Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

437results about How to "Adapt to industrial production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

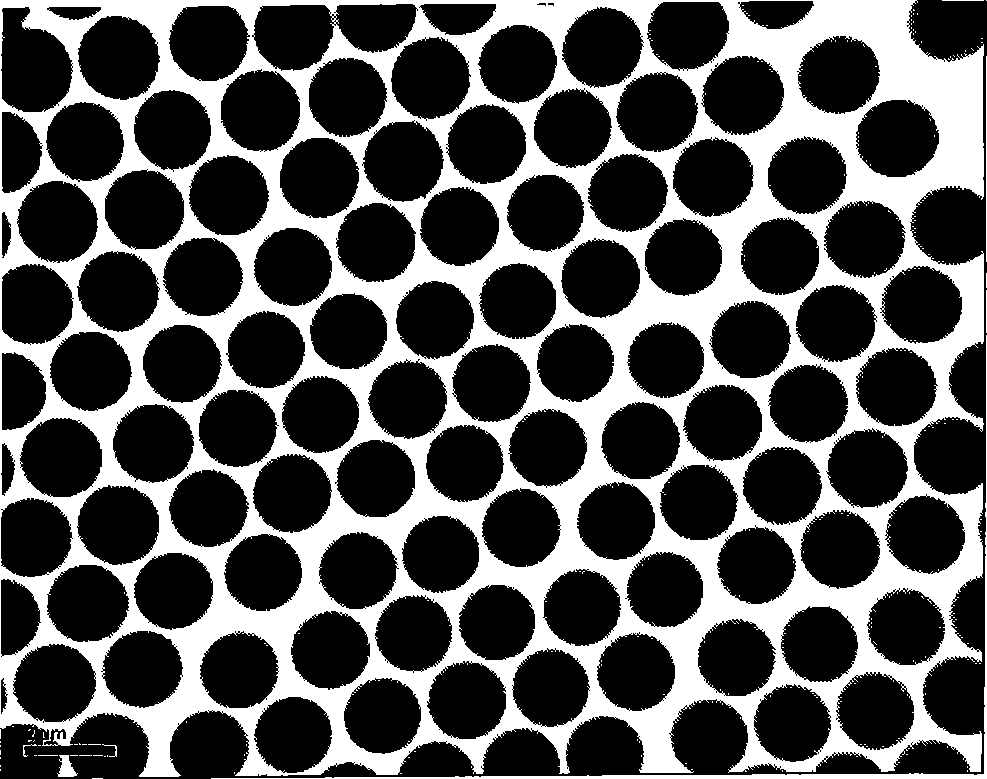

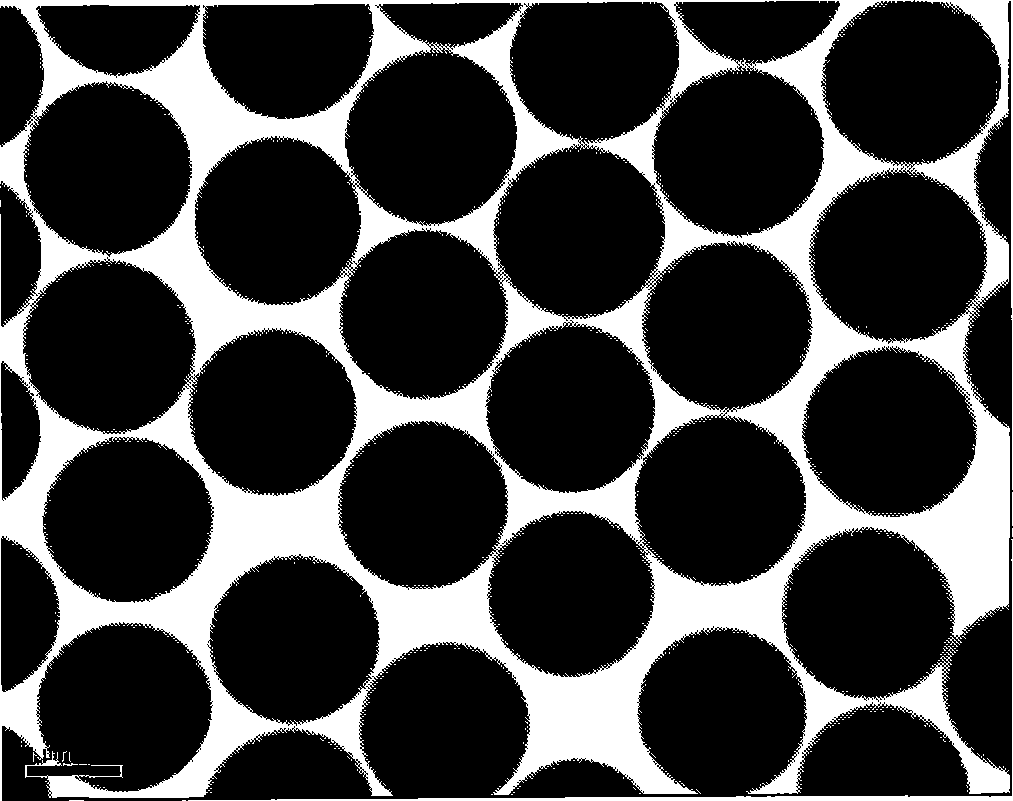

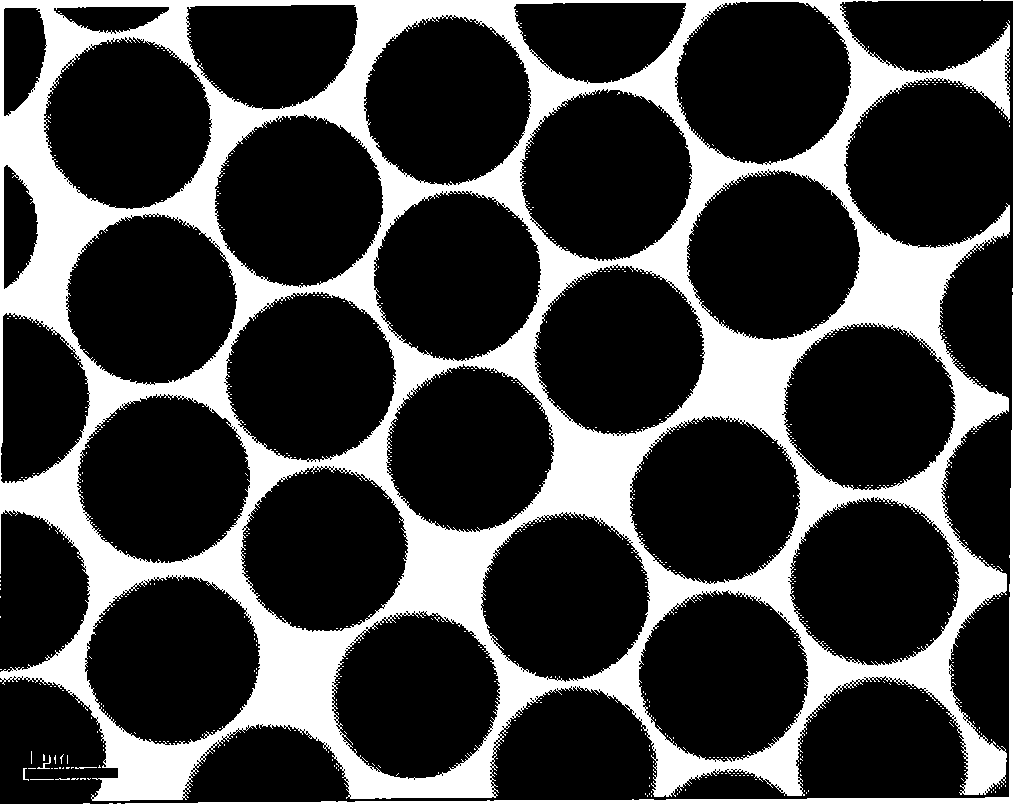

Process for producing cross-linked polymer microsphere with even grain diameter

The invention relates to a preparation method of crosslinked polymer microphere with uniform particle size. By adopting the process of dispersion and polymerization, styrene or acrylic ester is taken as a monomer; a monodisperse crosslinked polymer microphere with uniform particle size is prepared by steric hindrance dispersant and multi-functional crosslinker. The microphere has regular spherical and solid, a smooth surface, no damage or defect, and the strength and flexibility meet the requirements of producing ACF.

Owner:杜天鹏

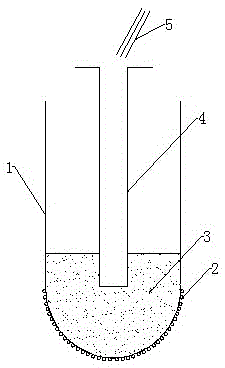

Purifying method for ultra-pure aluminum

The invention relates to a purifying method for ultra-pure aluminum. The purifying method specifically comprises the following steps: injecting molten aluminum with purity being 4N6 into a cast iron crucible, and heating the molten aluminum by a heating wire on the outer wall of the cast iron crucible for preserving the temperature of the molten aluminum to be 680-700 DEG C; stretching seed crystals above the cast iron crucible into a position 2-3cm under the liquid level of the molten aluminum, and introducing cooling gas to the other ends of the seed crystals to cool and crystallize the molten aluminum; spirally rotating the seed crystals in the cast iron crucible, thereby enabling the molten aluminum to carry out rotary motion in the cast iron crucible; and after the crystallizing is ended, quickly pulling out the seed crystals with crystallized ingots, and finally enabling the crystal seeds and the formed crystallized ingots to be in shape of inverted mushroom. The purifying method has the advantages of greatly reducing the purifying cost, and greatly improving the purifying efficiency and the purifying purity, and is suitable for industrial production.

Owner:NANTONG TADE ELECTRONICS MATERIAL TECH

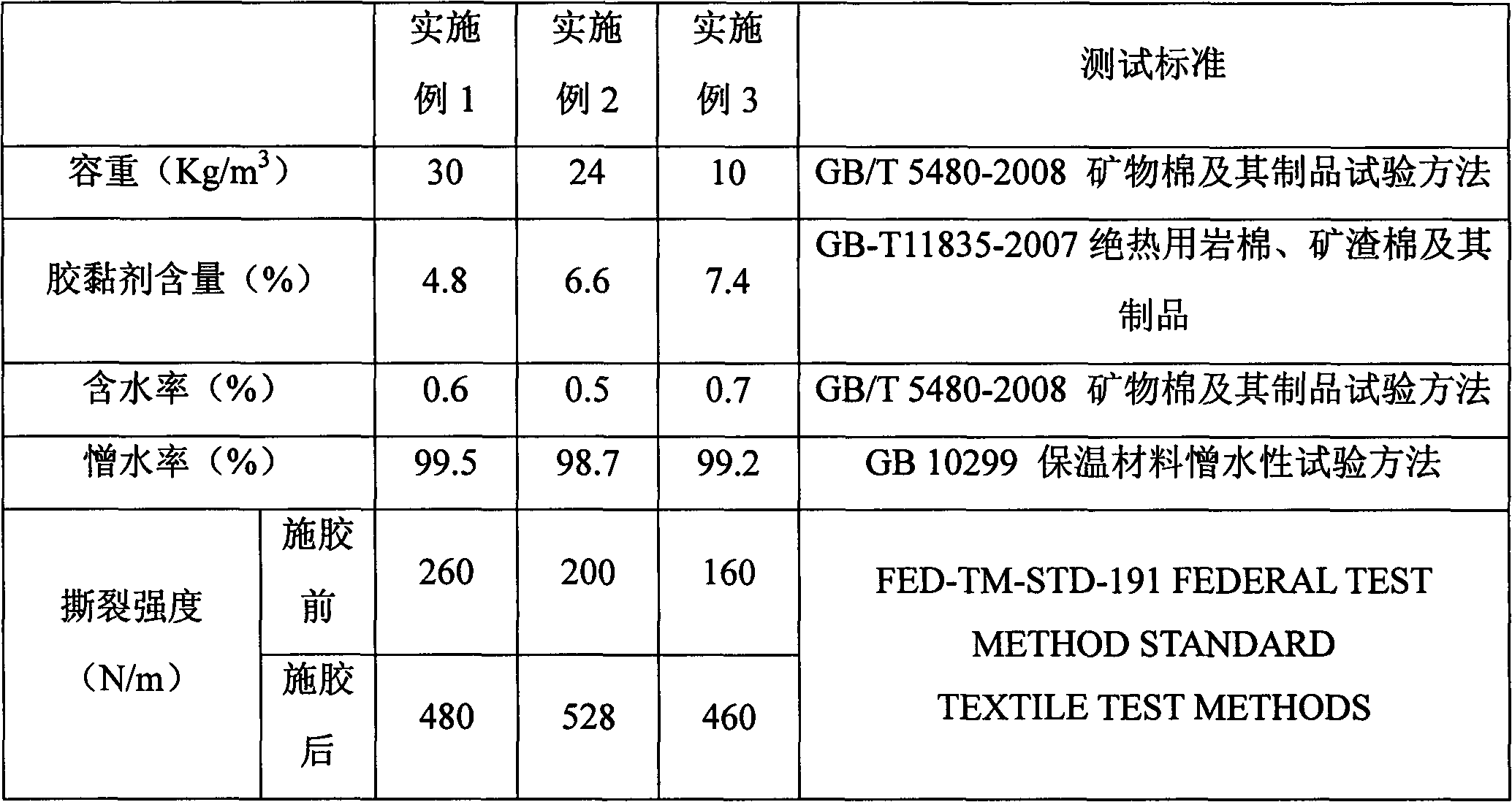

Hydrophobic type glass wool blanket and adhesive proportion thereof

InactiveCN103572503AImprove hydrophobicityIncrease elasticityMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesFiberThermal insulation

The invention discloses a hydrophobic type glass wool blanket and an adhesive proportion thereof. The hydrophobic type glass wool blanket is composed of centrifugal glass wool fibers and a highly hydrophobic adhesive, wherein the content of the adhesive is 3-25%, and the adhesive contains water soluble resin, a silane coupling agent, a moisture repellent, a curing agent, a pH conditioning agent, dust laying oil and softened water. According to the invention, the water soluble resin with good mobility serves as a raw material, so that the prepared glass wool blanket has excellent hydrophobic performances. At the same time, the invention relates to the adhesive proportion of the hydrophobic glass wool blanket. The adhesive product in the invention is excellent in bonding strength, hydrophobic performances, hydrolytic resistance, rebound resilience and corrosion resistance, and widens the application field of the glass wool blanket, such that the glass wool blanket can be used for thermal insulation and sound insulation in the fields of buildings, aviation, aerospace, navigation and the like.

Owner:陈照峰 +1

High-purity DHA algae oil ethyl ester and preparation method for transferring high-purity DHA algae oil ethyl ester into glyceride

ActiveCN103880672AIncrease percentageHigh in DHAOrganic compound preparationPreparation by ester-hydroxy reactionMicroorganismTransesterification

The invention discloses a DHA algae oil ethyl ester and a preparation method thereof. The method comprises the following steps: carrying out ethyl-esterifying on crypthecodinium cohnii DHA grease and then purifying trough a secondary molecular distillation method to obtain high-purity DHA ethyl ester. The invention further discloses a DHA glyceride and a method for transferring the DHA algae oil ethyl ester into glyceride. The method comprises the following steps: mixing the DHA algae oil ethyl ester with glycerinum in a material tank, feeding the mixed material in a reactor having immobilized lipase, performing transesterification to replace out the ethanol, recycling through a condenser, and flowing the reacted mixture back to the material tank, circularly reacting for 5-60 hours, and finally returning to the material tank, wherein the glyceride product is obtained by performing molecule distillation on the material. The method disclosed by the invention is suitable for the industrial production, the DHA greased produced from the microorganism is used as the raw material, the percent content of the DHA is greatly improved, the ethyl ester is transferred into the glyceride, the ethanol is avoided, the side effect after eating is not generated, and the utilization degree of the DHA algae oil ethyl ester in vivo is effectively improved.

Owner:JIANGSU ZHONGBANG PHARMA

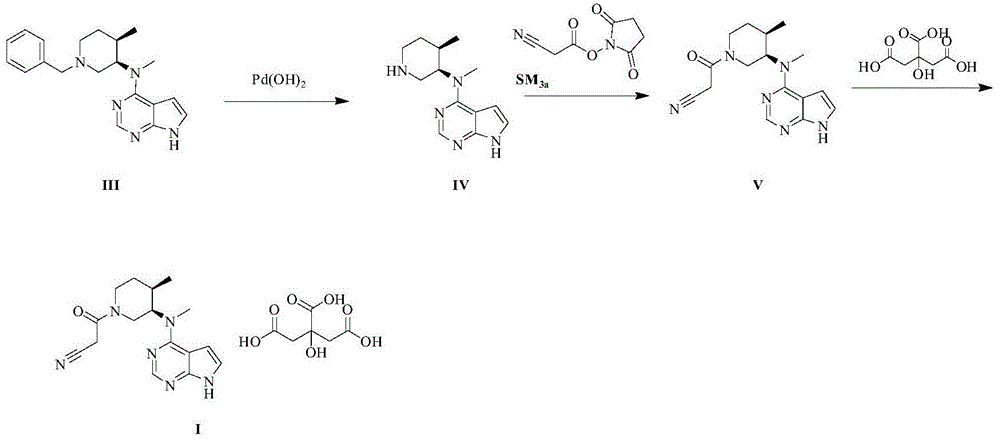

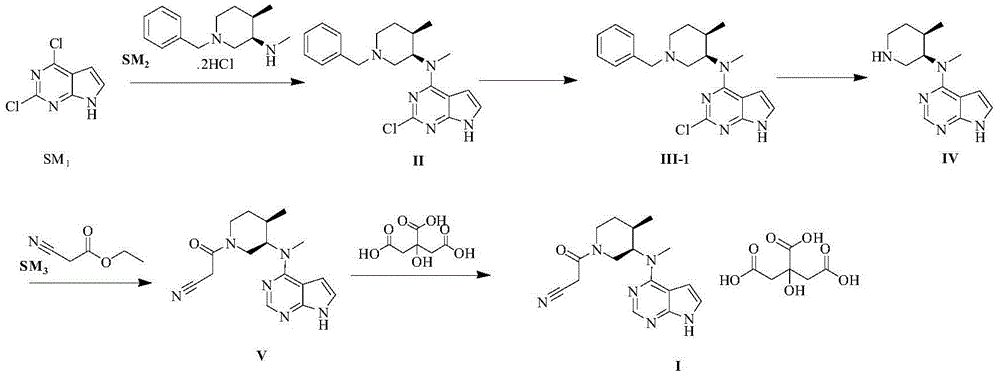

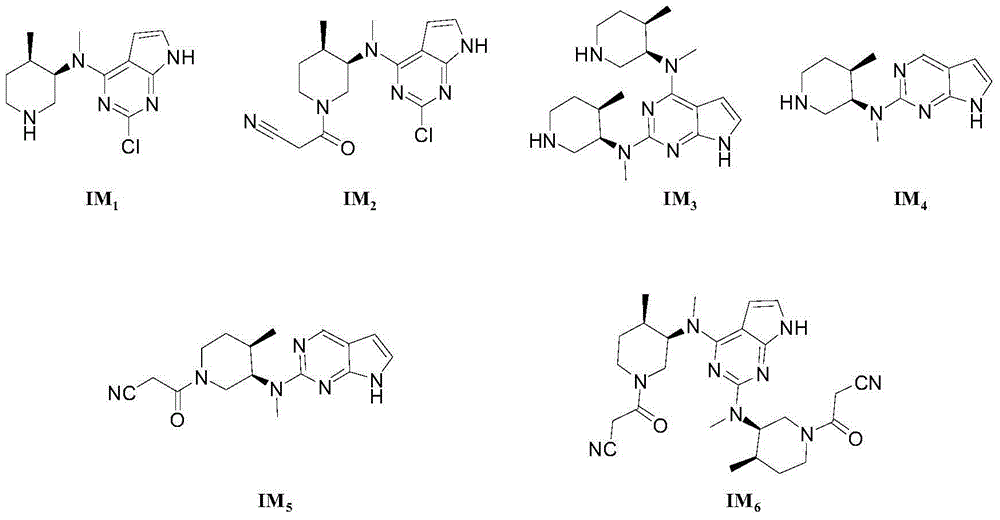

Industrial production method applicable to citric acid tofacitinib

InactiveCN104788461AReduce manufacturing costHigh purityOrganic chemistryBulk chemical productionTofacitinibActive ingredient

The invention relates to an industrial production method applicable to citric acid tofacitinib. The invention relates to a novel industrial production method of a high-purity orally taken JAK inhibitor and a medicine for treating rheumatoid arthritis. Raw materials are subjected to substitution, protecting group removal, reduction debenzylation, condensation and salifying to obtain a compound shown in a formula I, and the defects of a synthetic route reported in existing literatures that the impurity content in the prepared finished product is high, cost is high and yield is low are overcome. The novel industrial production method provided by the invention has the advantages that cost of a used reagent is low, environmental pollution is hardly caused, operation is easy, and short time is consumed, so that the novel industrial production method is applicable to industrial production; meanwhile, product quality is good, total impurity content is low, content of each individual impurity is controlled to be 0.1% or below, the finished product is controlled to be in a single stable crystal form, and medicinal-grade raw material requirements can be met.

Owner:NANJING CHENGONG PHARM CO LTD

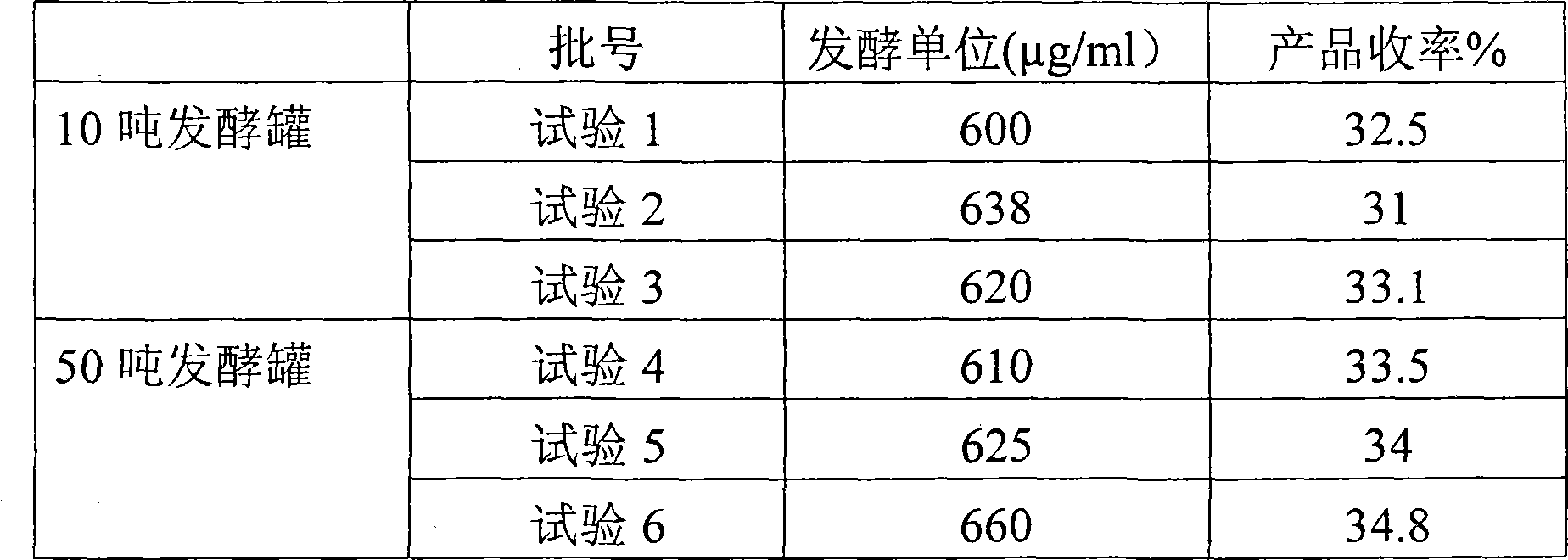

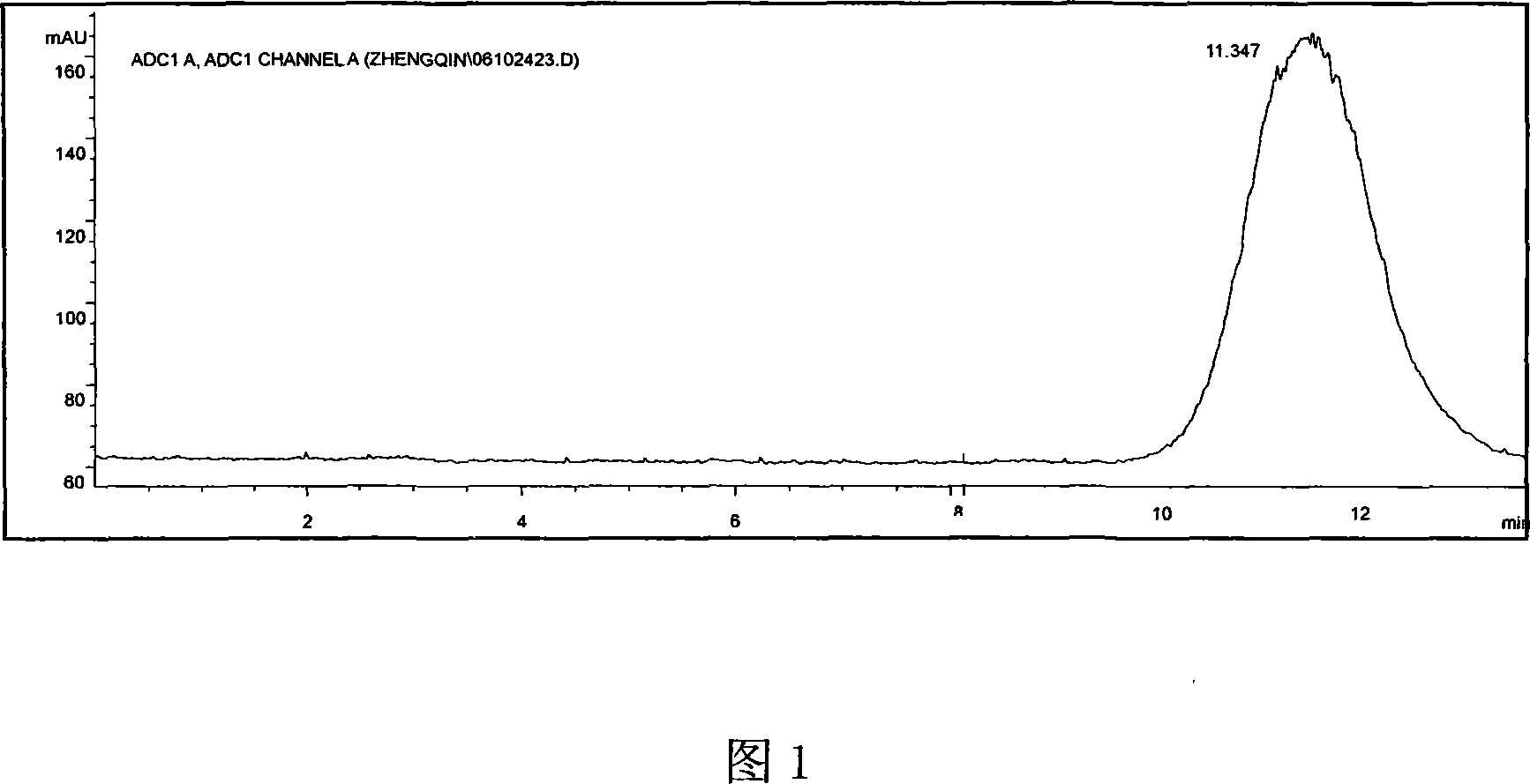

Streptomyces hygroscopicus and use thereof

ActiveCN101486976AIncrease production capacityImprove fermentation effectBacteriaMicroorganism based processesStreptomyces hygroscopicusMicrobiology

The invention discloses a streptomyces hygroscopicus and applications thereof. The streptomyces hygroscopicus strain is preserved in China Center for Type Culture Collection with CCTCC NO. of M 207200 and the preservation date of December 14th, 2007. The strain with CCTCC NO. of M 207200 is a currently-separated natural strain with high sirolimus yield and excellent fermentation performance. The fermentation yield of the sirolimus-producing strain can reach over 600ug / ml, has relatively less fermentation byproducts, lowers post extraction difficulty, can reach the product yield of over 30 percent, and is applicable to industrial production.

Owner:HANGZHOU HUADONG MEDICINE GRP PHARMA RES INST +1

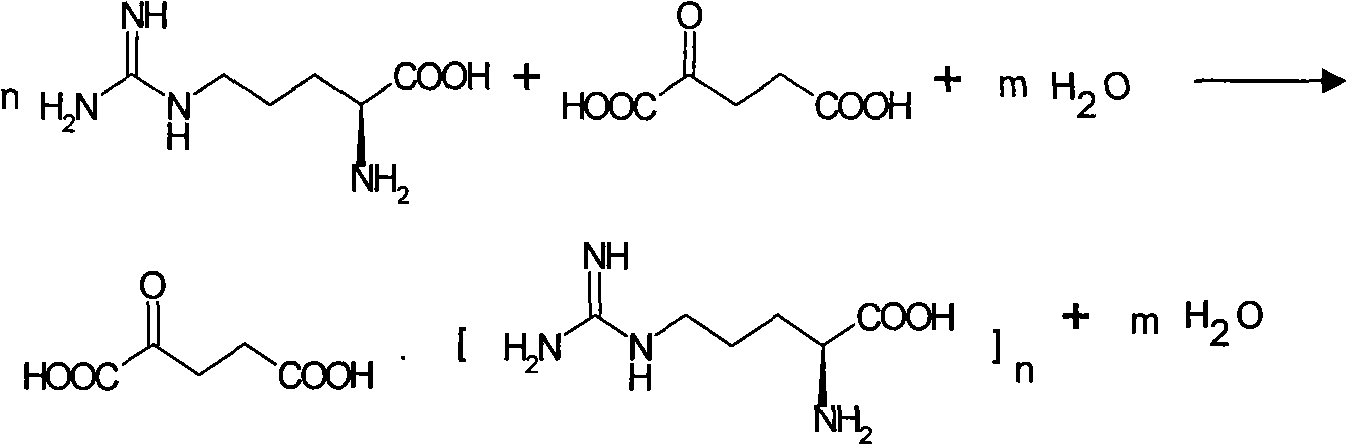

Preparation method of crystal L-arginine alpha-ketoglutarate

InactiveCN101591271AReasonable workmanshipSimple stepsOrganic chemistryFood preparationArginineL-arginine alpha-ketoglutarate

The invention relates to a preparation method of crystal L-arginine alpha-ketoglutarate, comprising the following steps: preparing water solution of L-arginine, and slowly adding alpha-ketoglutaric acid into the water solution, wherein the mol ratio of L-arginine and alpha-ketoglutaric acid is 1:1 or 2:1; reducing pressure and concentrating the alpha-ketoglutaric acid at 50-80 DEG C after complete dissolution, removing water accounting for 20-60 percent of the total volume and cooling to 20-30 DEG C; slowly adding an organic hydrophilic solvent or a mixed solvent of a polar hydrophilic solvent and a non-polar hydrophilic solvent; and carrying out temperature reduction, crystallization, filtering, washing and vacuum drying to obtain the crystal L-arginine alpha-ketoglutarate. Compared with the prior art, the invention has the advantages of reasonable process, simple steps, easy operation, good crystal form of the obtained product, difficult caking, convenient transportation and use, high purity (more than or equal to 98 percent) and high yield (80-86 percent) of the product, and the like, and is suitable for industrialization production.

Owner:上海汉飞生化科技有限公司

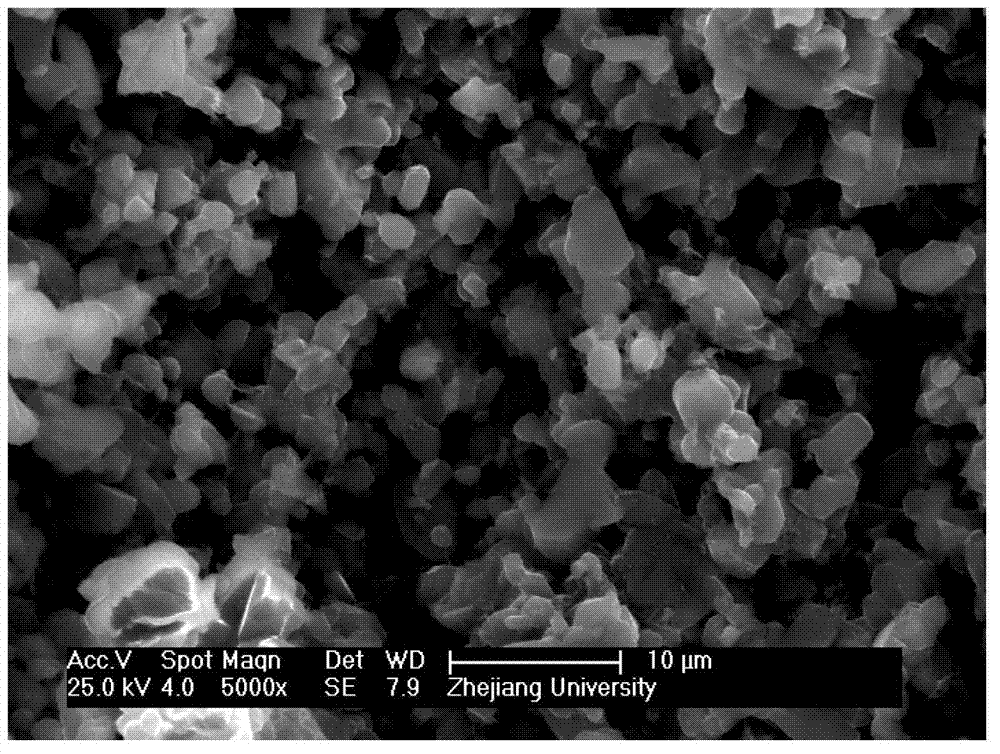

Binary nanometer cooperative reinforcing and toughening silicon carbide ceramics and preparing method thereof

The invention discloses a method for preparing binary nanometer cooperative reinforcing and toughening silicon carbide ceramics, and silicon carbide powder, yttrium aluminum garnet, nano particles and nano crystal whickers are taken as the main raw materials. The method comprises the following steps: 1) the main raw materials, a binder and a dispersant are added into de-ionized water, after being ball-milled and mixed, water-base silicon carbide slurry is prepared; 2) the water-base silicon carbide slurry is sprayed and dried by adopting a spray granulation technology; 3) the obtained silicon carbide granulating powder is formed by adopting pre-pressing of dry pressing and final pressing of cold isostatic pressing; and 4) the obtained green body of silicon carbide is put in a vacuum non-pressure sintering furnace to be treated, thus obtaining the binary nanometer cooperative reinforcing and toughening silicon carbide ceramics. The invention also discloses the binary nanometer cooperative reinforcing and toughening silicon carbide ceramics prepared in the method. The silicon carbide ceramics have the advantages of large flexural strength, good fracture toughness and the like.

Owner:ZHEJIANG UNIV

Method for preparing MDG-1 polysaccharide of lilyturf root

InactiveCN101050241AShort timeLow costOrganic active ingredientsCardiovascular disorderAlcoholOphiopogon Japonicus Root

This invention discloses a method for preparing Ophiopogon japonicus polysaccharide MDG-1 with anti-myocardial ischemia function. The method comprises: extracting Ophiopogon japonicus roots with water, precipitating with alcohol to obtain crude polysaccharide, separating by ultrafine filtration, eluting the concentrate with water in a macroporous weak-base anion exchange resin, collecting eluates 4-8 volume times of the column, incorporating the eluates, and drying to obtain Ophiopogon japonicus polysaccharide MDG-1 with purity greater than or equal to 90%. The method has such advantages as short time and is suitable for mass production.

Owner:SHANGHAI UNIV OF T C M

Silicon carbide short fiber toughened and strengthened silicon carbide ceramics and preparation method thereof

The invention discloses a preparation method of silicon carbide short fiber toughened and strengthened silicon carbide ceramics, which takes silicon carbide powder, yttrium aluminum garnet and silicon carbide short fiber as the main materials and sequentially comprises the following steps of: 1) adding the main materials, a caking agent and a dispersant into de-ionized water and preparing water-based silicon carbide slurry after ball-mill mixing; 2) adopting a sponging drying technique to carry out spray drying to the water-based silicon carbide slurry; 3) adopting 160-200MPa to carry out dry pressing and shaping to the obtained strengthened silicon carbide palletizing powder to obtain a silicon carbide biscuit; and 4) arranging the silicon carbide biscuit in a vacuum pressureless sintering furnace for sintering to obtain the silicon carbide short fiber toughened and strengthened silicon carbide ceramics. The invention simultaneously provides the silicon carbide short fiber toughened and strengthened silicon carbide ceramics prepared by the method. The silicon carbide ceramics is characterized by larger fracture toughness, high mechanical strength, and the like.

Owner:ZHEJIANG UNIV

Preparation method of high-porosity silicon-carbide porous ceramics

ActiveCN102807384ALow raw material costHomogeneous microstructureCeramicwareSpray GranulationPolyvinyl alcohol

The invention discloses a preparation method of high-porosity silicon-carbide porous ceramics. According to the preparation method, 60 to 80% of silicon-carbide powder, 10% of boron carbide, 5 to 25% of iron oxide and 5% of polyvinyl alcohol by weight are adopted as raw materials, and the steps of mixing, spray granulation, extrusion forming, drying and sintering are sequentially carried out, wherein the technical conditions for sintering are as follows: a dried biscuit is sintered for 10 to 15 hours at 2100 to 2200 DEG C through pressureless sintering technology so as to obtain the high-porosity silicon-carbide porous ceramics. The silicon-carbide porous ceramics prepared by the method disclosed by the invention has the characteristics of controllable aperture size, high apparent porosity, and relatively large specific surface area, and strength of the silicon-carbide porous ceramics meets the application requirement.

Owner:ZHEJIANG UNIV

A method for preparing expandable graphite or graphene by utilizing waste cathode carbon formed in electrolytic aluminum production

ActiveCN107200320AComplete structureImprove thermal conductivityGrapheneBulk chemical productionSlurryDeoxygenation

A method for preparing expandable graphite or graphene by utilizing waste cathode carbon formed in electrolytic aluminum production is disclosed. The method includes (1) a step of crushing, adding a strong oxidant and water into the crushed product, stirring, rolling or wet-grinding the mixture, and performing a hydrothermal oxidation reaction; (2) a step of controlling the temperature, pressurizing, feeding supercritical or liquid carbon dioxide, mixing the mixture by stirring the mixture, allowing the mixture to stand, adjusting the temperature and pressure, performing separation to obtain aqueous slurry and graphite oxide slurry fluid, and washing the graphite oxide slurry fluid with water to remove impurities; and (3) a step including 1) a manner of performing atomization, expansion and stripping to remove the carbon dioxide; or 2) a manner of adding a reactant for reduction, and then performing atomization, expansion and stripping to remove the carbon dioxide, or further performing denitrification and deoxygenation; or 3) a manner of adding a fluorinating agent, heating the mixture, performing a fluorinating reaction, and performing atomization, expansion and stripping to remove the carbon dioxide. Expanded graphite powder, graphene powder, denitrified deoxygenated graphene powder or fluorinated graphene powder which are prepared by the method have excellent properties. The method is simple, efficient, clean, free of secondary pollution, low in energy consumption and suitable for industrial production.

Owner:长沙紫宸科技开发有限公司

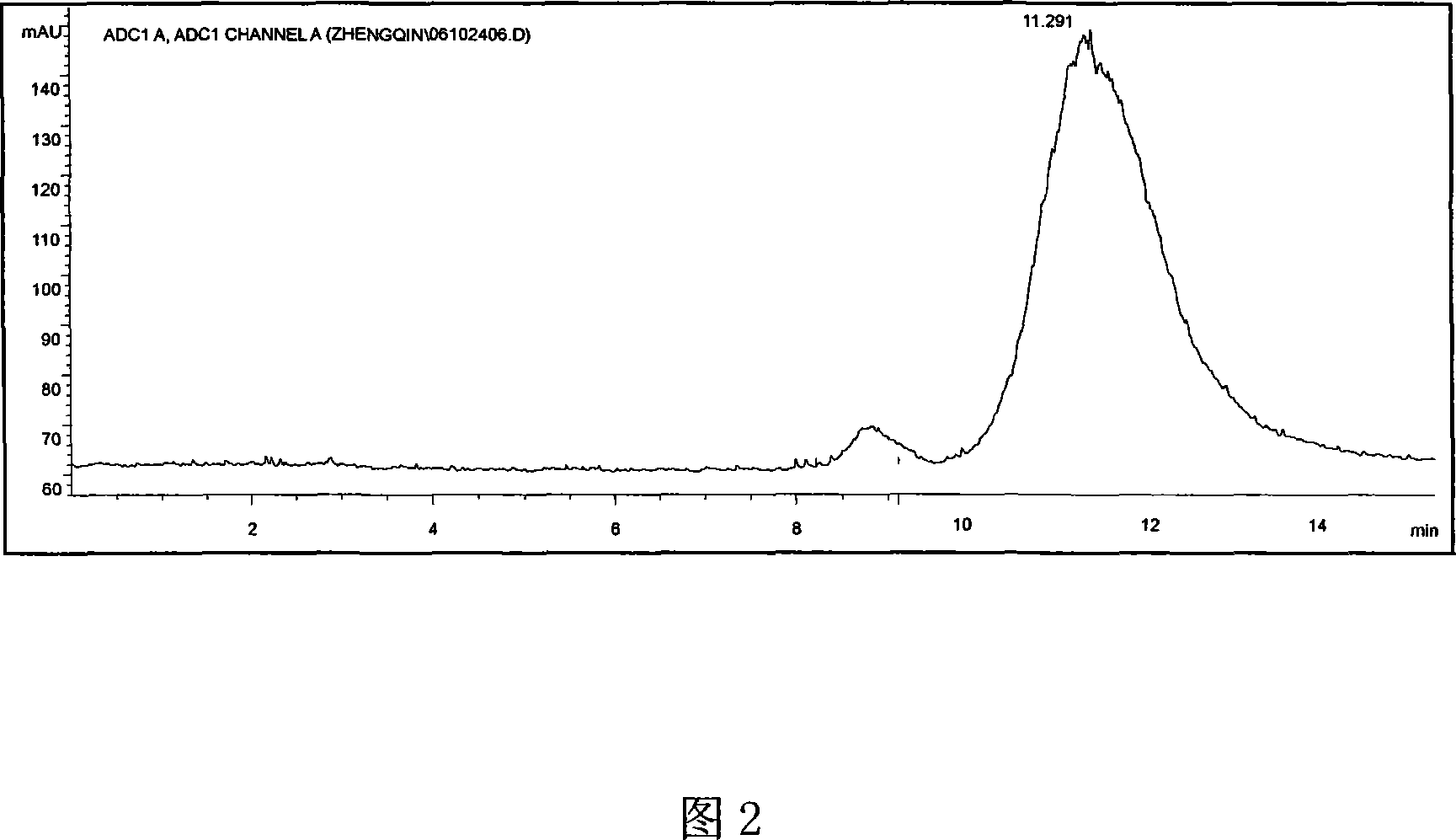

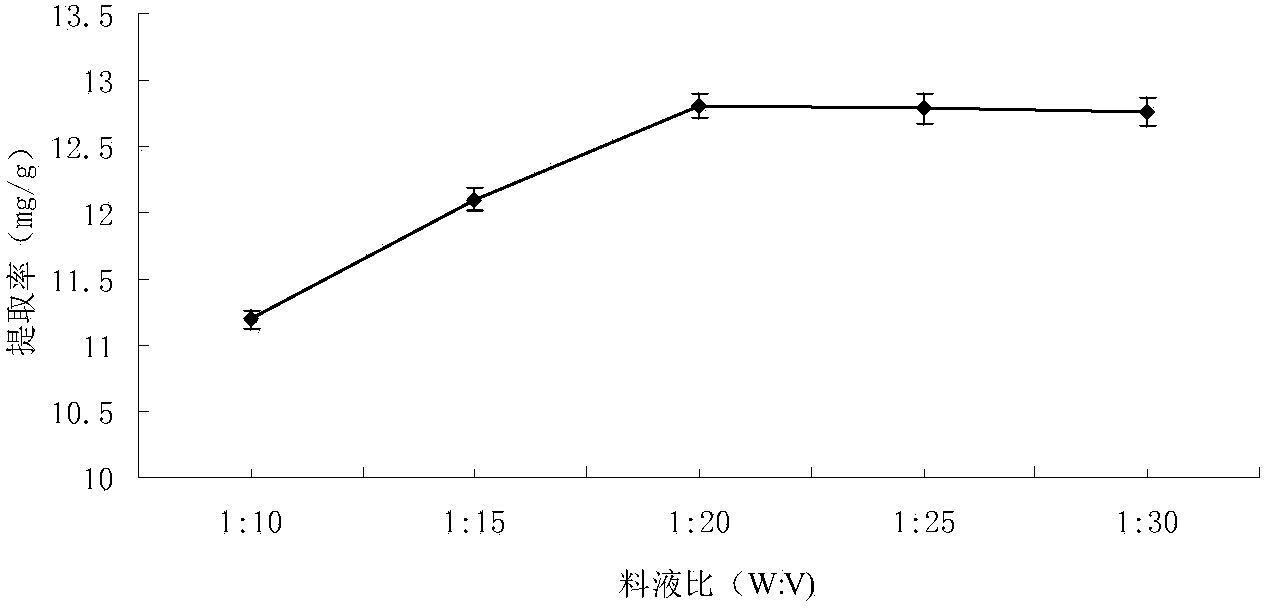

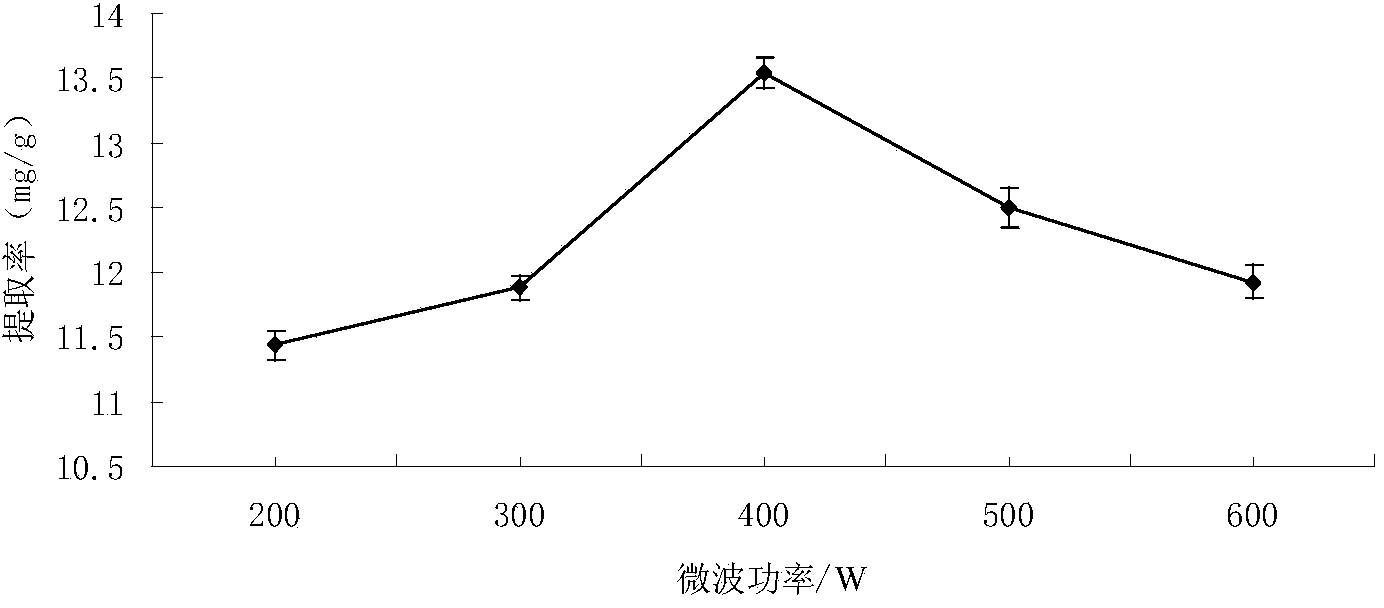

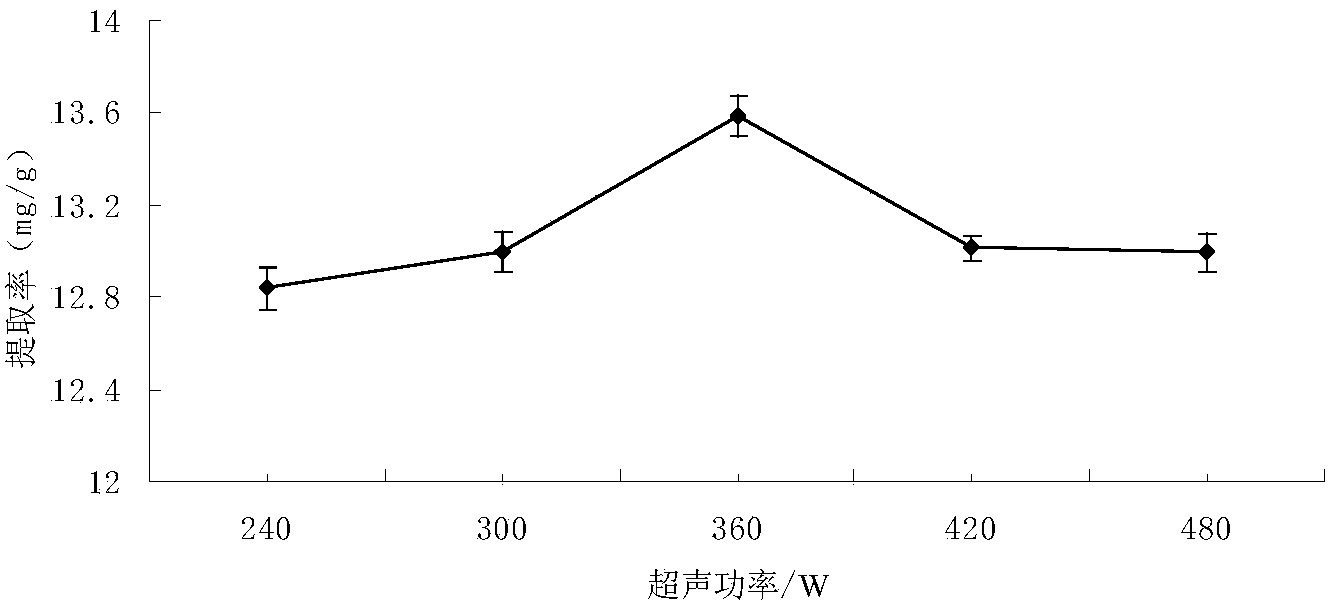

Cornus officinalis total saponins obtained by response surface method optimized ultrasonic-microwave synergetic extraction and method for extracting total saponins from cornus officinalis

ActiveCN104107208AIncrease profitEasy to handleMetabolism disorderImmunological disordersCornus officinalisMicrowave power

The invention provides a method for extracting cornus officinalis total saponins by response surface method optimized ultrasonic-microwave synergetic extraction. The method comprises the following steps: (1) treating materials to obtain cornus officinalis powder; (2) performing ultrasonic-microwave synergetic extraction to obtain a total saponin sample solution; and (3) purifying by macroporous resin, concentrating and drying eluent to obtain powdered cornus officinalis total saponins. The cornus officinalis total saponins can be prepared by the extracting method. According to the method, the cavatition effect of ultrasonic wave and the high-performance infrared heating effect of microwave are combined, so that a sample can be quickly, effectively and reliably treated, the extraction time is shortened, the extraction efficiency is improved, the material-liquid ratio, the microwave power, the ultrasonic power and the extraction time can be respectively limited while the extract structure is guaranteed, and the extraction rate of the cornus officinalis total saponins is 13.96mg / g and is increased by up to 20 percent. The method has high raw material utilization rate, is effective and saves time, can be used for greatly saving cost, and is suitable for industrial production.

Owner:SHAANXI NORMAL UNIV

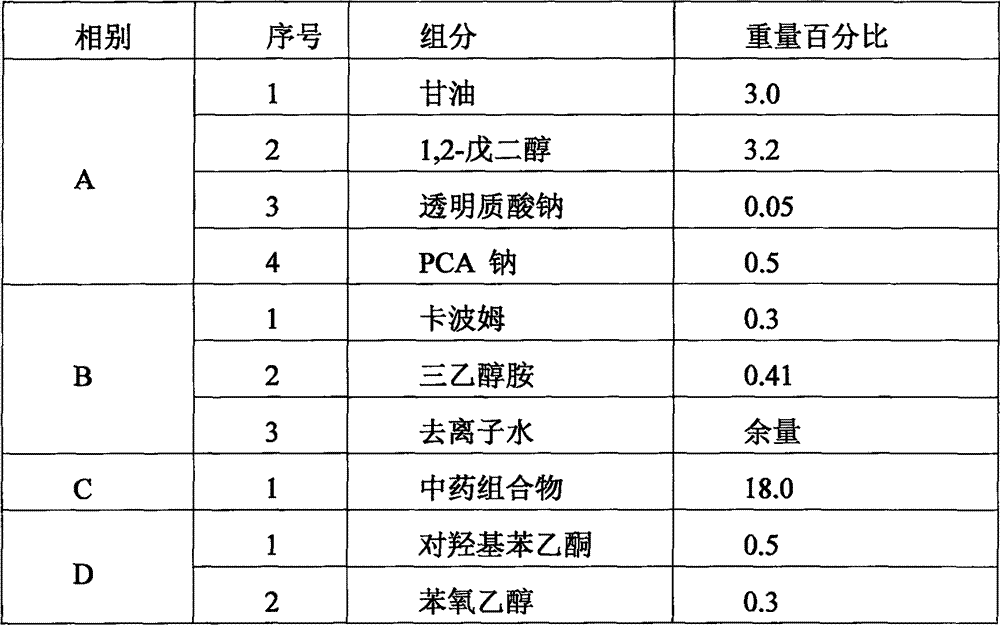

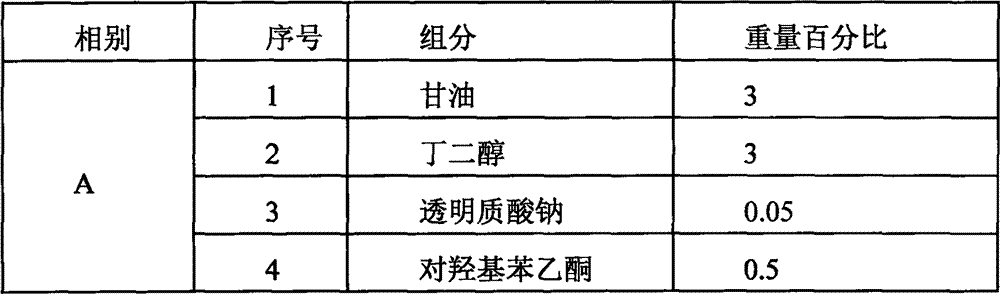

Traditional Chinese medicine composition with effect of sensitive skin repairing and fermented substance and application thereof

ActiveCN107349302ASuppress allergic reactionsImprove immunityCosmetic preparationsToilet preparationsBelamcanda chinensisCuticle

The invention relates to the technical field of traditional Chinese medicine, in particular to a traditional Chinese medicine composition with the effect of sensitive skin repairing and a fermented substance and application thereof. In order to achieve the purpose of sensitive skin repairing, the traditional Chinese medicine theory in our country serves as guidance, traditional Chinese medicine raw materials are screened through extensive experiments for a long time, dried rehmannia roots, radix pseudostellariae, fructus cnidii, fructus kochiae, licorice, radix gentianae, belamcanda chinensis and oroxylum indicum are effectively combined together, and a mixture or an extract which is obtained through water extraction is obtained. The effects of all the raw materials can generate the synergistic effect; the traditional Chinese medicine composition has the effects that a skin allergic reaction is inhibited, skin immunity is improved, quick repair of a skin lesion part is promoted, and a skin cuticle barrier is reconstructed; and when the traditional Chinese medicine composition is applied to cosmetics, the significant sensitive skin repair and protection effects are achieved.

Owner:温州古木生物科技有限公司

Blueberry scented tea and preparation method thereof

The invention discloses blueberry scented tea. The blueberry scented tea is prepared from the following raw materials in parts by weight: 40-50 parts of dried blueberry granules, 5-15 parts of blueberry leaves, 30-40 parts of roses and 5-15 parts of a flavor substance. The blueberry scented tea disclosed by the invention is unique in taste and convenient to drink; moreover, a preparation process is simple, a blueberry utilization rate is increased, economic benefits of blueberry farmers are improved, and utilization on blueberry effective ingredients is further enhanced. Compared with the current fruit scented tea, the blueberry scented tea prepared by the invention is purple, tastes sour and sweet, reserves rose scent and is not muddy after being brewed, is consistent with modern people's requirements on natural, healthy, safe and delicious drink, and is ideal in stability, convenient to store and instant to drink.

Owner:ZHENJIANG LVJIAN AGRI SCI & TECH DEV

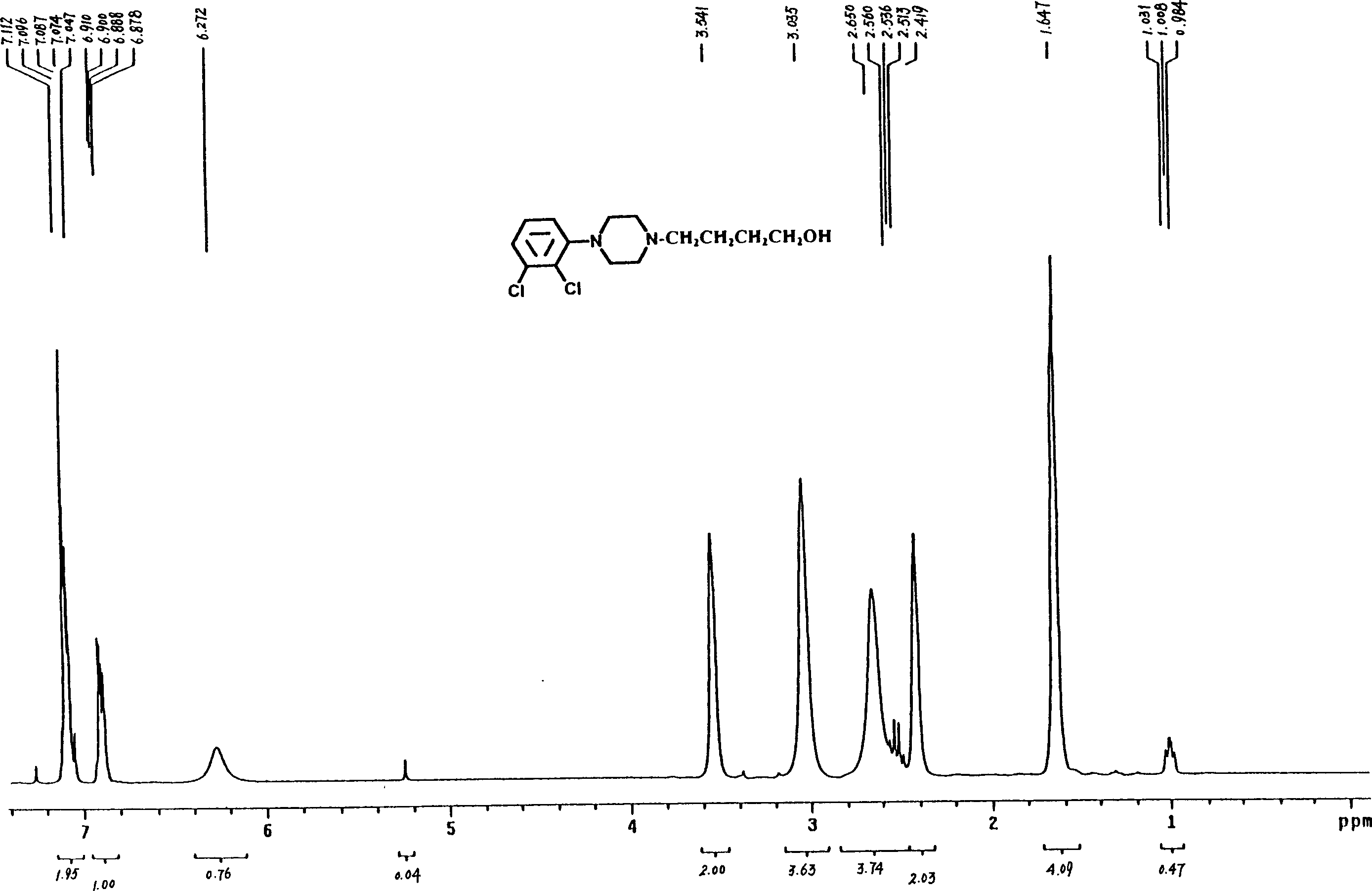

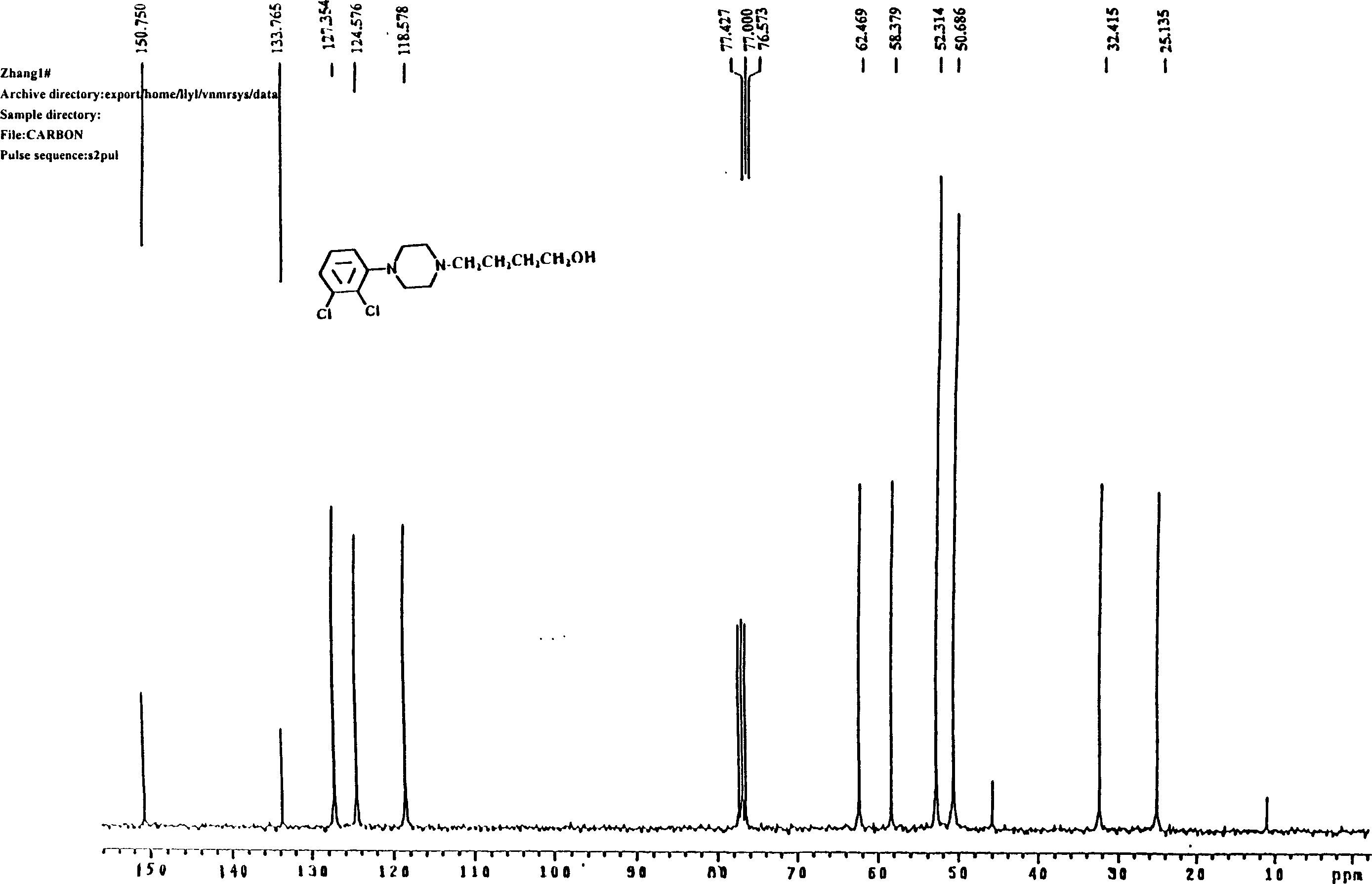

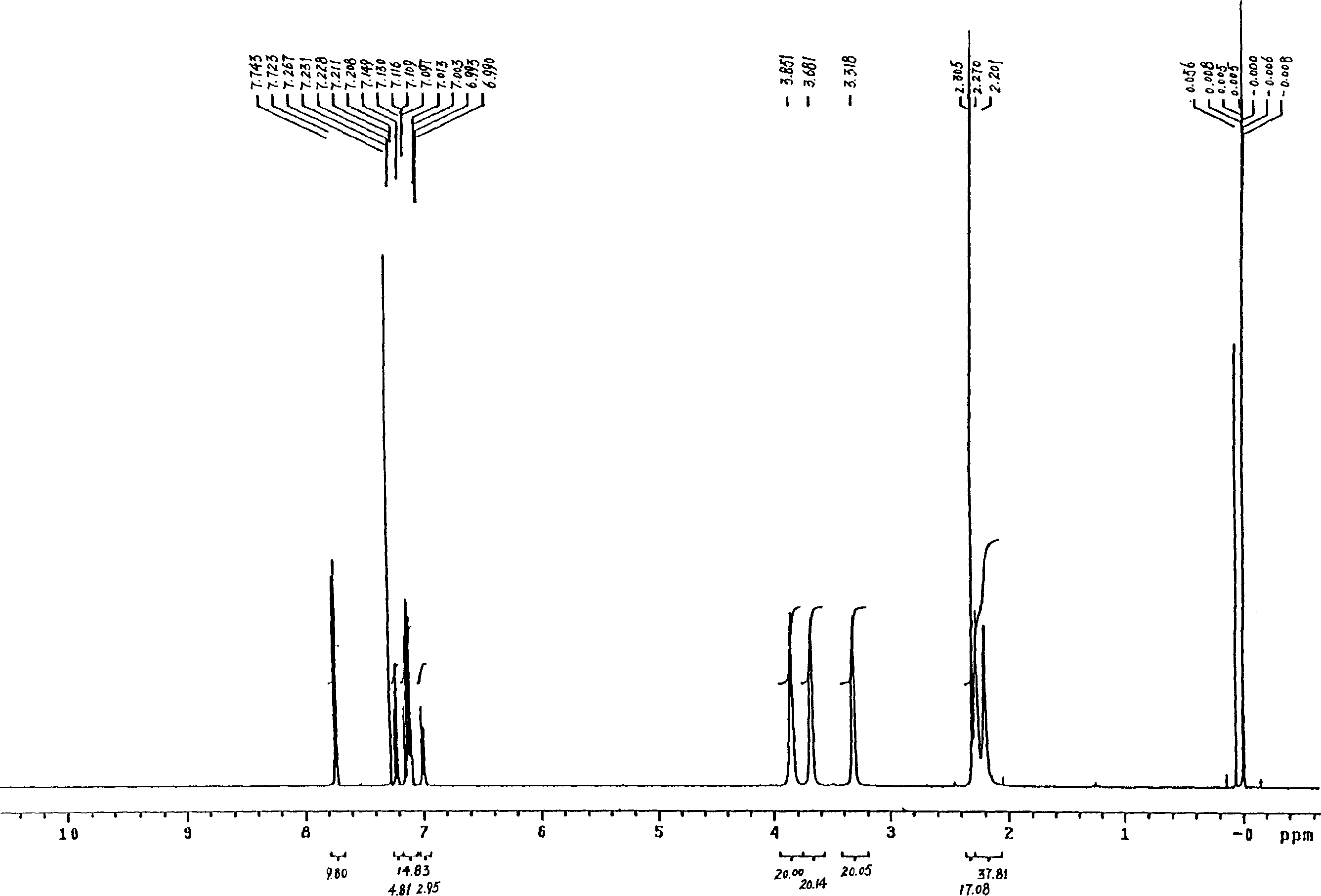

Process for Producing Aliprazo

InactiveCN1576273AStrong response specificityHigh yieldOrganic chemistryPurification methodsAripiprazole

The present invention relates to the preparation process of Aripiprazole. Aripiprazole is prepared with two kinds of compound and through condensation. The preparation process of the present invention has mild reaction condition, less side products, simple operation and controllable quality of the intermediate, and the Aripiprazole product of the present invention may reach relevant medicine standard without needing several times of re-crystallization.

Owner:重庆凯林制药有限公司 +1

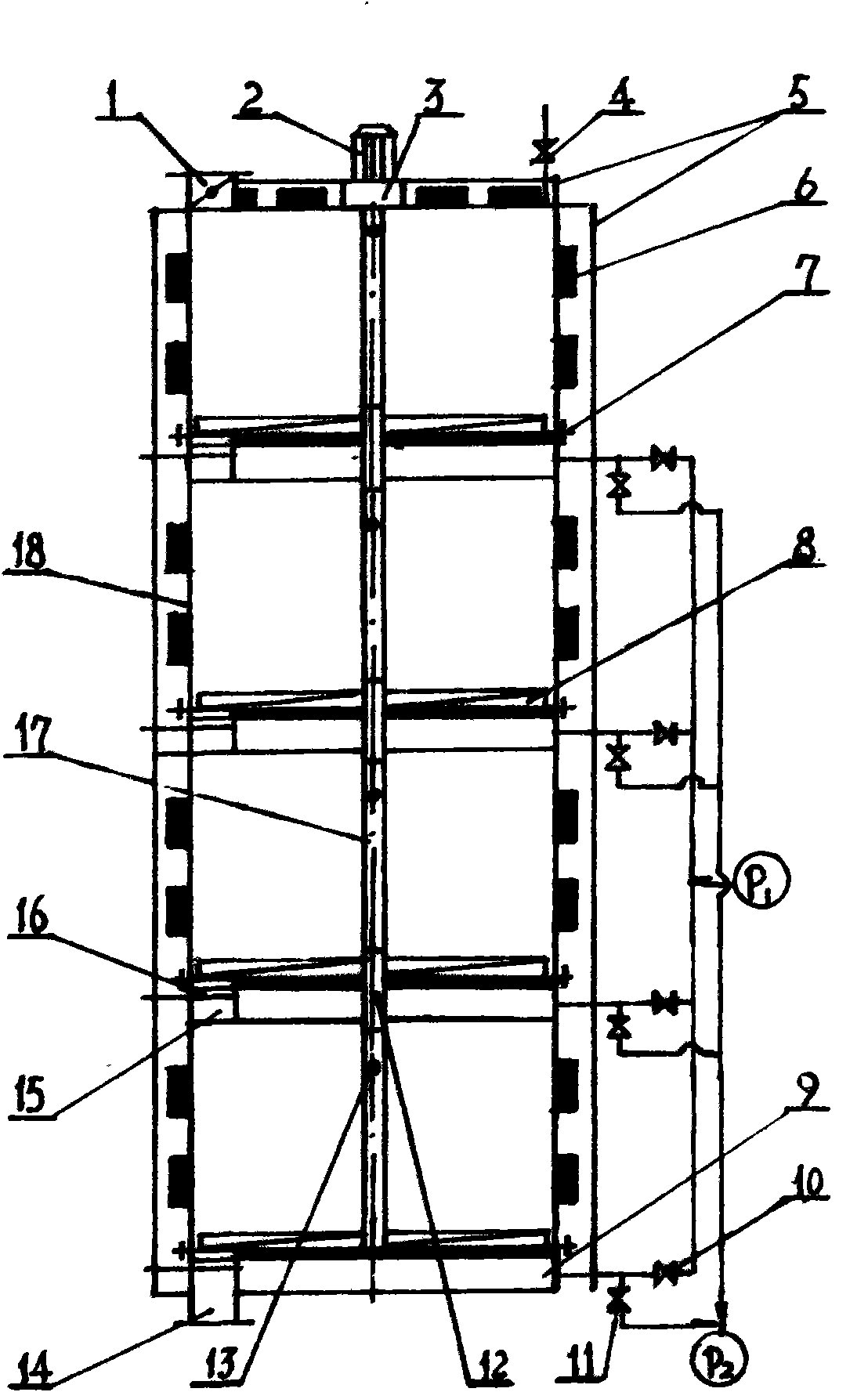

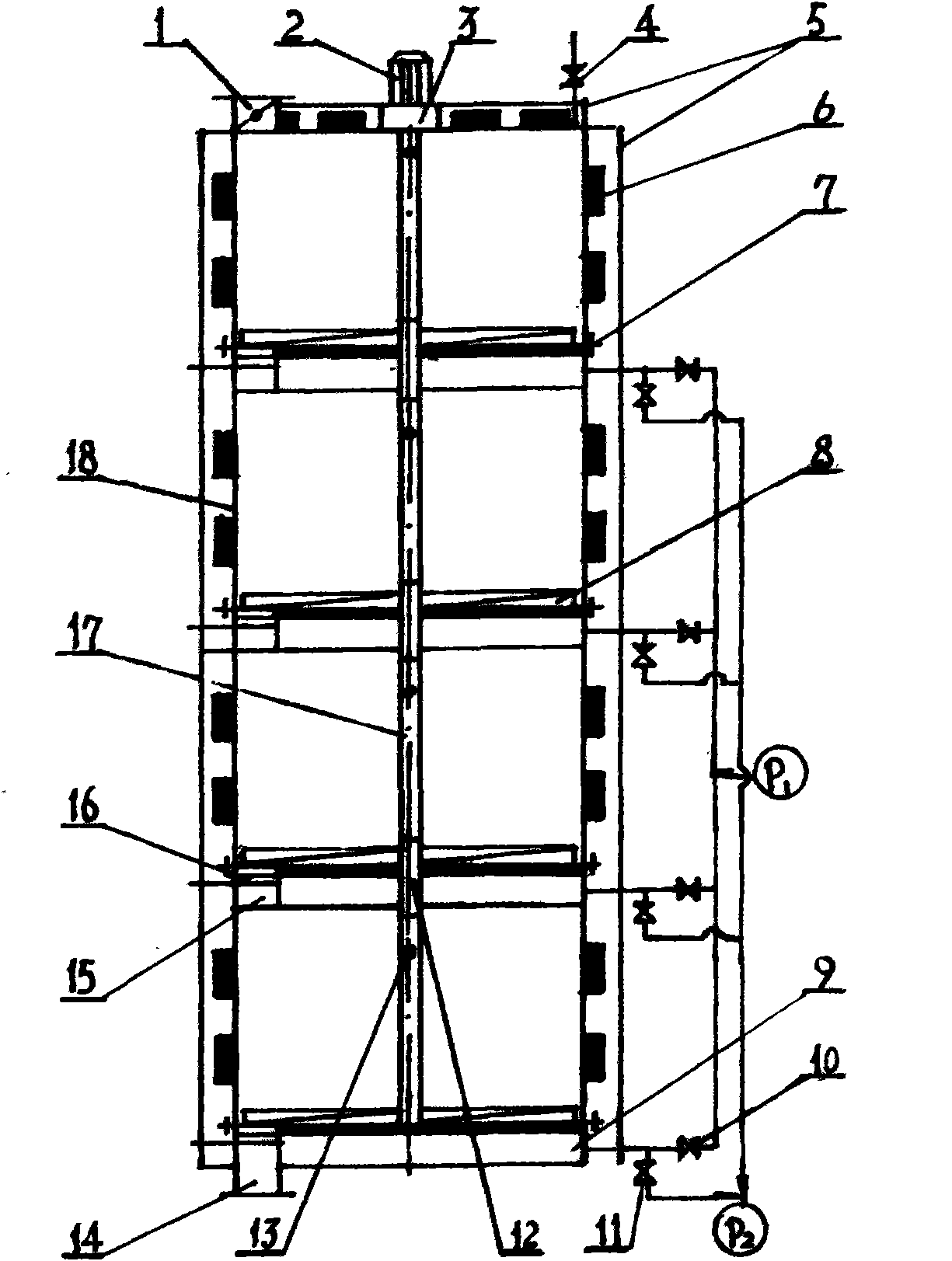

Dry microwave extraction device

InactiveCN101850190AImprove qualityHigh yieldEnergy based chemical/physical/physico-chemical processesSolid solvent extractionMicrowaveAdditive ingredient

The invention relates to a device for wetly extracting effective ingredients in a plant by using microwave. The device consists of an extraction component, a stirring component and a microwave radiation heating component. The device is characterized in that the extraction component consists of a plurality of circular barrels with filter screen cavities and baiting flat gate valves; the stirring component consists of a motor, a speed reducer, a stirring shaft, a sealing shaft sleeve and a plurality of layers of stirring paddles; and the microwave radiation heating component consists of a plurality of groups of microwave generators arranged on the top and the periphery of the barrels and a protective cover. The device directly radiates and heats a dry plant material by adopting microwave and then adopts an extraction method by adding a solvent so as to greatly save the energy consumption and the extraction time and improve the quality and yield of a subject matter; and the device can be widely applied to the industries of pharmacy, food and chemical engineering.

Owner:郑小非

Layered vacuum insulation board core material and preparation method thereof

InactiveCN102628538ASlow heat transferImprove insulation performanceThermal insulationPipe protection by thermal insulationHealth organizationVacuum insulated panel

The invention discloses a layered vacuum insulation board core material and a preparation method thereof. The thickness of the vacuum insulation board core material is between 5 and 50mm, the coefficient of heat conductivity is between 0.018 and 0.03 W / mK, and the vacuum insulation board core material is formed by overlying a plurality of layers of glass fiber mats and can be prepared into vacuum insulation boards with high-efficient thermal insulation. According to the layered vacuum insulation board core material, continuous glass fiber with 6 to 13 mu m of diameter and 5 to 20mm of length is used and cannot be sucked into the deep parts of human lungs after being authenticated by world health organization, so that the layered vacuum insulation board core material is safe and harmless, meets the requirements of materials, can be used at ease for a long time and solves the problems of sanitation and safety of vacuum insulation board products.

Owner:周介明 +1

High temperature resistant resin-based friction material

InactiveCN107606005AImprove performanceImprove wear resistanceOther chemical processesFriction liningSocial benefitsFiber

The invention discloses a high temperature resistant resin-based friction material. The material is composed of the following raw materials of, by weight, 6-10 parts of modified phenolic resin, 6-8 parts of butadiene-acrylonitrile rubber powder, 4-8 parts of reinforced fibers, 10-14 parts of a friction modifier, 2-4 parts of an epoxy resin lubricant, and 12-14 parts of a filler. According to the high temperature resistant resin-based friction material provided by the invention, phenolic resin is modified through a cashew nut shell oil modifier, and the modified phenolic resin is more excellentin performance and applied to preparation of the resin-based friction material; the abrasion resistance, the high temperature resistance and the friction coefficient stability of the prepared resin-based friction material are improved; and sources of the raw materials are extensive, and the high temperature resistant resin-based friction material is applicable to industrial production and has good economical and social benefits.

Owner:SUZHOU CUINAN ELECTRONICS TECH CO LTD

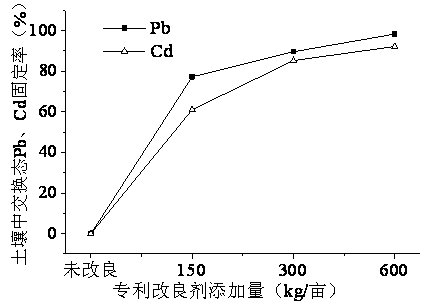

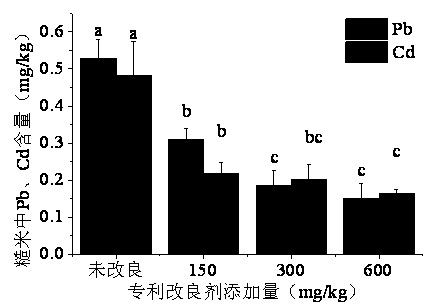

Lead-cadmium compound conditioner for rice field soil as well as preparation and application methods thereof

ActiveCN103143557BReduce absorptionControl activityContaminated soil reclamationSepioliteCadmium pollution

The invention discloses a lead-cadmium compound conditioner for rice field soil as well as preparation and application methods of the lead-cadmium compound conditioner. The conditioner is composed of the raw materials in mass fractions: 30-50% of calcium carbonate, 5-10% of hydroxyapatite, 20-30% of sepiolite and 20-30% of zeolite; the preparation of the conditioner comprises the following steps of: weighing various raw materials according to the mass fractions of the components of the lead-cadmium compound conditioner; continuously stirring the various raw materials in a stirring device for at least 30 min, and thoroughly stirring and evenly mixing all the materials; and the method of application of the conditioner comprises the following steps of: (1) analyzing the total quantity of lead and cadmium in the rice field and the content of lead and cadmium in exchange state; (2) determining the pollution level of the rice field soil by using an evaluation model; (3) applying the lead-cadmium compound conditioner according to the lead-cadmium pollution level in the rice field, and applying the lead-cadmium compound conditioner to the slightly polluted rice field at 100-150 kg / mu, to the mildly polluted rice field by 150-300 kg / mu and to medium-polluted rice field at 300-600 kg / mu, and balancing and stabilizing for 10-15 days; and (4) analyzing and measuring the content of lead and cadmium in exchange state in the rice field, and if the fixed rate is lower than 90%, additionally applying the conditioner at 100-150 kg / mu.

Owner:廖柏寒 +1

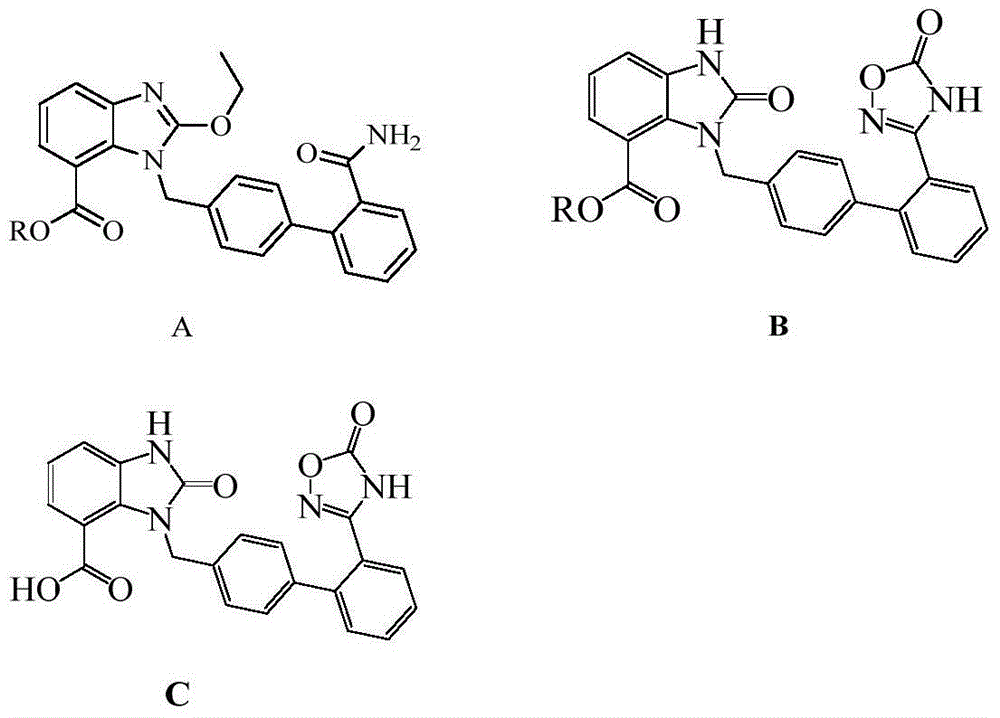

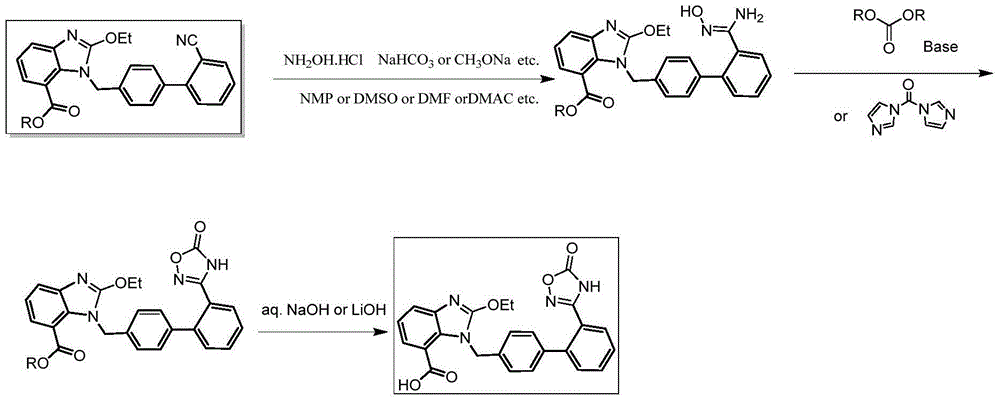

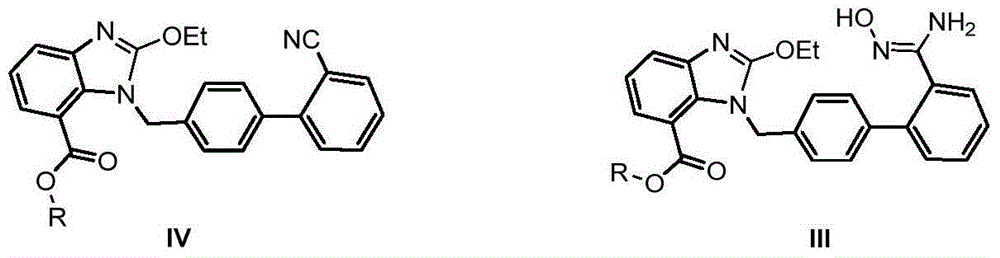

Industrial production method of azilsartan

The invention provides an industrial production method of azilsartan. The method comprises the following steps: 1) replacing hydroxylamine hydrochloride and organic alkali or inorganic alkali in a polarity aprotic solvent and centrifuging to obtain a homogeneous system, adding candesartan C6 alkyl ester (a compound shown in formula IV) and reacting at 90-110 DEG C to obtain a compound shown in formula III; and 2) dissolving the compound shown in formula III and a carbonylation reagent in the polarity aprotic solvent, adding in the organic alkali or inorganic alkali and reacting at 0-40 DEG C to obtain a compound shown in formula II, and carrying out alkaline hydrolysis to obtain azilsartan. By adopting the preparation method, the production cost of azilsartan is greatly reduced, an expensive and unstable hydroxylamine solution is not used, the reaction temperature is lowered, the product quality is well improved, the requirement for medicinal level is met, and individual impurity is controlled below 0.1%, which is superior to the ICH requirement of the EU (European Union).

Owner:合肥远志医药科技开发有限公司

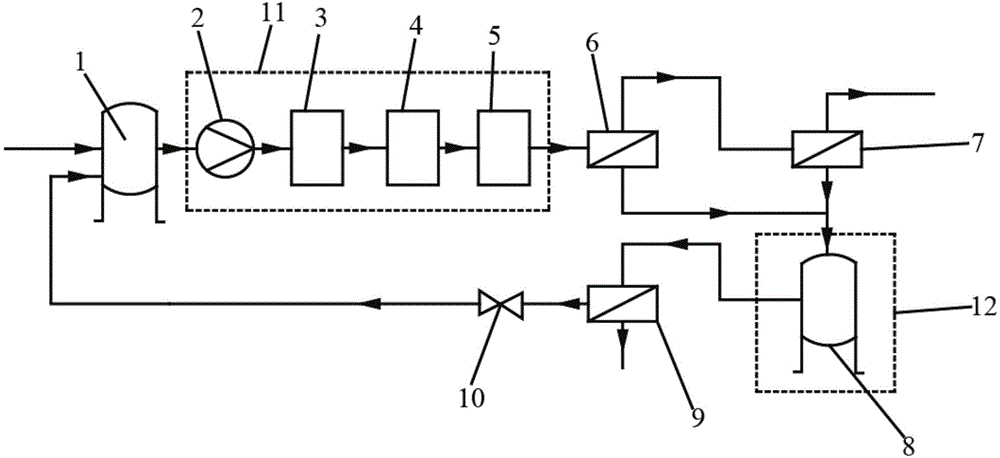

Device system for purifying by utilizing gas separation membrane

ActiveCN104587804AFully purifiedHigh recovery rateDispersed particle separationNoble gas compoundsHydrogenProduct gas

The invention discloses a device system for purifying by utilizing a gas separation membrane. The device system comprises a mixing device, a pretreatment unit and three gas separation membrane units, wherein two ends of the mixing device are respectively communicated with a raw material gas and the pretreatment unit; a gas passes through the pretreatment unit and enters a gas inlet of the first gas separation membrane unit; an impermeable gas of the first gas separation membrane unit is communicated with a gas inlet of the second separation membrane unit; impermeable gases of the first and second gas separation membrane units pass through a mixed flow tank, and are communicated with a gas inlet of the third separation membrane unit; an impermeable gas outlet of the third separation membrane unit is provided with a backpressure control valve, and is communicated with a gas inlet of the mixing device for cyclic purification; the impermeable gas of the second separation membrane unit is a tail gas; the permeable gas of the third separation membrane unit is a product gas. According to the invention, three membrane units are used for purifying independently so as to completely purify gases, such as helium, hydrogen, carbon dioxide, and the recycling rate is relatively high; the device system is simple and compact in structure, and is applied to industrial production.

Owner:甘泳

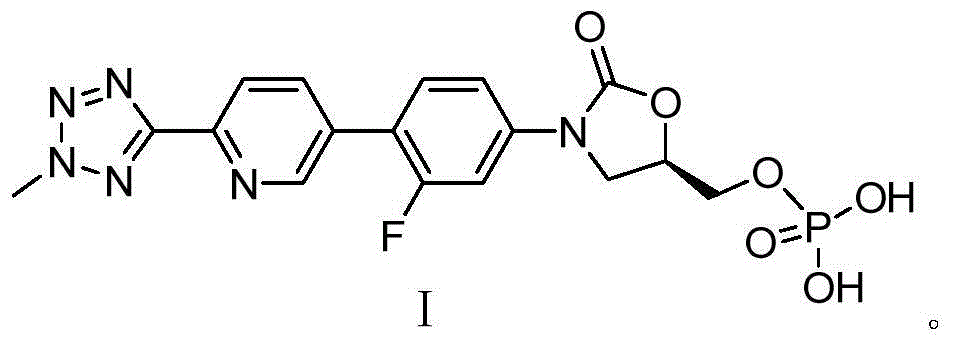

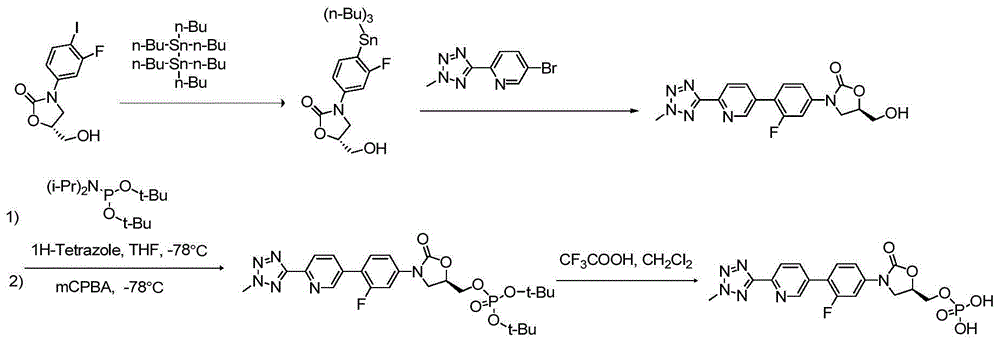

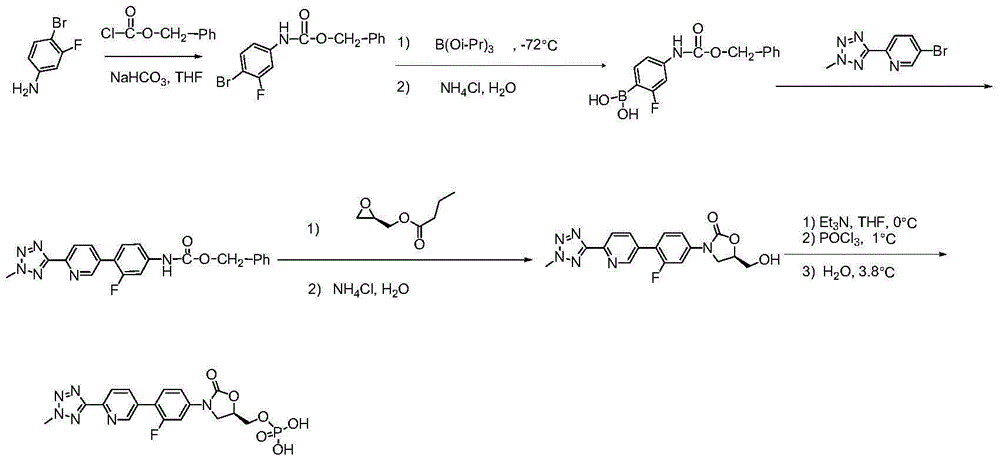

Preparation method for tedizolid phosphate

ActiveCN105418678AHigh purityAvoid it happening againGroup 5/15 element organic compoundsChemical industryPhosphate

The invention belongs to the field of medicine chemical industry and particularly relates to a preparation method for tedizolid phosphate. According to the preparation method provided by the invention, intermediates in the steps and the final product are high in purity. In addition, by using diiso-propylamido dibenzyl phosphite as a phosphorylation reagent, a dimerized product is further avoided, so that the preparation method provided by the invention is higher in yield. The preparation method provided by the invention is relatively short in route and mild in reaction condition, and further avoids use of toxic, irritant and strongly corrosive reagents, so that the preparation method is green and environmentally friendly. Meanwhile, ultralow temperature reaction is avoided, so that the preparation method is simple to operate, and the tedizolid phosphate is easy to prepare and high in production efficiency. Thereofe, the preparation method provided by the invention is suitable for industrial production.

Owner:CHIA TAI TIANQING PHARMA GRP CO LTD

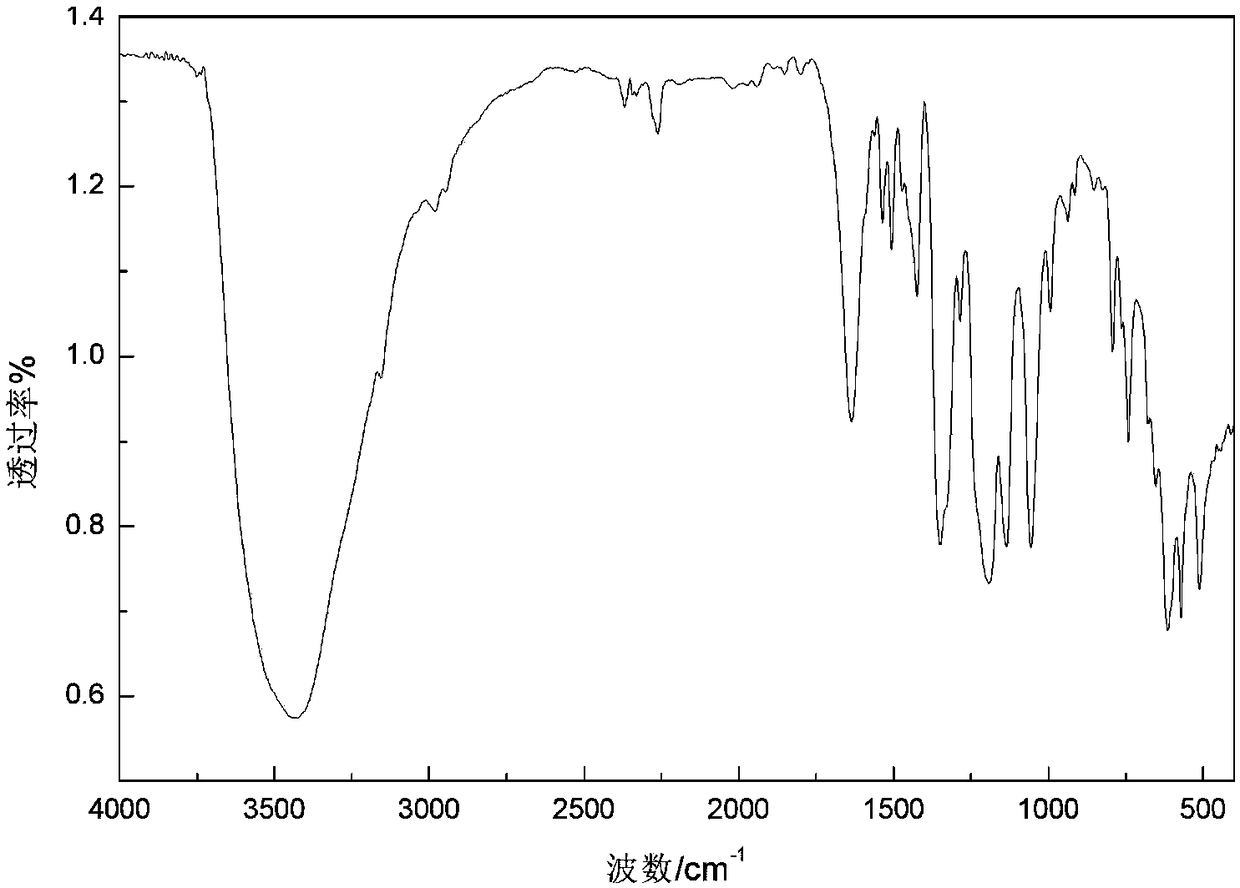

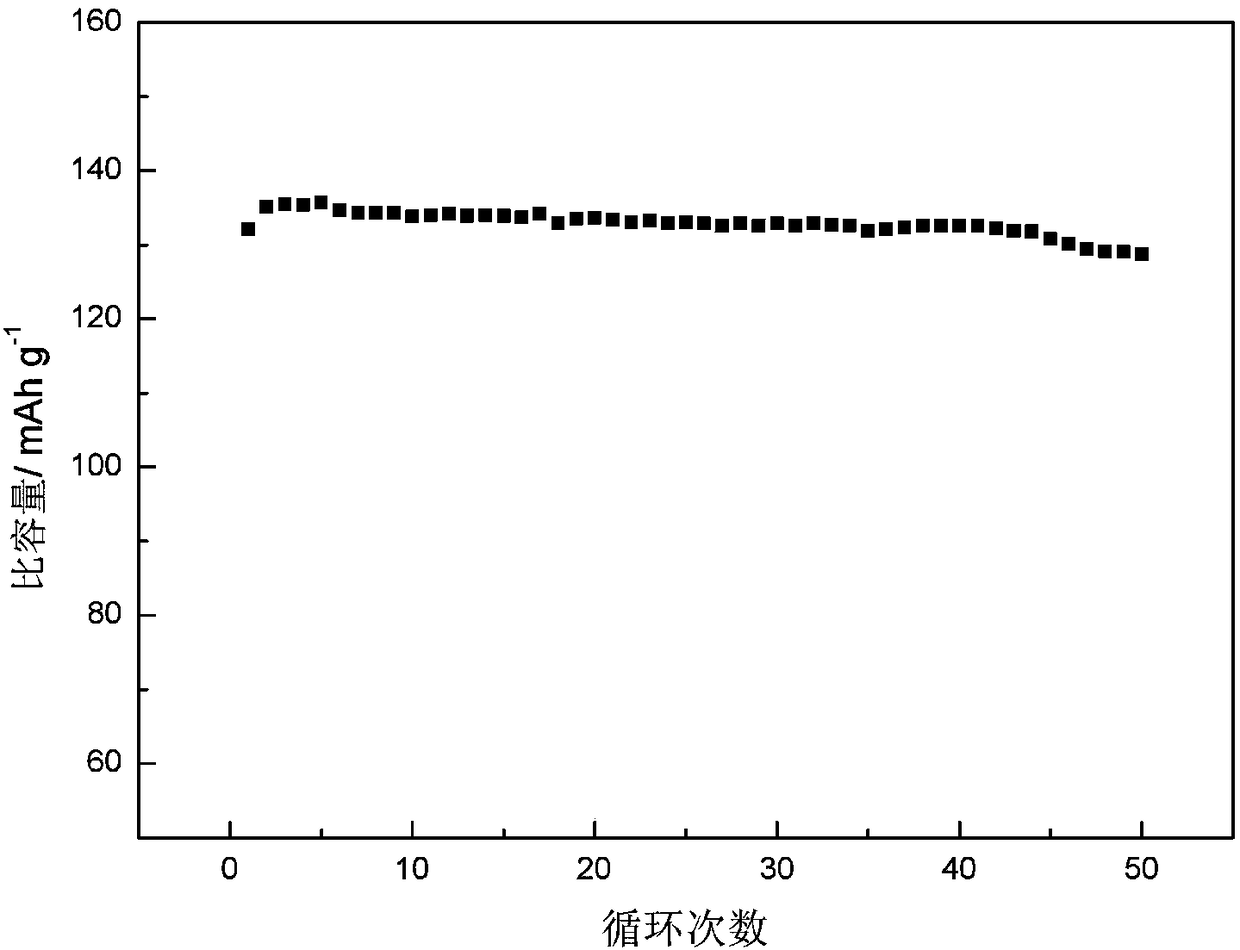

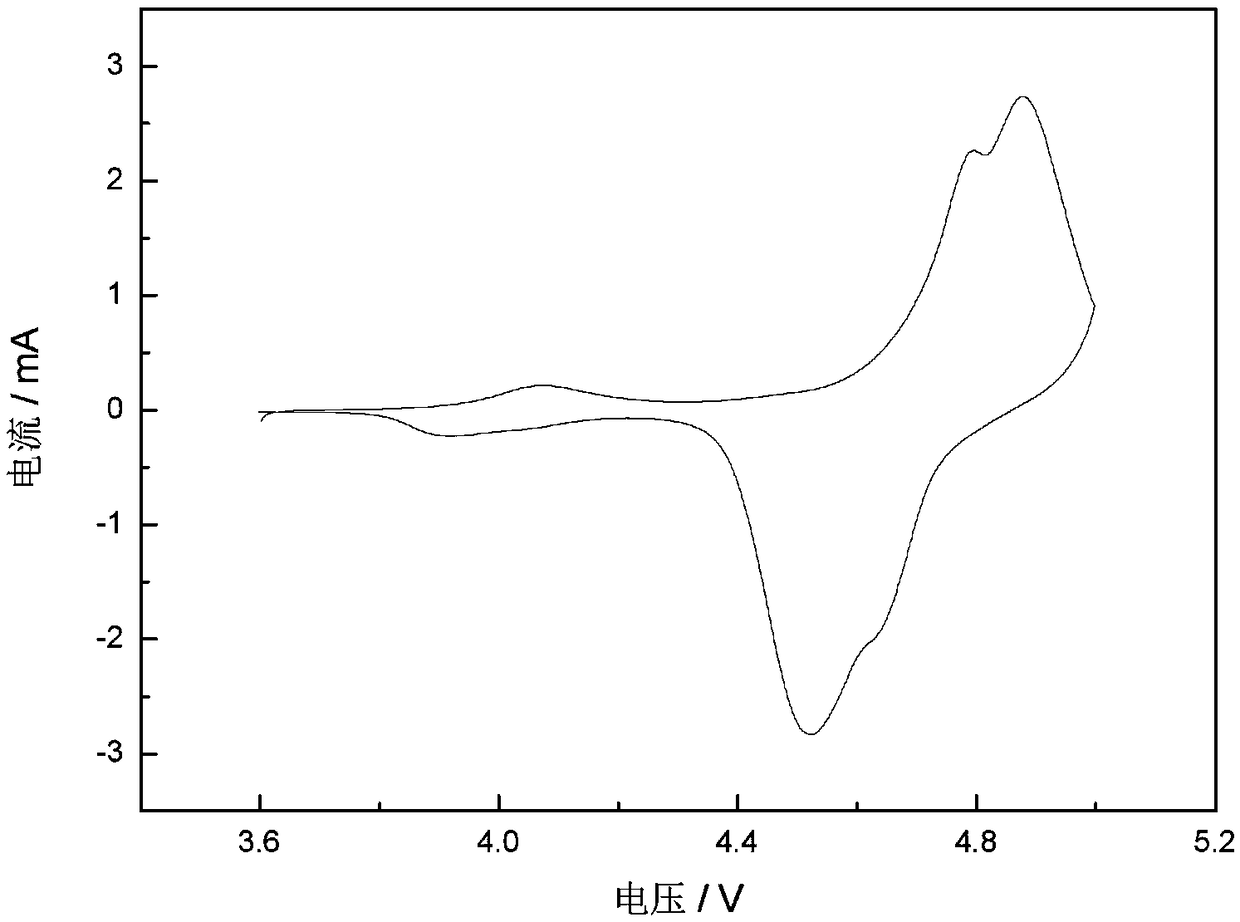

Imidazolium-based ionic liquid and preparation method and application thereof

PendingCN108586348AImprove electrochemical stabilityWide electrochemical stabilitySecondary cellsSulfonic acid amide preparationElectrolytic agentElectrical battery

The invention relates to an imidazolium-based ionic liquid and a preparation method and application thereof. The ionic liquid has a structural formula shown in the description, wherein n1 is 2 or 3 or4, n2 is 0 or 1, and Y- is BF4- or PF6- or TFSI- or N(CN)2- or (FSO2)2N-. By adopting triple substitution and introducing electron donating groups and electron withdrawing groups, the imidazolium-based ionic liquid has two different types of unsaturated bond structures of nitrile groups and alkenyl groups; in the preparation process, suitable parameters are selected to introduce nitrile groups. When serving as a lithium ion battery electrolyte, the imidazolium-based ionic liquid can improve the electrochemical window of the electrolyte; by applying the imidazolium-based ionic liquid to high-voltage lithium ion batteries with LiNi0.5Mn1.5O4 as the positive electrode material, the safety and electrochemical properties of the lithium ion batteries can be improved.

Owner:HEBEI UNIV OF TECH

Beta-glucosaccharase, beta-glucosaccharase mutant and application

ActiveCN104531637AIncrease hydrolysis rateSame enzyme activityBacteriaMicroorganism based processesCelluloseAlglucerase

The invention discloses a composition which comprises an enzyme. The enzyme has the activity of glucosaccharase, and provides a degrading function in cellulose degradation. The enzyme is a protein shown in (a) or (b), wherein (a), the amino acid sequence of the is shown as SEQ ID NO:1; (b), one or several amino acid are displaced, removed out or added into the amino acid sequence in the (a), and the protein is derived from the (a) and has the activity of the glucosaccharase. DNA molecules of the enzyme are coded. Carriers are recombined and comprise the DNA molecules and adjusting sequences connected with the DNA molecules and used for conducting expressions. Host cells comprise the DNA molecules or the recombined carriers. Compared with the beta-glucosaccharase (with the amino acid sequence of SEQ ID NO:1), a beta-glucosaccharase mutant with the amino acid sequences of SEQ ID NO:6 and SEQ ID NO:7 has the beneficial effects that the heat stability is improved; and the hydrolysis rate of compound enzyme liquid can be improved in enzyme system compounding.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Purification of human myocardium troponin I and preparation method of its monoclonal anti-body

InactiveCN1495196AHigh content accuracyGood homologyImmunoglobulins against animals/humansFermentationBALB/cMonoclonal antibody

The present invention discloses a method for purifying human myocardium troporin I, preparing its monoclonal antibody and determining its content by using one-step process. It adopts affinity chromatography to purity human myocardium troponin I, and utilizes the purified myocardium troponin I and BALB / c mouse to immunoprepare the monoclonal antibody of said myocarbium troponin I, and establishes a method for determining myocardium troponin I content by means of one-step process. It can be extensively used for diagnosing heart disease.

Owner:上海润东生物科技有限公司

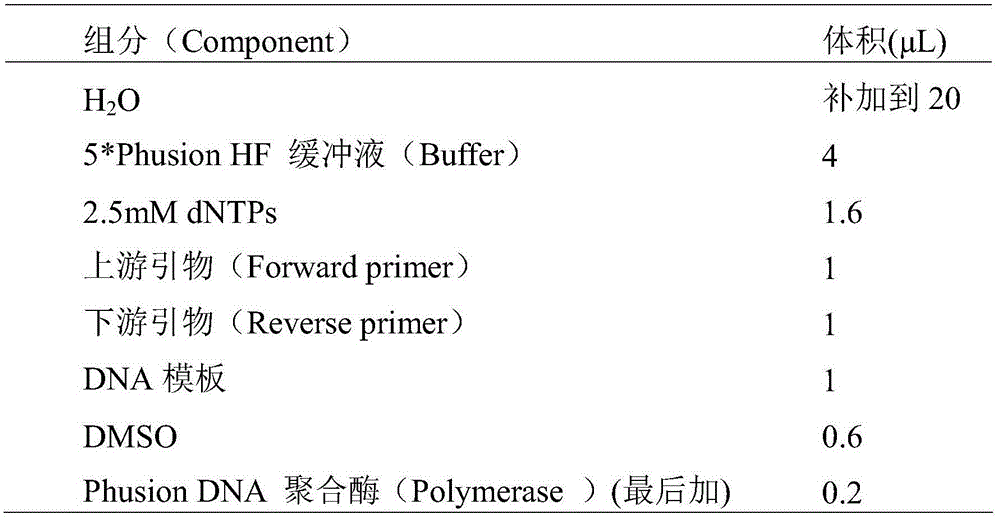

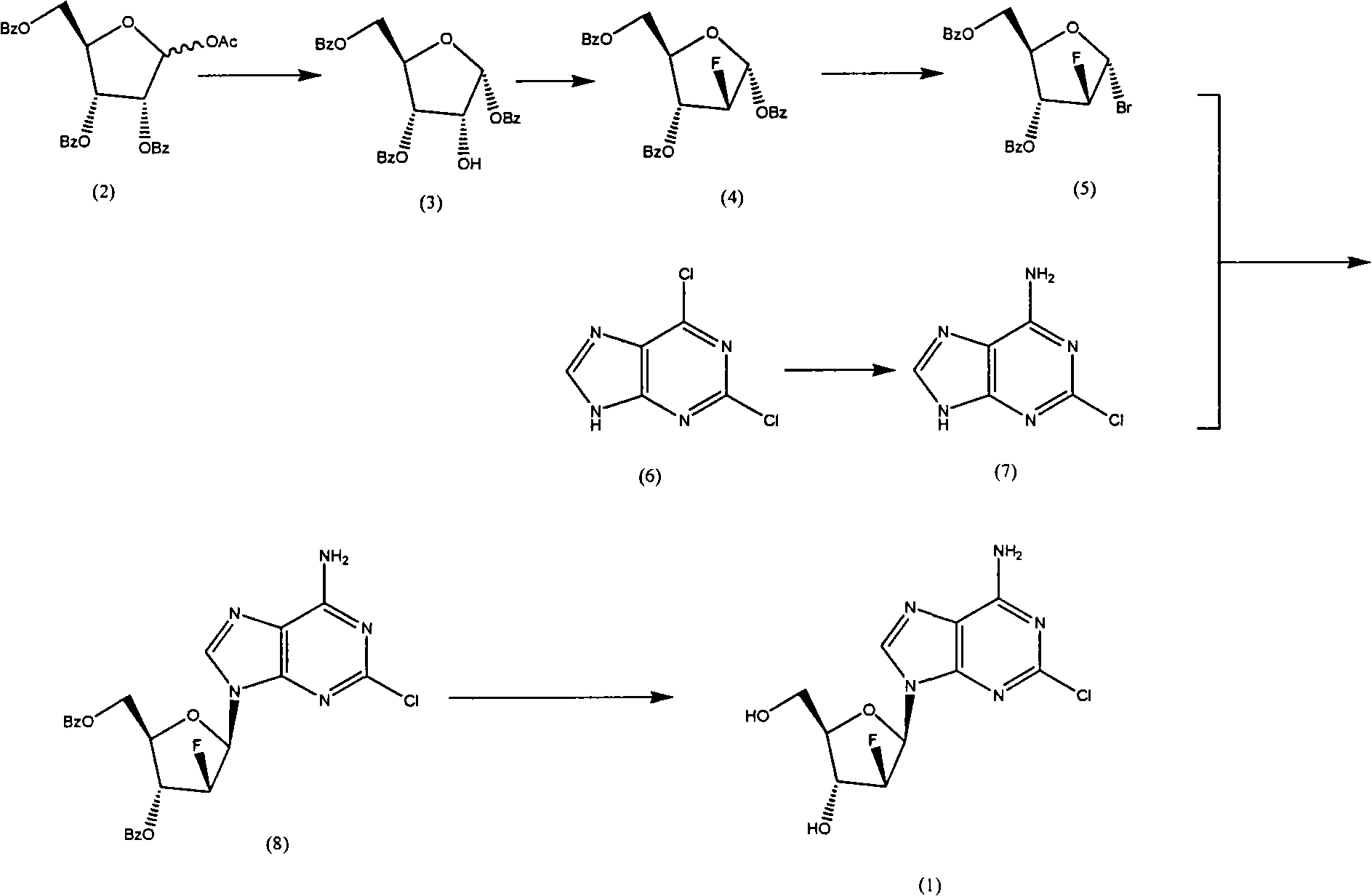

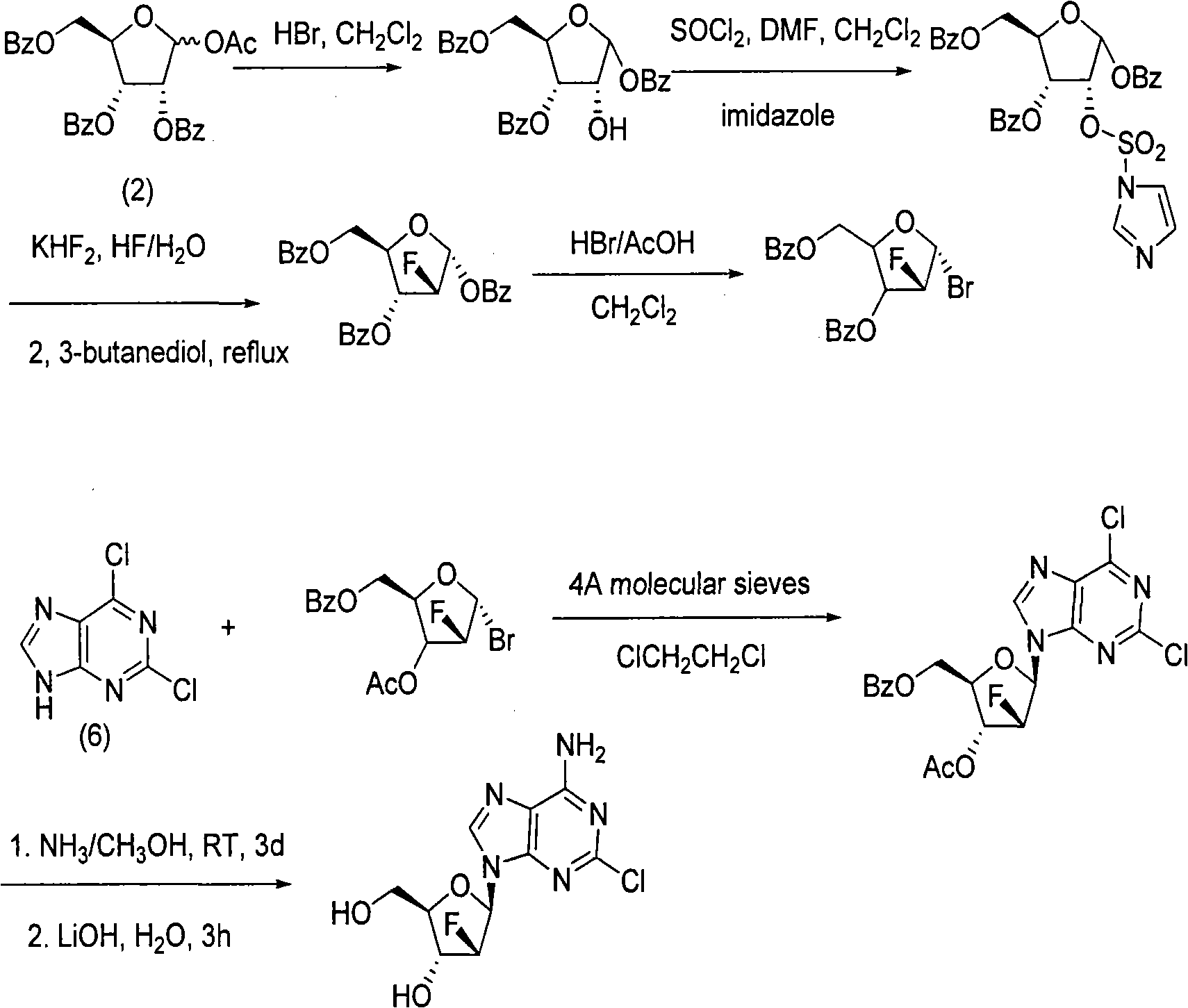

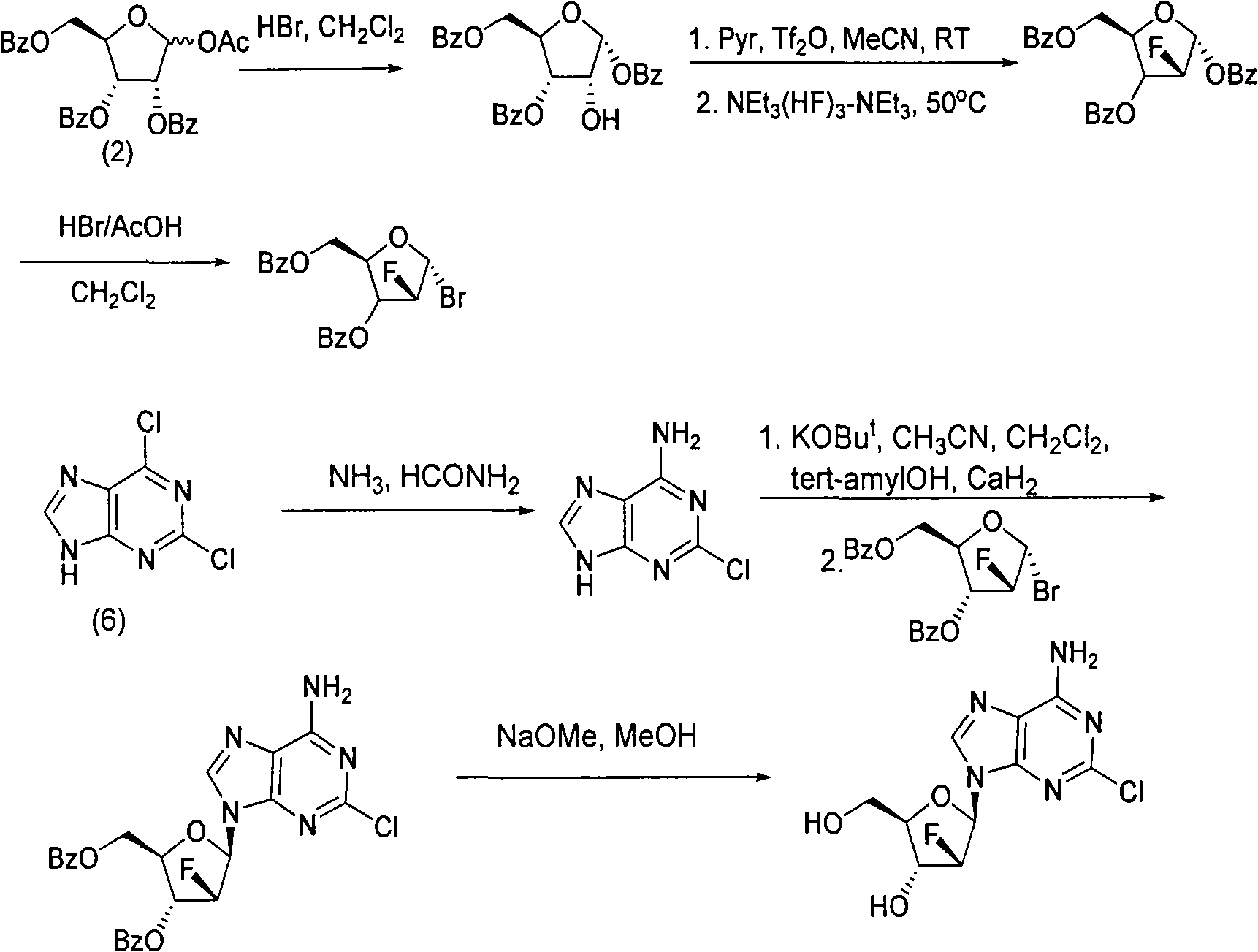

Synthesis method of clofarabine of nucleoside analogues

InactiveCN101555267AMild conditionsEasy to operateSugar derivativesAntineoplastic agentsSynthesis methodsPurine

The invention provides a novel synthesis method of clofarabine , that is 6-amino-2-Cl-9-(2-deoxidation-2-Fl-Beta-D-ribofuranose)-9H-purine for treating leukemia, which comprises the following steps of crystallization, fluoridation, bromination reaction, ammonia reaction, selection reaction and methanol reaction. The invention has simple synthesis procedure, mild condition, easy operation, low cost, high yield and easy amplification, and adapts to the industrial production.

Owner:杭州容立医药科技有限公司

Innocent treatment method for arsenic containing mixed salt

The invention relates to an innocent treatment method for arsenic containing mixed salt. The method comprises the following steps of: (1) uniformly mixing arsenic containing mixed salt and slag or / and cullet, and controlling the content of arsenic in the mixed material at1.0-4.8wt% to obtain a mixed material; (2) feeding the mixed material into a furnace, heating to 1150-1250 DEG C, and insulating and melting for 0.4-2.4 hours to obtain melt; and (3) pouring the melt to a die to prepare solid or entering into water for water-quenching while the melt is still hot to obtain particle arsenic containing solid. The method for treating the arsenic containing mixed salt is free from environmental hidden danger, and free from secondary pollution, and the whole process is simple in flow, short in processing time, simple and convenient to operate, low in energy consumption, and suitable for industrialized production.

Owner:锡矿山闪星锑业有限责任公司

Surface processing material and its preparation method

InactiveCN107793812ANo consumptionPurify continuouslyPolyurea/polyurethane coatingsEmulsion paintsChemical reactionOxygen

The invention provides a surface processing material, which comprises an emulsion varnish coating and a nanometer noble metal grain; the surface processing material can catalyze oxygen in the indoor air and indoor harmful gas such as formaldehyde, benzene, ammonia, TVOC and others, and accelerates the oxidation-reduction effect, and decompose harmful gas to be carbon dioxide, water and harmless matters; meanwhile, the nanometer noble metal grain cannot participate in any chemical reaction during the process of catalyzing the oxygen and harmful gas; therefore, the nanometer noble metal grain cannot be consumed, the indoor air purification effect can be durably displayed for a long time. Besides, the invention further provides a preparation method of the surface processing material.

Owner:深圳砺剑超能材料有限公司

Preparation technology for edge-sealing strip subjected to co-extrusion molding

InactiveCN104015324AImprove adhesionReduce production processNon-macromolecular adhesive additivesMacromolecular adhesive additivesMedium density fiberboardCo extrusion

The invention relates to the technical field of preparation of edge-sealing strips, and concretely relates to a preparation technology for an edge-sealing strip subjected to co-extrusion molding. The preparation technology comprises the following technological steps: step A, performing co-extrusion on a substrate-layer raw material and a hot-melt-adhesive-layer raw material possessing a same color, so as to prepare the edge-sealing strip possessing the substrate layer and the hot-melt-adhesive layer; B, cooling and curing the edge-sealing strip; and C, for usage, using hot wind or a hot gas or laser to melt the hot-melt-adhesive layer of the edge-sealing strip, so as to enable the face of the edge-sealing strip, which possesses the hot-melt-adhesive layer, to be adhered to a product to be subjected to edge sealing. The adhesive force of the hot-melt-adhesive layer is high, and degumming phenomenon is avoided. By employing hot wind or the hot gas or laser for melting the hot-melt-adhesive layer, edge sealing is performed. Seamless connection between the edge-sealing strip and a product to be subjected to edge sealing, such as medium density fiberboards, shaving boards, plywood and other artificial plates, is realized, and a hot melt adhesive is not needed for coating, so that a production process of coating a hot melt adhesive is saved, the product quality and the production efficiency are substantially improved, the production and application cost is reduced, and the preparation technology is relatively suitable for industrialized production.

Owner:DONGGUAN HUALI INDUSTRIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com