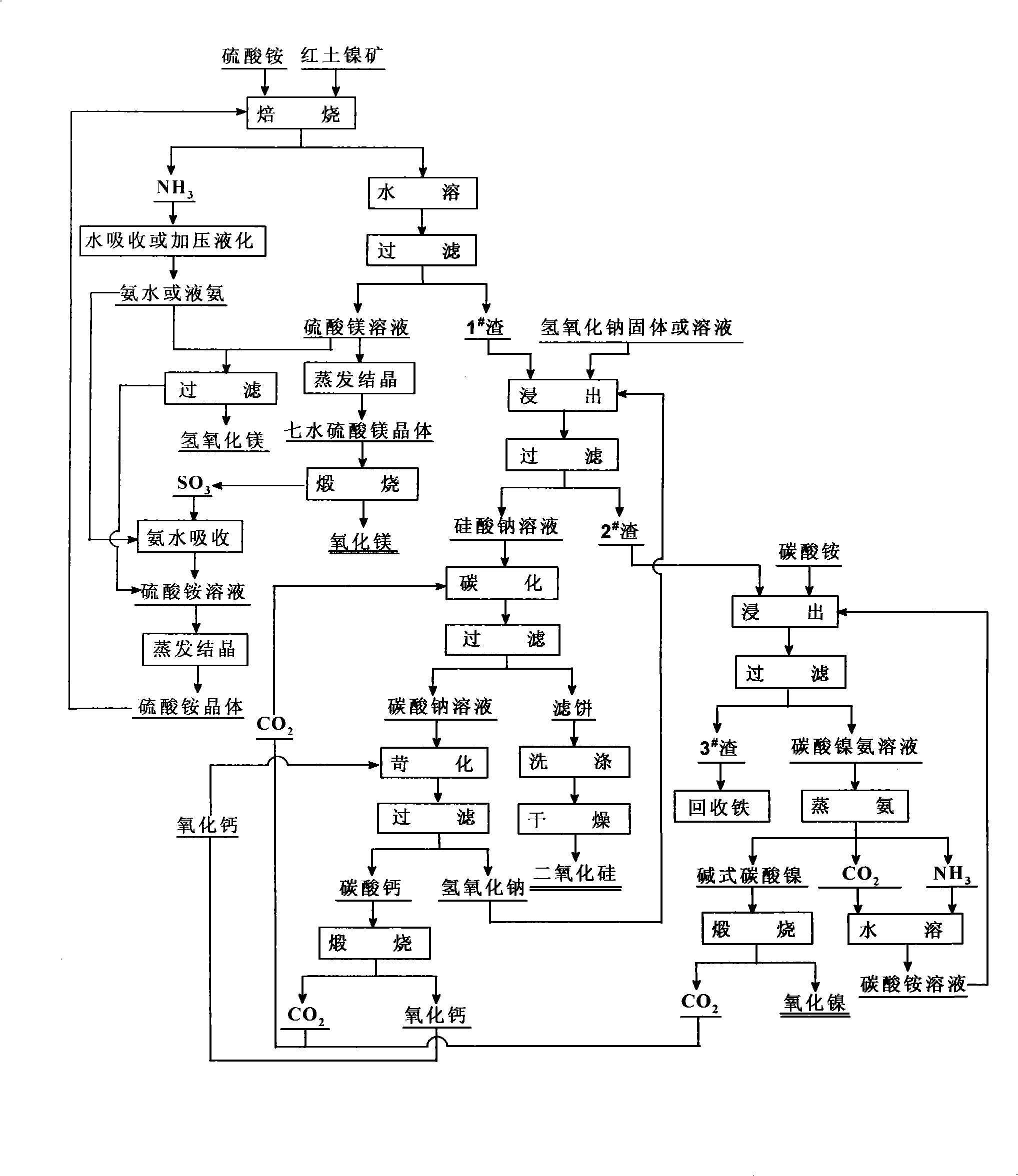

Method for preparing magnesia, silicon dioxide and nickel oxide products from lateritic nickel ore

InactiveCN101525143AHigh value-added comprehensive utilizationCause secondary pollutionSilicaNickel oxides/hydroxidesDiiron TrioxideSODIUM SILICATE SOLN

The invention relates to a method for preparing magnesia, silicon dioxide and nickel oxide products from lateritic nickel ores. The method comprises the following steps: (1), crushing, grinding and roasting the lateritic nickel ores with ammonium sulfate; (2), dissolving and filtering roasted products; (3), evaporating, condensing and crystallizing filtrate to prepare magnesium sulfate; (4), dehydrating and calcining the magnesium sulfate to prepare magnesia; (5), reacting filter residue with an alkaline solution or molten caustic soda, leaching and filtering the product of reaction to obtain a sodium silicate solution; (6), carbonizing, decomposing, filtering, washing and drying the sodium silicate solution to prepare the silicon dioxide; (7), leaching and filtering the residual filter residue by an ammonium carbonate solution; and (8), distilling ammonia from the filtrate and calcining the filtrate to prepare the nickel oxide. The residual residue is ferric oxide containing a small amount of impurities and can be used as an iron-making raw material or deep processed into a product with a high added value. The method is suitable for processing various lateritic nickel ores, has simple technological process and simple and convenient equipment, does not emit solid, liquid and gas waste or cause secondary pollution and uses lower cost to realize the high added value comprehensive utilization of lateritic nickel ore resources.

Owner:NORTHEASTERN UNIV

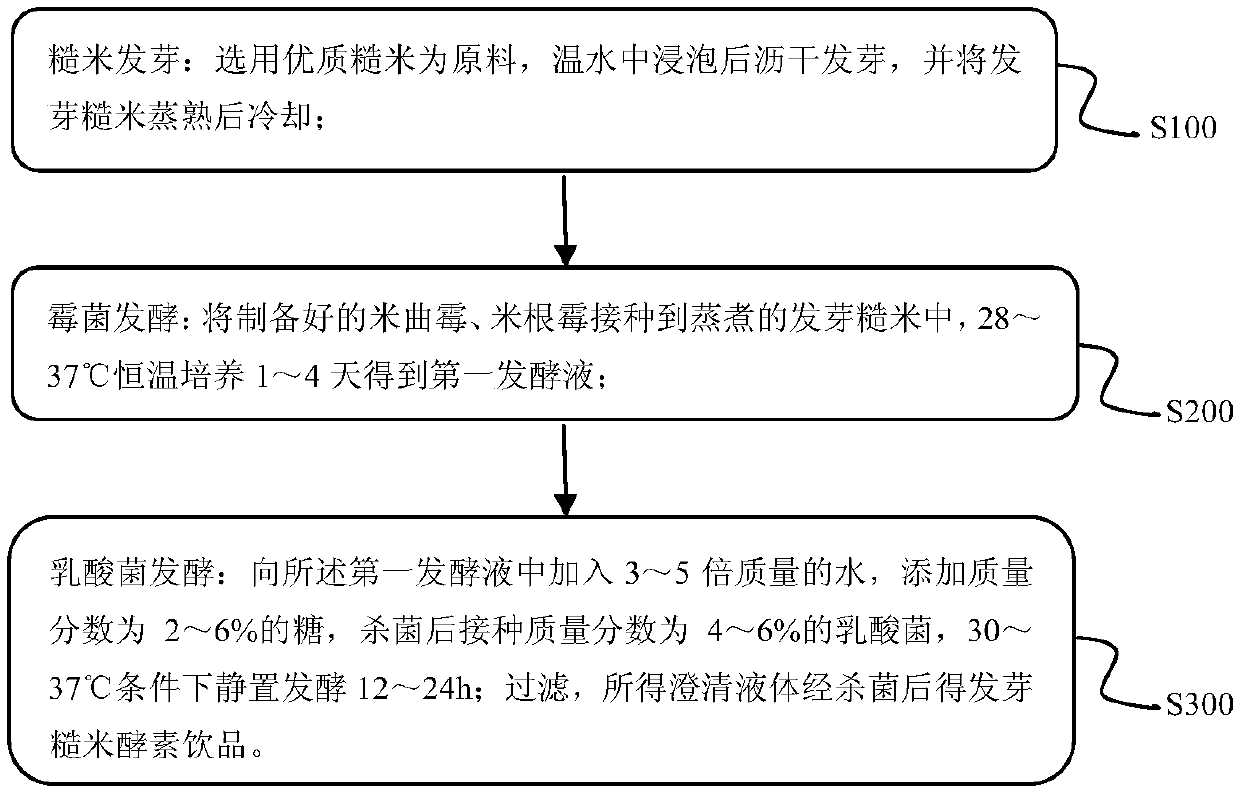

Method for preparing germinated brown rice ferment drink

InactiveCN108013305ASweet and sour tasteEasy to eatFood ingredient functionsAdditive ingredientEnzyme system

The invention relates to a method for preparing a germinated brown rice ferment drink. Germinated brown rice is processed in an Aspergillus oryzae and Rhizopus oryzae mixed culture manner, is decomposed by using the enzyme system complementarity, and is inoculated with lactic acid bacteria to carry out fermentation. The prepared germinated brown rice ferment drink is rich in organic acids, variousfree amino acids, soluble dietary fibers, and active components which are gamma-aminobutyric acid and SOD, and has the advantages of sour-sweet mouthfeel, convenience in drinking, no additives, excellent nutrition and healthcare effects, great improvement of the raw material utilization rate in a two-stage fermentation process, and great solving of resource wastes of existing brown rice having bad mouthfeel.

Owner:WUHAN SUNHY BIOLOGICAL

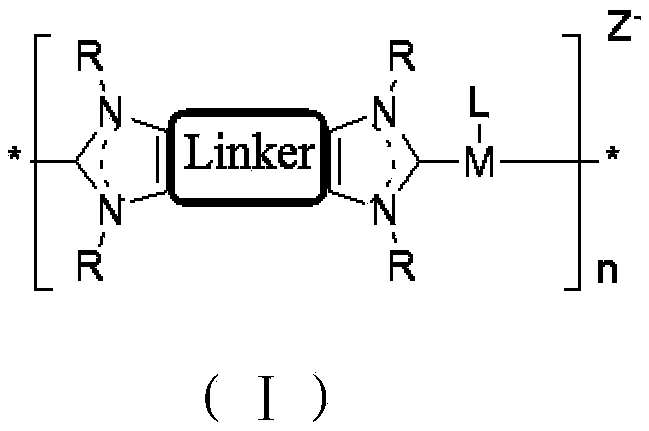

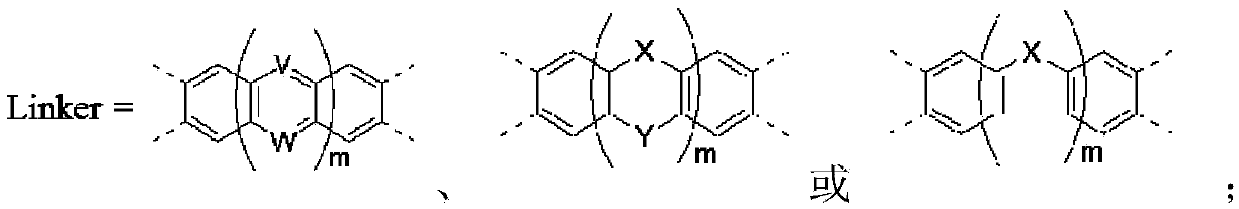

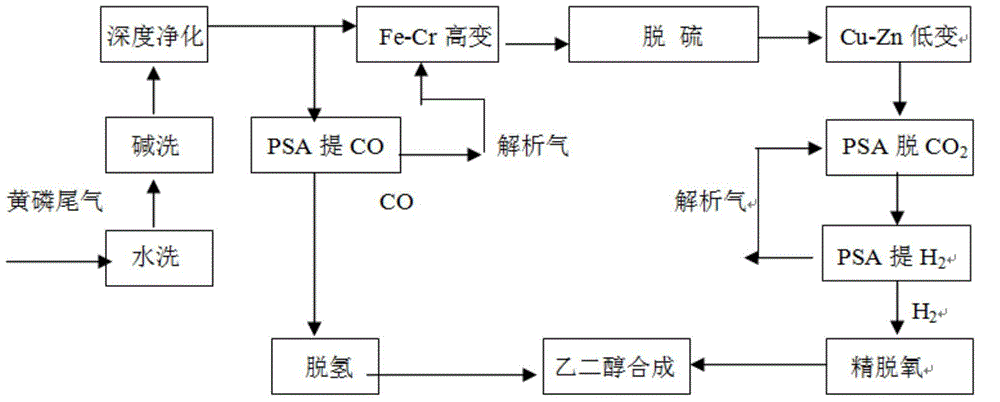

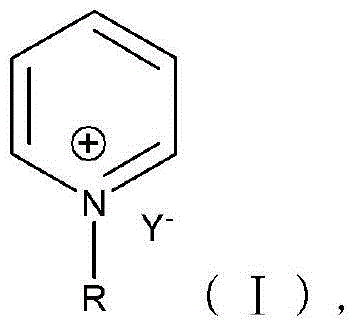

Azacyclocarbene metal coordination polymer and preparation method thereof, and application of azacyclocarbene metal coordination polymer as catalyst

ActiveCN106046057AImprove stabilityHigh catalytic activityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCelluloseCarbene

The invention specifically relates to an azacyclocarbene metal coordination polymer and a preparation method thereof, and application of the azacyclocarbene metal coordination polymer as a catalyst, belonging to the technical field of preparation and application of heterogeneous catalysts. The azacyclocarbene metal coordination polymer provided in the invention has a general structural formula (I) and can be prepared by reacting a bis(imidazole) salt with a metal precursor under alkaline conditions and carrying out coordination assembling. The azacyclocarbene metal coordination polymer is applicable to catalysis of oxydehydrogenation of a variety of alcohols and derivatives thereof, carbohydrate compounds, cellulose or lignin and to high-efficiency preparation of lactic acid and derivatives thereof. The novel self-loaded catalytic system integrates the advantages of homogeneous catalysis and heterogeneous catalysis, and can realize high-efficiency, high-selectivity and considerable conversion of biomass polyol raw materials under mild conditions; and the catalyst has the advantages of high-efficiency recovery, repeated usability, etc., and has good application prospect in preparation of lactic acid and hydrogen by using industrial catalysis approaches.

Owner:FUDAN UNIV

Stable chemical nickel-plating plating solution and preparation method thereof

InactiveCN101586236AImprove stabilityNo generationLiquid/solution decomposition chemical coatingChemistryCompound (substance)

The invention discloses a stable chemical nickel-plating plating solution and a preparation method thereof. The plating solution comprises following substances per liter: 3-10g of succinic acid, 20-25g of sodium acetate, 8-20ml of lactic acid, 4-16g of citric acid, 1-7ml of propanoic acid, 8-20g of malic acid, 30-35g of sodium hypophosphite, 30-35g of nickel sulfate and 1-9mg of aminothiourea. The preparation method comprises steps of dissolving succinic acid and sodium acetate in water, adding lactic acid, using sodium carbonate to adjust pH=3-4 of solution, then adding citric acid, propanoic acid, malic acid, sodium hypophosphite, nickel sulfate and aminothiourea, at last using sodium carbonate to adjust pH=3.8-4.1 of solution. Compared with the prior art, the plating solution has high stability with no chlorine when using, and high tolerance.

Owner:CHERY AUTOMOBILE CO LTD

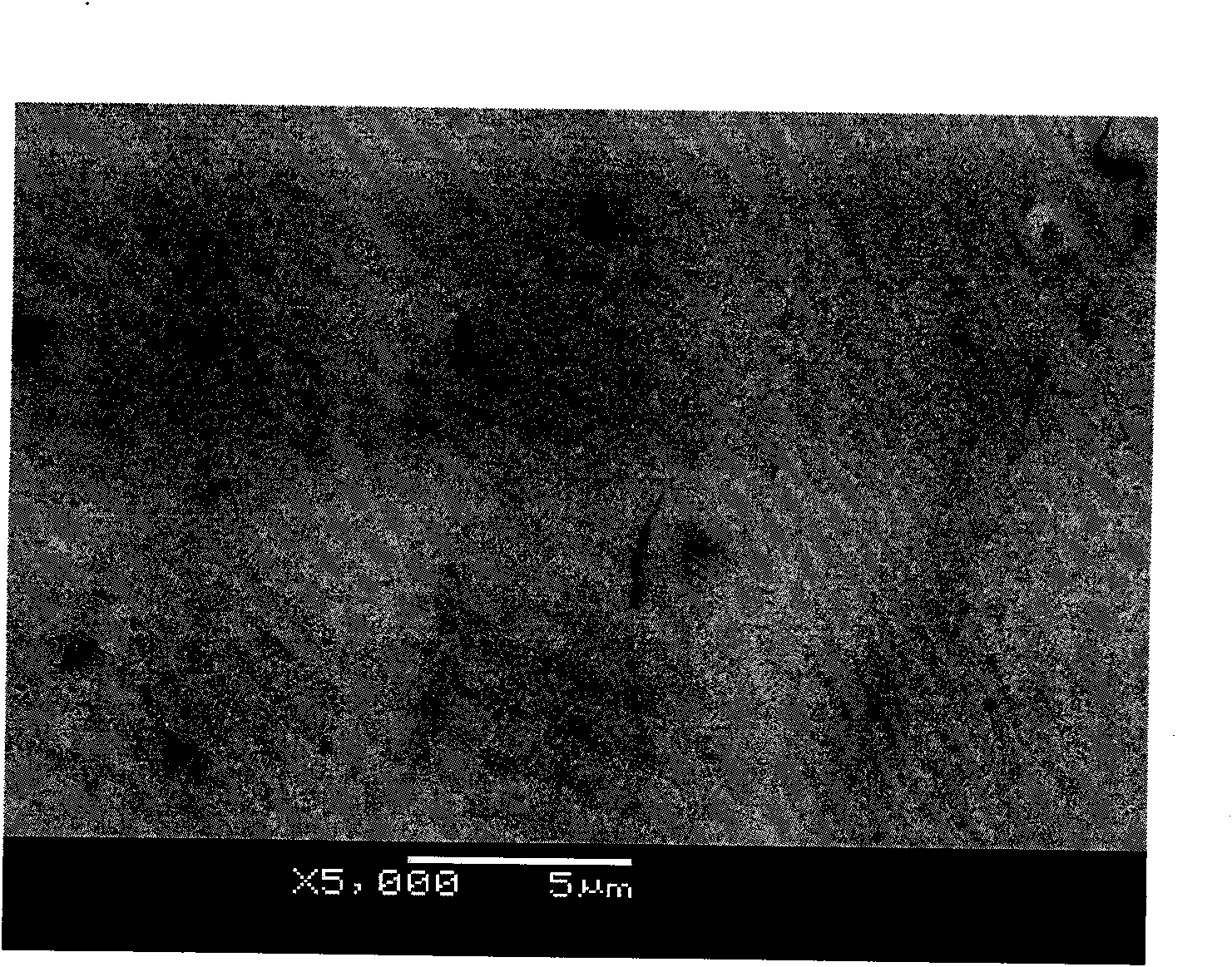

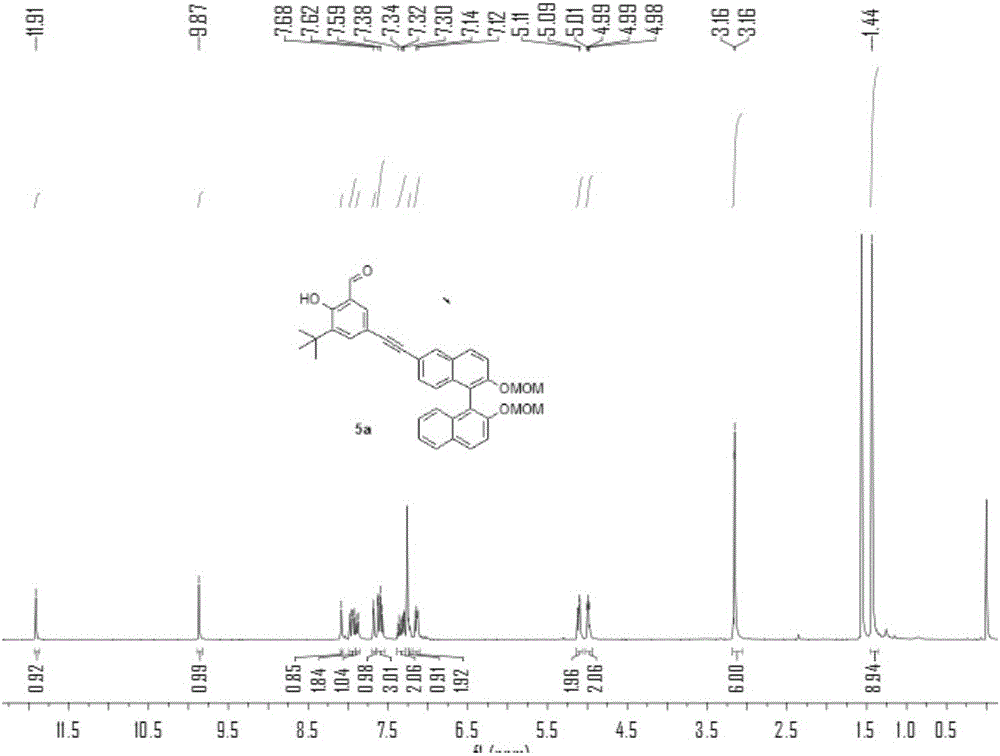

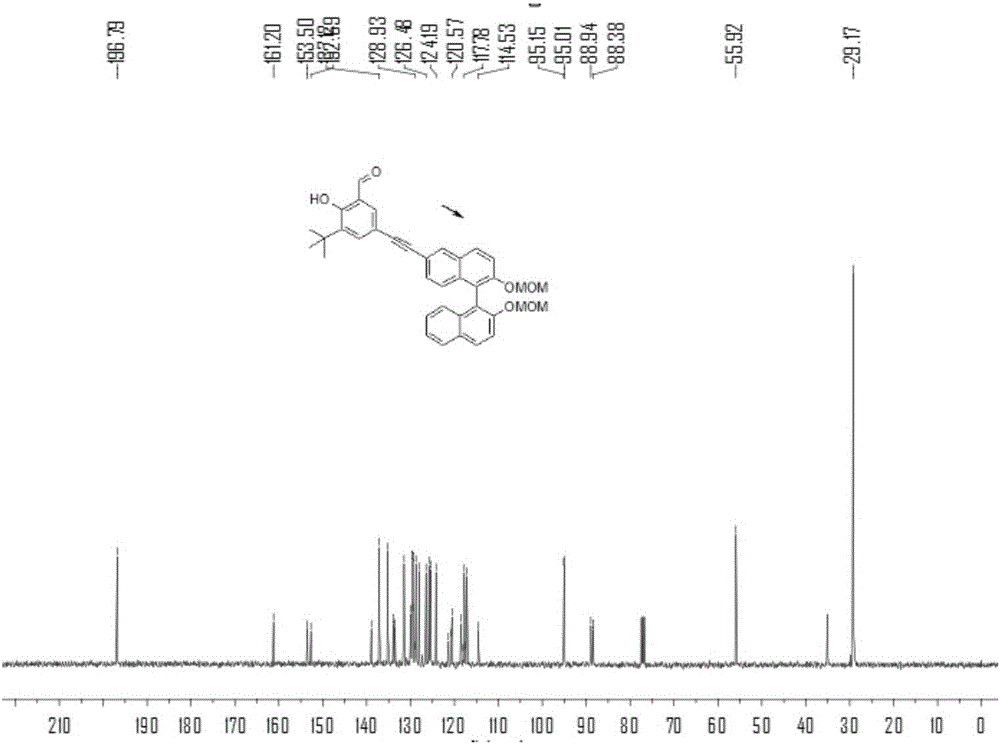

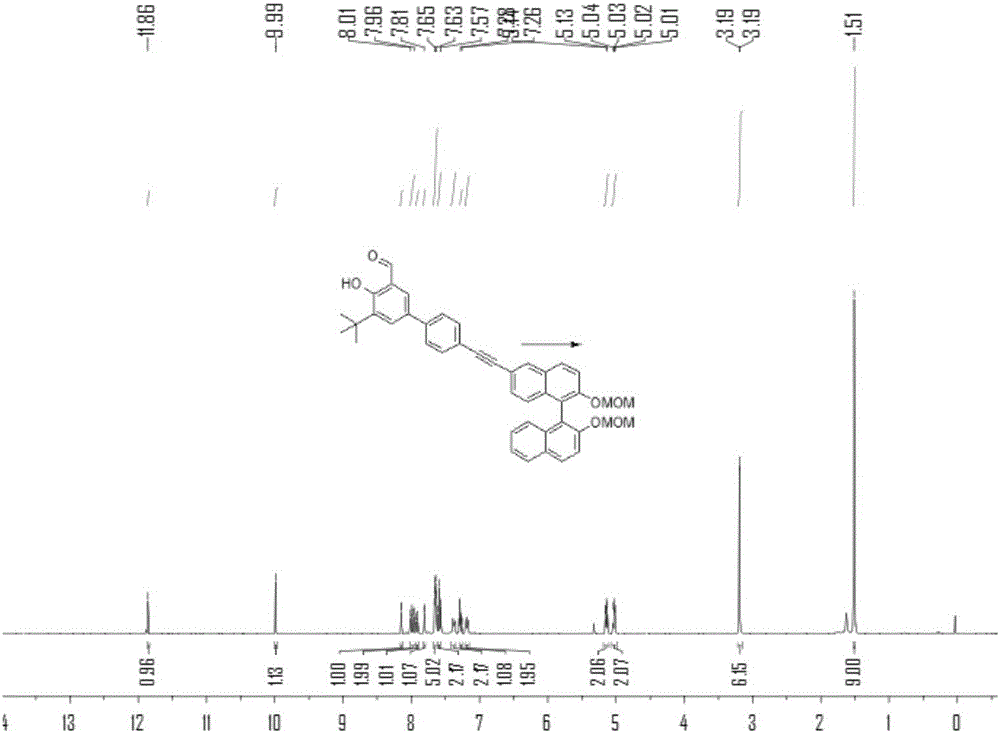

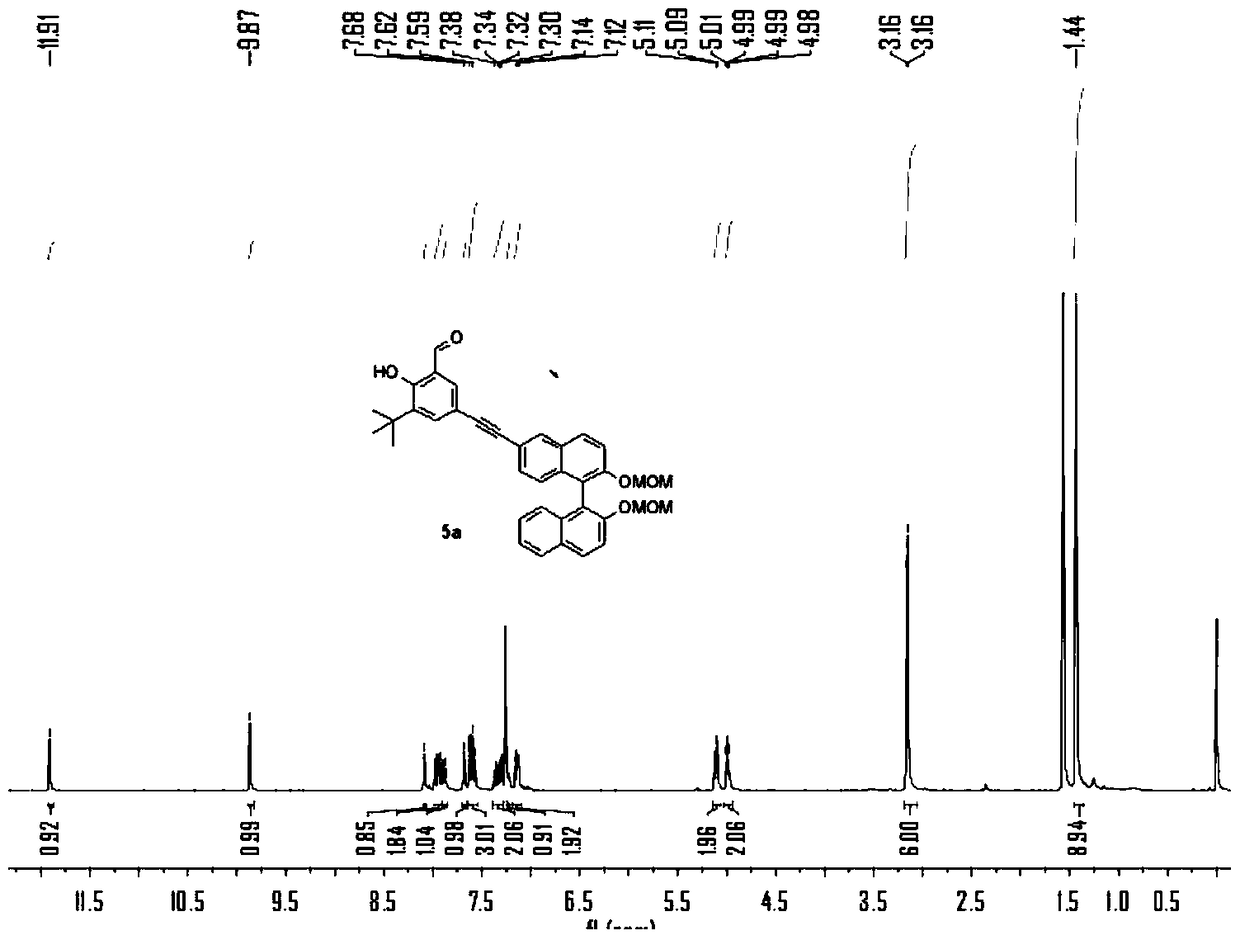

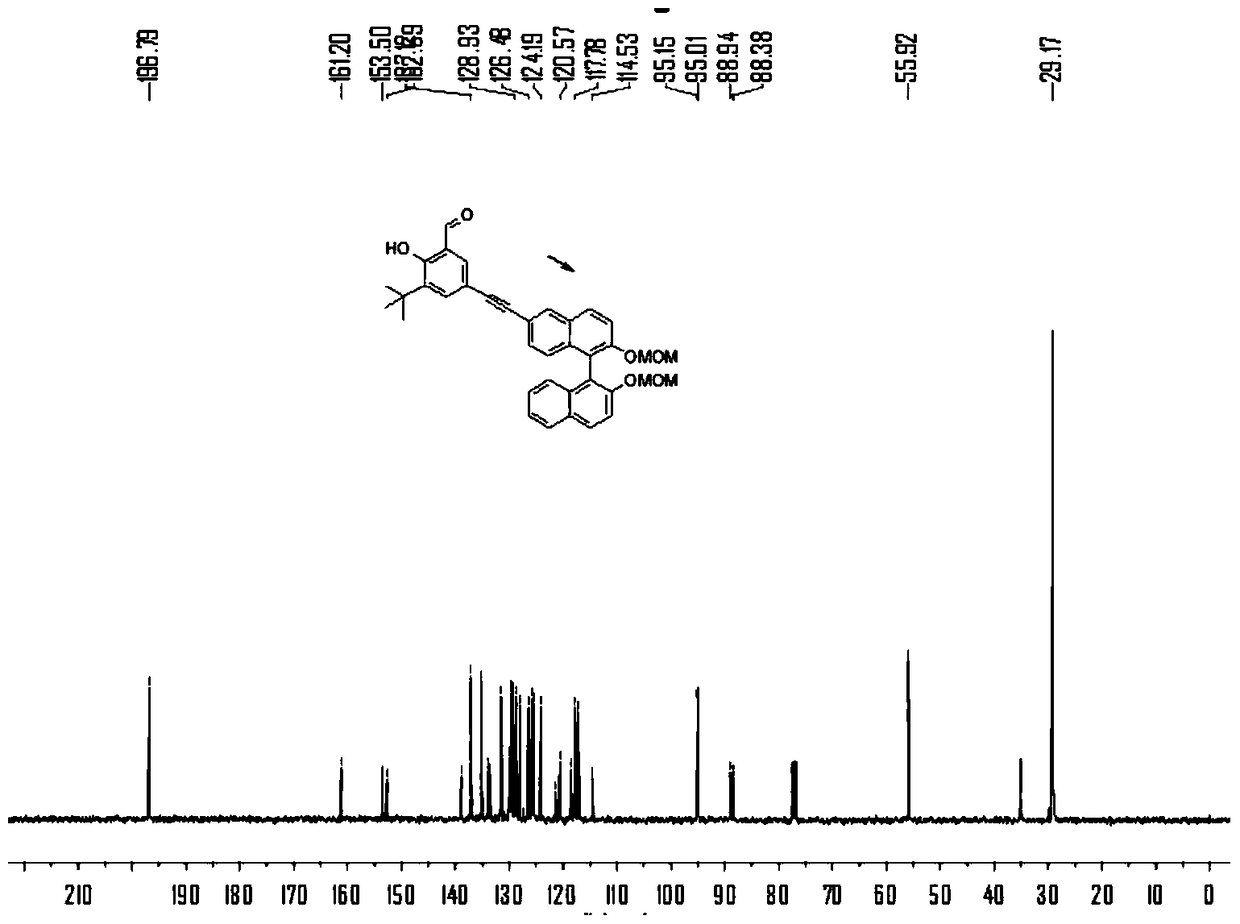

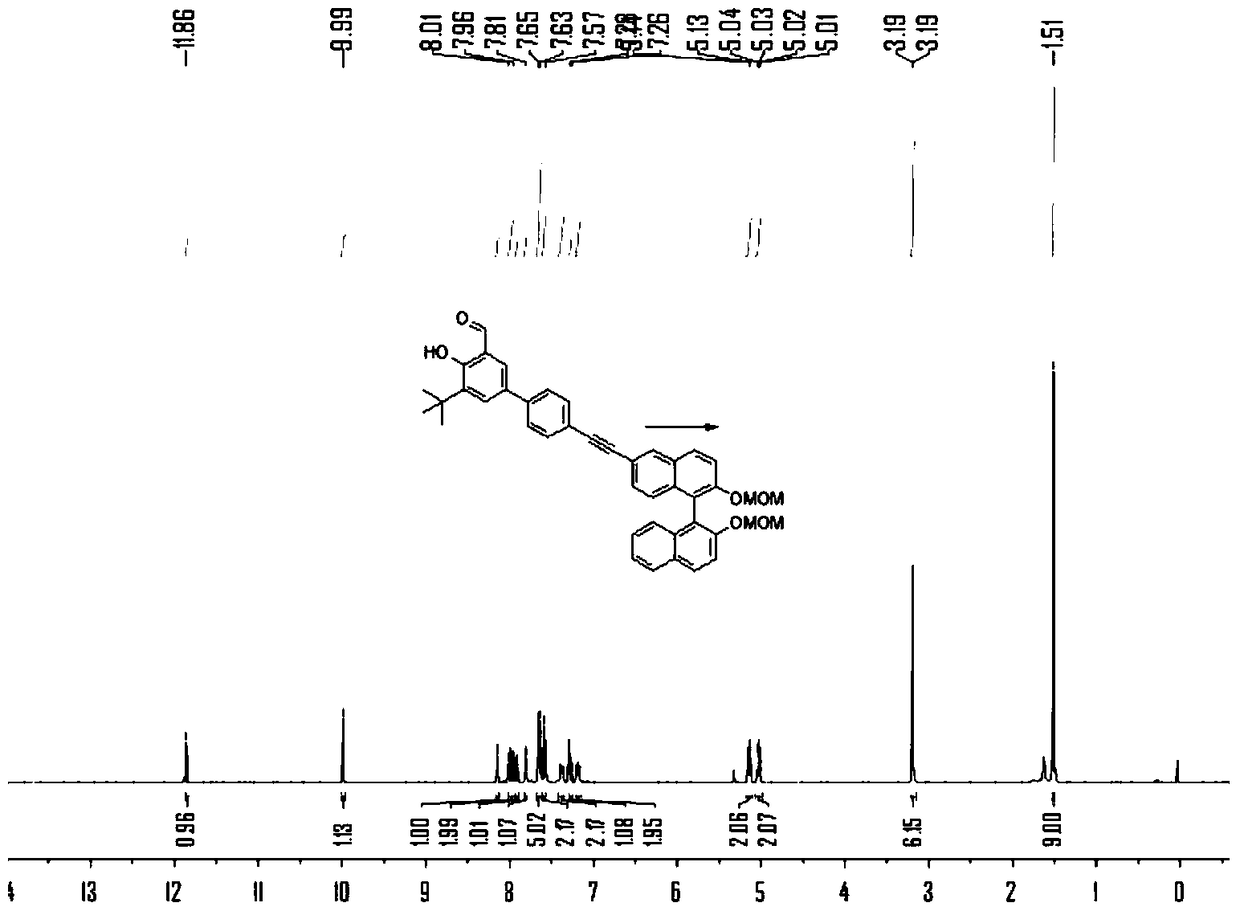

Novel chiral polydentate ligand, metal-organic coordination polymer formed through coordination, and application of metal-organic coordination polymer

InactiveCN105130842AEasy to synthesizeEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsImino compound preparationAlcoholHomogeneous catalysis

The invention belongs to the technical field of heterogeneous catalysts, and specifically relates to design and synthesis of a novel chiral polydentate ligand, a novel chiral metal-organic coordination polymer, which is prepared through the coordination-driven self-assembly between the chiral polydentate ligand and a metal precursor, and an application of the polymer as a heterogeneous catalyst in asymmetric epoxide ring-opening reactions for preparing chiral amino alcohol. The provided chiral coordination polymer prepared from the chiral polydentate ligand can be used to catalyze the asymmetric epoxide ring-opening reactions so as to prepare chiral amino alcohol efficiently and high-selectively. The novel self-supported catalyst system combines the advantages of homogenous catalysis and heterogeneous catalysis, can prepare chiral amino alcohol under mild conditions, can be recycled efficiently and reused for several times, and has a good application prospect in catalytic chiral amino alcohol preparation in industry.

Owner:FUDAN UNIV

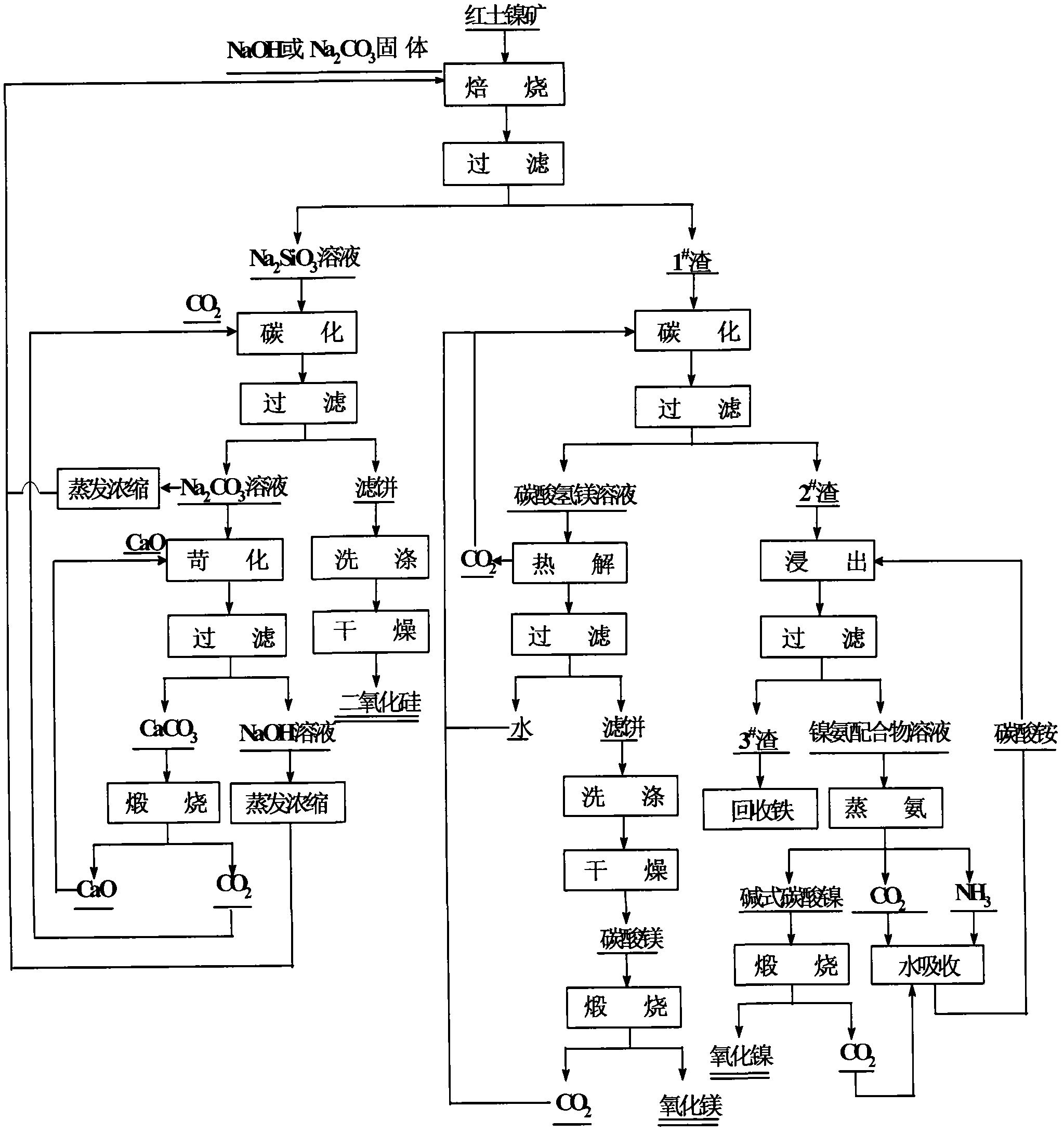

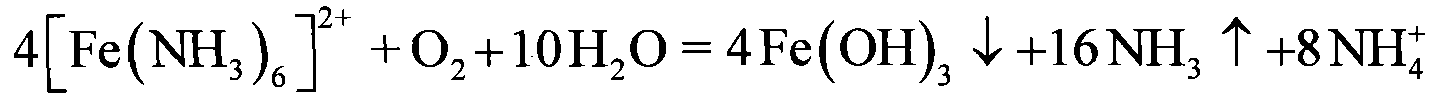

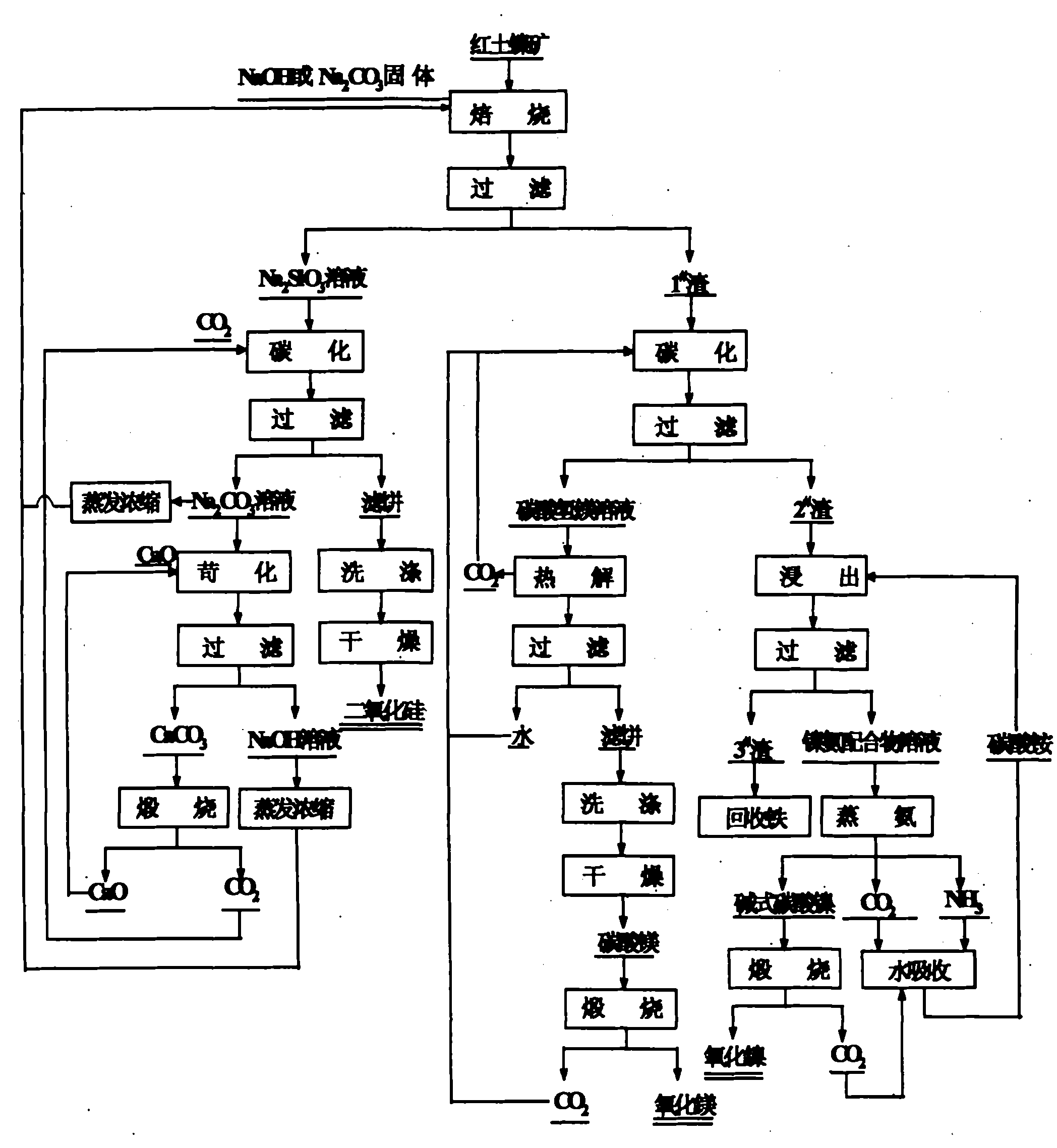

Method for comprehensive exploitation and utilization of silicon, magnesium, iron, and nickel in laterite-nickel ore

A method for comprehensive exploitation and utilization of silicon, magnesium, iron, and nickel in laterite-nickel ore comprises the following steps: roasting laterite-nickel ore with alkali, soaking in water and filtering the roasted clinkers to obtain a sodium silicate solution; processing the sodium silicate solution by carbonation decomposition method to prepare silica, processing the filter residues by carbonization and leaching to obtain a magnesium bicarbonate solution; performing thermal decomposition to prepare magnesium carbonate, allowing residual filter residues to react with ammonium carbonate, filtering, processing the filtrate by ammonia distillation and calcination to prepare nickel oxide. Residual residues are mainly ferric oxide containing a few impurities, and the residues can be used as raw materials for ironmaking, or can be deep processed to prepare products with high added value. The invention is suitable for processing various laterite-nickel ore, has the advantages of simple process flow and simple equipment, realizes the high-added-value, green and comprehensive utilization of laterite-nickel ore resources and the recycling utilization of chemical raw materials, is free of discharge of waste residues, waste liquids, or waste gases, and meets the requirements of industrial production.

Owner:NORTHEASTERN UNIV

Method for decolorizing tea oil by adopting mixed decolorizing agent

InactiveCN102399629ASimple decolorization processComply with industrial production requirementsFatty-oils/fats refiningHeating temperatureChemistry

The invention relates to a decolorizing method for tea oil. The decolorizing method comprises the following steps of: weighing non-decolorized tea oil, and heating the non-decolorized tea oil under a vacuum condition; adding a certain amount of mixed decolorizing agent to the tea oil; stirring the mixture under the condition that the heating temperature is kept unchanged; cooling and centrifuging the tea oil after the tea oil is decolorized for a certain time; and separating the tea oil from the decolorizing agent to obtain a decolorized finished tea oil product. The decolorizing method disclosed by the invention have the advantages of simpleness and convenience for operation and high working efficiency; and the tea oil processed by using the method disclosed by the invention has the advantages of light color and luster and good transparency. According to the decolorizing method disclosed by the invention, quality and preservation stability of the tea oil are improved; and a good example is provided for the development of tea oil industry as well as the comprehensive utilization of resources.

Owner:ANHUI AGRICULTURAL UNIVERSITY

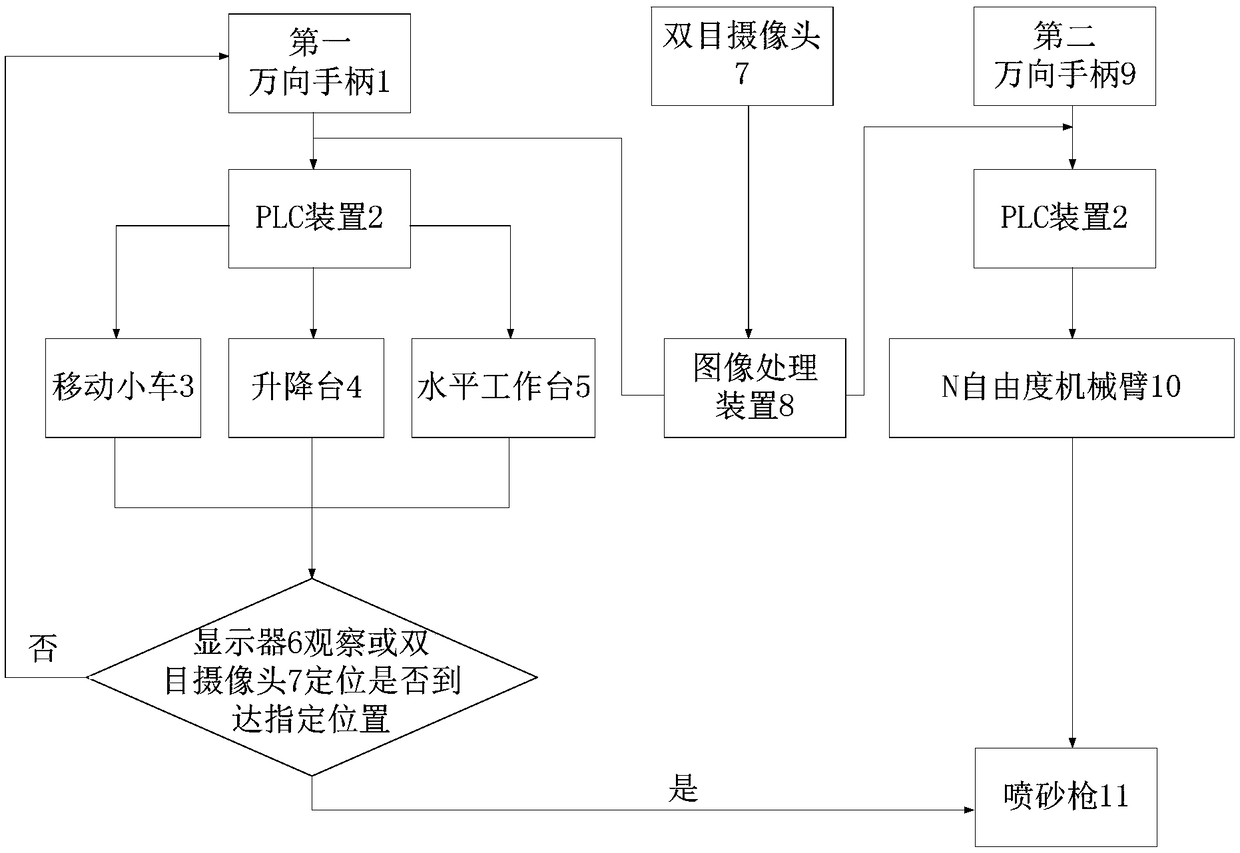

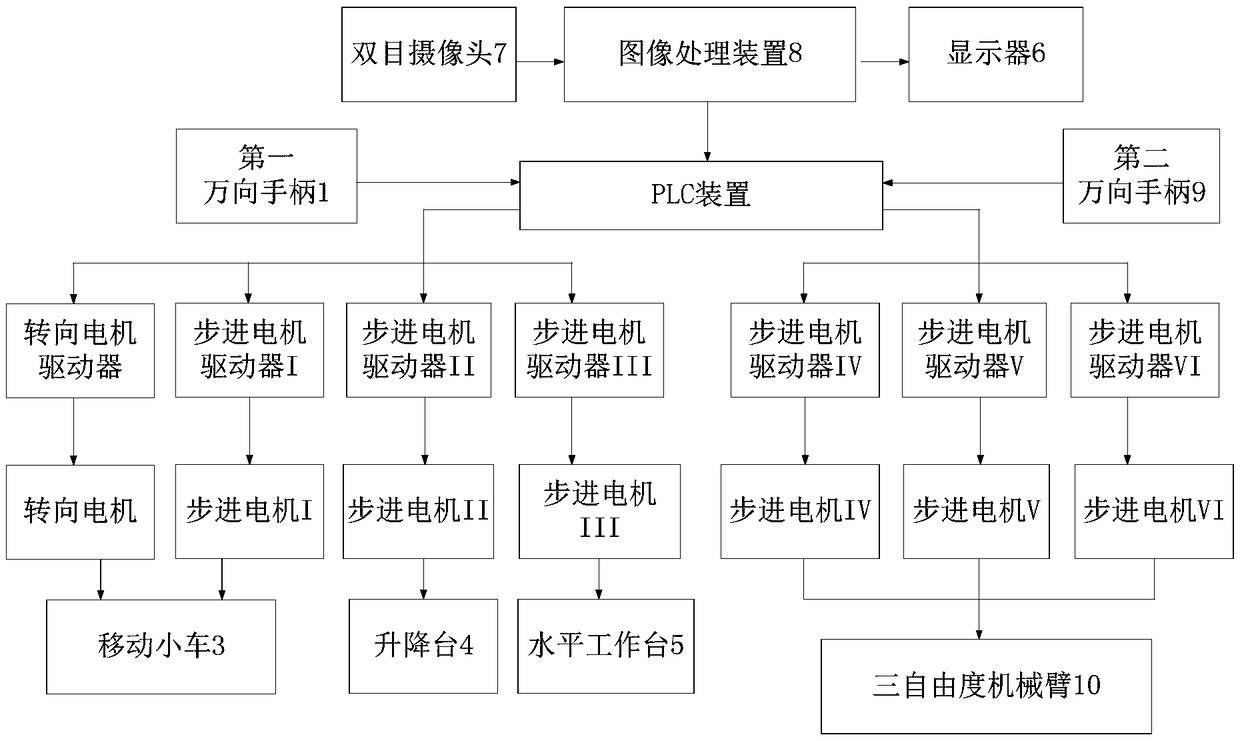

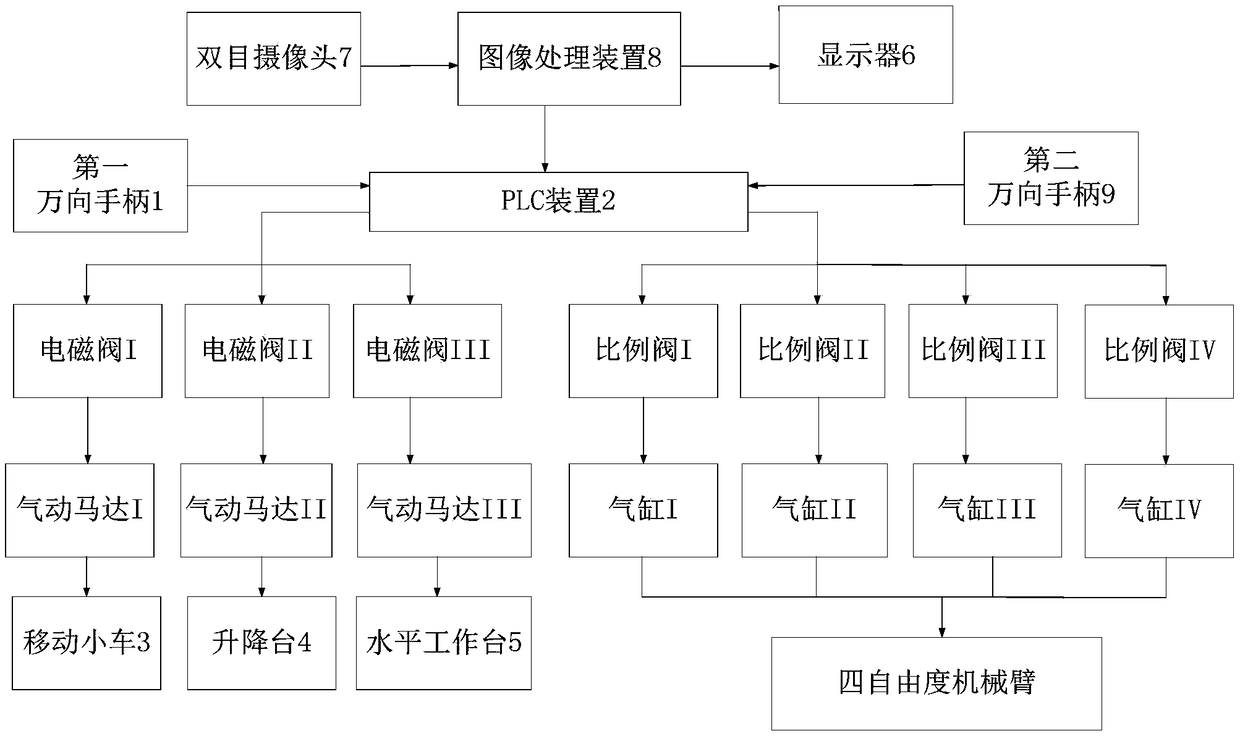

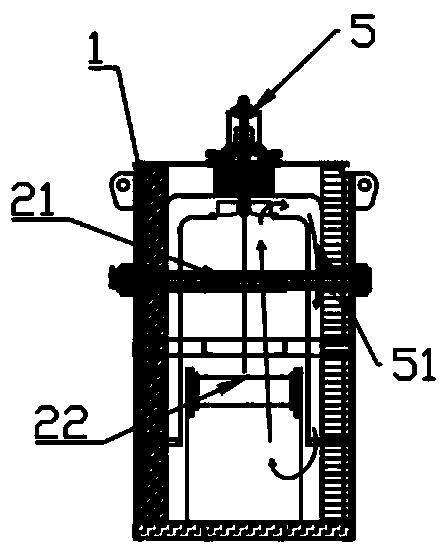

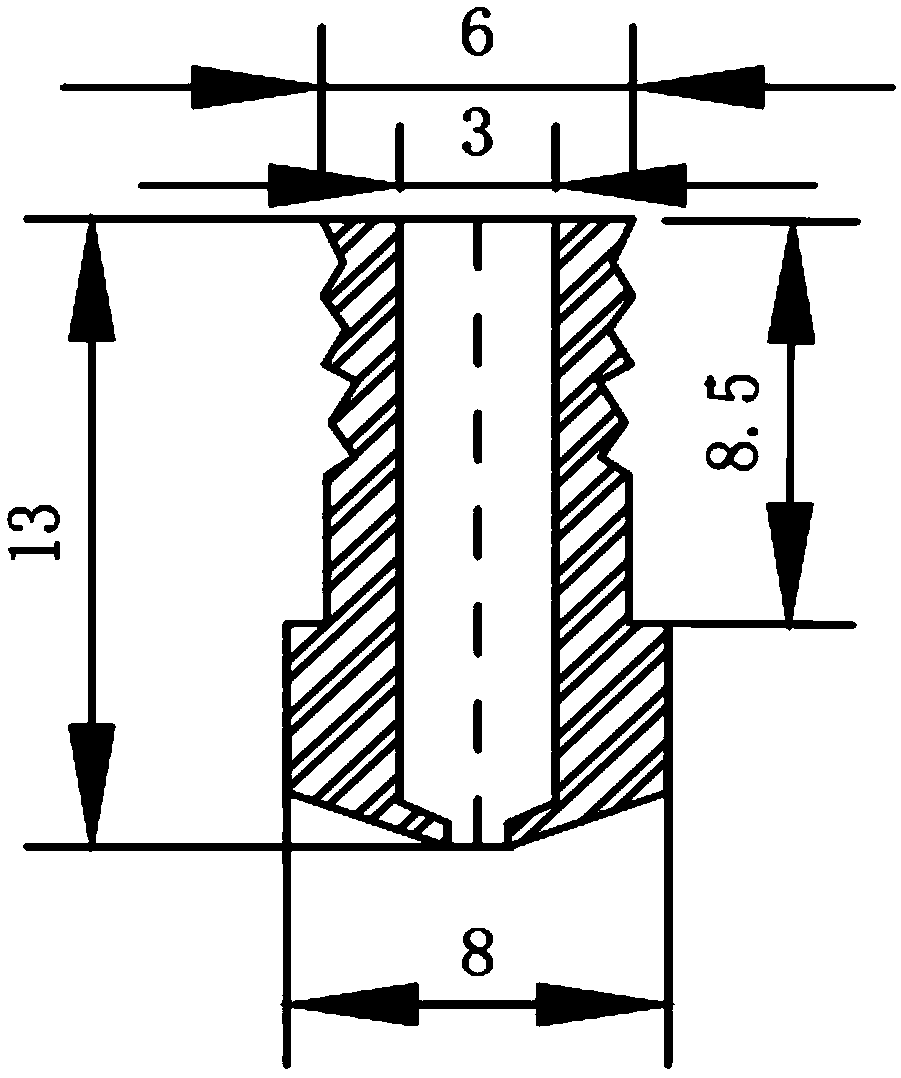

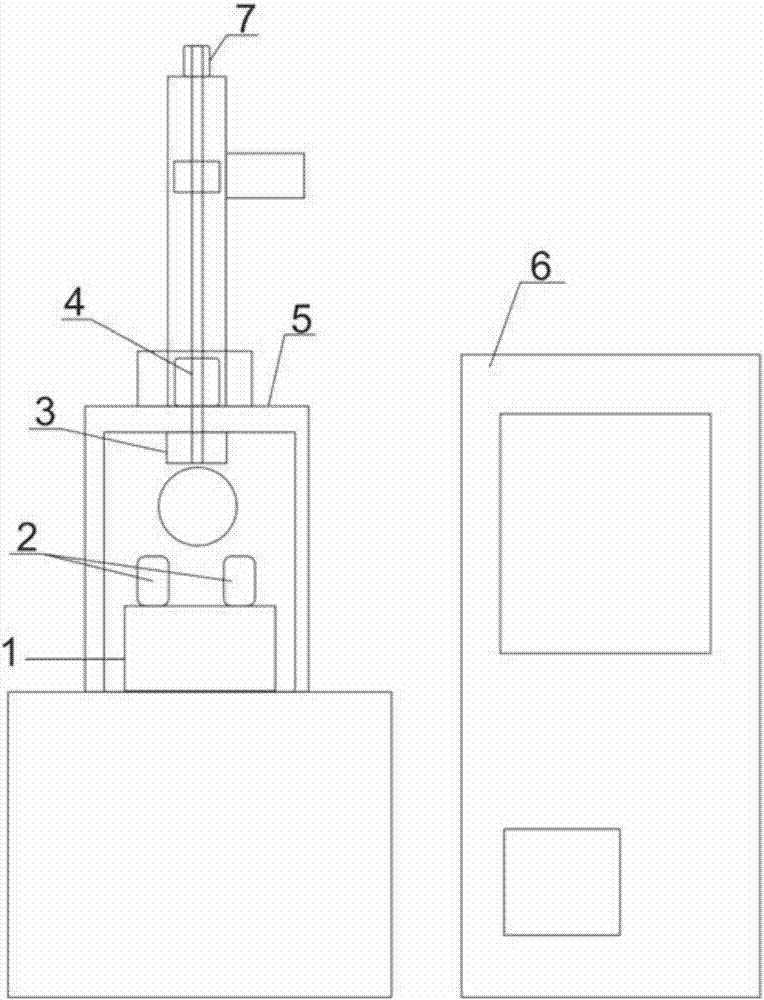

Mobile sandblasting robot control system

PendingCN108789171ALow costImprove performanceBlast gunsAbrasive machine appurtenancesDrive wheelAutomatic control

The invention discloses a mobile sandblasting robot control system which comprises a moving trolley, a lifting table, a horizontal working table, N mechanical arm movement drive devices, a sandblasting gun, a PLC device, a binocular camera and an image processing device; the moving trolley is provided with at least one trolley movement drive device used for driving wheels to move and / or / steer; thelifting table is fixed on the top of the moving trolley and is provided with a lifting table movement drive device used for driving the lifting table to move up and down; the horizontal working tableis fixed on the top of the lifting table and is provided with a sliding block movement drive device capable of driving a sliding block on the horizontal working table to perform reciprocating movement; the bottom ends of the N mechanical arm movement drive devices are fixed on the sliding block; the N mechanical arm movement drive devices are provided with movable joints used for controlling mechanical arms respectively; the sandblasting gun is fixed at the top end of the N-degree-of-freedom mechanical arm; and the PLC device is used for controlling each drive device. The mobile sandblastingrobot control system realizes automatic control through mutual matching of various equipment, moves to a position to be in sandblasting of a sandblasting piece to finish sandblasting operation, is stable and reliable in work and accords with the industrial production requirements.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

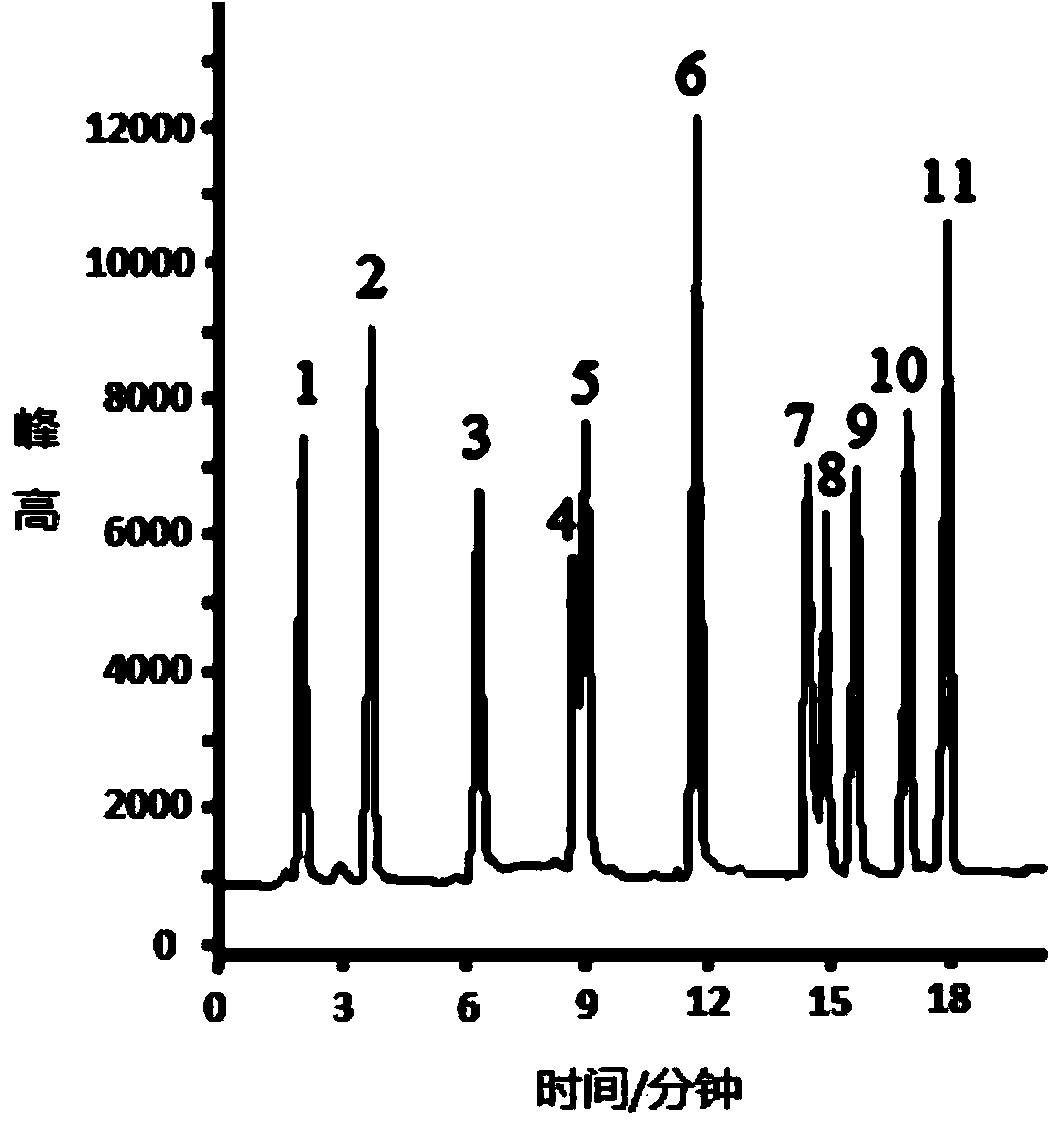

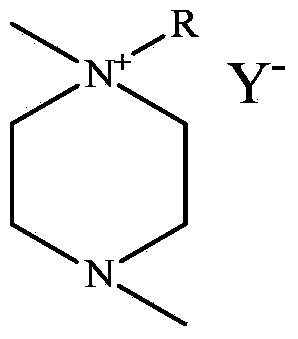

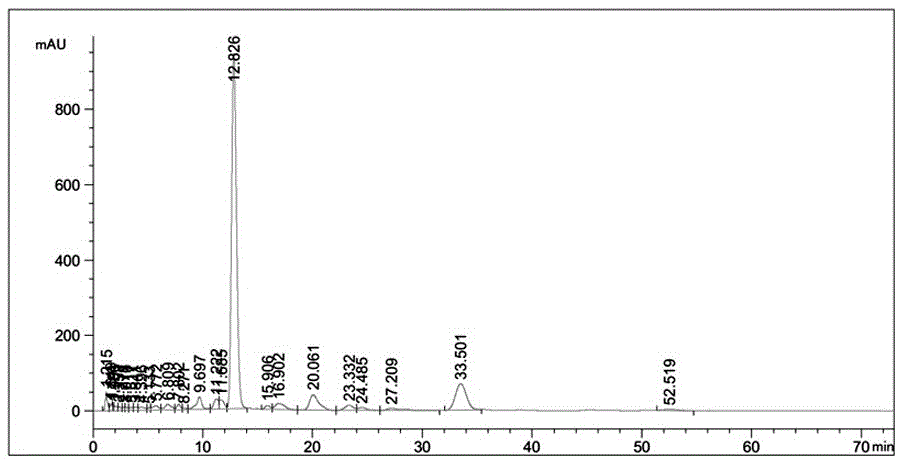

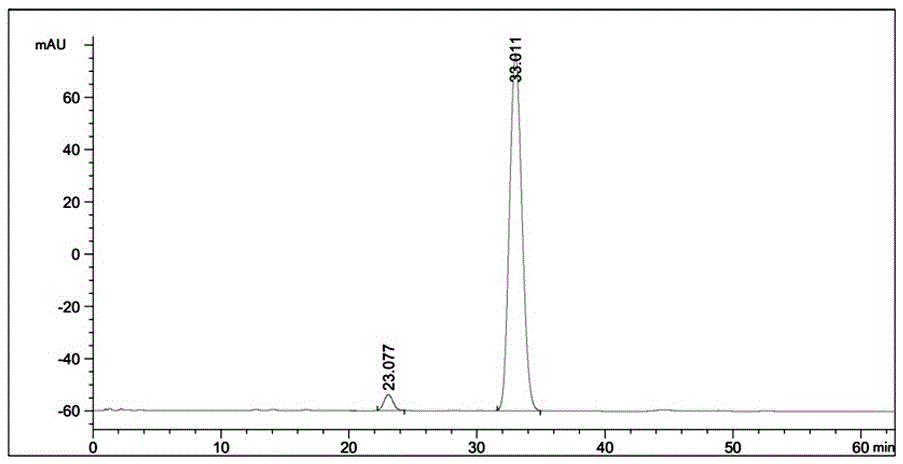

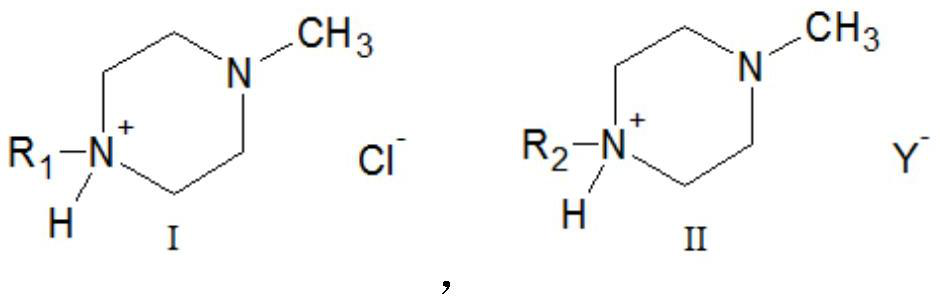

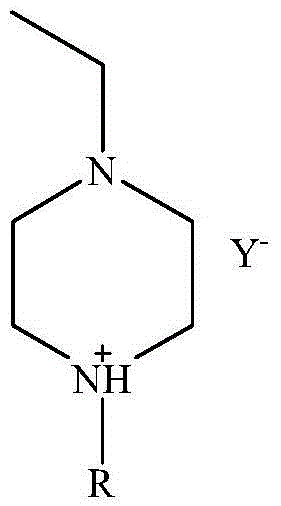

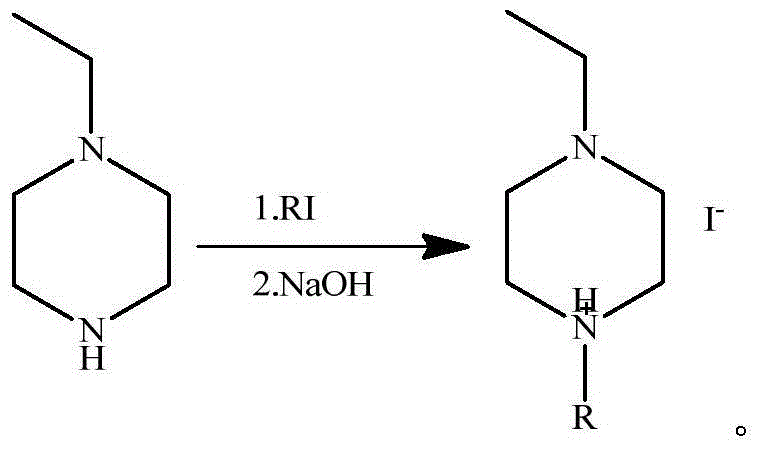

1, 4-dimethyl-1-alkyl piperazine ionic liquid as well as preparation method and applications thereof

InactiveCN103709123ASimple processShort cycleOther chemical processesDispersed particle separationStationary phaseGas phase

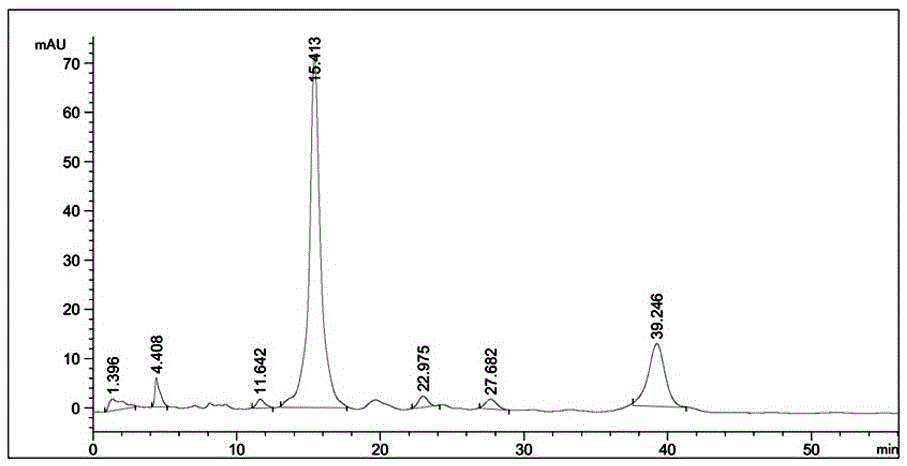

The invention discloses a 1, 4-dimethyl-1-alkyl piperazine ionic liquid. The chemical structural general formula of the 1, 4-dimethyl-1-alkyl piperazine ionic liquid is as shown in the specification, wherein the R is straight-chain alkyl of C1-C10; the negative ion Y<-1> is Cl<-1>, Br<-1>, I<-1>, C4F9SO3<-1>, C4H9OSO3<-1>, C6H13OSO3<-1>, C8H17OSO3<-1>, (CF3SO2)2N <-1>, (CF3SO2)3C<-1>, (C2F5SO2)2N<-1> or (C2F5SO2)3C<-1>. The invention further discloses a preparation method of the 1, 4-dimethyl-1-alkyl piperazine ionic liquid. The preparation method is simple in process and short in preparation cycle and has the advantages that the product yield reaches above 70%, and the product purity can reach above 96%. The invention further discloses the application of the 1, 4-dimethyl-1-alkyl piperazine ionic liquid serving as a gas chromatography stationary phase and the application of the 1, 4-dimethyl-1-alkyl piperazine ionic liquid in sulfur dioxide gas absorption.

Owner:ZHEJIANG UNIV +1

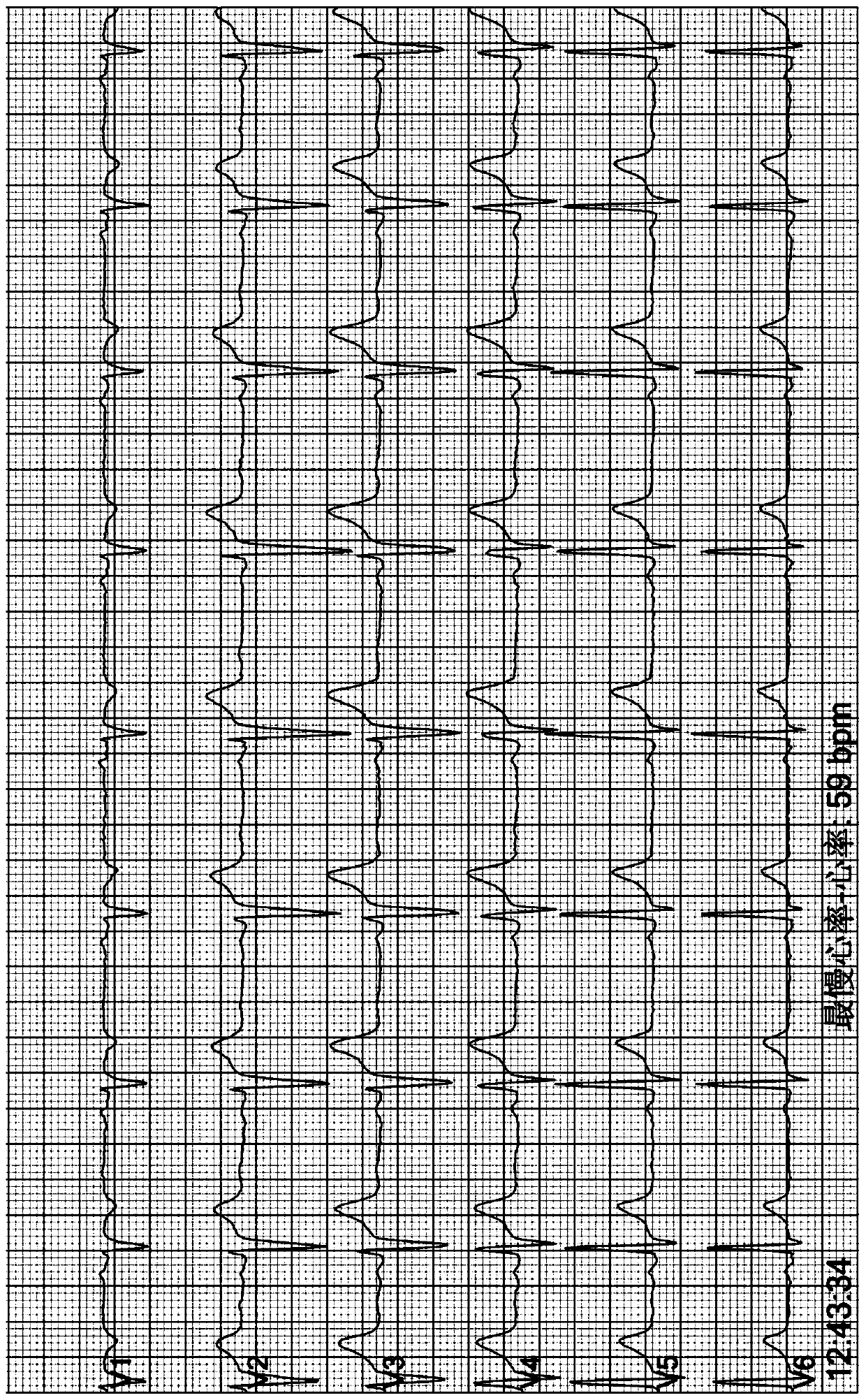

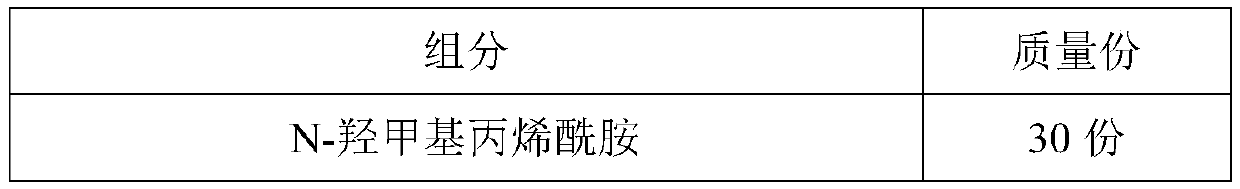

Light-cured cross-linked conductive hydrogel as well as preparation method and application thereof

ActiveCN111057186AAvoid it happening againWell mixedDiagnostic recording/measuringSensorsPolymer scienceCross linker

The invention discloses light-cured cross-linked conductive hydrogel as well as a preparation method and application thereof. The light-cured cross-linked conductive hydrogel is prepared from the following components in parts by mass: 12 to 40 parts of a monomer, 3 to 9 parts of a neutralizer, 0.07 to 0.3 part of a cross-linking agent, 20 to 65 parts of a humectant, 4 to 10 parts of a conductive agent, 0.3 to 5 parts of a thickening agent, 0.2 to 1.2 parts of a photoinitiator and 20 to 70 parts of water, wherein the monomer is an acrylamide monomer. The invention also discloses a preparation method of the light-cured cross-linked conductive hydrogel, and an application of the light-cured cross-linked conductive hydrogel in preparation of an electrocardio-electrode patch. The light-cured cross-linked conductive hydrogel has the characteristics of strong conductivity, good biocompatibility and the like. The disposable electrocardio-electrode patch prepared from the gel can keep good contact with the skin for a long time without dryness and is non-irritant to the skin, and the obtained electrocardio-signals are stable in potential, clear in waveform and convenient to operate.

Owner:GUANGDONG PROV MEDICAL INSTR INST

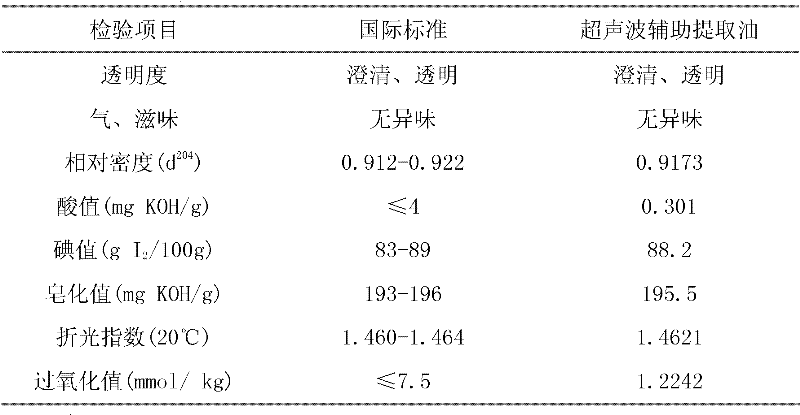

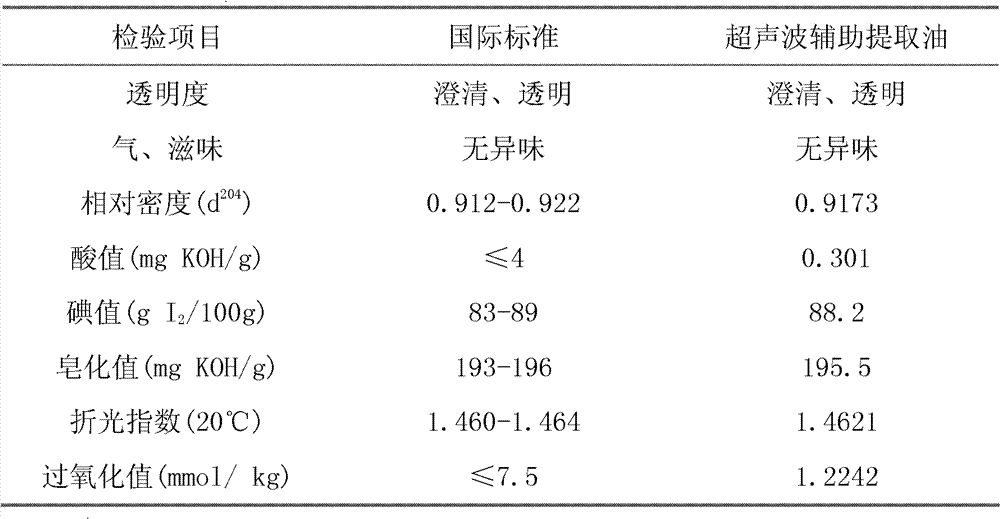

Ultrasound-assisted tea oil extraction method

InactiveCN102388987ASimple extraction processComply with industrial production requirementsEdible oils/fatsCamellia oleiferaUltrasonic assisted

The invention provides an ultrasound-assisted tea oil extraction method. Tea seeds are used as raw materials and the ultrasound-assisted tea oil extraction method comprises the following steps of: harvesting and sorting tea seeds, drying, shelling and crushing, sieving, weighing, adding an extraction solvent, performing ultrasound-assisted extraction, separating, evaporating and recovering the solvent, and obtaining tea oil. The extraction process is simple, processing cost is low, extraction efficiency is high, and tea-oil tree resources can be fully utilized.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Preparation method of protein stored in camellia oleifera abel cakes

InactiveCN102363626AAbundant resourcesImprove resource utilizationPeptide preparation methodsCamellia oleiferaCentrifugation

The invention provides a preparation method of protein stored in camellia oleifera abel cakes. According to the method, camellia oleifera abel cakes are adopted as a raw material. The preparation method of protein stored in the camellia oleifera abel cakes comprises steps that: a camellia oleifera abel cake raw material is processed through an appropriate pretreatment after oil extraction; the material is processed through alkali extraction; the extract is processed through frozen centrifugation; an obtained supernatant is processed through acid precipitation and frozen centrifugation; an obtained precipitate is processed through dialysis; an obtained product is processed through vacuum lyophilisation, such that the protein is obtained. The protein is then processed through functional property researches and evaluations. The extraction method provided by the invention is advantaged in simple technology, low processing cost, and high extraction rate. With the method, camellia oleifera abel resources can be fully utilized.

Owner:ANHUI AGRICULTURAL UNIVERSITY

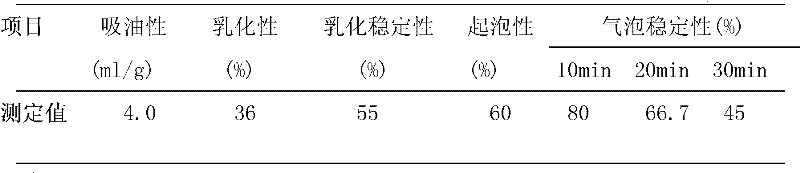

Method for comprehensively utilizing yellow phosphorus tail gas

ActiveCN105194996ALess investmentLow operating costHydrogen separation using solid contactDispersed particle separationHigh concentrationOxygen

The invention relates to a method for comprehensively utilizing yellow phosphorus tail gas. The method is characterized by comprising the steps that after the yellow phosphorus tail gas is washed by water and alkali, H2S, COS, CS2, PH3, AsH3, HF, HCN, HCl, carbonyl metal and O2 in the yellow phosphorus tail gas can be removed through deep purification including the steps of removal of sulfur, phosphorus, arsenic, fluorine, chlorine, HCN, carbonyl metal and oxygen; then one part of yellow phosphorus tail gas which is deeply purified is used for separating CO through pressure swing adsorption, and the other part of yellow phosphorus tail gas is used for preparing high-concentration H2 through transformation; the volume ratio of the yellow phosphorus tail gas used for separating out the CO through pressure swing adsorption to the yellow phosphorus tail gas used for synthesizing the H2 through transformation is 1:1-1:3. The prepared pure CO and the prepared pure H2 are used as fed gases and can be used for producing ethylene glycol (EG). Based on the characteristic that the components of the yellow phosphorus tail gas are complex, the method for comprehensively utilizing the yellow phosphorus tail gas is provided. The yellow phosphorus tail gas can be utilized reasonably and effectively, environmental pollution is reduced and cyclic and economical utilization of resources is realized.

Owner:HAISO TECH

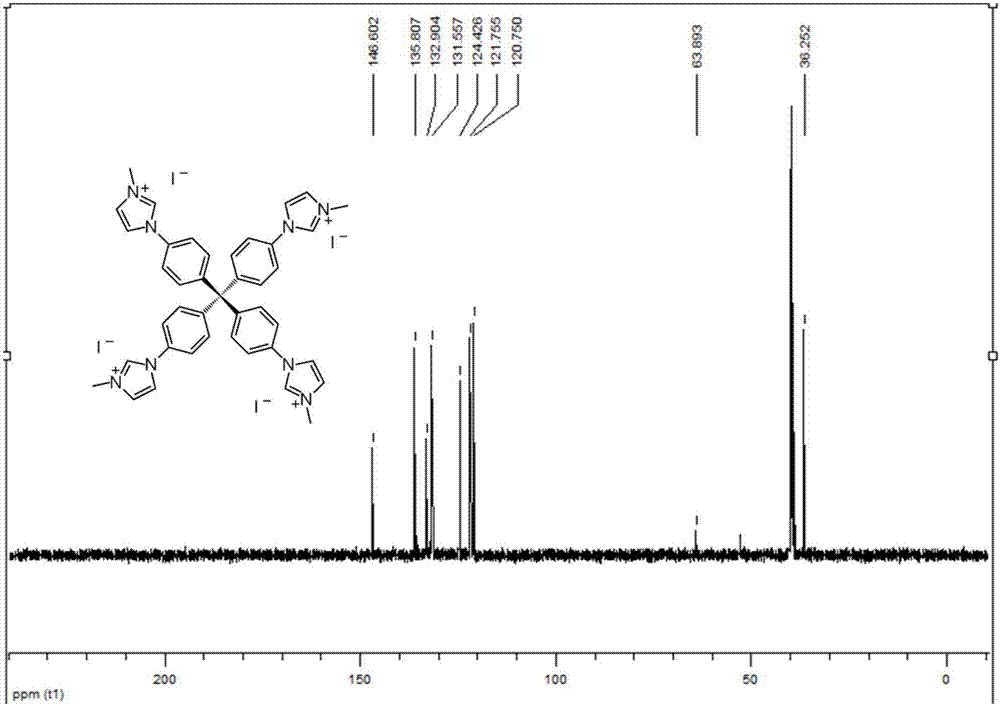

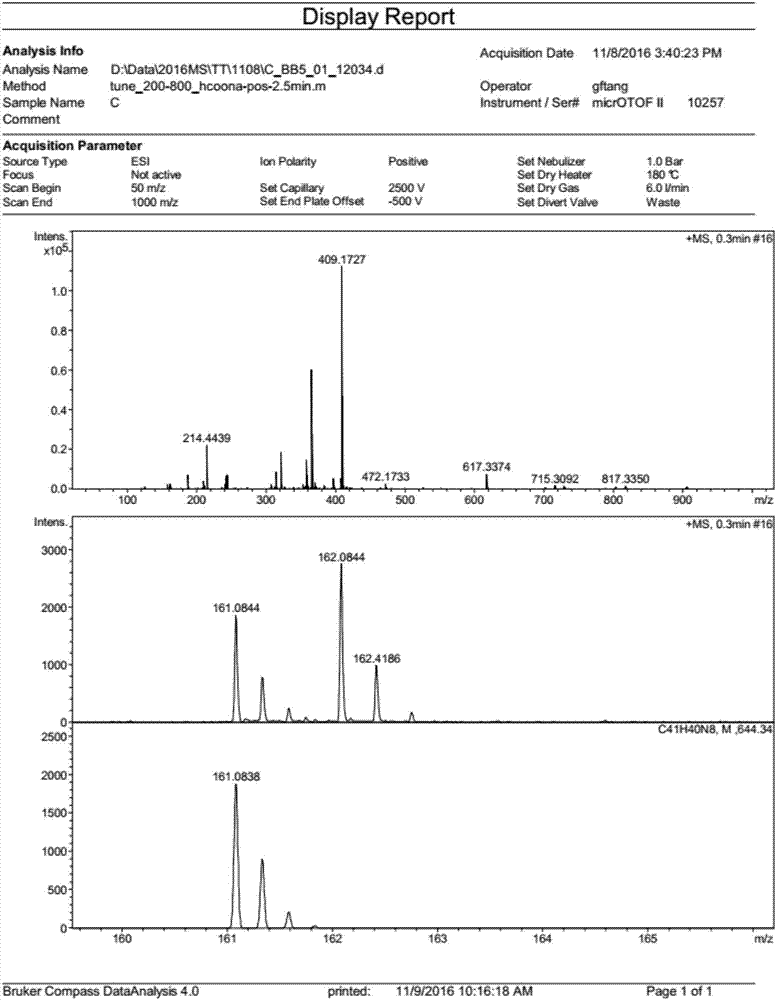

Three-dimensional N-heterocyclic carbene metal coordination polymer, preparation method and application thereof

ActiveCN107501564AImprove stabilityHigh catalytic activityOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsCarbeneGamma-Valerolactone

Belonging to the technical field of heterogeneous catalysts, the invention specifically relates to a three-dimensional N-heterocyclic carbene metal coordination polymer, a preparation method and application thereof. The three-dimensional N-heterocyclic carbene metal coordination polymer provided by the invention can utilize a tetradentate imidazole salt to react with a metal precursor under an alkaline condition, and coordination assembly is conducted to obtain the three-dimensional N-heterocyclic carbene metal coordination polymer. The three-dimensional N-heterocyclic carbene metal coordination polymer can be used for catalyzing the hydrogenation cyclization reaction of biomass levulinic acid and levulinic acid derivative to prepare gamma-valerolactone and derivatives thereof efficiently. The three-dimensional self-loaded catalytic system combines the advantages of homogeneous catalysis and non-homogeneous catalysis, and can realize efficient, high selectivity and mass conversion of biomass keto acid raw material under very mild condition, also the catalyst has the advantages of high efficiency recovery and repeated recycle, and has very good application prospect in preparation of gamma-valerolactone in an industrial catalysis way.

Owner:FUDAN UNIV

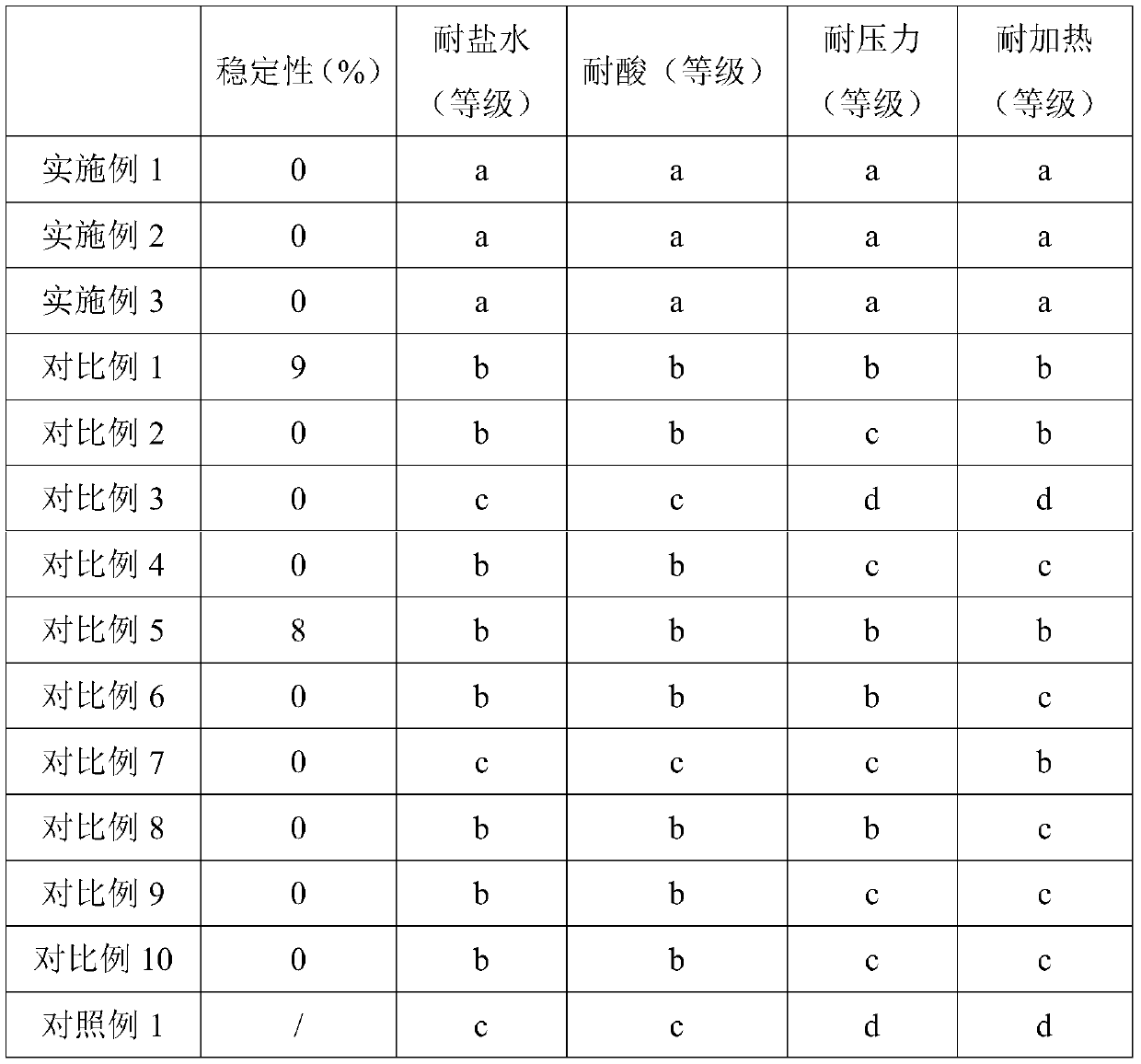

Phosphorus-free, nitrogen-free and chromium-free stainless steel passivation solution

ActiveCN111441044AExtended service lifeSimple processMetallic material coating processesMartensitic stainless steelSS - Stainless steel

The invention relates to the technical field of stainless steel surface treatment. More specifically, the invention provides a phosphorus-free, nitrogen-free and chromium-free stainless steel passivation solution. The phosphorus-free, nitrogen-free and chromium-free stainless steel passivation solution is at least prepared from the following raw materials in percentage by mass: 1 to 5 percent of oxidizing agent, 1 to 5 percent of film-forming agent, 3 to 10 percent of complexing agent, 0.01 to 0.2 percent of penetrating agent, 0.5 to 2 percent of film curing agent and the balance of deionizedwater, wherein the film curing agent is dicarboxylate with 8 to 13 carbon atoms. The phosphorus-free, nitrogen-free and chromium-free stainless steel passivation solution provided by the invention canform a layer of stable corrosion-resistant organic complex passivation film on the surface of martensite stainless steel, is good in film forming effect and high in compactness, has relatively high corrosion resistance retentivity under saline solution, heating and acid environments as well as under pressure steam, and can prolong the service life of the martensite stainless steel.

Owner:深圳市钝化技术有限公司

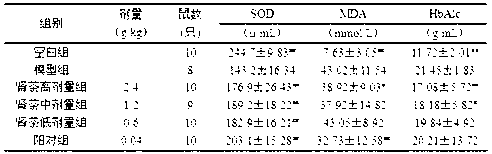

Folium orthosiphoni effective part for treating diabetic nephropathy and preparation method

InactiveCN103127214ASimple extraction methodEffective in treating diabetic nephropathyMetabolism disorderUrinary disorderPharmaceutical drugTraditional medicine

The invention discloses a folium orthosiphoni effective part for treating diabetic nephropathy and a preparation method, which comprises the following steps: 1) extracting folium orthosiphoni and concentrating; 2) applying a folium orthosiphoni extract onto column; and 3) eluting, collecting and concentrating folium orthosiphoni effective part. The folium orthosiphoni effective part is mixed with current drug and a food excipient for preparing drugs, food and health care products for treating diabetic nephropathy. The extracted effective part has high content, the content of general flavone can reach more than 50%, and reach five types of traditional Chinese medicine materials standard, an eluent has no toxicity, and the preparation method is suitable for industrial production.

Owner:中国医学科学院药用植物研究所云南分所

Heat exchanger for slow cooling and preheating of isothermal normalizing furnace

InactiveCN104164546AInner circulation speed controllableImprove full recyclingMaintainance of heating chambersPreheating chargesThermal energyCombustion

The invention discloses a heat exchanger for slow cooling and preheating of an isothermal normalizing furnace. An upper layer of combustion flue and a lower layer of combustion flue are arranged in a furnace body of the isothermal normalizing furnace; a preheating section is arranged at the front end of the upper layer of combustion flue; a heating insulation section is arranged at the middle and rear end of the upper layer of combustion flue; a slow cooling section is arranged at the front end of the lower layer of combustion flue; a rapid cooling section and an isothermal section are sequentially arranged on the middle and rear end of the lower layer of combustion flue along the conveying direction of materials; and transmission net bands are arranged inside the upper layer of combustion flue and the lower layer of combustion flue. Particularly, the furnace body forms a heat convection zone at the front ends of the upper and lower layers of combustion flues in a penetrating manner while the heat exchanger is arranged inside the heat convection zone, and is provided with a fan at the top of the heat convection zone, and an air flue which extends to the lower layer of combustion flue in a semi-closed manner; and air inside the heat convection zone flows through the upper layer of combustion flue, the fan and the air flue from the lower layer of combustion flue in an internal cycle. By application of the heat exchanger disclosed by the invention, the internal cycle speed for slow cooling and preheating of the isothermal normalizing furnace can be controlled, full recycling utilization of heat energy is greatly improved, and the industrial production requirements of outstanding energy conservation and emission reduction are met.

Owner:苏州新凌电炉有限公司

Preparation method and application of polyoxometalate crystal

ActiveCN106957313AEasy to makeNo need for harsh reaction conditionsOrganic chemistryMolecular sieve catalystsMANGANESE ACETATEVilanterol trifenatate

The invention belongs to the technical field of organocatalysis and in particular relates to a preparation method and application of a polyoxometalate crystal. The preparation method disclosed by the invention comprises the following steps: by taking Na2WO4.2H2O, NaVO3.2H2O, disodium hydrogen phosphate, manganese acetate and benzyl tri-n-butylammonium chloride as raw materials, preparing the heteropolyacid crystal. Catalyzed preparation of an anti-asthma drug vilanterol trifenatate intermediate is realized by taking the polyoxometalate crystal as a catalyst. The defect in the conventional process that a strong base is adopted is overcome, the pressure for environmental protection is alleviated, the process route is green and environment-friendly, and the requirements on the conventional industrial production are met.

Owner:山东本源晶体科技有限公司

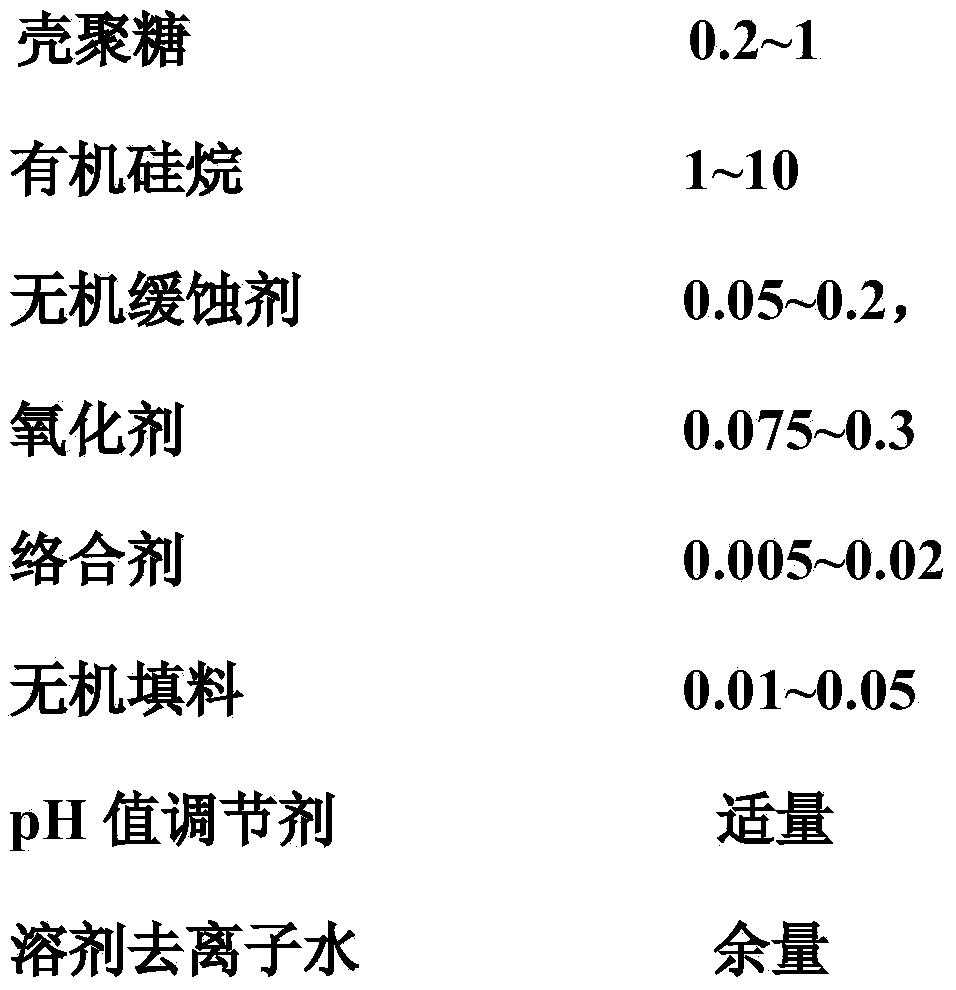

Chitosan modified surface treatment liquid for galvanized color-coated board and preparation method thereof

InactiveCN102409331BWith self-healing functionImprove corrosion resistanceMetallic material coating processesChromium freeSolvent

The invention provides a chitosan modified surface treatment liquid for a galvanized color-coated board and a preparation method thereof and belongs to the technical field of galvanized color-coated board surface treatment. The surface treatment liquid provided by the invention has the following components by weight percent: 0.2-1 of chitosan, 1-10 of organic silicon, 0.05-0.2 of inorganic corrosion inhibitor, 0.075-0.3 of oxidizing agent, 0.005-0.02 of complexing agent, 0.01-0.05 of inorganic filling material, a proper amount of pH regulating agent and the balance of deionized water. For a container, the corrosion inhibitor is intelligently released according to the destructive degree of a metal surface. The chitosan modified surface treatment liquid is characterized in that chitosan is not only used as a main film substance but also as a container for storing the corrosion inhibitor, and chitosan can intelligently release the corrosion inhibitor according to the destructive degree of the metal surface, thereby forming an intelligent paint film on the metal surface. In the invention, a chitosan raw material is sufficiently supplied and has low price, thus being beneficial to reduction of cost. The chitosan modified surface treatment liquid provided by the invention dose not contain chromium of any valence state and is an environmentally-friendly chromium-free passivating liquid.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method of gliquidone intermediate

The invention provides a preparation method of a gliquidone intermediate. A one-step process is employed to replace the traditional two-step process, and the method includes: taking 7-methoxy-2, 4, 4-trimethyl-1, 3(2H, 4H)-isoquinoline dione as the starting raw material for addition with 4-(2-aminoethyl)-benzenesulfonamide in a xylene solution of sodium hydroxide, thus generating 4-(2-(3, 4-dihydro-7-methoxy-4, 4'-dimethyl-1, 3-dioxo-2(1H)-isoquinolyl)ethyl)benzenesulfonamide directly. The method avoids reversible reaction in the two-step process, and significantly improves the product generation rate. In addition, a small dose of sodium hydroxide is added in the reaction process, thereby greatly reducing the output of waste alkali water, and avoiding environmental pollution.

Owner:天津药物研究院药业有限责任公司

Method for treating avermectin oil

ActiveCN106046085ASolve the problem of difficult storageAvoid harmSugar derivativesSugar derivatives preparationAlkaneHydrocarbon solvents

The invention provides a method for treating avermectin oil. The method comprises the following steps: a, a halogenated hydrocarbon solvent is added to the avermectin oil, the obtained solution is stirred at the temperature of 30-70 DEG C to dissolve the avermectin oil, and a homogeneous solution is obtained; b, the solution is cooled to 5-0 DEG C, a solventing-out agent is added and stirred, stirring is continued for 1-2 h after crystallization, and crystallized slurry is obtained, wherein the solventing-out agent is an alkane solventing-out agent; c, the crystallized slurry is subjected to suction filtration or centrifugal separation at normal temperature, and effective ingredient powder of avermectin is obtained. Almost all the effective ingredient B1a in the avermectin oil is extracted with a solventing-out crystallization method, the yield is as high as 96%, meanwhile, the avermectin oil is changed into powder from original oil which is difficult to treat and store, the problem that the avermectin oil is difficult to store is solved, harm or possible harm of the environment and crops caused by the avermectin oil is avoided, vendible oil prepared from toxic solvents such as toluene and the like is avoided, and safety and environment friendliness are realized.

Owner:HEBEI XINGBAI AGRI SCI & TECH CO LTD

Forming method of fiber-reinforced sandwich-structure composite material

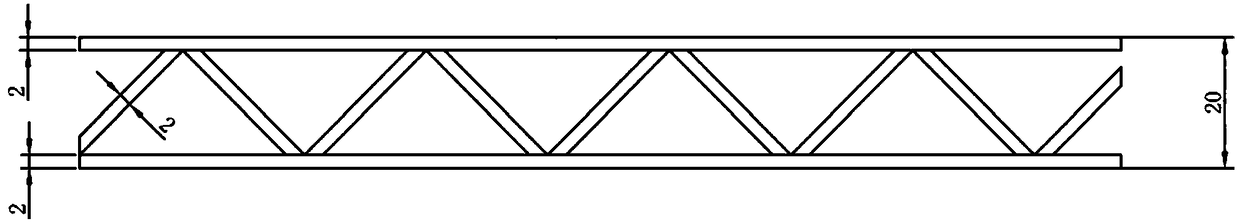

PendingCN109177148AImprove bending resistanceImprove impact resistanceAdditive manufacturing apparatus3D object support structuresCompression moldingFiber reinforcement

The invention is suitable for the technical field of sandwich-structure composite materials and discloses a forming method of a fiber-reinforced sandwich-structure composite material. A sandwich structure is prepared by using a 3D (three-Dimensional) printing technology; the sandwich shape can be freely designed without chemical bonding and compression molding forming; a designed mold is relatively high in precision; on one hand, the material formed by the 3D printing technology is relatively high in precision; the sandwich-structure material prepared by the method is relatively high in precision, and meets the requirements of industrial production; on the other hand, by adding the high-performance fiber-reinforced material, the bending resistance and impact resistance of the sandwich structure can be further improved so that the performances thereof can approach or even reach the performance of a solid to implement the lightweight and high-performance effect; and the forming method ofthe fiber-reinforced sandwich-structure composite material has huge market economic values and wide application prospects.

Owner:ZHEJIANG SCI-TECH UNIV

Two-source controllable SiO production system and production method

ActiveCN106966398ASolve technical problems with low production efficiencyQuality improvementChemical industrySilicon oxidesThermodynamicsSilicon monoxide

Provided are a two-source controllable SiO production system and a production method. The technical problem of low production efficiency of a traditional SiO production system can be solved. The two-source controllable SiO production system comprises a double-crucible sending heating part and a static collecting device, wherein the double-crucible sending heating part is arranged in a stainless steel vacuum cavity and comprises double crucibles and two sensing heating coils, and the two sensing heating coils are arranged outside the double crucibles respectively. The static collecting device comprises a collecting pipe and a collecting rod, wherein the inside of the collecting pipe is a static metal collecting cavity, the collecting rod is arranged in the collecting pipe, and the collecting pipe is arranged above the stainless steel vacuum cavity and communicated with the inside of the stainless steel vacuum cavity. The two-source controllable SiO production system further comprises an electric control cabinet, wherein the electric control cabinet is connected with the sensing heating coils. The two-source controllable SiO production system adopts two-source control and can accurately control reaction conditions, a silicon monoxide production period can be shortened, energy consumption can be reduced, large-scale silicon monoxide production can be achieved, and the exploratory research requirements of the scientific research institutions can be also met.

Owner:合肥科晶材料技术有限公司

Ultrasound-assisted tea oil extraction method

InactiveCN102388987BSimple extraction processComply with industrial production requirementsEdible oils/fatsCamellia oleiferaUltrasonic assisted

The invention provides an ultrasound-assisted tea oil extraction method. Tea seeds are used as raw materials and the ultrasound-assisted tea oil extraction method comprises the following steps of: harvesting and sorting tea seeds, drying, shelling and crushing, sieving, weighing, adding an extraction solvent, performing ultrasound-assisted extraction, separating, evaporating and recovering the solvent, and obtaining tea oil. The extraction process is simple, processing cost is low, extraction efficiency is high, and tea-oil tree resources can be fully utilized.

Owner:ANHUI AGRICULTURAL UNIVERSITY

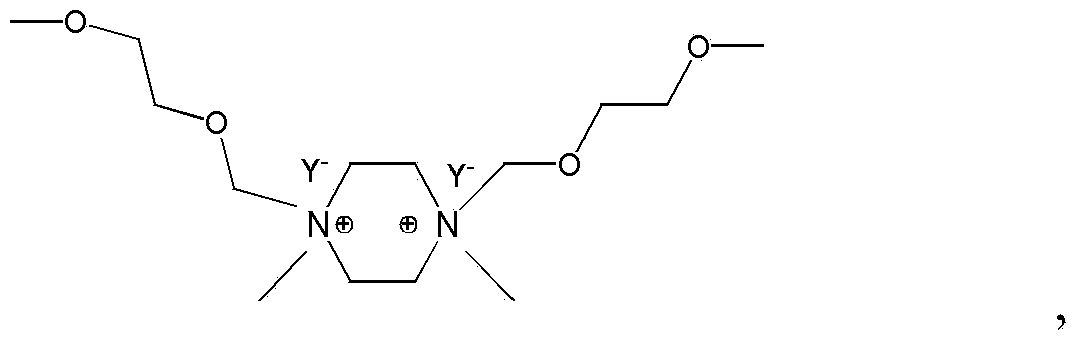

A kind of piperazine composite ionic liquid, its preparation method and its application in dissolving aramid fiber 1313

ActiveCN108069923BImprove stabilityRaw material economyOrganic chemistrySolid waste disposalPhysical chemistryToluene

The invention belongs to the field of synthesis and application of ionic liquids, and in particular relates to a preparation method of a piperazine compound ionic liquid, and its application to catalytic degradation and dissolution of aramid fiber 1313. The preparation method comprises the following steps: Step 1: chloroalkane ( R 1 Cl) and N-methylpiperazine react in toluene solution to obtain the formula I ionic liquid; Step 2: chloroalkane (R 2 Cl) and N-methylpiperazine react in a toluene solution, then filter (the product is a solid) or liquid separation (the product is a liquid), after concentration, add HY (anionic acid) at room temperature, complete the reaction, and dry Finally, the ionic liquid of formula II is obtained; step 3: after mixing the ionic liquids of formula I and formula II, the temperature is raised and stirred, and the compound ionic liquid is obtained after drying.

Owner:浙江蓝德能源科技发展有限公司

A method for decolorizing acidified oil by using compound decolorizing agent

ActiveCN104673491BLow priceSimple decolorization processFatty-oils/fats refiningIron powderRoom temperature

The invention relates to a method for decolorizing acid oil with a compound decolorizing agent. The method comprises the following steps: (1) heating acid oil which is not decolorized to 70-80DEG C, and keeping the temperature constant; (2) adding the following materials into the acid oil in sequence in a constant-temperature environment: 25vol% of ammonium hydroxide, iron powder, aluminum powder and 30vol% of hydrogen peroxide, wherein the addition amount of ammonium hydroxide is 1-5 percent of the weight of the acid oil, the addition amount of iron powder is 0.1-0.5 percent of the weight of the acid oil, addition amount of aluminum powder is 0.1-0.3 percent of the weight of the acid oil addition amount of hydrogen peroxide is 10-30 percent of the weight of the acid oil; then performing stirring and decolorizing for 40-80min at 70-80DEG C; and (3) cooling the decolorized acid oil to room temperature to obtain finished decolorized acid oil. The method provided by the invention is simple to operate and low in cost, and the acid oil processed by the method changes from black into bright yellow and is greatly improved in luster and transparency. According to the method, the external color of the acid oil is greatly improved while the quality of the acid oil is guaranteed so as to provide a good example for comprehensive utilization of the acid oil.

Owner:中国-阿拉伯化肥有限公司

Novel Chiral Multidentate Ligands, Coordination-Formed Metal-Organic Coordination Polymer Catalysts and Their Applications

InactiveCN105130842BEasy to synthesizeEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsImino compound preparationPolymer sciencePtru catalyst

The invention belongs to the technical field of heterogeneous catalysts, and specifically relates to design and synthesis of a novel chiral polydentate ligand, a novel chiral metal-organic coordination polymer, which is prepared through the coordination-driven self-assembly between the chiral polydentate ligand and a metal precursor, and an application of the polymer as a heterogeneous catalyst in asymmetric epoxide ring-opening reactions for preparing chiral amino alcohol. The provided chiral coordination polymer prepared from the chiral polydentate ligand can be used to catalyze the asymmetric epoxide ring-opening reactions so as to prepare chiral amino alcohol efficiently and high-selectively. The novel self-supported catalyst system combines the advantages of homogenous catalysis and heterogeneous catalysis, can prepare chiral amino alcohol under mild conditions, can be recycled efficiently and reused for several times, and has a good application prospect in catalytic chiral amino alcohol preparation in industry.

Owner:FUDAN UNIV

Method for preparing nanometer iron oxide red

The invention provides a method for preparing nanometer iron oxide red. The method comprises the following steps of: adding proper amount of H2C2O4 to solution of ferrous salt, boiling and stirring the mixed solution to form yellow precipitate, standing the mixed solution, removing supernatant, adding 3 percent H2O2 solution, filling O2 to the mixed solution under a continuously stirring condition, keeping a proper temperature and pH value until the oxidizing reaction is completed, removing excessive H2O2 and then filtering the mixed solution while the mixed solution is still hot; and after filtering, washing and drying the precipitate, mixing the precipitate with proper amount of ammonium bicarbonate, burning the mixture, and grinding the mixture to obtain the nanometer-grade powdery iron oxide red. The method has the advantages of simple operation, low material cost, and small grain size and good product dispersibility.

Owner:ZHEJIANG UNIV

1-ethyl-4-alkylpiperazine ionic liquid and preparation method and application thereof

InactiveCN103772300BEasy to prepareRaw material economyOrganic chemistryDispersed particle separationEthyl groupIonic liquid

The invention discloses 1-ethyl-4-alkylpiperazine ionic liquid which has the following chemical structural general formula: (img file='DDA0000450589630000011.TIF' wi='232' he='424' / ), wherein R is C3-C8 linear alkyl; Y- is I-, BF4-, PF6-, (CF3SO2)2N-, (C2F5SO2)2N-SCN- or N (CN)2-. The invention also discloses a method for preparing the 1-ethyl-4-alkylpiperazine ionic liquid. The method is simple in process and short in preparation cycle, the yield of the product can be over 80 percent, and the purity can be over 95 percent. Moreover, the invention also discloses application of the 1-ethyl-4-alkylpiperazine ionic liquid in deep desulfurization of oil and sulfur dioxide gas absorption.

Owner:ZHEJIANG UNIV +1

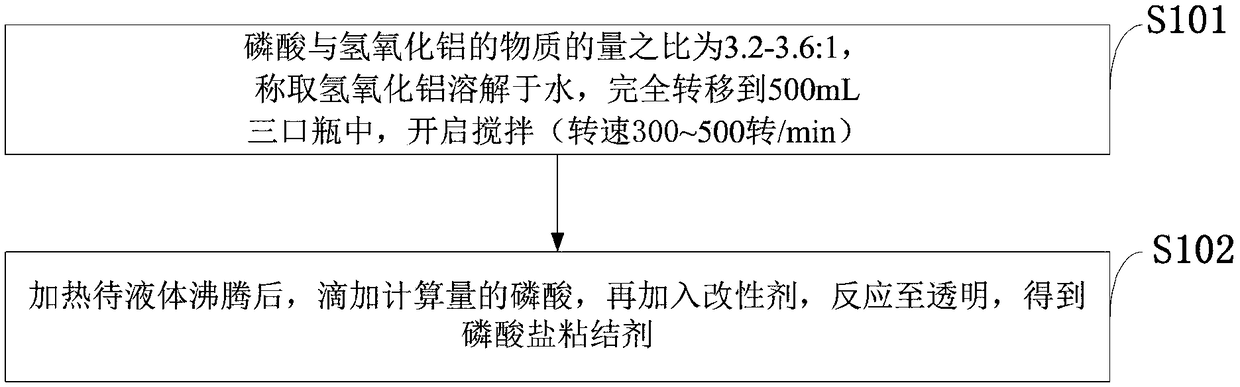

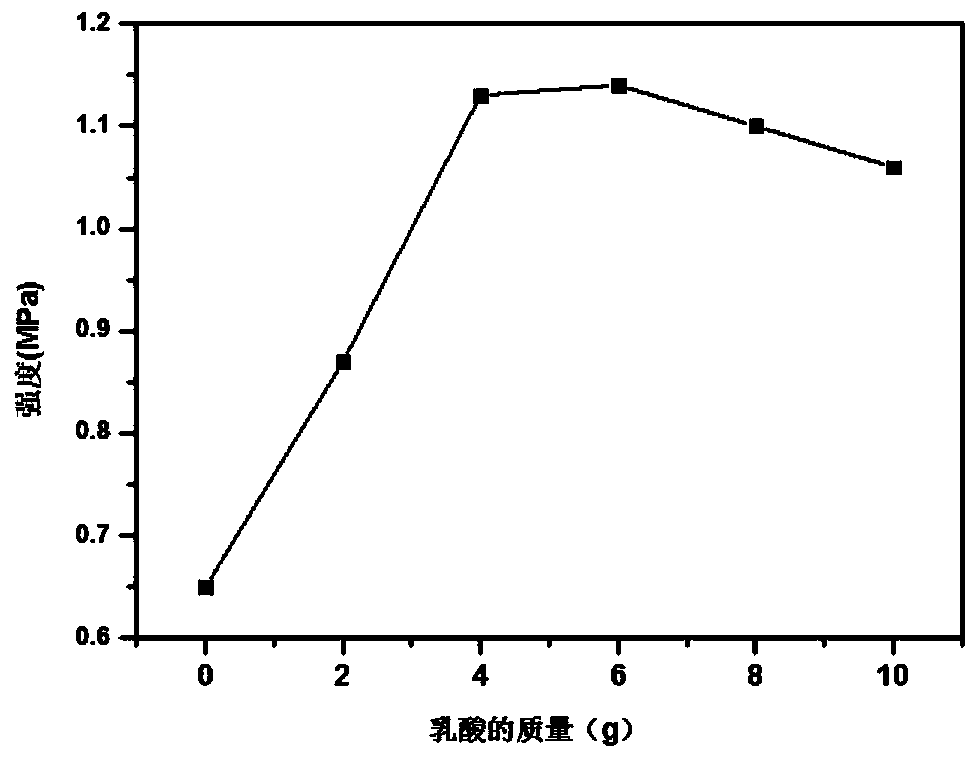

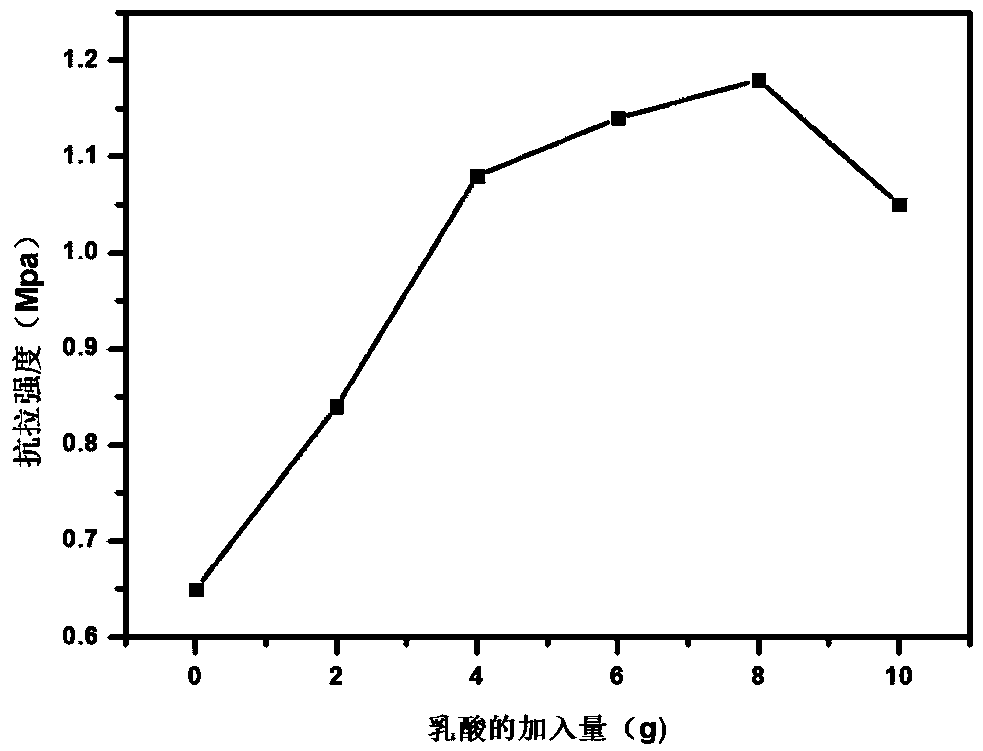

Phosphate inorganic binder based on lactic acid and polylactic acid modification and preparation method thereof

InactiveCN106734861BImprove stabilityImprove moisture resistanceFoundry mouldsFoundry coresPhosphateCalcium Binder

The invention discloses a phosphate inorganic binding agent based on lactic acid and polylactic acid modification and a preparing method of the phosphate inorganic binding agent. The neutralization of the phosphate inorganic binding agent ranges from 3.2 to 3.6, 4.0 g-10.0 g of a modifying agent of lactic acid or polylactic acid is added to 100 mL of the binding agent, 5 g-10.0 g of a curing agent of metal oxide is added in the sand mixing process, and the substance amount ratio of phosphoric acid to aluminum hydroxide is 3.2-3.6:1. According to the phosphate inorganic binding agent based on lactic acid and polylactic acid modification and the preparing method of the phosphate inorganic binding agent, stability and moisture absorption resistance of self-hardening sand and room-temperature comprehensive strength of the self-hardening sand are improved, detection is conducted in a detection center of a certain university, and the environment-friendly performance meets the requirement. Molding sand performance tests are carried out in a certain enterprise, and the results show that the requirement for industrial production is met; the problem of pollution of organic resin sand is solved through the phosphate binding agent, and moisture resisting performance, the comprehensive performance and the folding resisting strength of the sand are improved; and meanwhile, the composition is simple, the cost is low, the defects of the same kind of products are effectively overcome, and wide market prospects are achieved.

Owner:龚禧

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com