A kind of piperazine composite ionic liquid, its preparation method and its application in dissolving aramid fiber 1313

A technology of composite ions and ionic liquids, which is applied in the field of preparation of piperazine composite ionic liquids, can solve the problems of catalytic degradation and dissolution of aramid fibers that have not been reported in ionic liquids, and achieve easy large-scale preparation, good stability, and stable properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

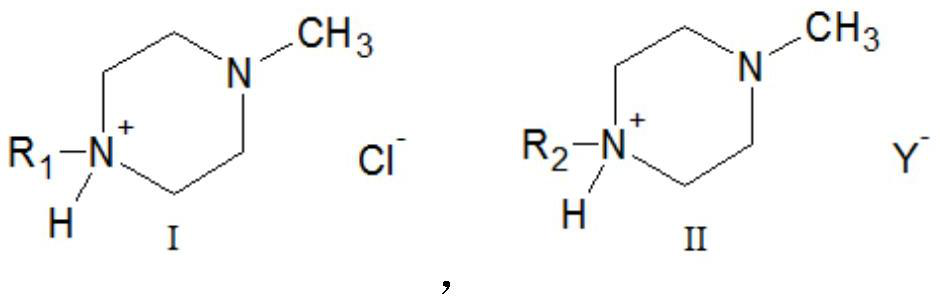

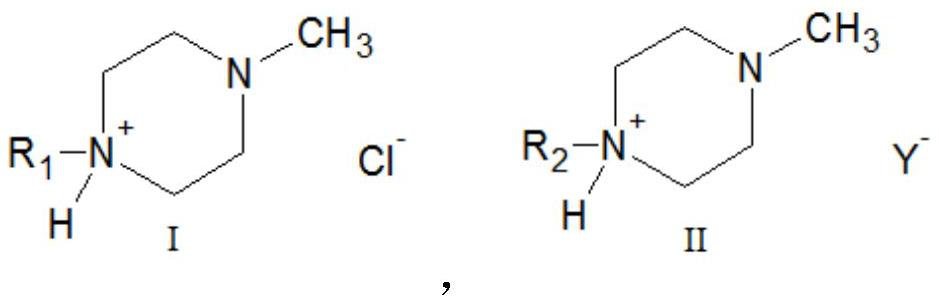

Image

Examples

Embodiment 1

[0046] Example 1: Preparation of 1-ethyl-4-methylpiperazine chloride salt and 1-butyl-4-methylpiperazine bisulfate composite (1:1) ionic liquid

[0047]Synthesis of 1-ethyl-4-methylpiperazine chloride salt: take a sealed reaction kettle lined with polytetrafluoroethylene liner, add 2.0mol of 1-chloroethane, 200ml of toluene and 1.0mol of N-methylpiperazine Add magnetrons, magnetically stir, seal the reaction kettle, transfer to a constant temperature magnetic stirrer, stir and react at 80°C for 48h, after the reaction is completed, cool to room temperature, filter to remove the toluene in the solution and the impurities contained therein, and obtain The crude product was washed with n-heptane, using 100ml each time, and washed 3 times. After filtration and vacuum drying at 50°C, 1-ethyl-4-methylpiperazine chloride salt was obtained with a purity of 98% and a yield of 93%.

[0048] Synthesis of 1-butyl-4-methylpiperazine hydrogen sulfate: take a sealed reactor lined with polyt...

Embodiment 2

[0050] Example 2: Preparation of 1-propyl-4-methylpiperazine chloride salt and 1-hexyl-4-methylpiperazine bisulfate composite (1:2) ionic liquid

[0051] Synthesis of 1-propyl-4-methylpiperazine chloride salt: except that 2.0 mol of 1-chloroethane was replaced by 1.5 mol of 1-chloropropane, and reacted at 100°C for 24 hours, the rest were the same as in Example 1 Synthesis of 4-methylpiperazine chloride salt. Under these conditions, 1-propyl-4-methylpiperazine chloride salt was obtained with a purity of 95% and a yield of 90%.

[0052] Synthesis of 1-hexyl-4-methylpiperazine hydrogen sulfate: except that 1-chlorobutane is replaced by 1-chlorohexane, and the reaction time is 72h, the rest are the same as 1-butyl-4-methyl in Example 1 Synthesis of piperazine bisulfate. Under these conditions, 1-hexyl-4-methylpiperazine hydrogen sulfate was obtained with a purity of 95% and a yield of 88%.

[0053] Preparation of composite ionic liquid: except that the molar ratio is 1:2, othe...

Embodiment 3

[0055] Preparation of 1-hexyl-4-methylpiperazine chloride salt and 1-butyl-4-methylpiperazine p-toluenesulfonate composite (1:3) ionic liquid 1-hexyl-4-methylpiperazine Chloride salt synthesis: except that 2.0 mol of 1-chloroethane was replaced by 3.0 mol of 1-chlorohexane, and reacted at 130°C for 72 hours, the rest were the same as the 1-ethyl-4-methylpiperazine chloride salt in Example 1 synthesis. Under these conditions, 1-hexyl-4-methylpiperazine chloride salt was obtained with a purity of 96% and a yield of 94%.

[0056] Synthesis of 1-butyl-4-methylpiperazine p-toluenesulfonate: except that 100g of concentrated sulfuric acid was replaced by 172.2g of p-toluenesulfonic acid, and reacted at 100°C for 60h, the rest was the same as that of 1-butyl-4 in Example 1 - Synthetic synthesis of methylpiperazine bisulfate. Under these conditions, 1-butyl-4-methylpiperazine p-toluenesulfonate was obtained with a purity of 97% and a yield of 96%.

[0057] Preparation of composite i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com