Preparation method of protein stored in camellia oleifera abel cakes

A technology of protein and camellia oleifera cake, which is applied in the field of preparation of stored protein in camellia oleifera cake, can solve the problems of extracting high-quality protein from camellia oleifera cake, achieve high extraction rate, good quality, and improve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Now take the laboratory implementation as an example, and the non-limiting examples are described as follows:

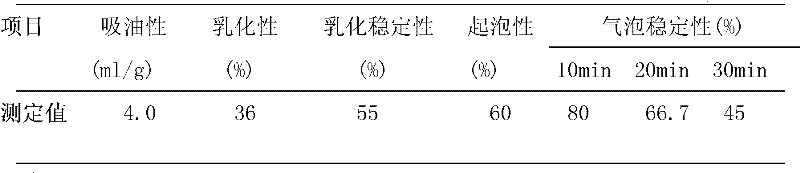

[0032] Dry the tea seed cake raw material after oil extraction under vacuum conditions at 40-65°C and crush it; take 200g of the raw material that has been pulverized and completely degreased, add petroleum ether that is 4-5 times the weight of the oil tea cake powder, and heat it with petroleum ether Reflux for 7-10 hours, remove grease, separate and filter, evaporate the residual solvent, add NaOH solution with a pH of 10 according to the ratio of material to liquid 1:30, and soak at room temperature for 60-100min; Centrifuge under the condition of 1 / min for 20min, take the supernatant as the rough separation extract, adjust the pH value of the rough separation extract with 1mol / L HCl solution, make it reach the isoelectric point 5 of camellia oleifera protein, and keep the isoelectric point state Under these conditions, the protein precipitate was obtained ...

example 2

[0037] Dry the tea seed cake raw material after oil extraction under vacuum conditions at 40-65°C, and crush it; take 200g of the raw material that has been pulverized and completely degreased, add petroleum ether 4-5 times the weight of the oil tea cake powder and 2-4 grams For citric acid, heat and reflux with petroleum ether for 7-10 hours to remove grease, separate and filter to evaporate the residual solvent, add NaOH solution with a pH of 10 according to the ratio of material to liquid 1:30, and soak at room temperature for 60-100 minutes; the crude extract Centrifuge at 4°C for 20min at a speed of 6000r / min, take the supernatant as the crude separation extract, adjust the pH of the crude separation extract with 1mol / L HCl solution, and make it reach the isoelectric point of the camellia oleifera protein 5. Under the condition of maintaining the isoelectric point state, refrigerate and centrifuge to obtain the protein precipitate. Put the precipitate in deionized water f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com