Dry microwave extraction device

An extraction device and dry method technology, which is applied in the field of microwave dry extraction devices, can solve the problems of high product impurities, long extraction time, and difficulty in popularization, and achieve the goals of improving quality and yield, saving extraction time, and saving solvent consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

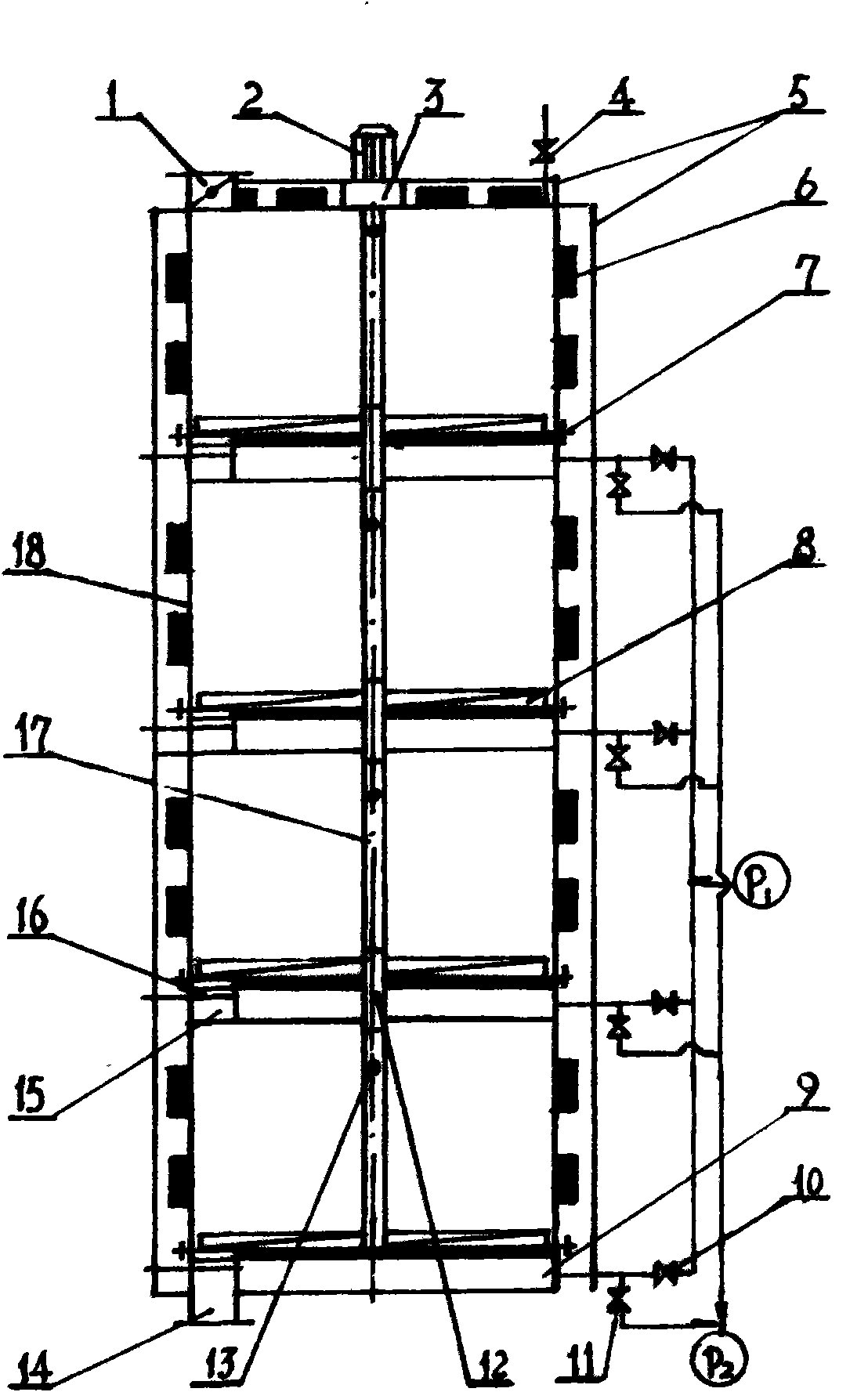

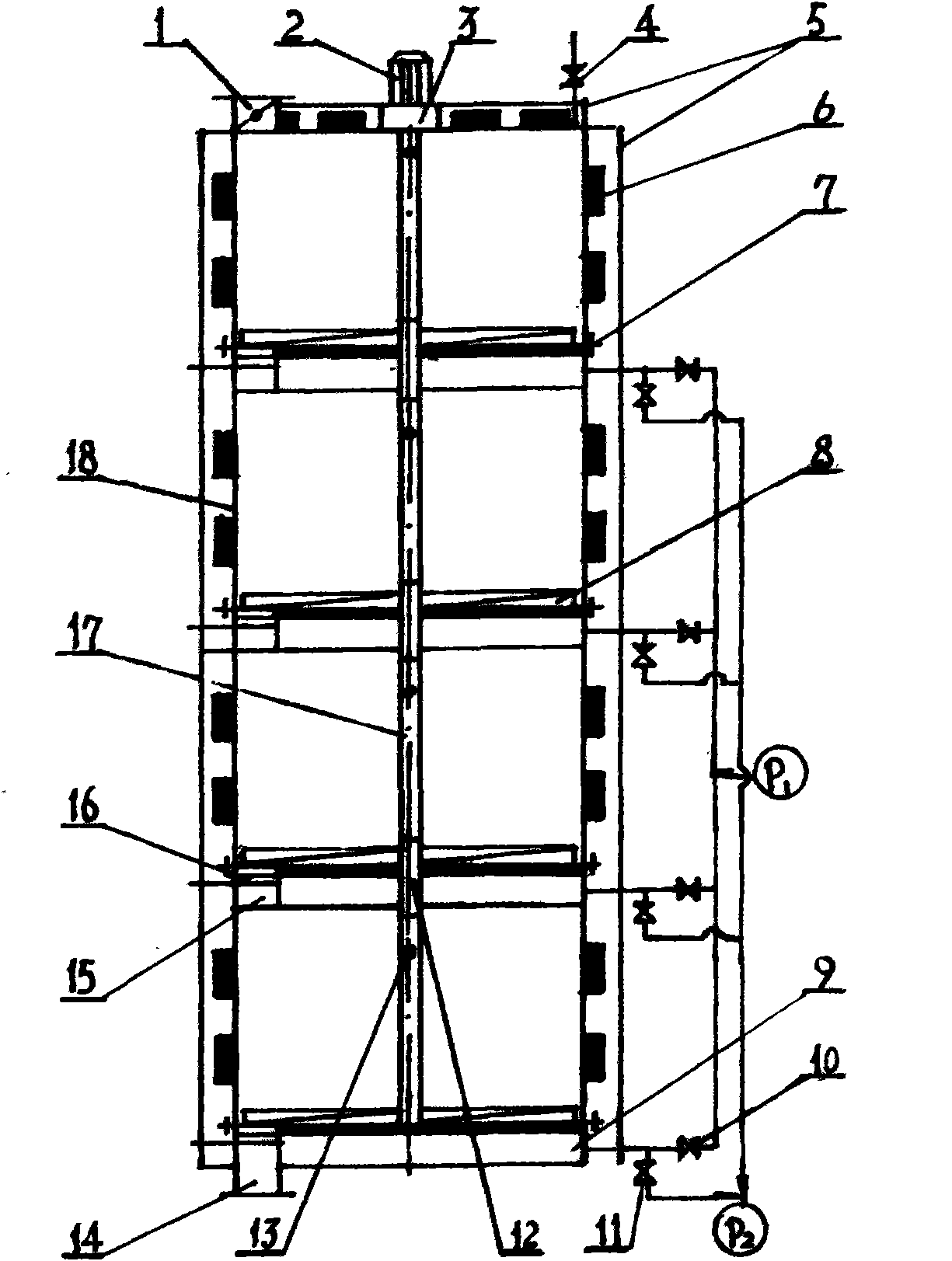

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0014] figure 1 In the process, after the motor 2 is started, the power drives the stirring shaft 17 and the stirring blade 8 to rotate through the reducer 3, and the subdivided plant dry material enters the first layer of extractor from the feeder 1, closes it after reaching the specified amount, and turns on the microwave When the generator 6 irradiates and heats the dry material to the specified requirements, the solvent is pumped by the solvent pump P 1 Through the solvent inlet gate valve 10 and the filter screen cavity 9, reversely press the extractor from the bottom of the material layer to extract the material. After reaching the process requirements of the stage, the mixed liquid is in the vacuum pump P 2 Under the suction of the generated negative pressure, it is discharged through the discharge gate valve 11, and then the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com