Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

100results about How to "Slow heat transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

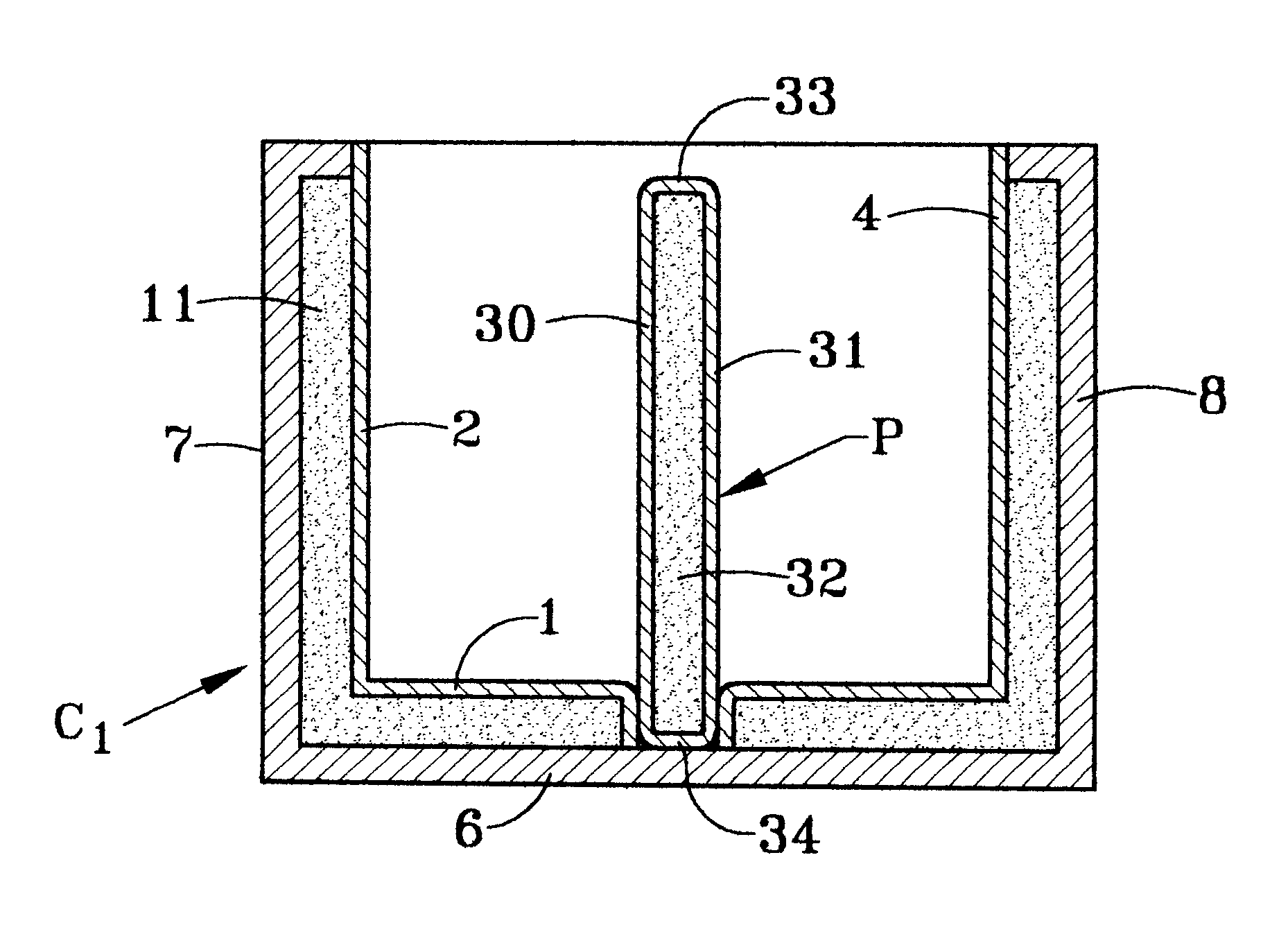

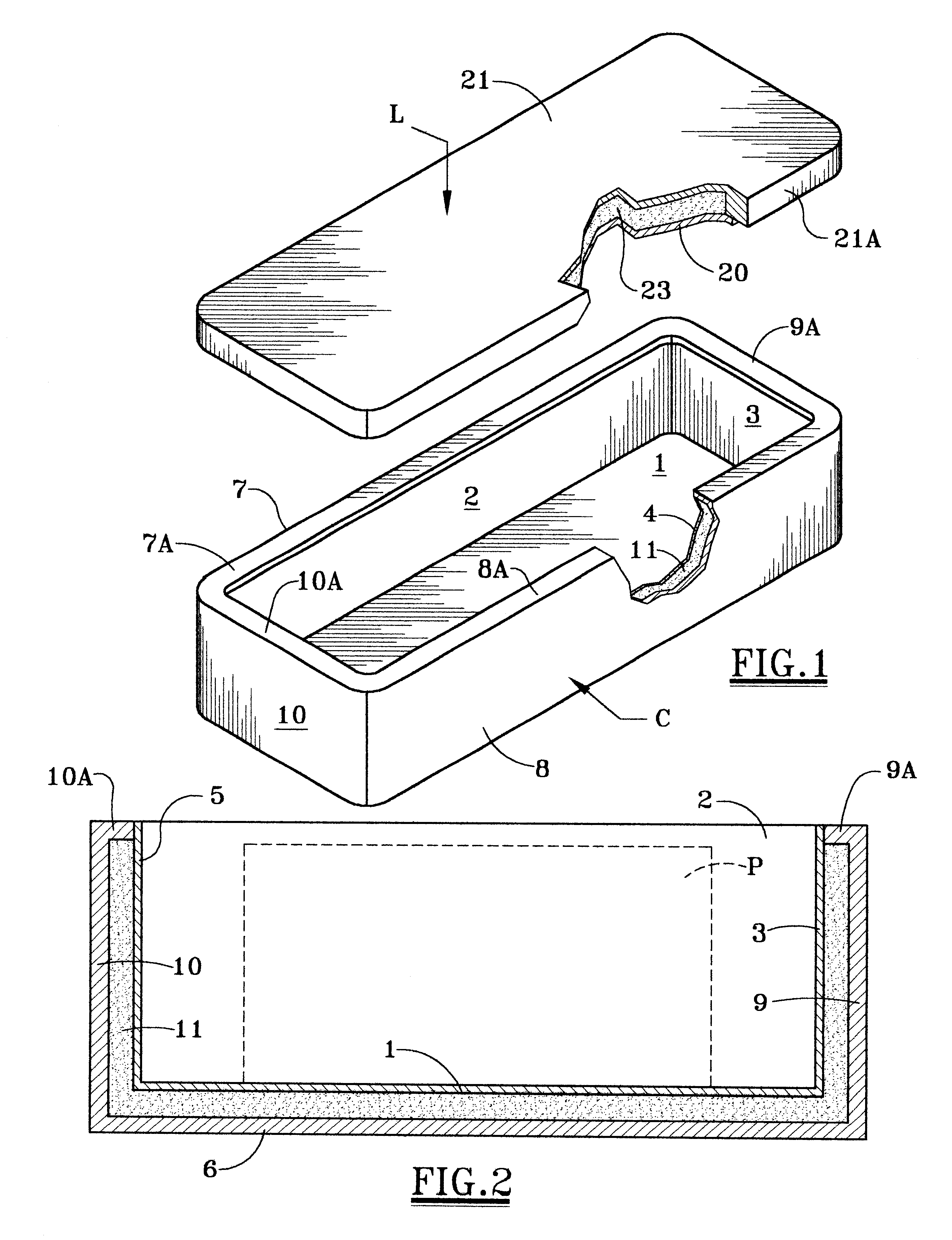

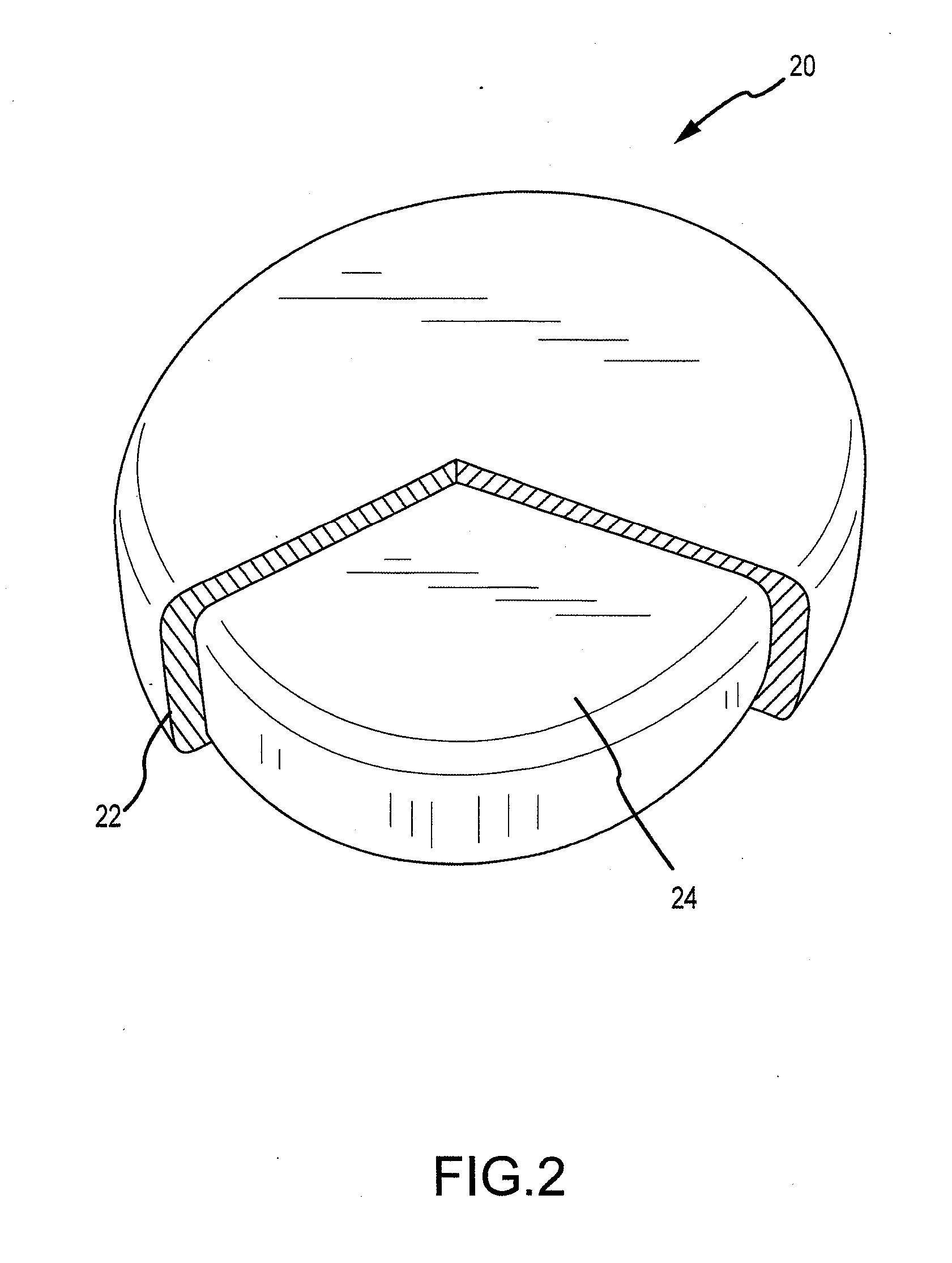

Rapid cooling food container

InactiveUS6318114B1Slow heat transferReduce the temperatureLighting and heating apparatusContainers with thermal insulationEngineeringAmbient air

A container for rapidly cooling and holding foods at safe temperatures for extended periods of time which includes an upwardly opening inner container in which foods may be placed and another container surrounding the inner container. An enclosed chamber is formed between the bottoms and side walls of the inner and outer containers and is provided with a slow-to-freeze, slow-to-thaw gelatinous material which may be frozen by placing the container in a low temperature freezer. The container is further characterized in that the bottom and walls of the inner container provide insulating properties which control the rate of heat transfer between the gelatinous material, when frozen, and foods placed in the container and further characterized in that the bottom and walls of the outer container provide insulating properties which substantially retard heat transfer between the gelatinous material, when frozen, and the ambient air which surrounds the container.

Owner:SLAUGHTER MARION W

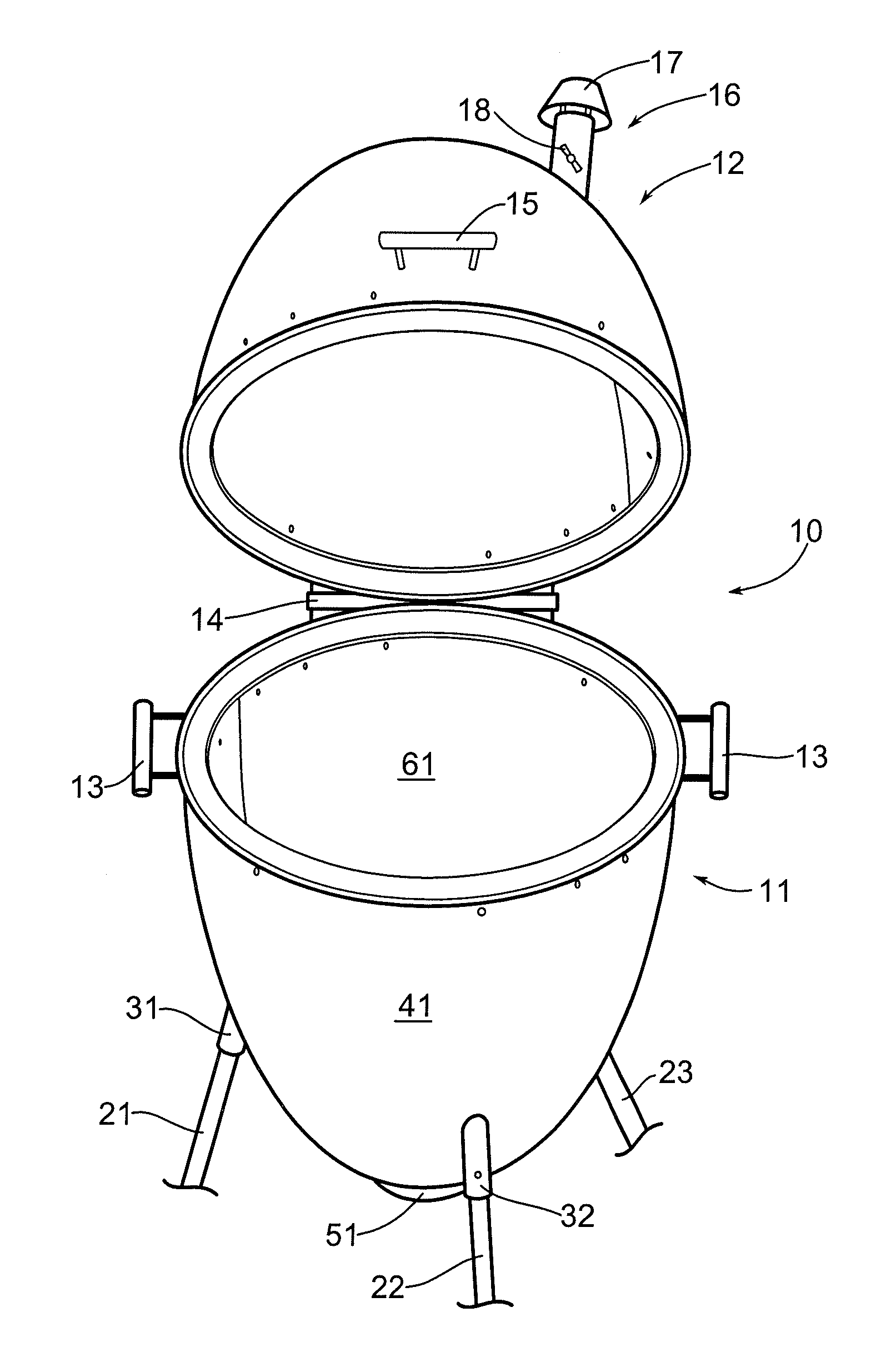

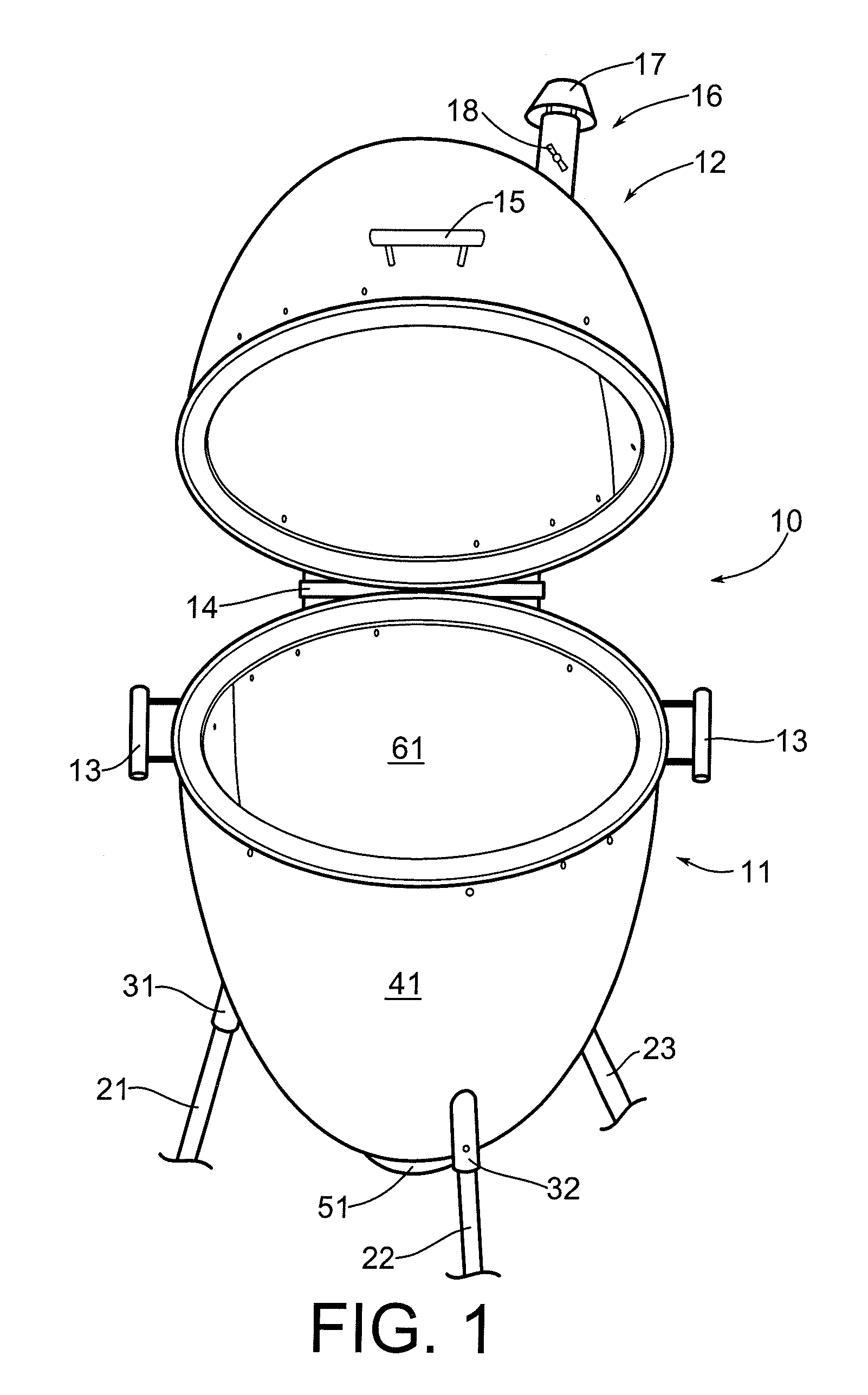

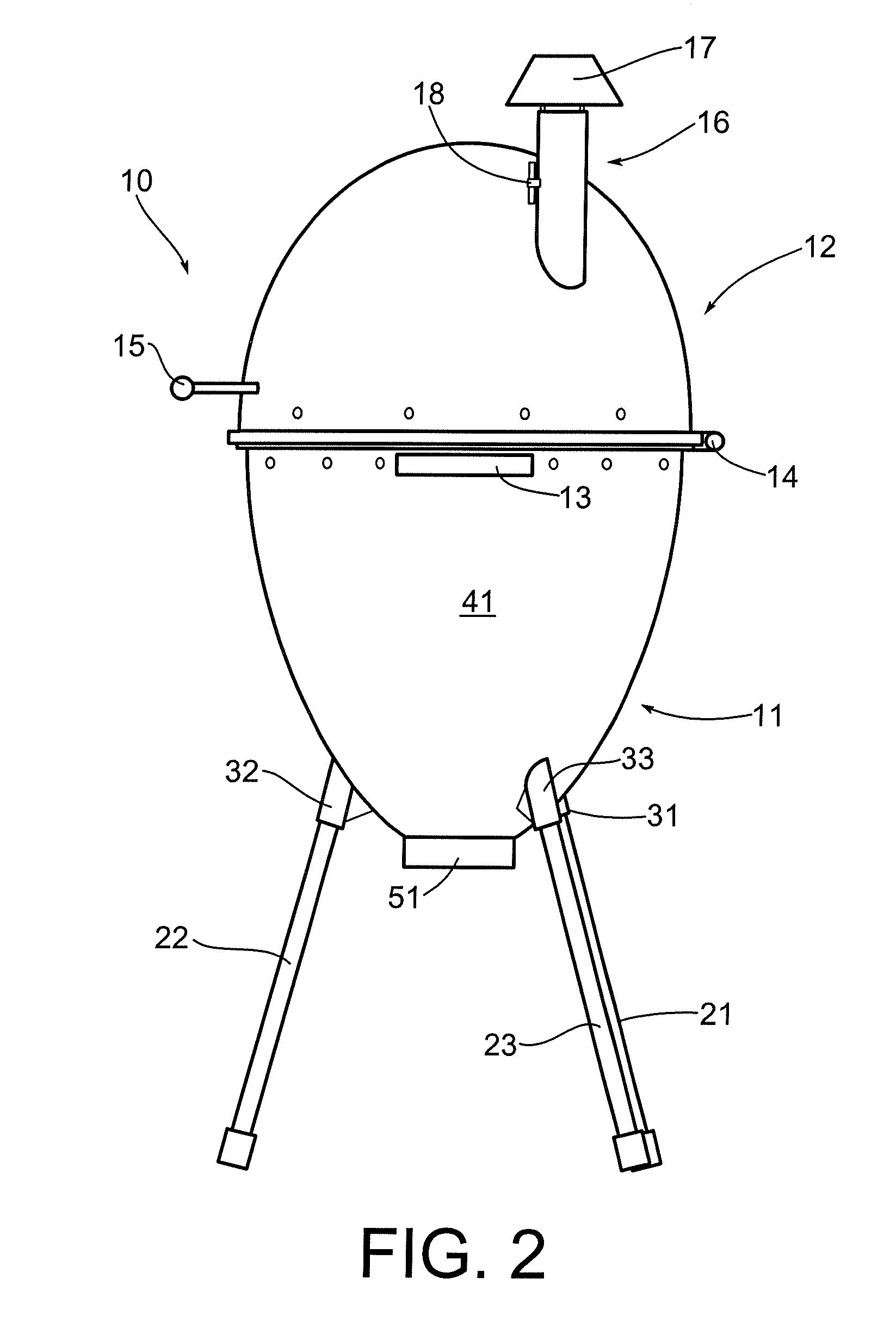

Non-ceramic outdoor cooker

InactiveUS20100258106A1Easier to purchase and take homeEasy to installDomestic stoves or rangesLighting and heating apparatusDouble wallEngineering

A non-ceramic, light-weight outdoor cooker made from formed sheet metal includes a double-walled kettle, with an inner wall spaced and insulated from an outer wall by an insulating layer. A domed lid is constructed similarly to the double-walled kettle and is hinged to the top of the kettle. By spacing the inner wall from the outer wall and providing an insulating layer, heat transfer to the outside of the cooker is greatly slowed. By constructing the structure of sheet metal, instead of ceramic, the cooker is light-weight, rugged, and economical to manufacture.

Owner:SIMMS JOHN LEE II

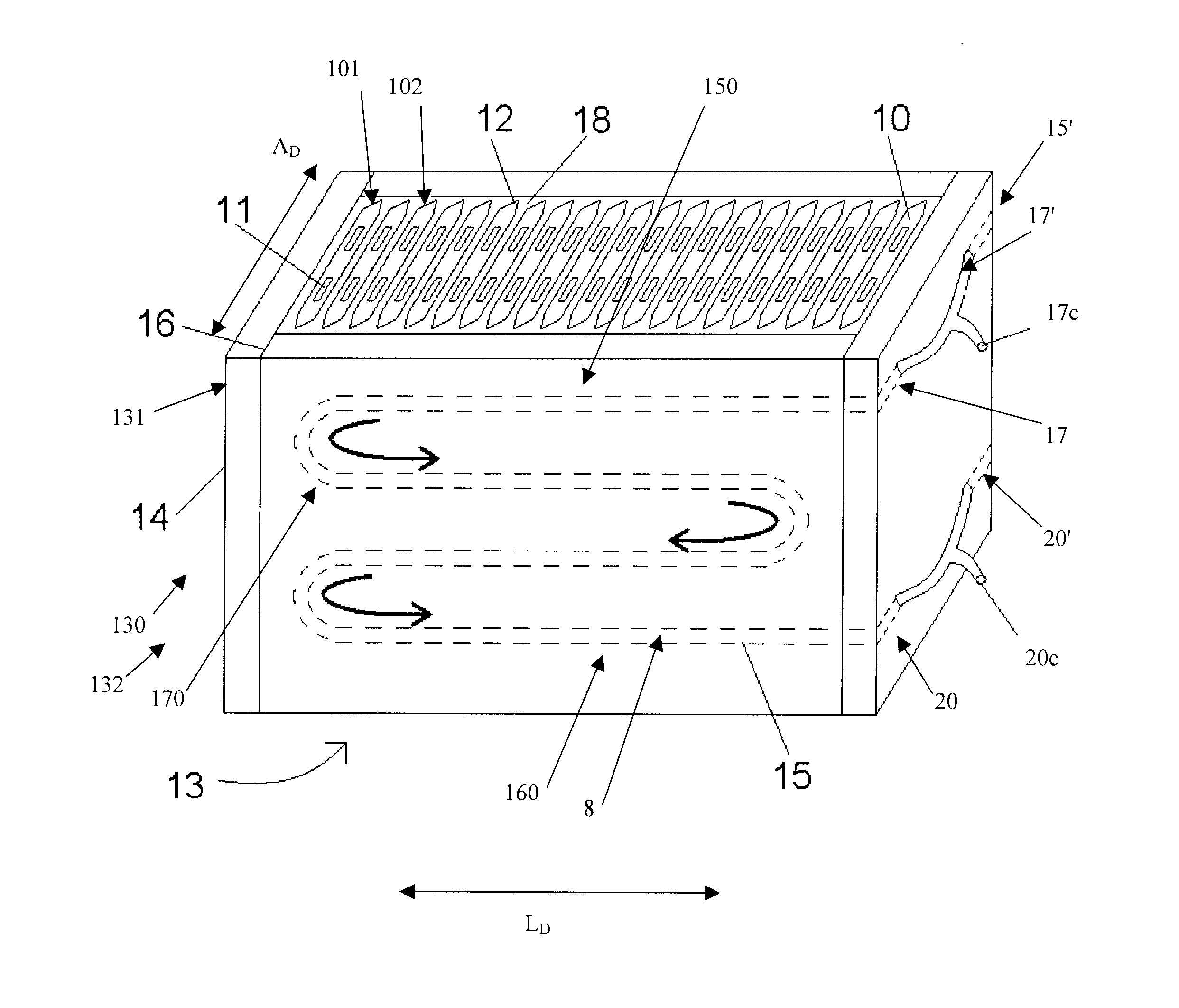

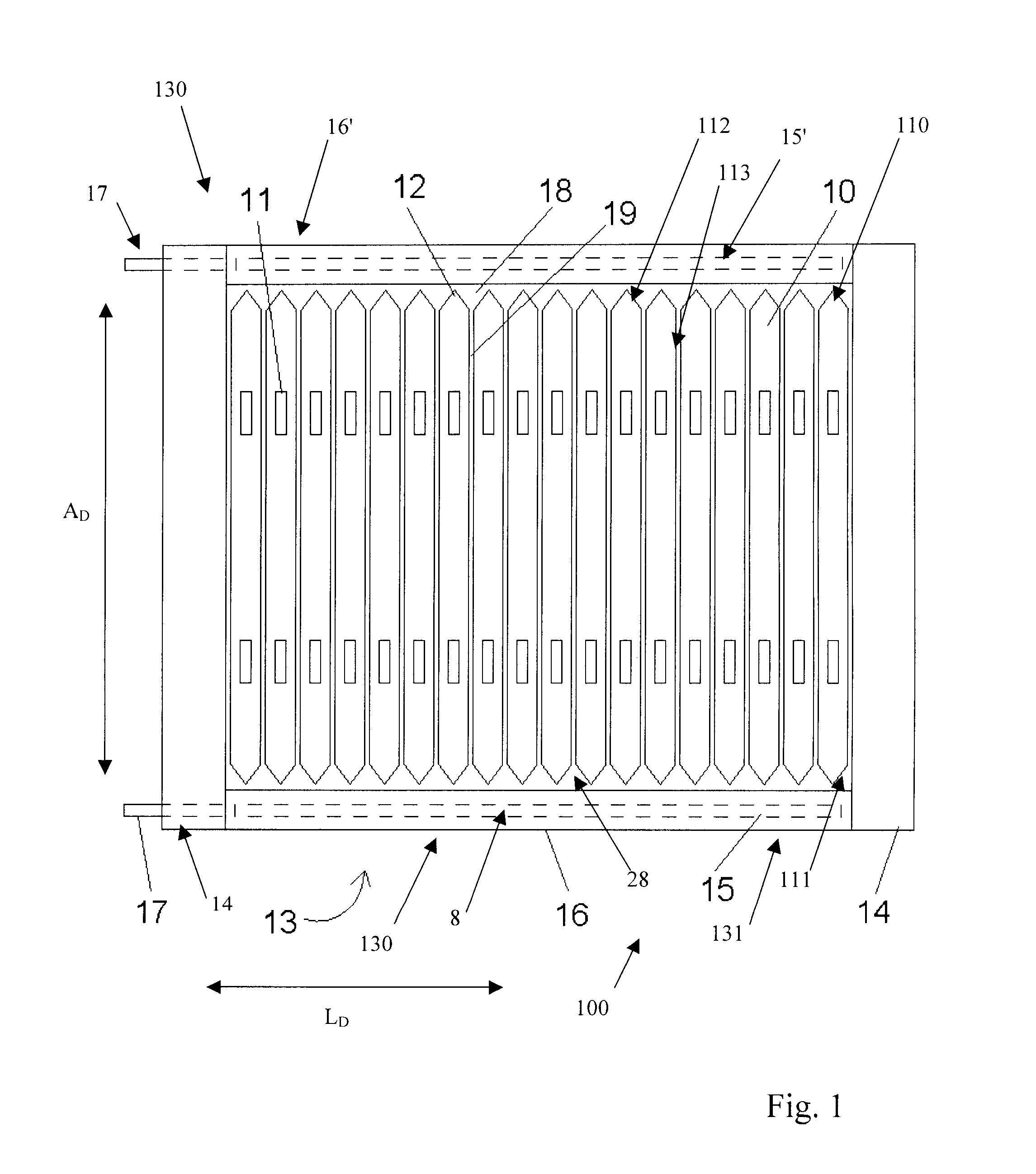

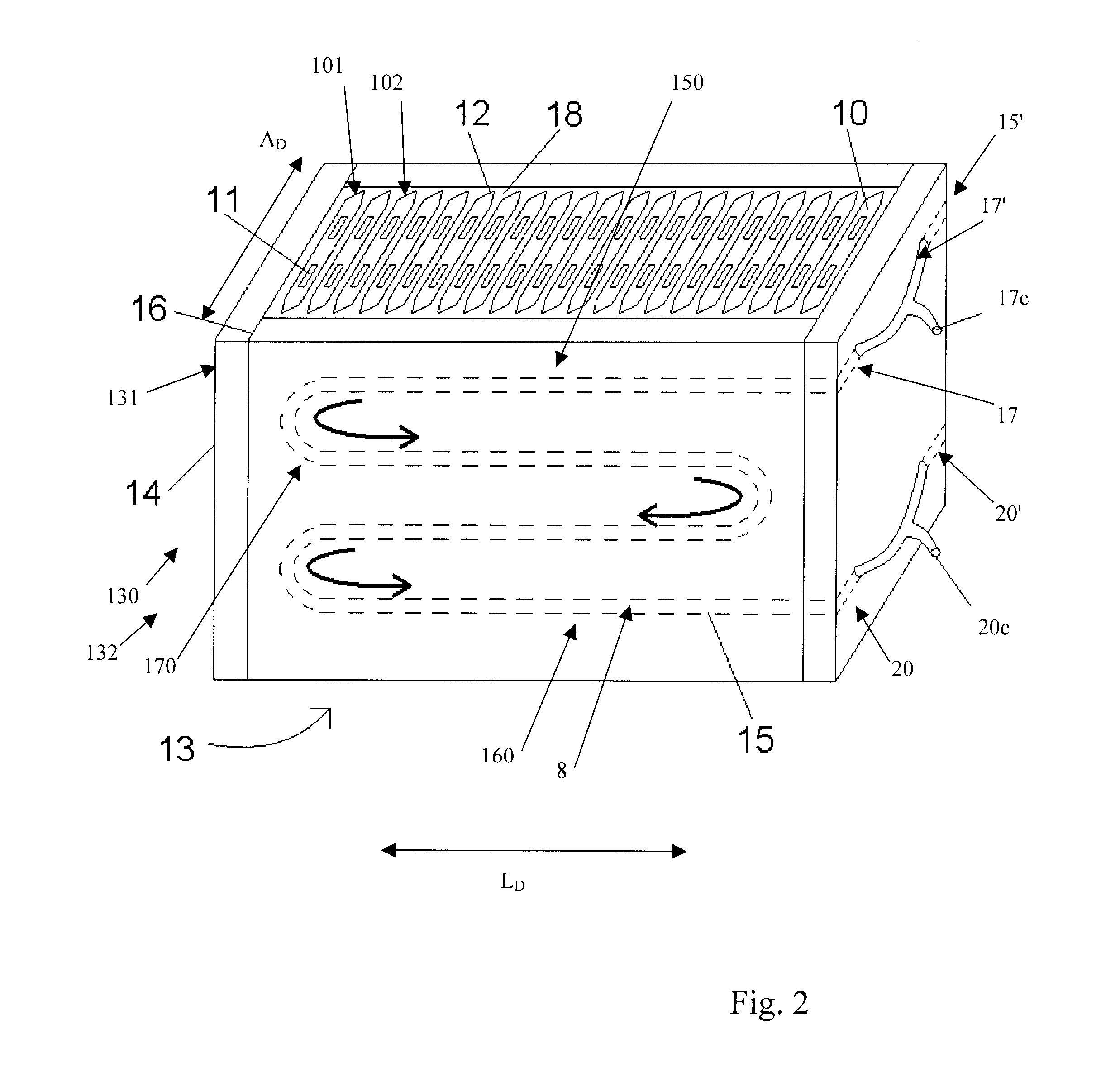

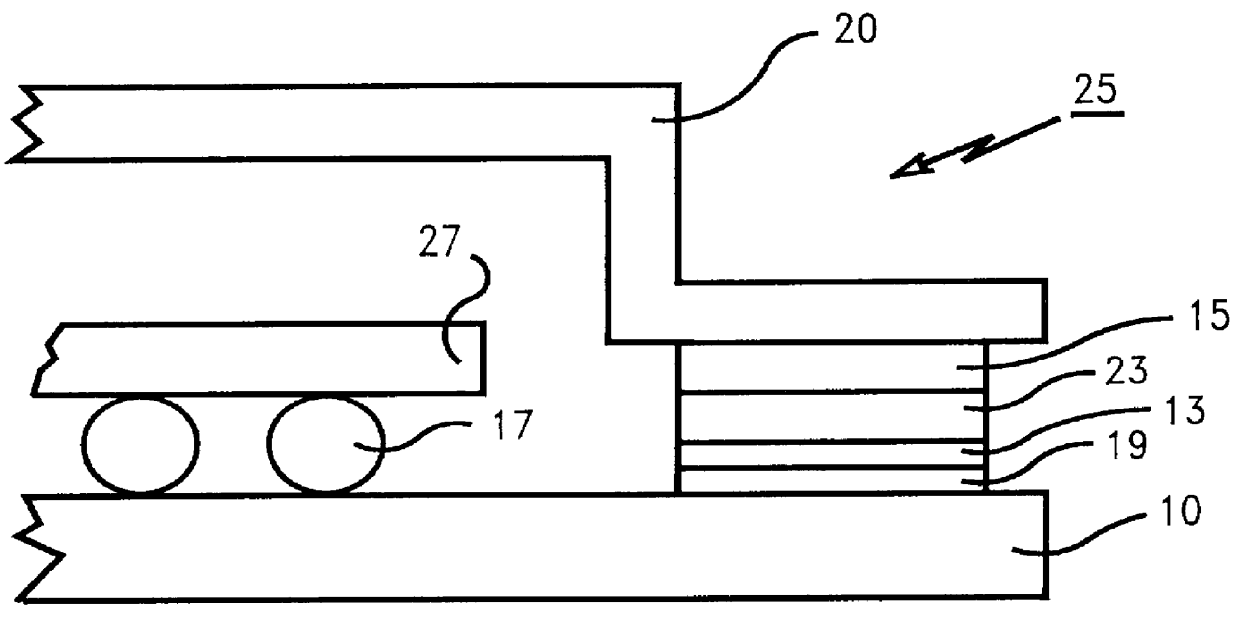

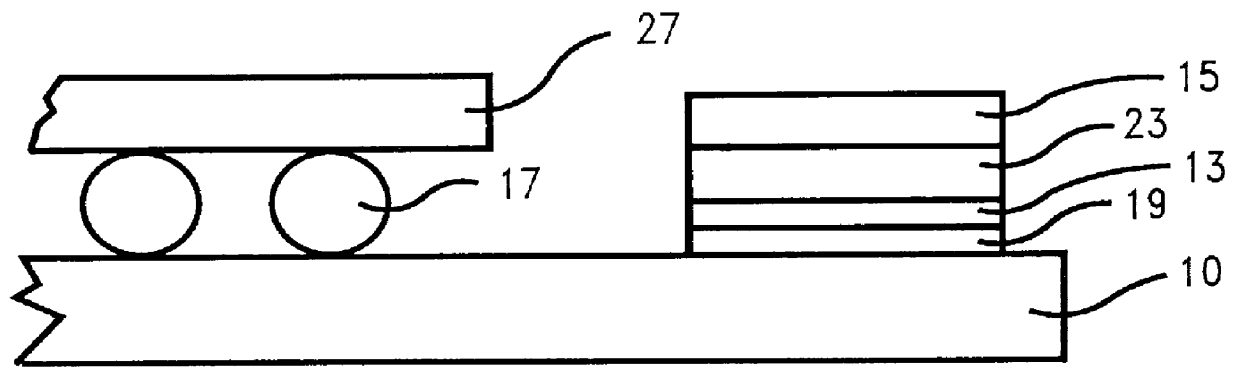

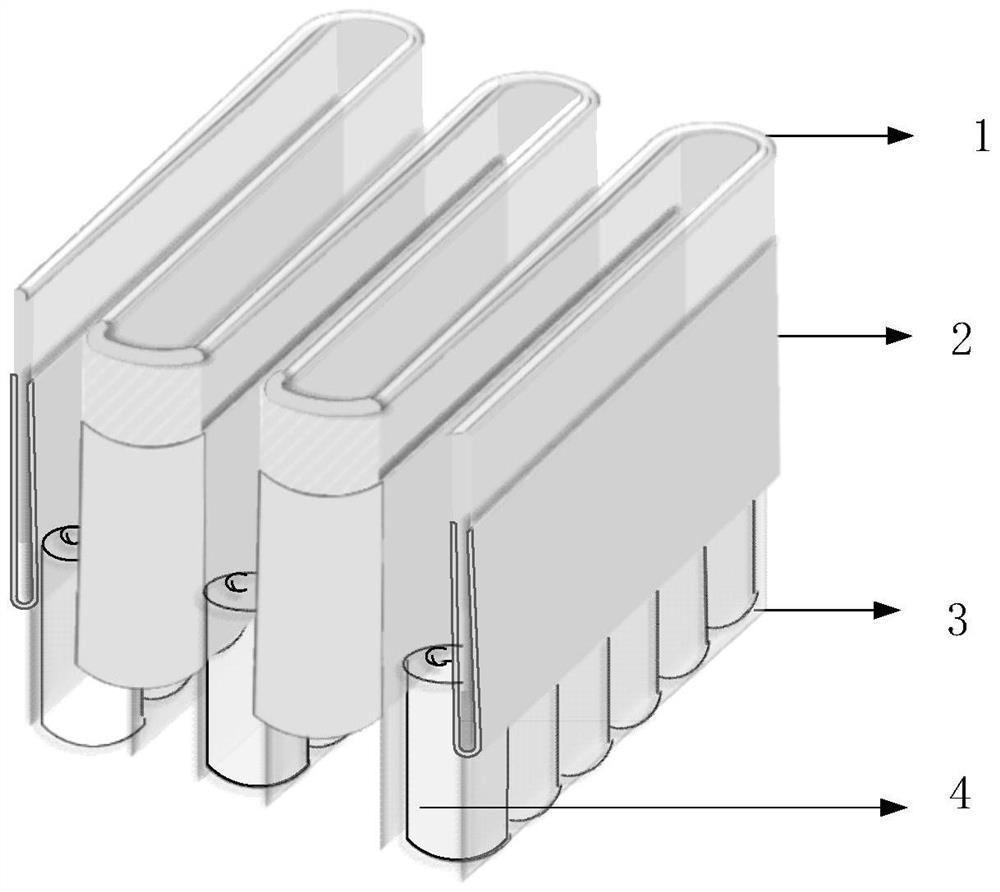

Fluid-cooled battery module containing battery cells

ActiveUS20140342195A1Protection from vibrationFacilitate conductionCell temperature controlSecondary cells charging/dischargingCooling fluidBattery cell

A battery module for receiving battery cells provides cooling through a cooling fluid. Chilled fluid travels first to the hottest part of the battery module and then continues to gradually less hot areas. As the chilled cooling fluid absorbs heat and travels to cooler parts of the battery module, the heat transfer between the fluid and the battery cells decreases because the temperature differential between the cells and cooling fluid decreases, providing a more even temperature distribution across the battery module. The cooling fluid may be contained in a conduit associated with one or more cooling plates. A plurality of slots provide a precise mechanical support for each battery cell, increasing the heat conduction from the cell to the battery module, protecting the battery module from vibration and decreasing contamination in case of thermal runaway or other damage to the cells.

Owner:ELECTROVAYA

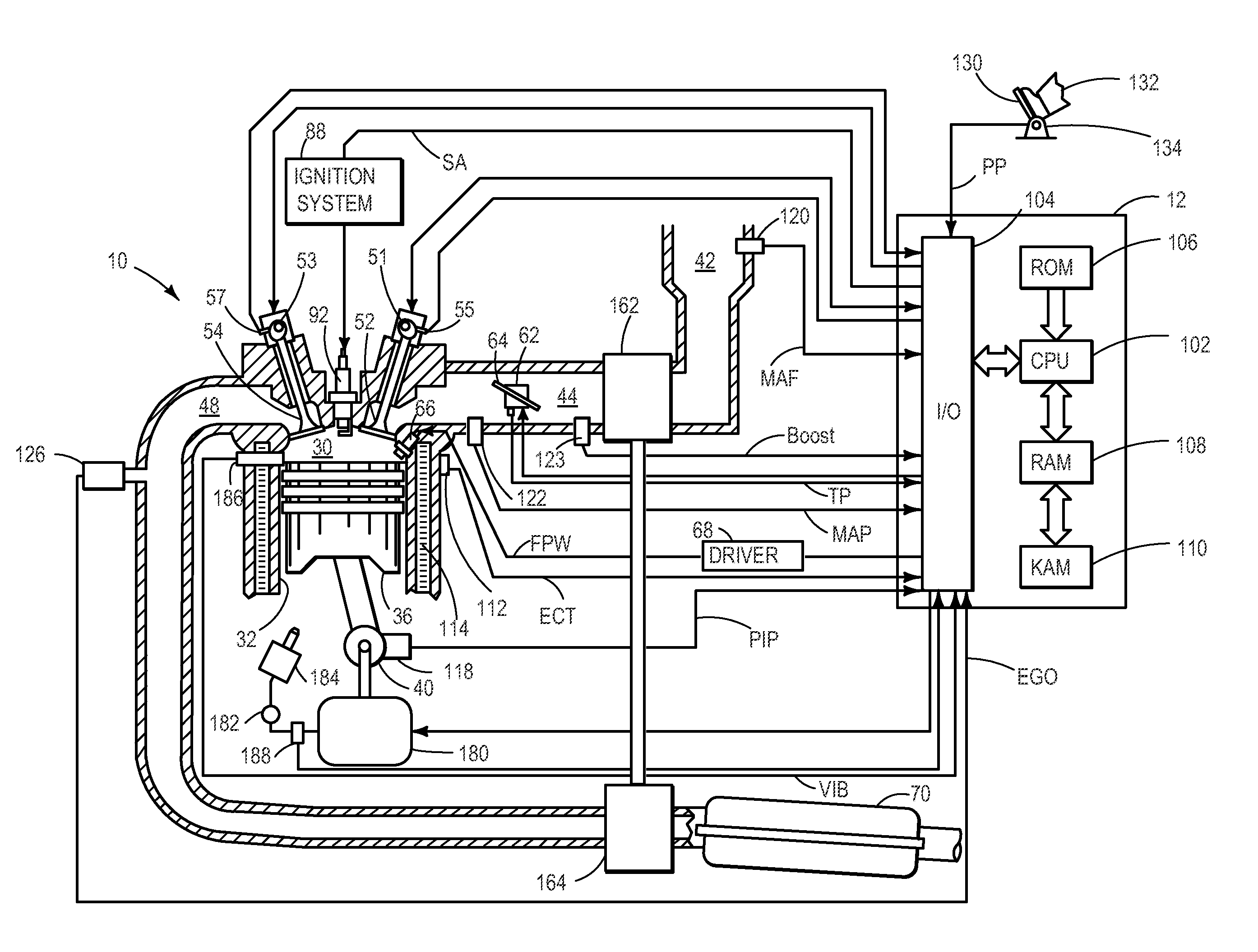

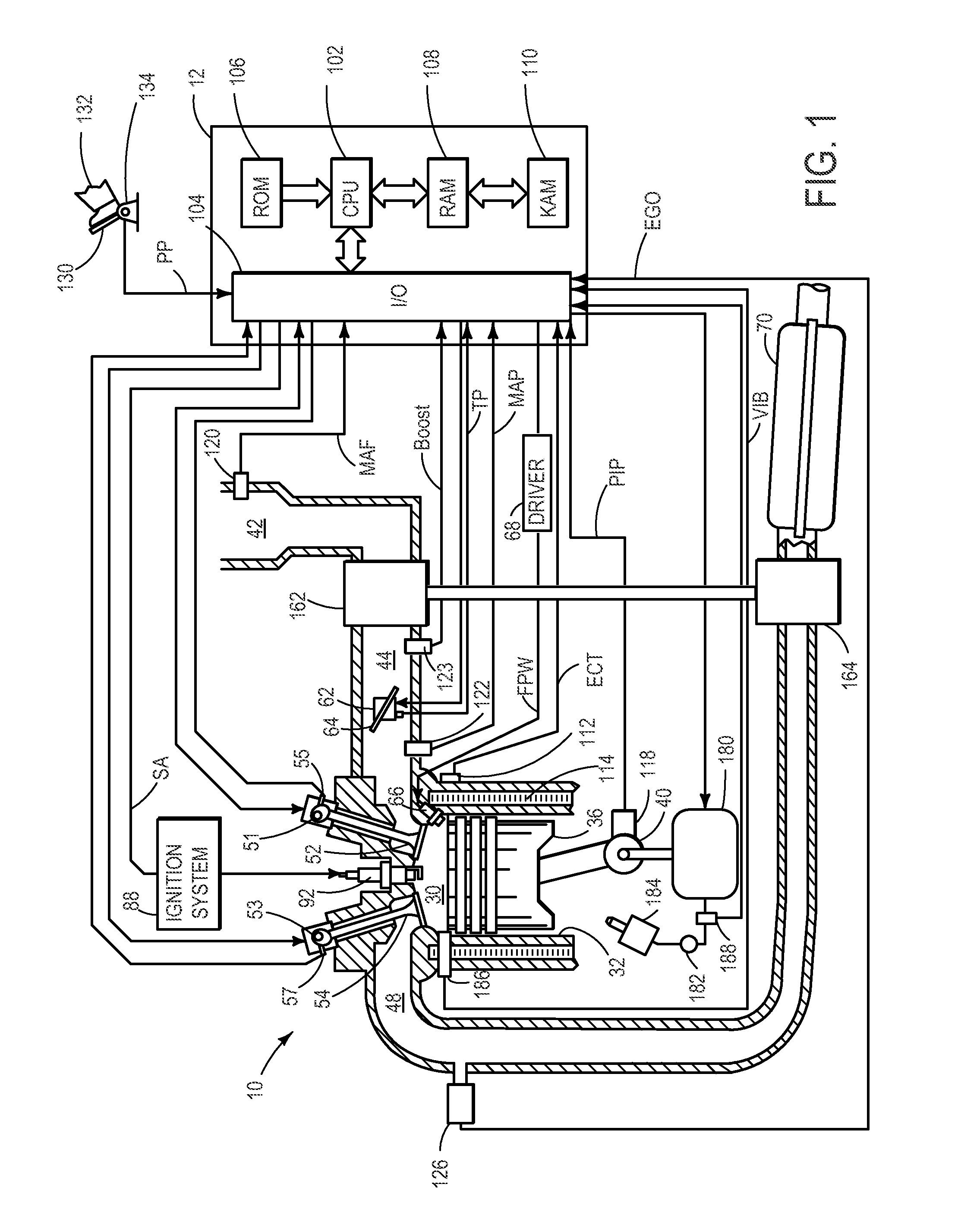

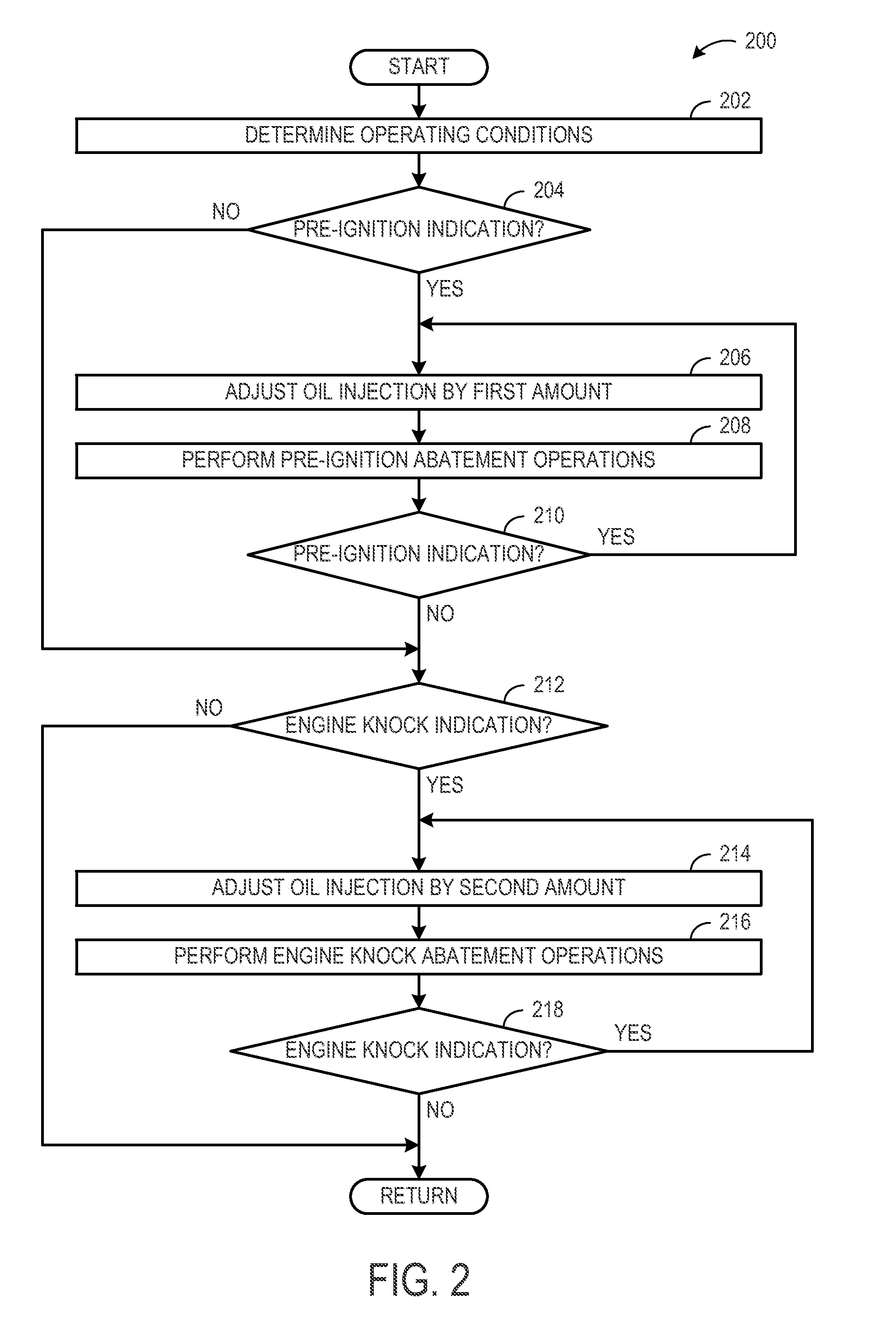

Approach for variable pressure oil injection

ActiveUS20110144882A1Provides a cooling effectCooling is reducedAnalogue computers for vehiclesLubrication of auxillariesVariable pressurePiston

Owner:FORD GLOBAL TECH LLC

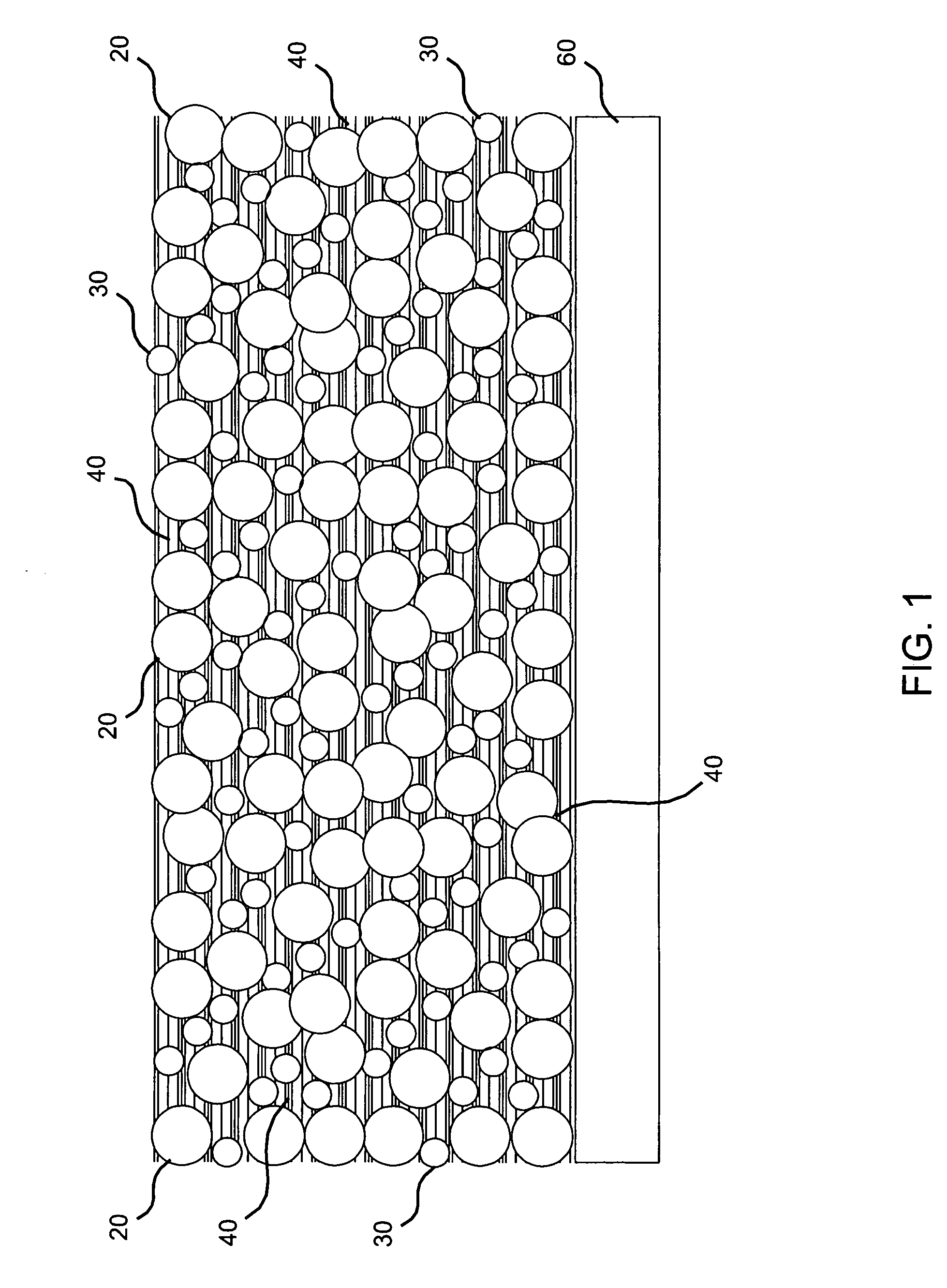

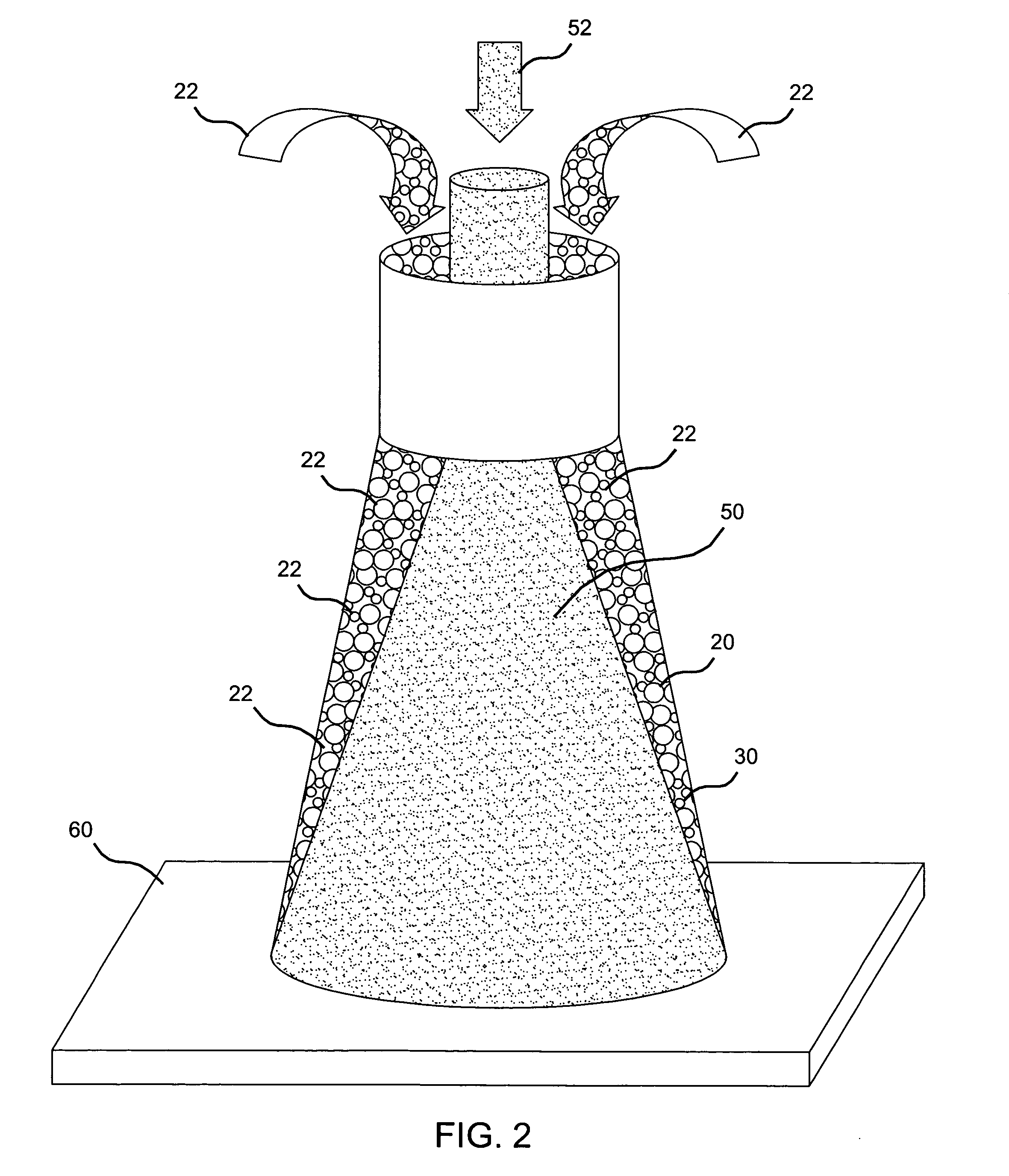

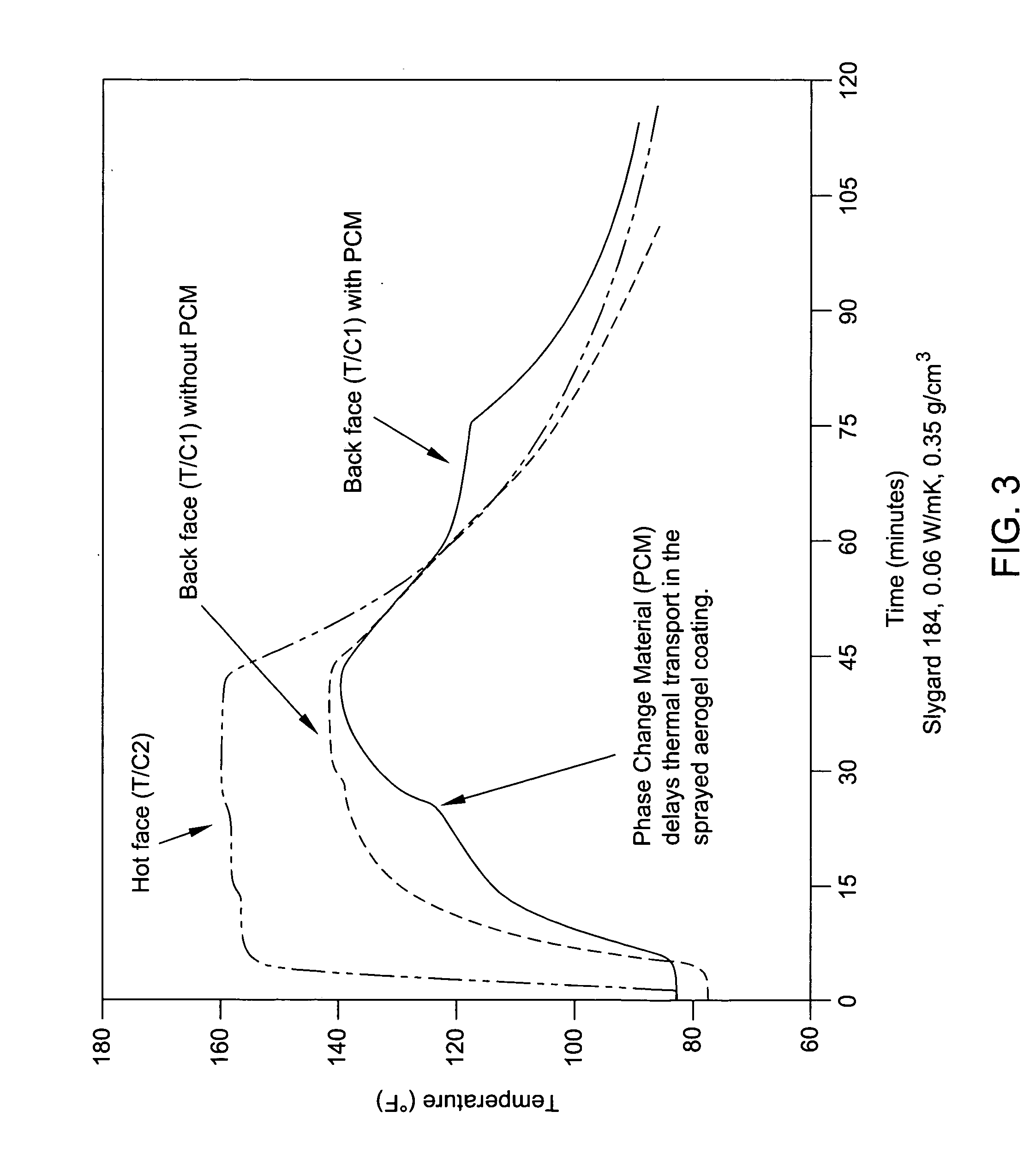

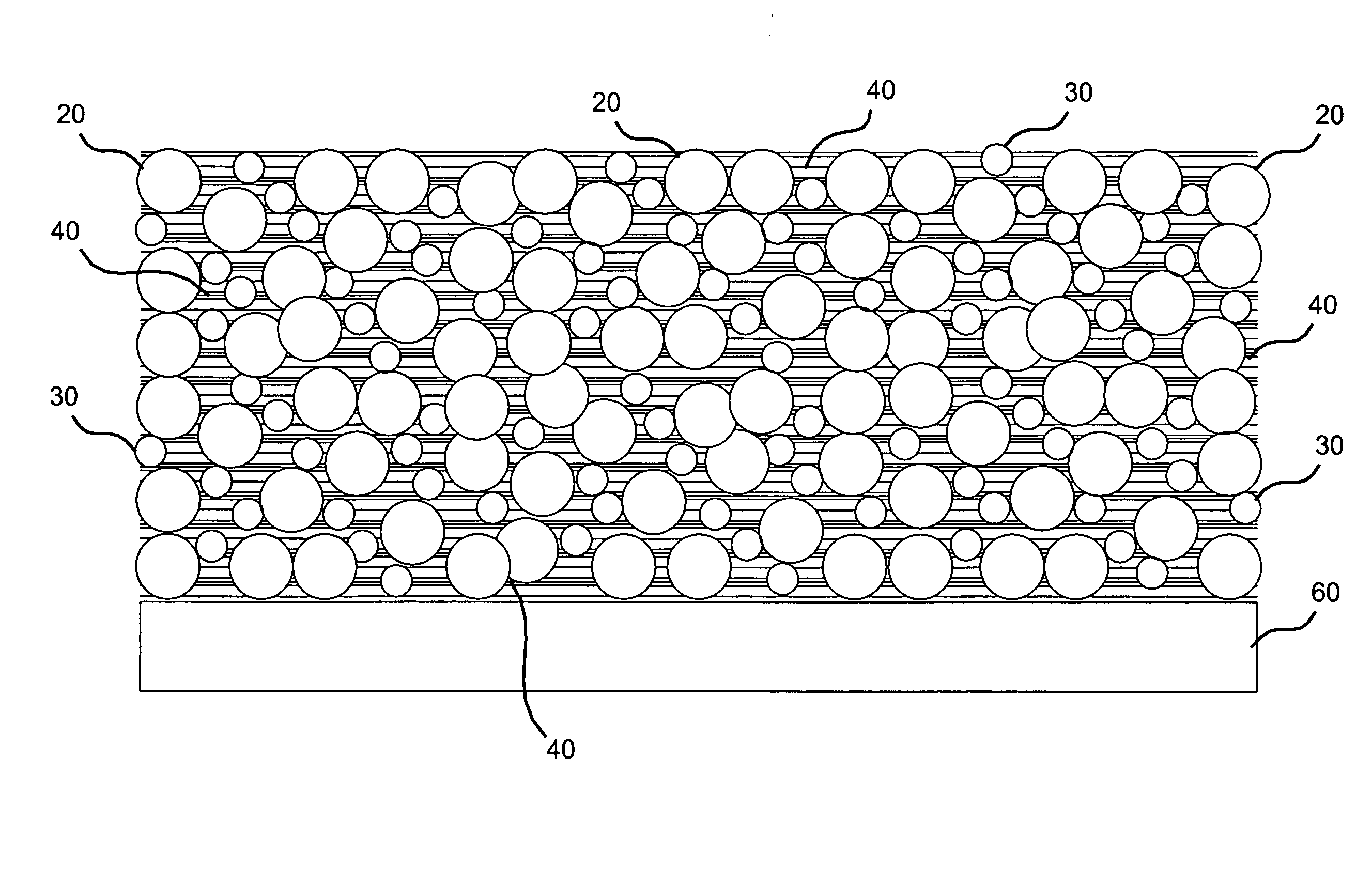

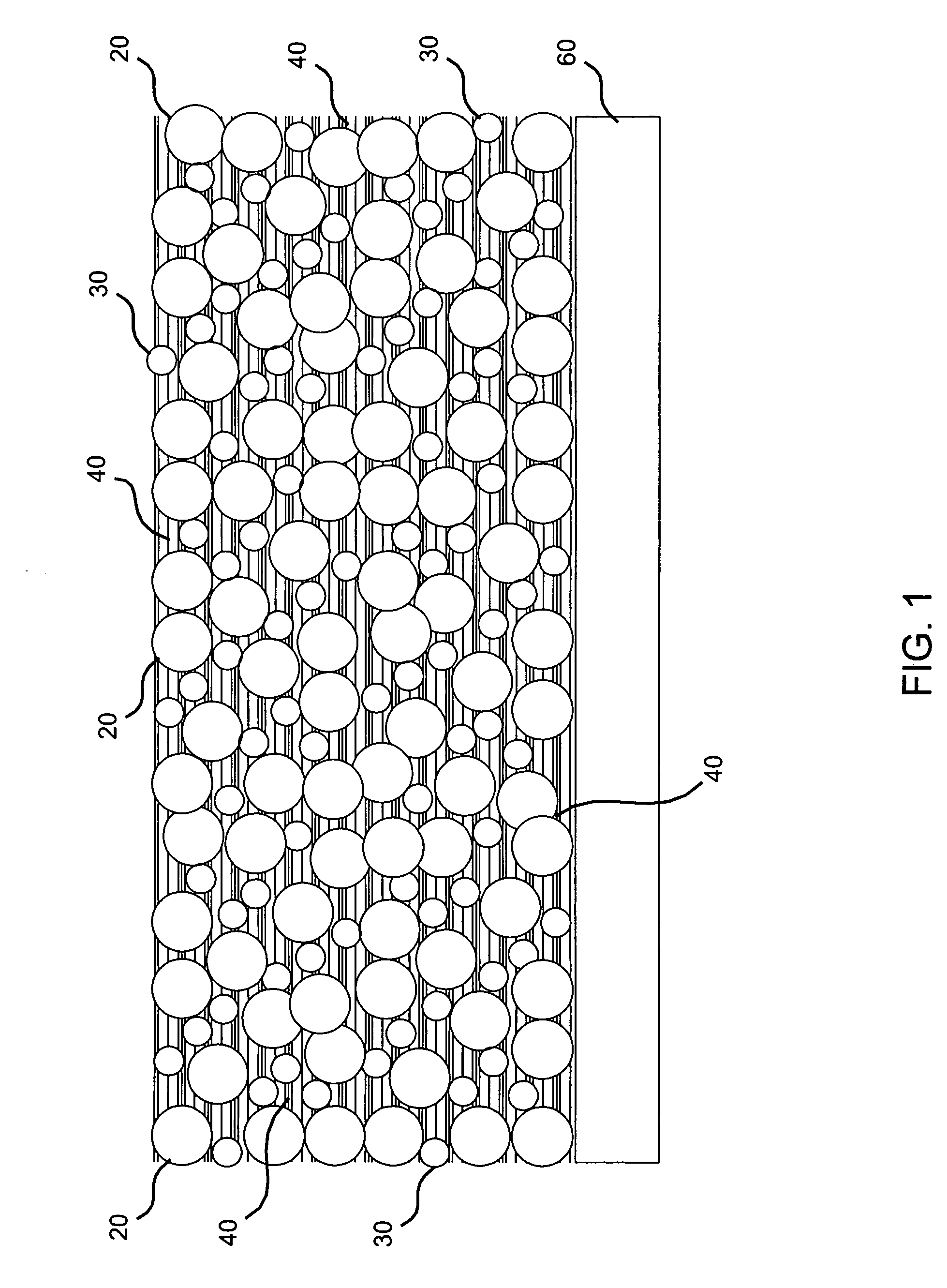

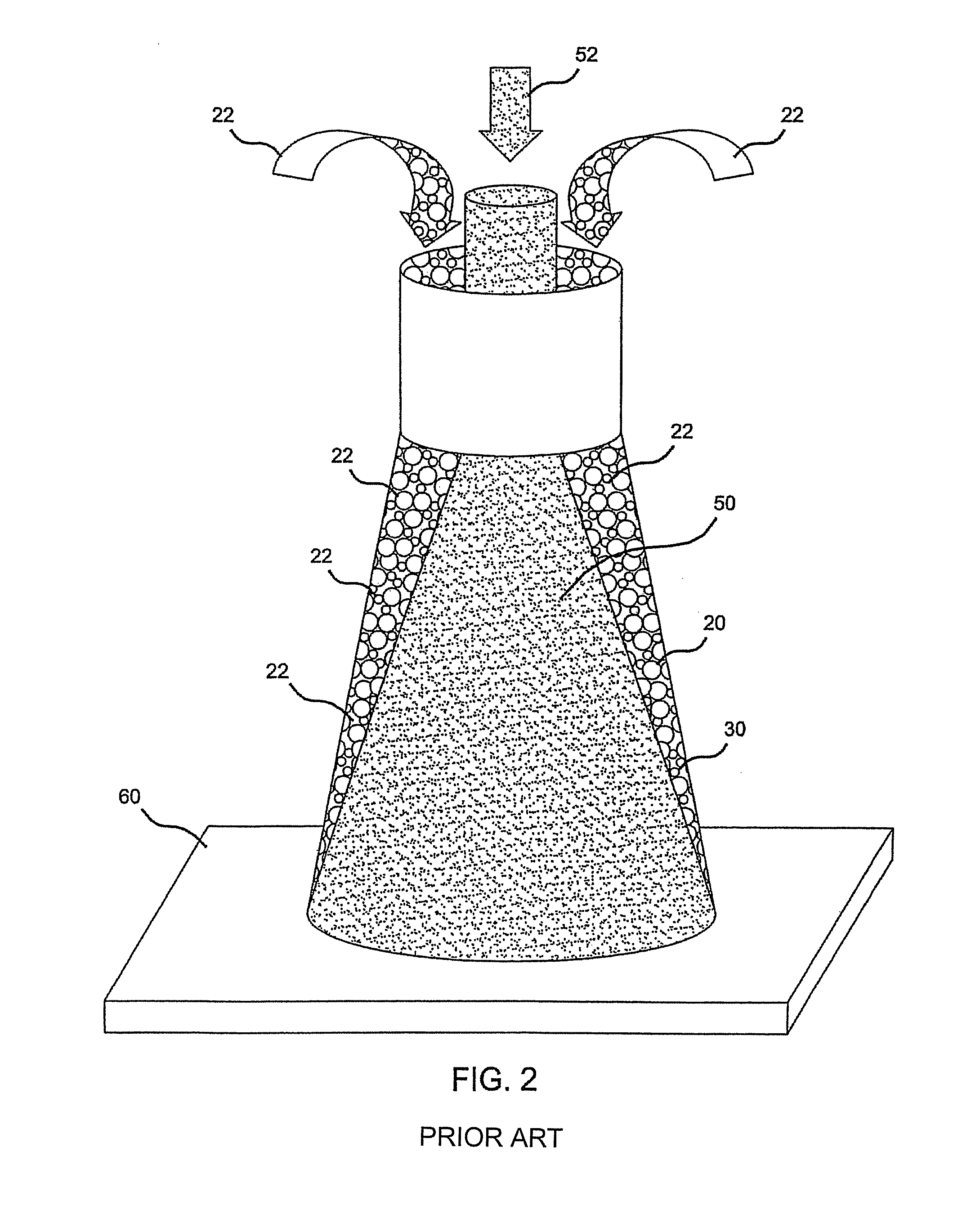

Composite of aerogel and phase change material

ActiveUS20070290392A1Improve thermal efficiencyGood delayThermal insulationLiquid/solution decomposition chemical coatingPhase-change materialMaterials science

In one aspect, the invention provides a body comprising particles containing an insulating aerogel material intermingled with particles containing a phase change material, and a binder forming a matrix retaining the intermingled particles. In another aspect, the invention provides a method of forming an insulating body comprised by applying first and second streams onto a substrate; the first stream comprising a binder and the second stream comprising particles containing aerogel material; and simultaneously applying a phase change material onto the substrate.

Owner:THE BOEING CO

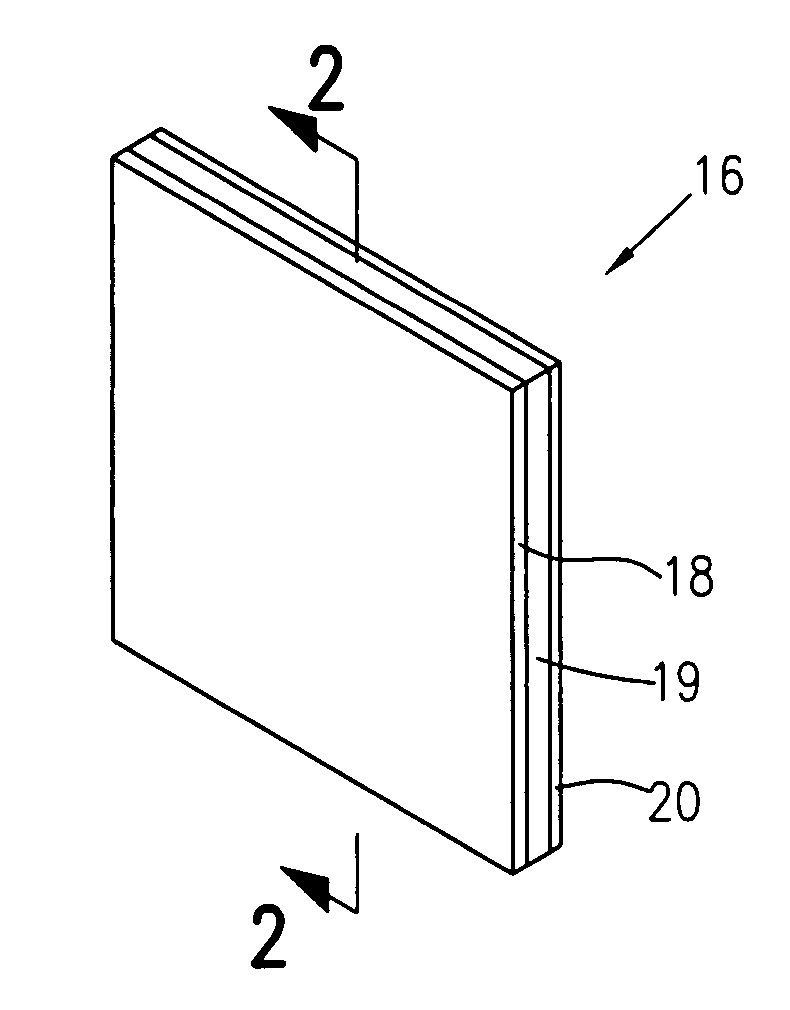

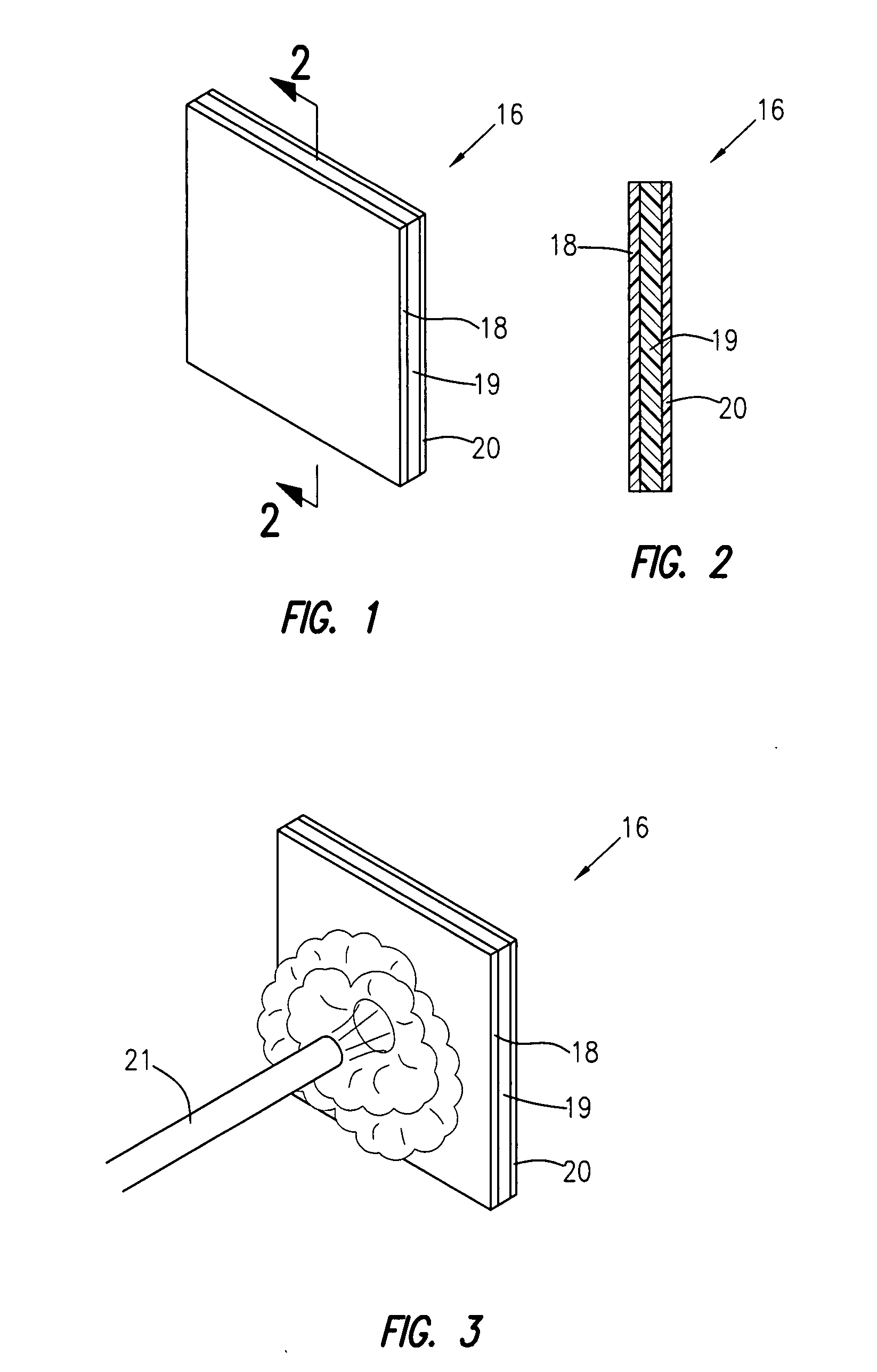

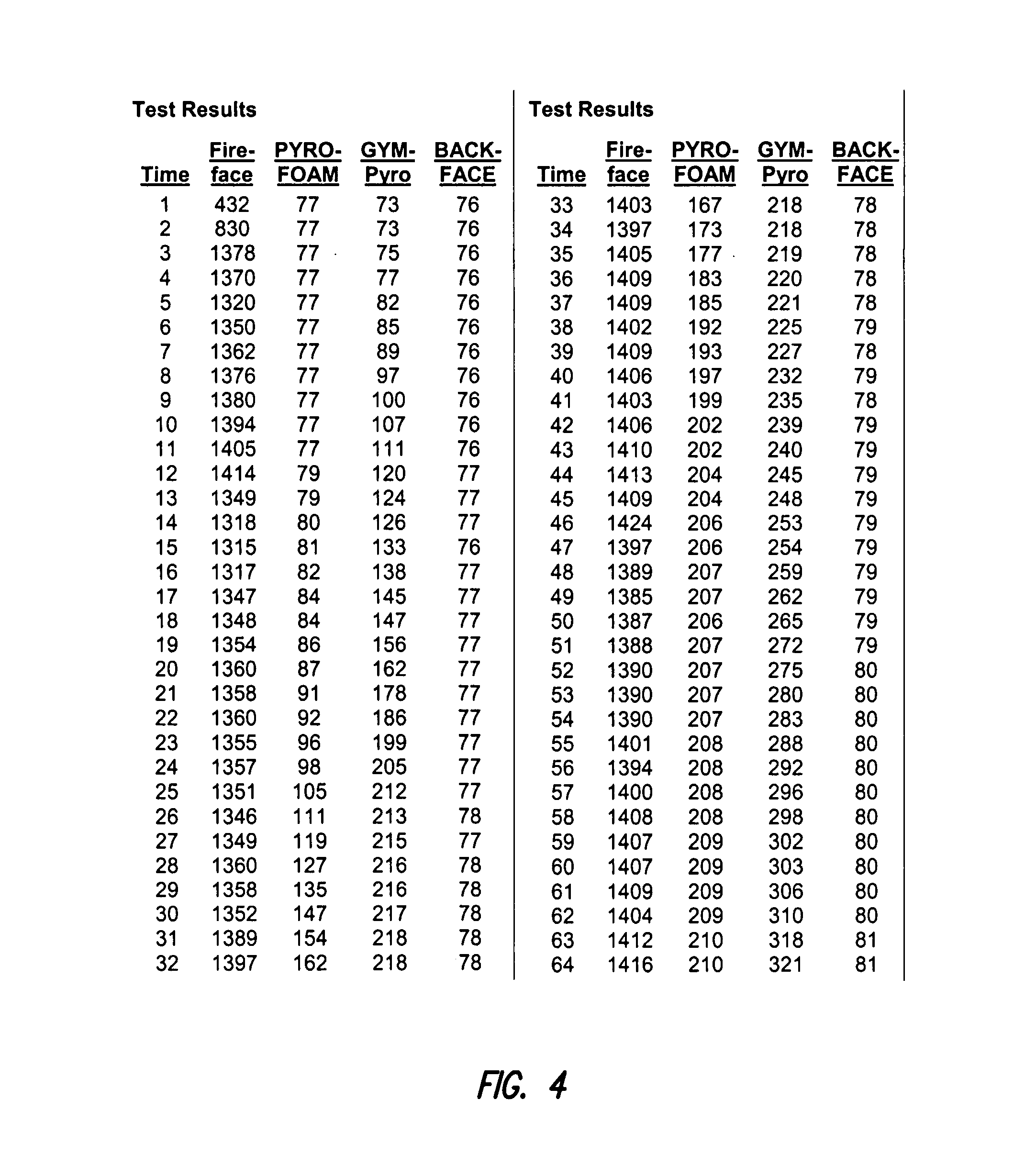

Layered fire retardant barrier panel

InactiveUS20080070024A1Withstands high-temperaturesSlow heat transferSynthetic resin layered productsCeramic layered productsFiberGlass fiber

A fire retardant barrier panel (16) comprising a first protective layer (18) of a first material and a fire resistant phenolic-based resin layer (19) bonded to the protective layer. The first material may be selected from the group consisting of gypsum, ceramic fiber, phenolic foam, basalt, fiberglass, carbon fiber, mineral wool and intumescent materials. The resin may be a phenol or phenolic resin. The fire retardant barrier panel may further comprise a second protective layer (20) bonded to the resin layer (19) such that the resin layer is between the first and second protective layers. The second protective layer (20) may be selected from the group consisting of gypsum, ceramic fiber, phenolic foam, basalt, fiberglass, carbon fiber, mineral wool and intumescent materials.

Owner:CURRAN WILLIAM F +1

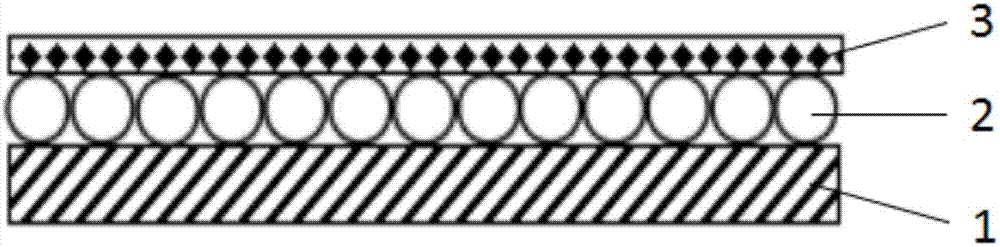

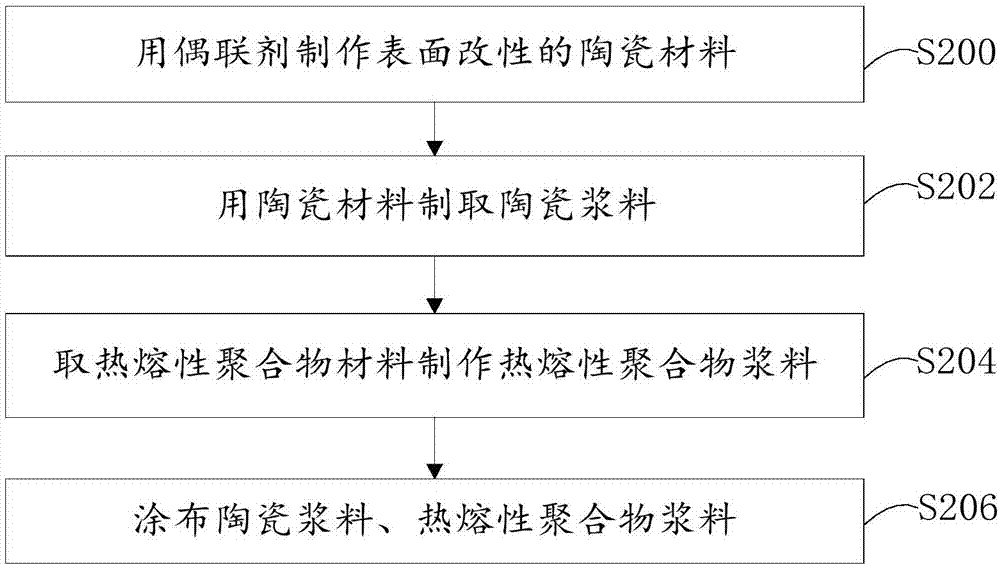

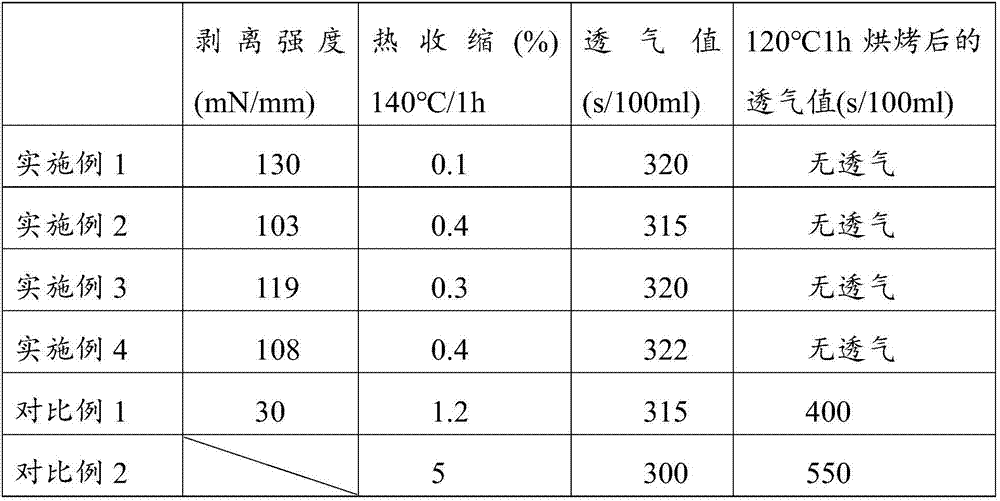

Diaphragm of lithium battery and preparation method thereof

InactiveCN106887559AGood high temperature resistancePrevent heat shrinkageCell seperators/membranes/diaphragms/spacersCeramic coatingCeramic particle

The invention provides a diaphragm of a lithium battery and a preparation method thereof. The diaphragm of the lithium battery comprises a base diaphragm, a ceramic coating and a hot melted polymer coating. The ceramic coating and the hot melted polymer coating are located on the same side of the base diaphragm, and the ceramic coating comprises a ceramic particle material and a first adhesive; the hot melted polymer coating comprises hot melted polymer material particles and a second adhesive. The problem of thermal closing and thermal contraction of the diaphragm is solved.

Owner:XUCHENG FUJIAN SCI & TECH

Hermetic sealing of a substrate of high thermal conductivity using an interposer of low thermal conductivity

InactiveUS6037193ASlow down heat transferHeat dissipation decreaseSemiconductor/solid-state device detailsSolid-state devicesThermal conductivityMetallic materials

The present invention relates generally to a new process for hermetically sealing of a high thermally conductive substrate, such as, an aluminum nitride substrate, using a low thermally conductive interposer and structure thereof. More particularly, the invention encompasses a hermetic cap which is secured to an aluminum nitride substrate using the novel thermal interposer. The novel thermal interposer basically comprises of layers of relatively high thermal conductive metallic materials sandwiching a core layer of low thermal conductive metallic material.

Owner:IBM CORP

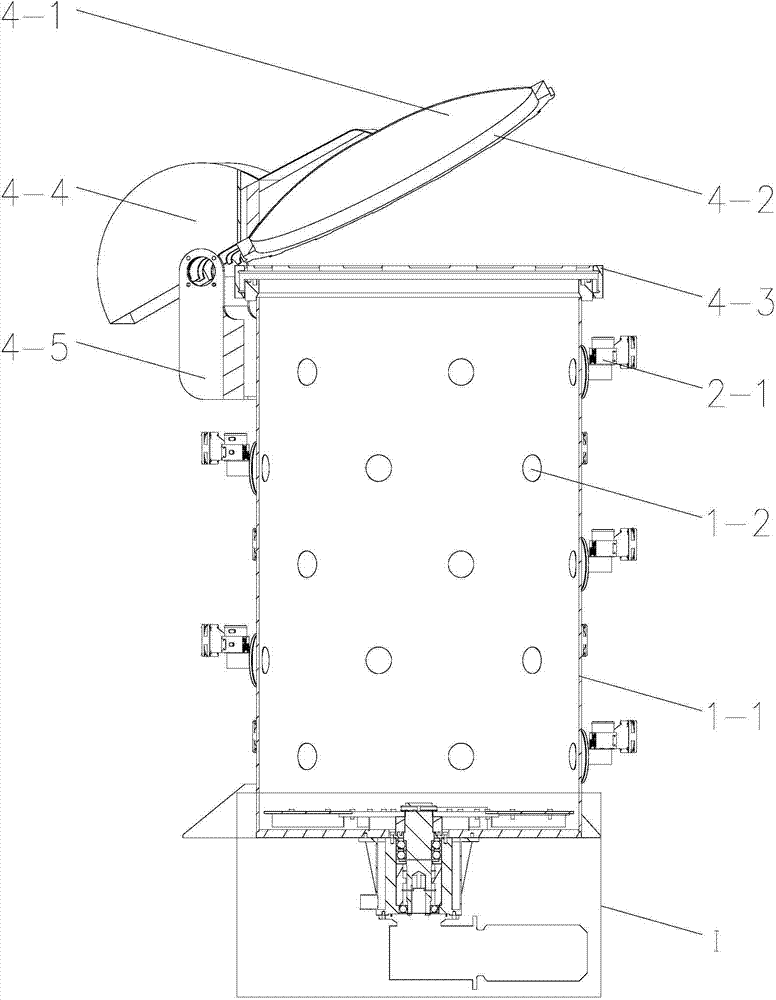

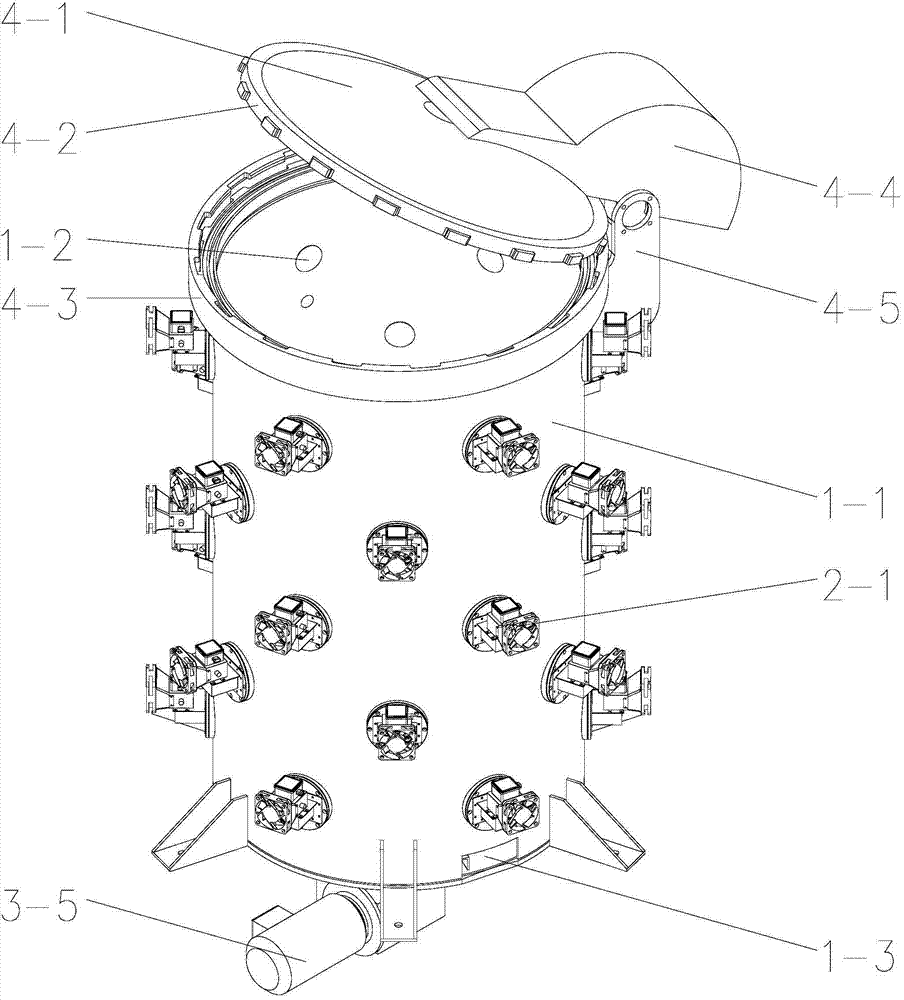

Tank furnace for producing basalt continuous fiber

ActiveCN101397182AHigh melting temperatureGuaranteed temperatureForehearthsTank furnacesMelting tankFiber

The invention relates to a tank furnace for producing basalt continuous filament and pertains to the technical field of novel inorganic non-metallic material processing equipment, the main characteristics are that the furnace body consists of a melting tank and material channels, the melting tank and the material channels are connected by non-submerged dog-holes, the melting tank is divided into a melting area and a homogenization area, a burner is arranged at the top of the furnace vertically, the burner guns of melting area and the feeding pipes are arranged in intervals, and the strong melting area of even feeding and even heating is formed. The material channels are arranged in three directions in the homogenization area of the melting tank, burner guns are arranged in the material channel in sections, the temperature of the fused mass in the material channels is guaranteed, more than 12 wiredrawing shaping areas are evenly arranged in each material channel so as to supply basalt melt mass for the wiredrawing bushing well, emptying devices are arranged at the tail part of the melting tank and the tail parts of all material channels, during the operation, the operation of discharging the meltwater can be carried out when impurities are stored in the meltwater for a long time or the varieties of raw materials are changed. The invention is in favor of improving the quality and industrialized production of the basalt continuous filament.

Owner:江苏天龙玄武岩连续纤维股份有限公司

Lightweight high-strength ultra heat preservation building block

InactiveCN101016204AImprove insulation effectSerialized continuously adjustableConstruction materialSolid waste managementSlagFoam glass

The invention discloses a light-quality high-strength hyper-insulating architectural block, which comprises the following parts: 20%-40% cement, 19%-25% coal slag, 12%-25% basalt, 5%-15% mineral slag and 6%-15% doped material, wherein the doped material is composed of 80%- 90% modifier material and 10%-20% composite additive; the modifier material is one or two or more composition of vermiculite, pumice, foam glass, pearlite or diatomite according to random proportion; the compound additive is composed of 2.3% sodium hexametaphosphate, 0.7% triethanolamine and residual calcium oxide or sodium sulphate or their composition according to certain proportion.

Owner:HEILONGJIANG HUIFENG ENERGY TECH DEV

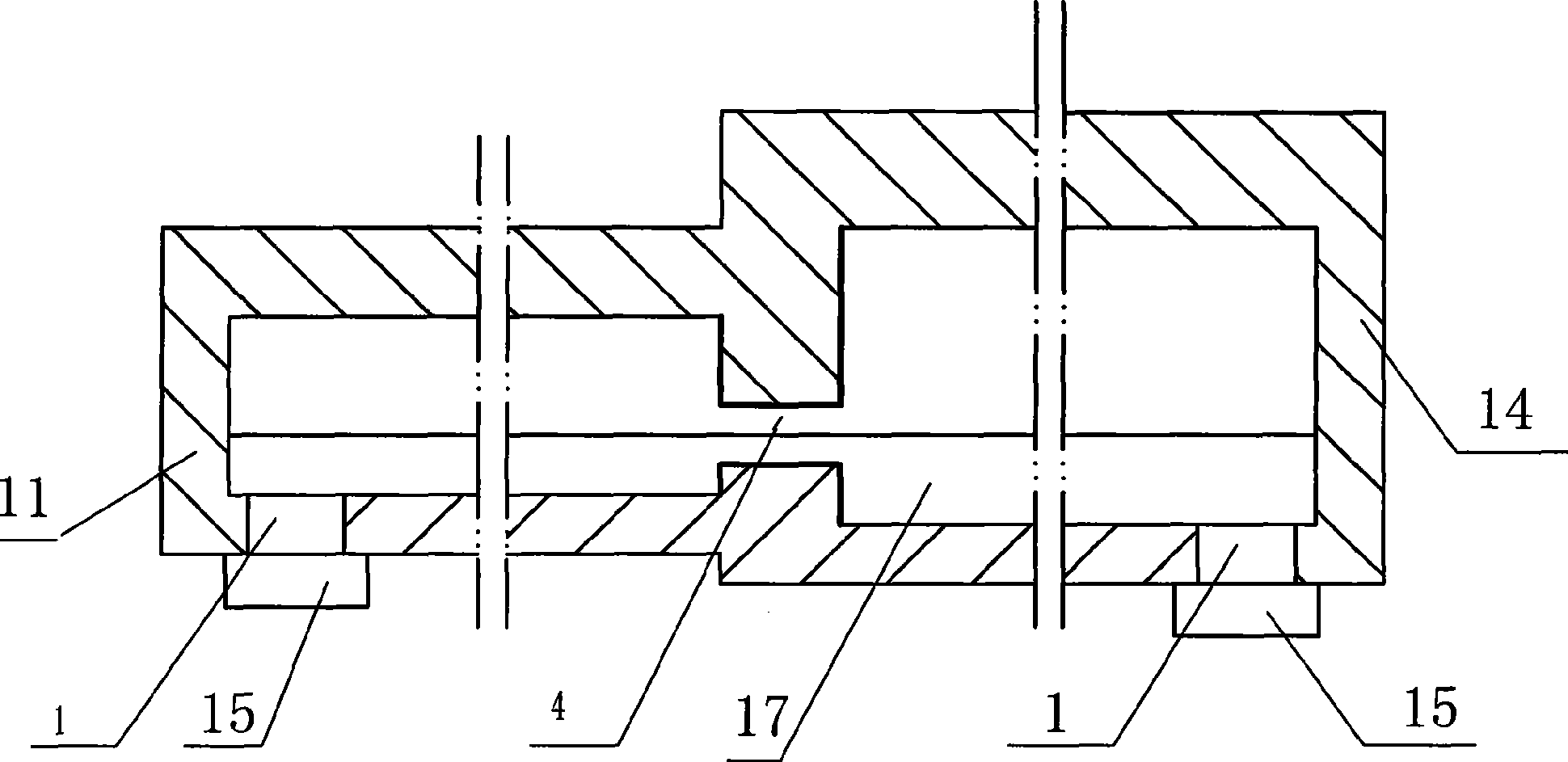

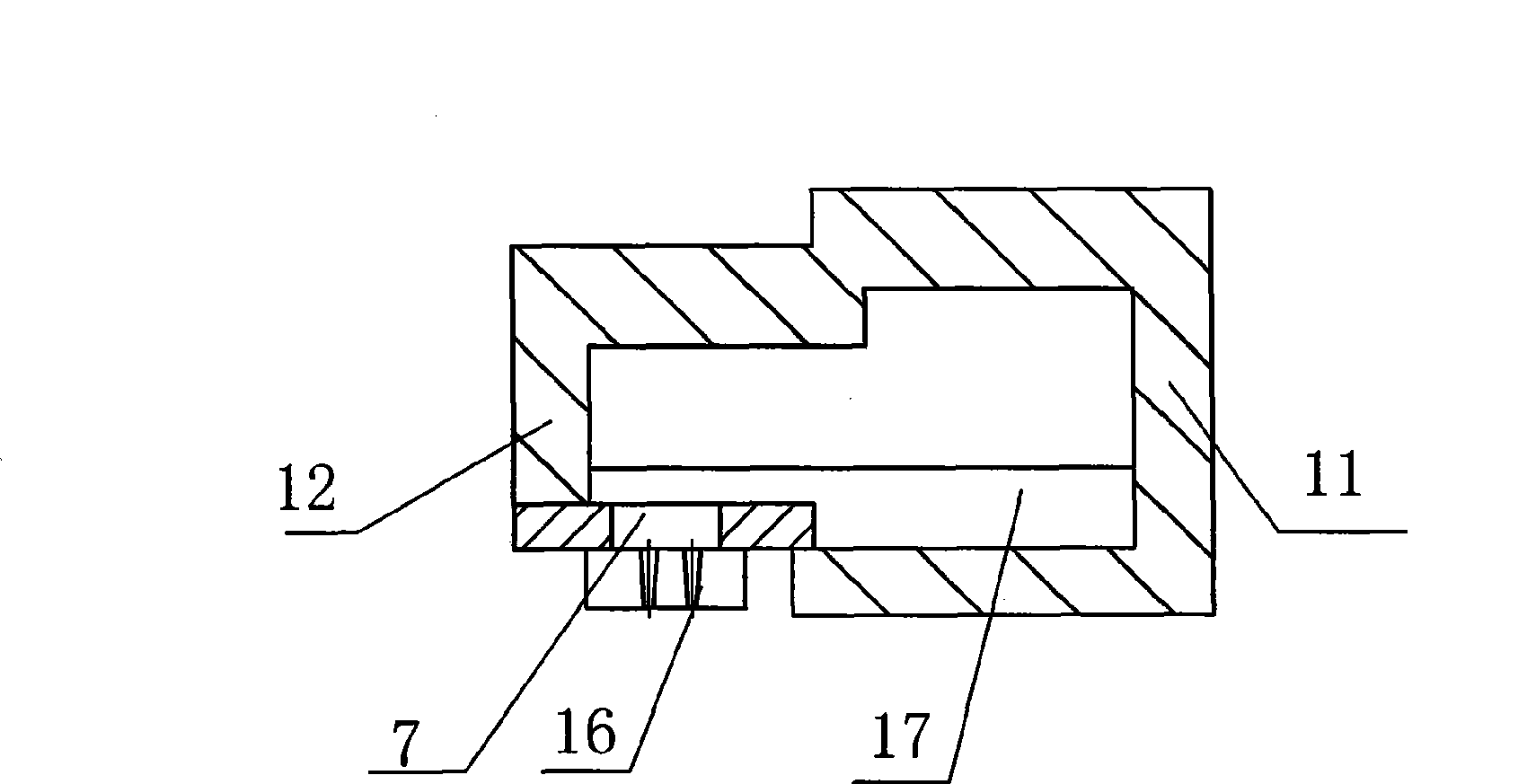

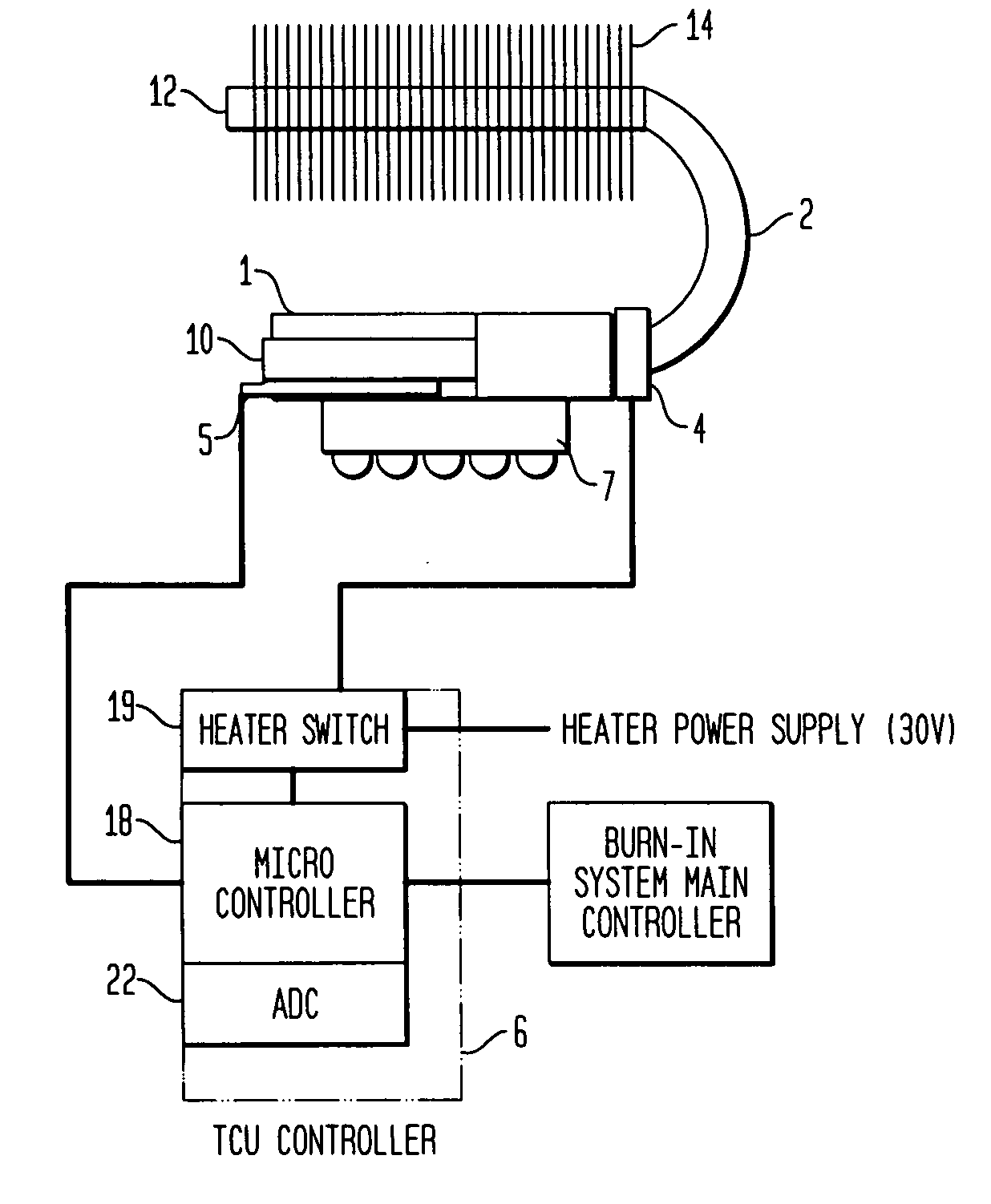

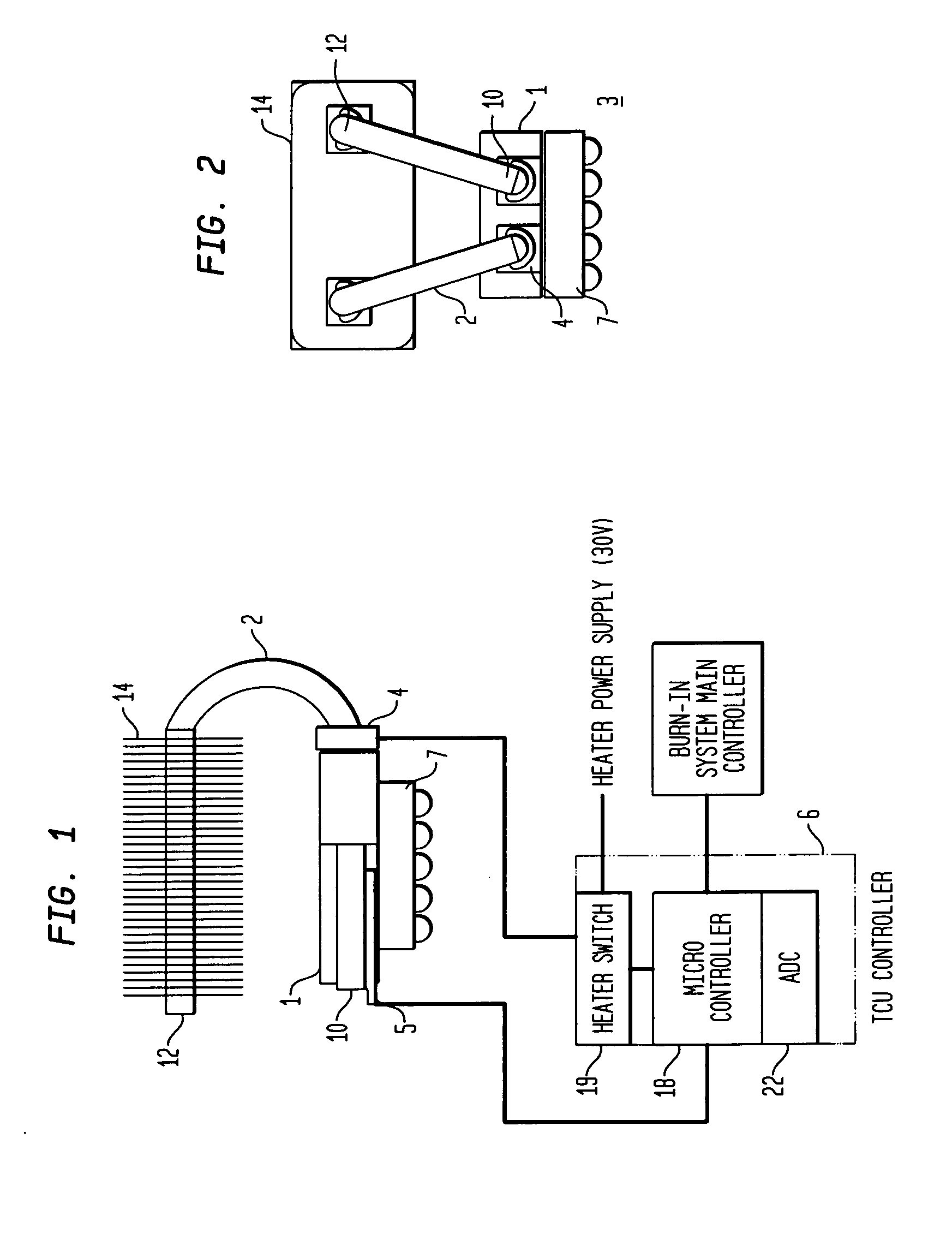

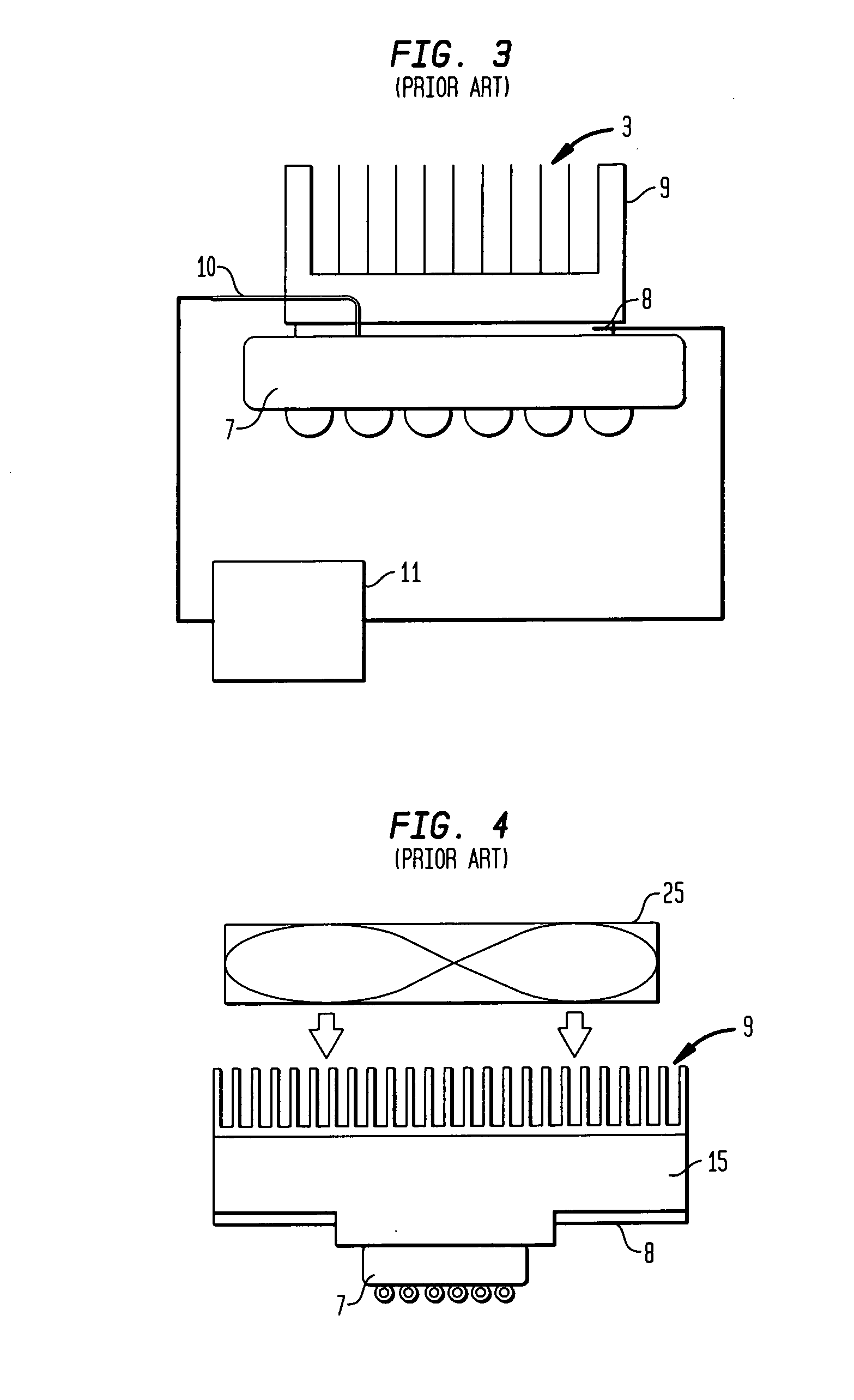

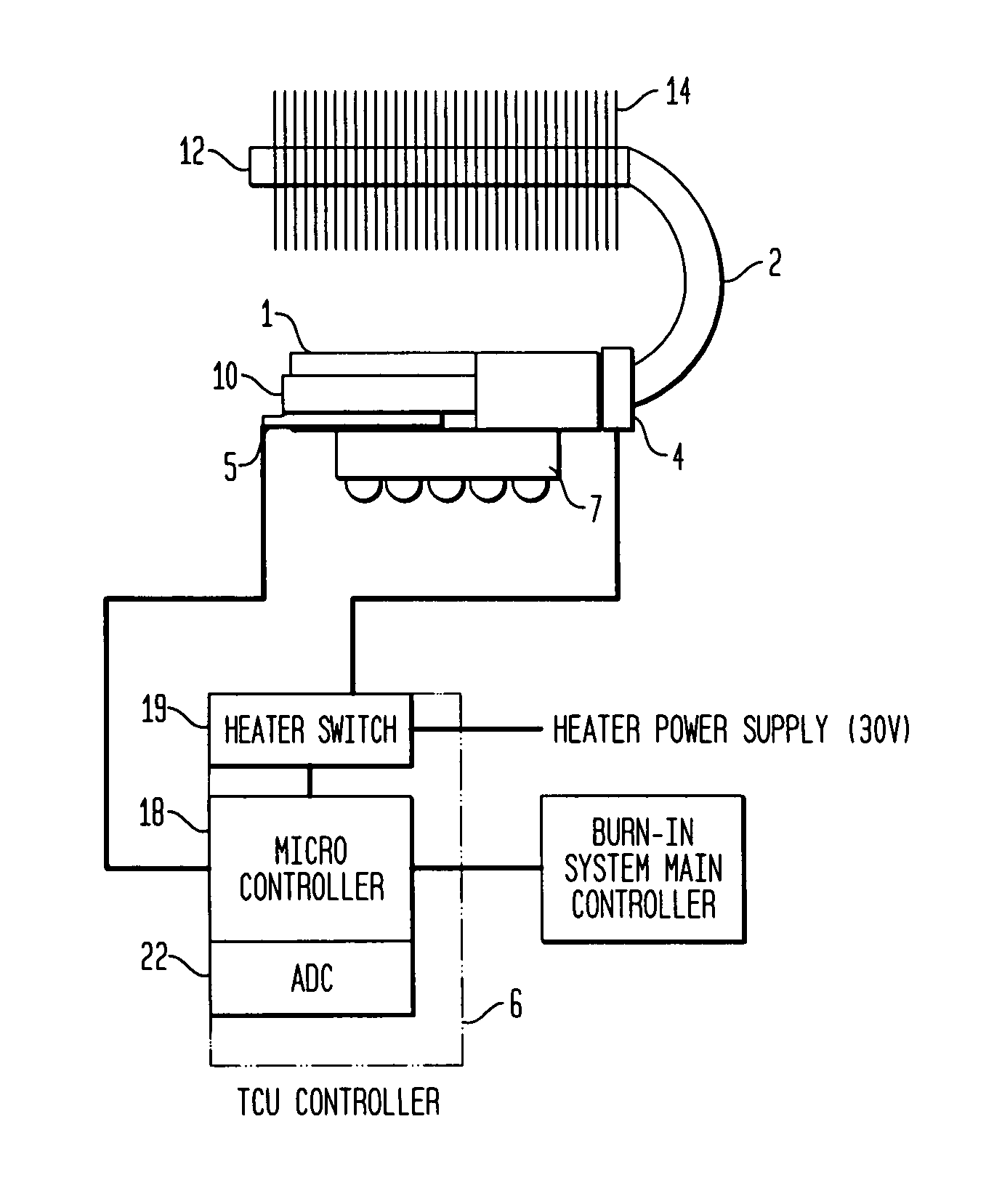

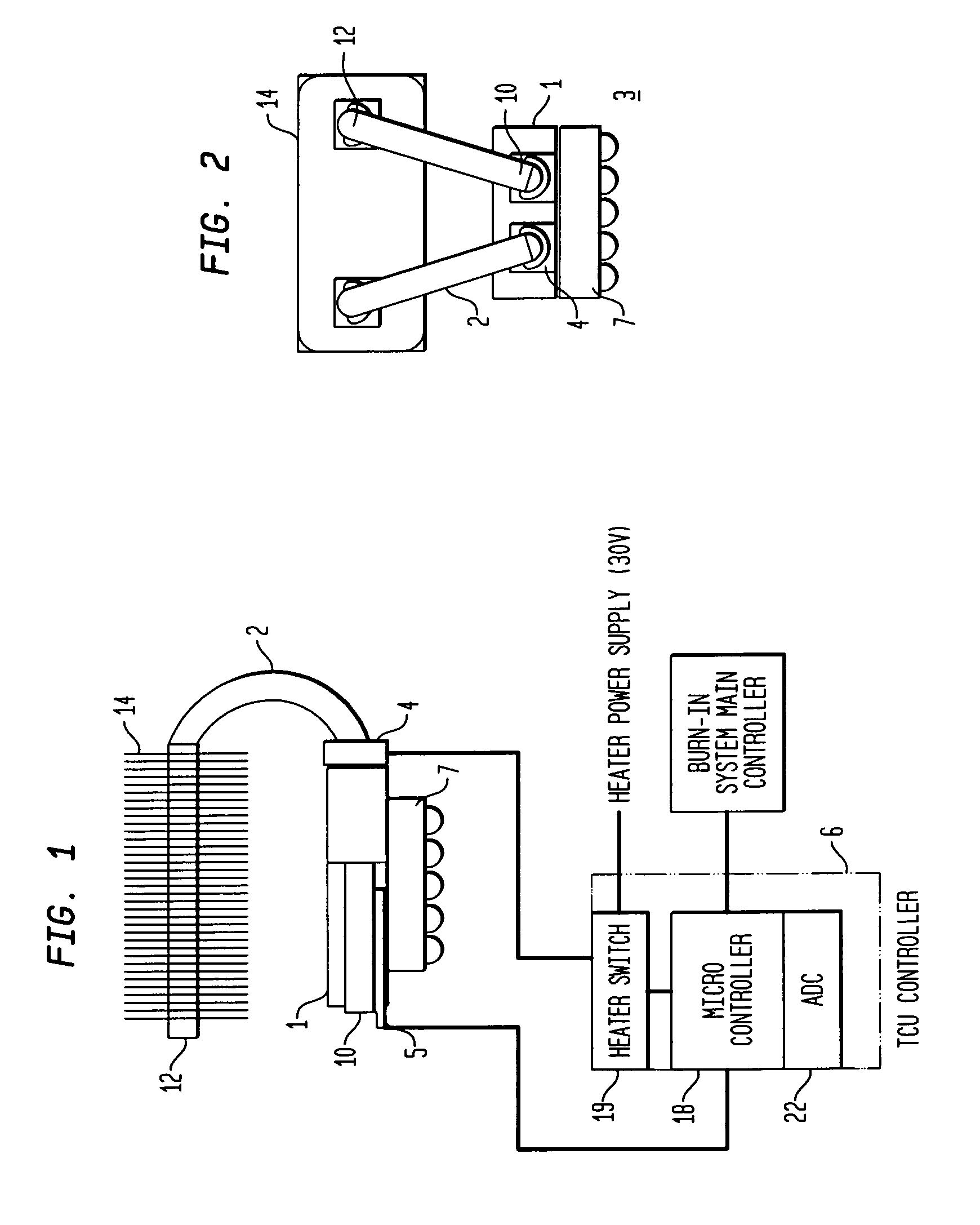

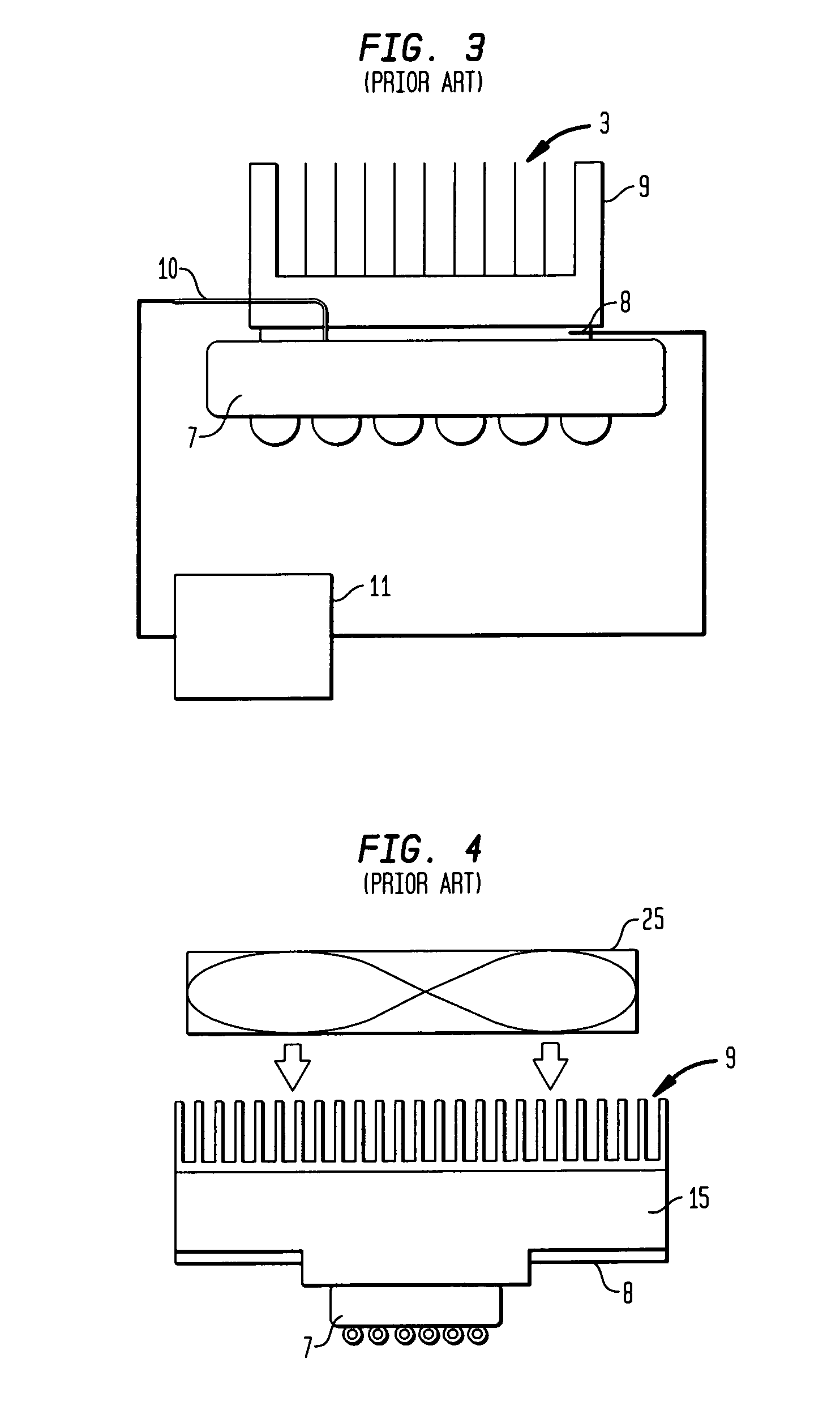

Thermal control unit for semiconductor testing

InactiveUS20090183866A1Reduces heat conducts heatReduce heat transfer rateSpace heating and ventilation safety systemsLighting and heating apparatusSemiconductorHeat pipe

A thermal control unit with a heat pipe that conducts heat away from a device under test during burn-in. The heat pipe has a heater that allows control of the rate at which heat is transferred from the DUT to the heat pipe. A sensor and controller are provided to control the heat in response to the measured temperature of the DUT. The sensor and controller control the heater to maintain the surface temperature of the DUT within a specified range.

Owner:KES SYST & SERVICE 1993 PTE

Composite of aerogel and phase change material

ActiveUS8003028B2Improve thermal efficiencyGood delayThermal insulationCeramic shaping apparatusPhase changePhase-change material

A method of forming a thermally insulating body that may involve co-depositing onto a substrate, particles containing aerogel material, particles containing phase change material, and a solution containing a binder and a carrier. The phase change material may have encapsulated phase change material particles in which a phase change substance encapsulated within durable capsules transitions from a solid to a liquid at a temperature greater than about 100 degrees Fahrenheit. The carrier may be removed after the co-deposition to form a solid thermally insulating body on the substrate.

Owner:THE BOEING CO

Thermal control unit for semiconductor testing

InactiveUS8274300B2Reduce probabilityReduce heat transfer rateSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringSemiconductor

A thermal control unit with a heat pipe that conducts heat away from a device under test during burn-in. The heat pipe has a heater that allows control of the rate at which heat is transferred from the DUT to the heat pipe. A sensor and controller are provided to control the heat in response to the measured temperature of the DUT. The sensor and controller control the heater to maintain the surface temperature of the DUT within a specified range.

Owner:KES SYST & SERVICE 1993 PTE

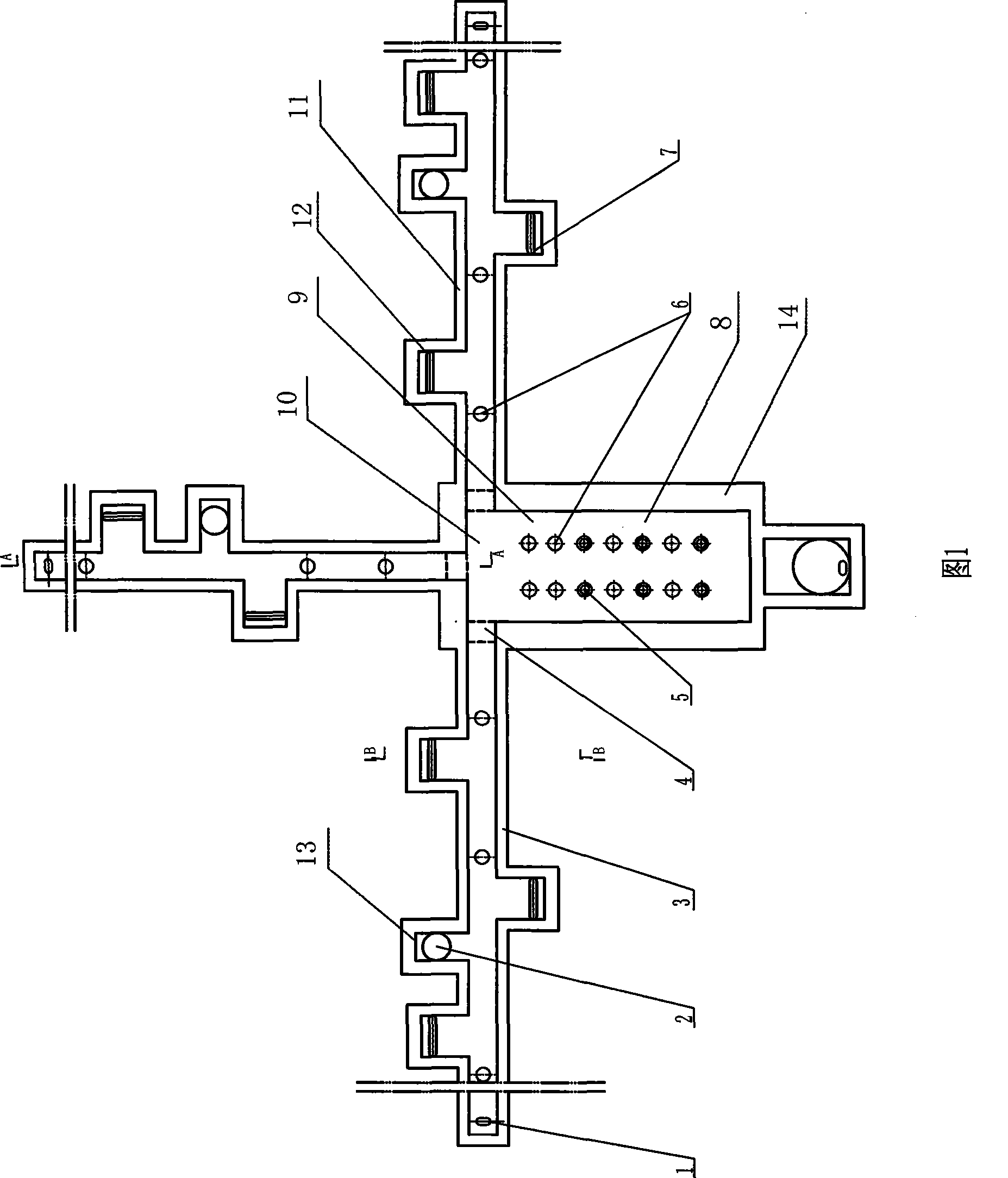

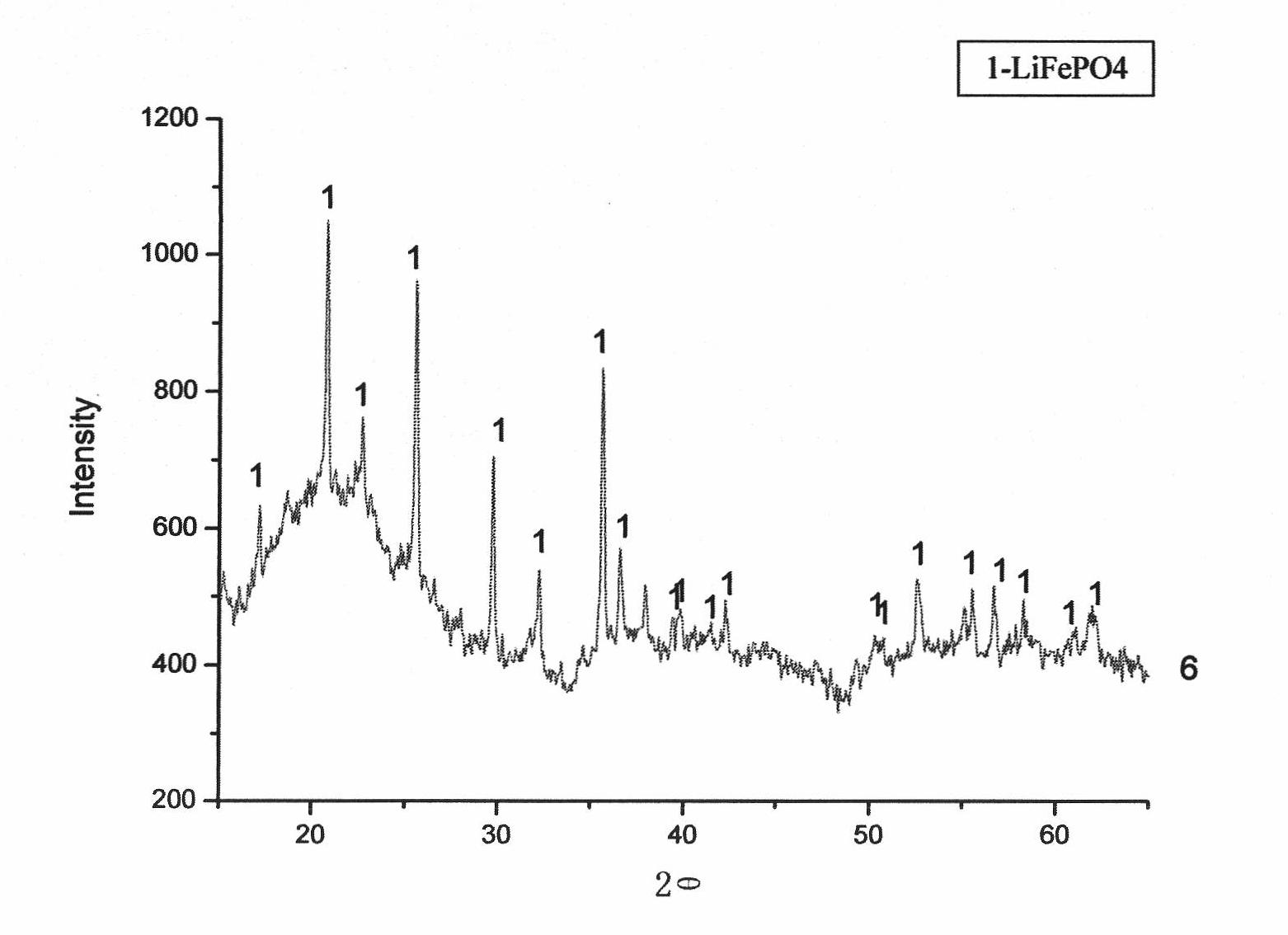

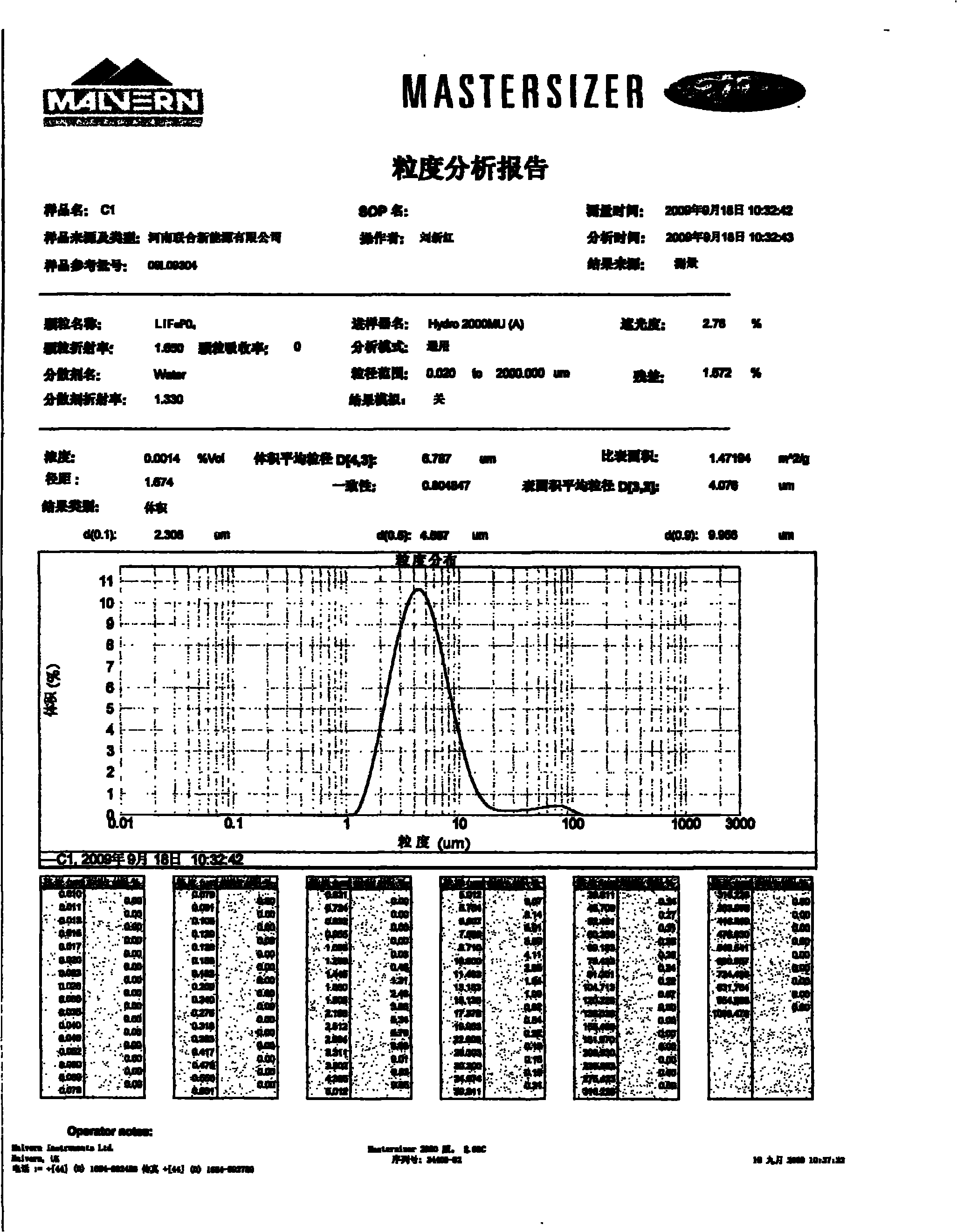

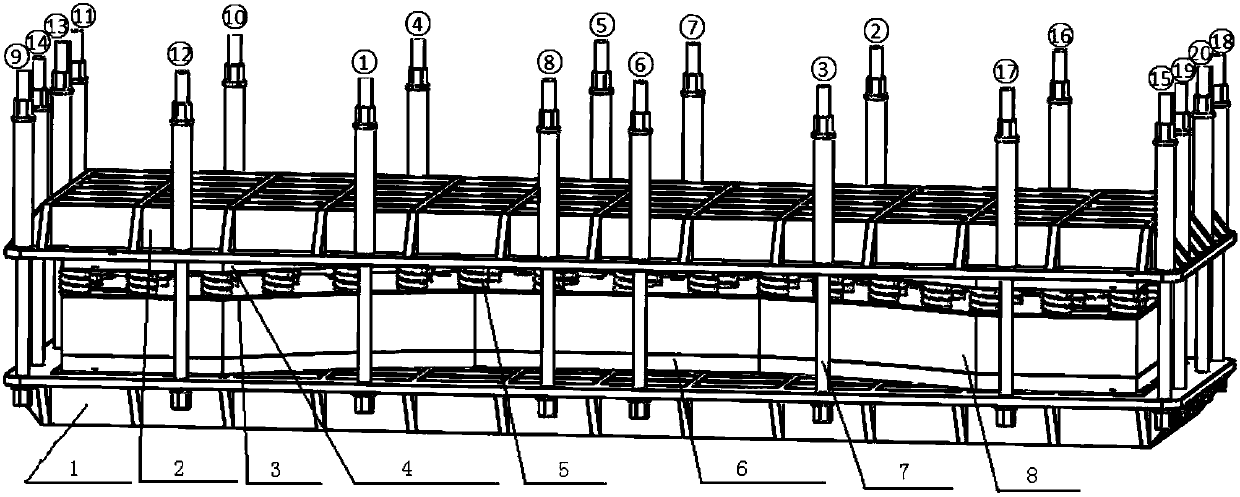

Method for preparing lithium iron phosphate by sintering lithium iron phosphate precursor and microwave sintering equipment

InactiveCN102092699APromote densificationEvenly distributedCell electrodesPhosphorus compoundsLithium iron phosphateControl treatment

The invention discloses a method and equipment for preparing lithium iron phosphate from a lithium iron phosphate precursor. The method comprises the three process steps of pretreatment of the lithium iron phosphate precursor material, pre-sintering and sintering; and in a non-oxidizing environment, the precursor material is heated by a certain number of microwave heaters, and the three process steps are finished by controlling treatment temperature and treatment time to finally prepare the lithium iron phosphate product. The equipment comprises a material inlet, a material feeding ventilation chamber, a pretreatment unit furnace, a pre-sintering unit furnace, a sintering unit furnace, a material discharging ventilation chamber, a cooling material discharging mechanism, a material outlet,a vacuumizing device, a protective gas input device and an equipment control circuit. In the method, the pretreatment and pre-sintering process steps are added to optimize a lithium iron phosphate microwave sintering process and solve keys problems on product quality control. The equipment provided by the invention realizes continuous microwave sintering by a plurality of unit furnaces so as to improve the sintering efficiency and realize large-scale industrial production.

Owner:HENAN UNION NEW ENERGY

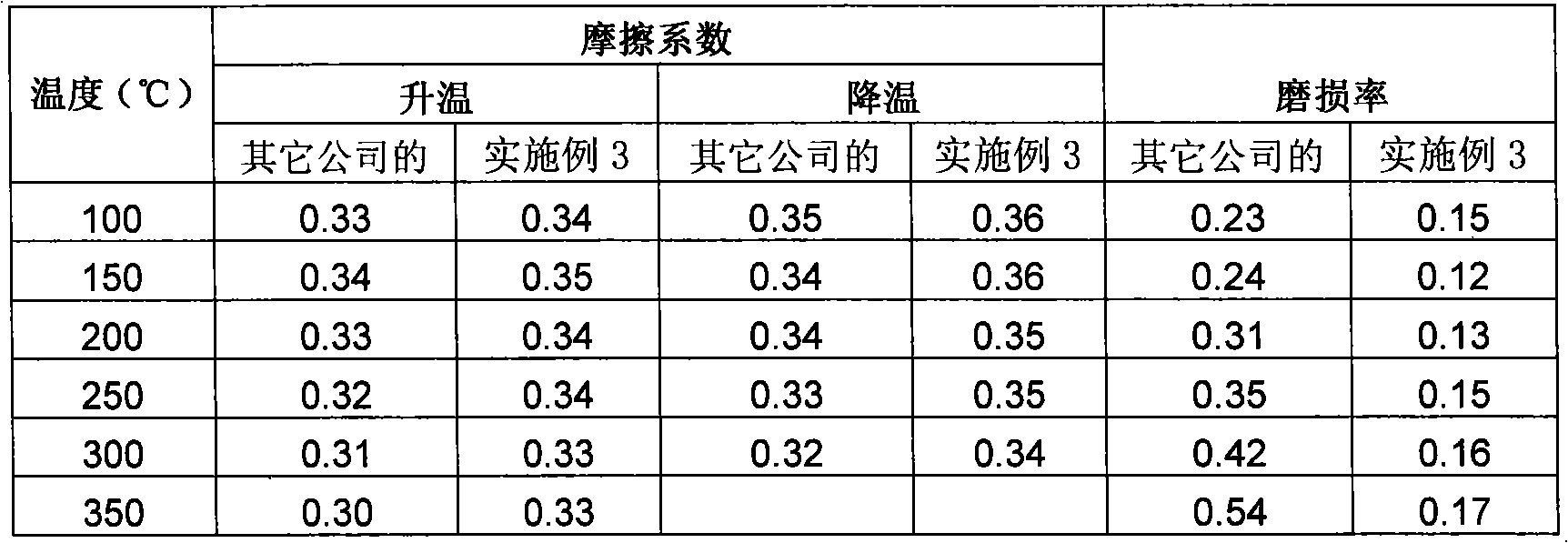

Fire-resistant micro-metal brake pad

ActiveCN101555913AMaterial environmental protectionReduce heat transferFriction liningAluminium silicateBrown iron oxide

A fire-resistant micro-metal brake pad is mainly composed of the following components according to weight percentages: 2-4% of nitrile rubber, 3-6% of tyre powder, 3-5% of expansion graphite, 4-8% of super-fine iron oxide powder, 9-13% of boron containing phenolic resin, 3-6% of chromite, 3-5% of magnetite, 5-8% of diatomite, 6-9% of E glass short fibre, 7-11% of grammite fibre, 6-9% of chopped steel fibre, 8-12% of viscose fibre, 0.5-1% of aluminium silicate hollow ball, 2-3% of heavy magnesia, 0.2-0.5% of zinc stearate, 0.5-1% of copper sulphide, 3-5% of calcined petroleum coke and 10-15% of barite. The material of the invention is environmentally-friendly and rust-less, the heat transmission is slow, the fire and thermal degradation resisting performance is good, and the service life is long. After the invention is used, the brake of the small automobile is sensitive, the brake is stable, no brake scream is generated, and the comfortable performance is good, thereby not damaging the couple plate.

Owner:摩擦一号制动科技(仙桃)有限公司

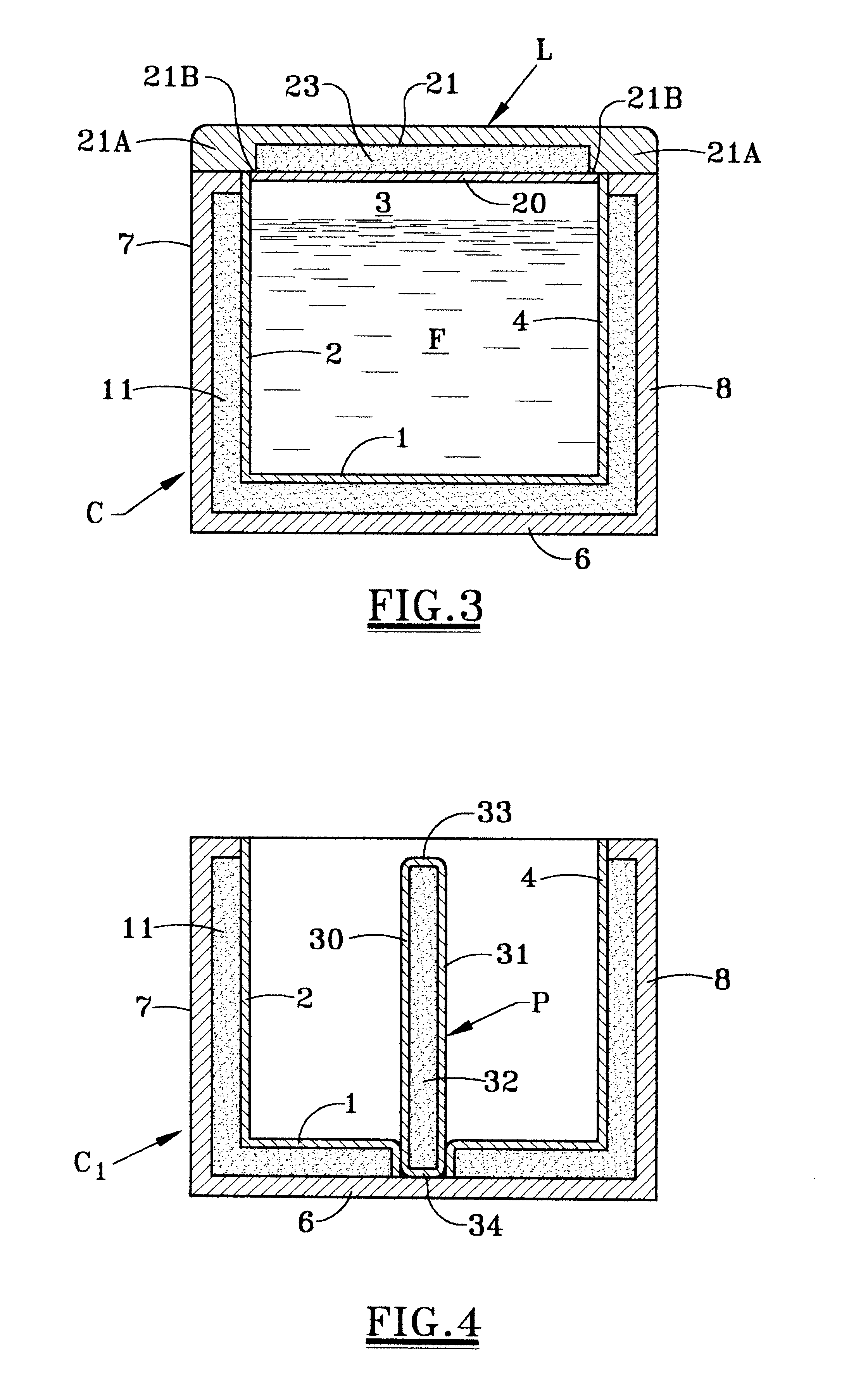

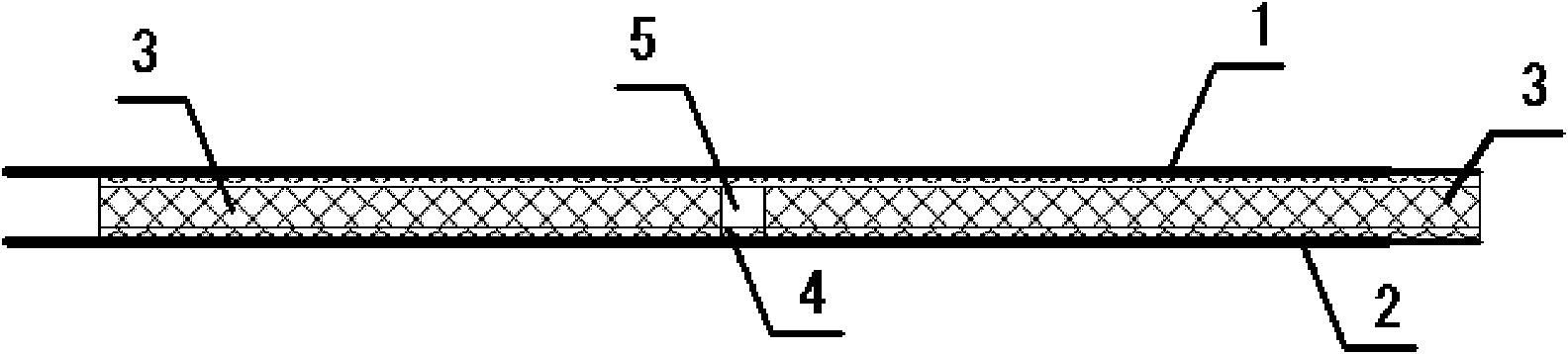

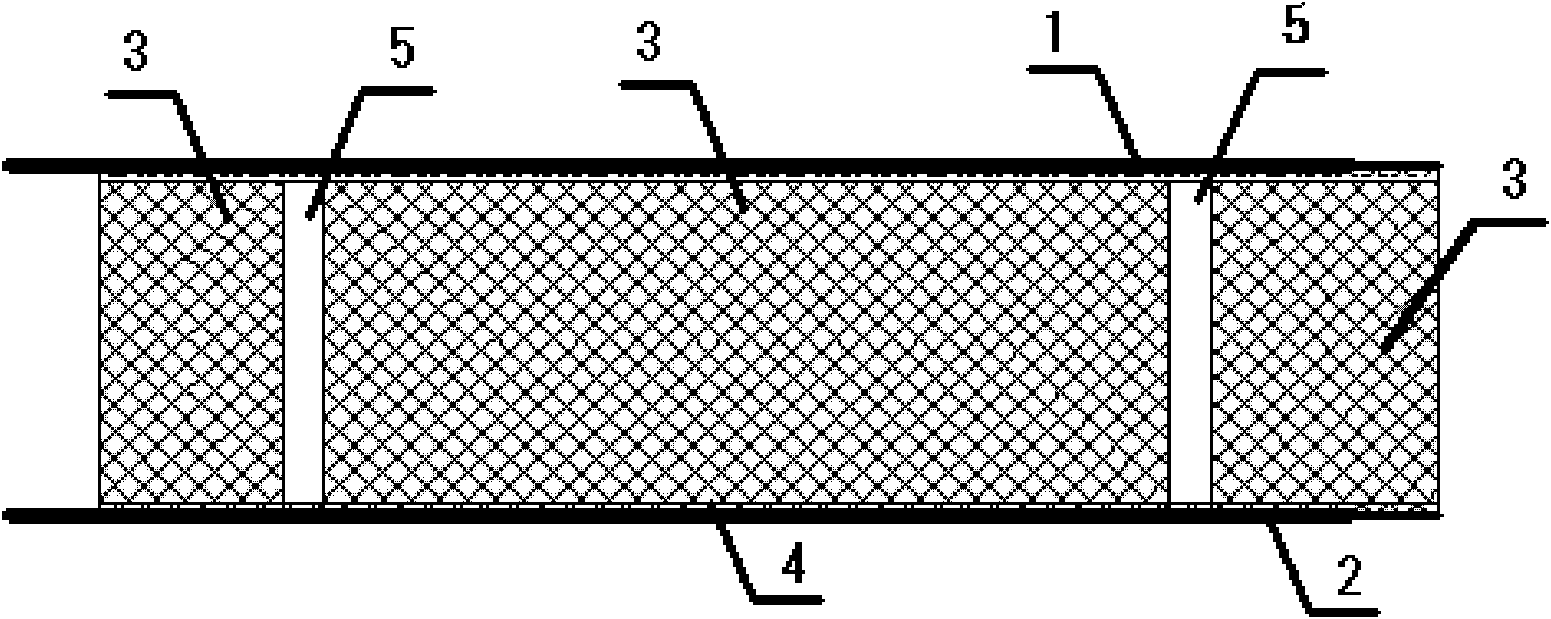

Colour steel sandwich panel with high combustibility grades and preparation method thereof

InactiveCN102218859ASlow heat transferReduce the degree of drippingMetal layered productsCombustibilitySandwich panel

The invention discloses a colour steel sandwich panel with high combustibility grades, which comprises an upper metal panel (1), a lower metal panel (2) and a light core material (3); and the light core material (3) is arranged between the upper metal panel (1) and the lower metal panel (2) and is integrally connected with a cementing compound layer (4) between the upper metal panel (1) and the lower metal panel (2) through the light core material (3); the colour steel sandwich panel with high combustibility grades is characterized in that: at least one fireproof parting strip (5) is arranged in the light core material (3) vertical to the upper metal panel (1) and the lower metal panel (2); and the thickness of the fireproof parting strip (5) is equal to that of the light core material (3). The invention also discloses a preparation method of the colour steel sandwich panel. The fireproof parting strip arranged in the colour steel sandwich panel can prevent flames from spreading, delay the heat transfer speed, weaken the drop melting degree of the light core material and the cementing compound, and greatly reduce the fire risk of the colour steel sandwich panel when in use. The preparation method is simple and convenient; moreover, the preparation method is also easy for control and industrial production.

Owner:应急管理部四川消防研究所 +1

Layered vacuum insulation board core material and preparation method thereof

InactiveCN102628538ASlow heat transferImprove insulation performanceThermal insulationPipe protection by thermal insulationHealth organizationVacuum insulated panel

The invention discloses a layered vacuum insulation board core material and a preparation method thereof. The thickness of the vacuum insulation board core material is between 5 and 50mm, the coefficient of heat conductivity is between 0.018 and 0.03 W / mK, and the vacuum insulation board core material is formed by overlying a plurality of layers of glass fiber mats and can be prepared into vacuum insulation boards with high-efficient thermal insulation. According to the layered vacuum insulation board core material, continuous glass fiber with 6 to 13 mu m of diameter and 5 to 20mm of length is used and cannot be sucked into the deep parts of human lungs after being authenticated by world health organization, so that the layered vacuum insulation board core material is safe and harmless, meets the requirements of materials, can be used at ease for a long time and solves the problems of sanitation and safety of vacuum insulation board products.

Owner:周介明 +1

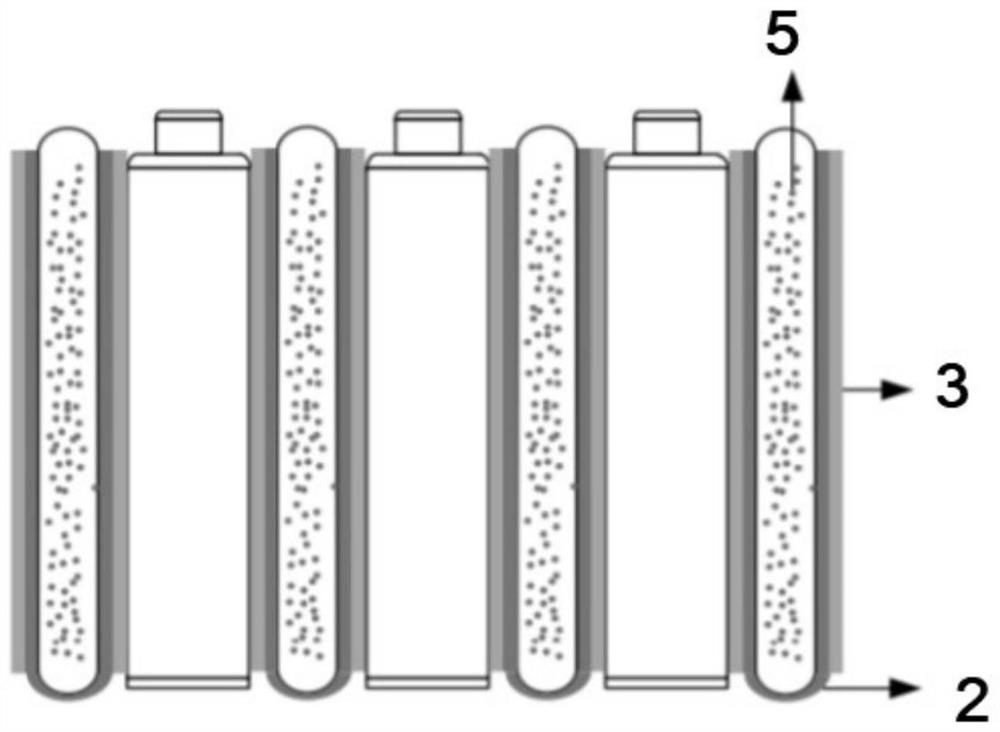

Energy storage power station battery thermal runaway protection system

InactiveCN112133980AImprove thermal conductivityImprove cooling effectSecondary cellsFire rescueElectrical batteryProcess engineering

The invention discloses an energy storage power station battery thermal runaway protection system which comprises solid-solid composite phase change material heat dissipation plates tightly attached to the two sides of battery modules. The battery modules are formed by connecting a plurality of single batteries in series, and the batteries are attached to the solid-solid composite phase change material heat dissipation plates through heat conduction and insulating double-faced adhesive tapes. Cold liquid plates are arranged between the adjacent battery module bodies, and the cold liquid platesare arranged between the battery modules in an S shape. Heat conduction silica gel layers are arranged between the solid-solid composite phase change material heat dissipation plates and the cold liquid plates, and the solid-solid composite phase change material heat dissipation plates are made of a paraffin / expanded graphite solid-solid composite phase change material. Al2O3 / H2O nano sol coolingliquid is adopted as cooling liquid in the cold liquid plates. Through combination of the solid-solid phase change material and the liquid cooling plates, efficient heat dissipation of a faulted thermal runaway battery is realized, and chain fire accidents caused by thermal runaway propagation of the battery are avoided.

Owner:国网陕西省电力公司汉中供电公司 +3

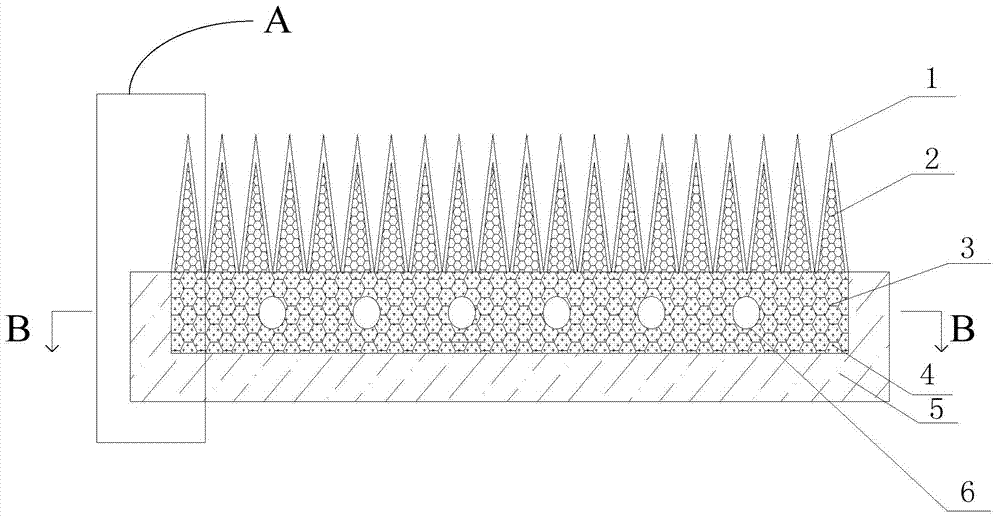

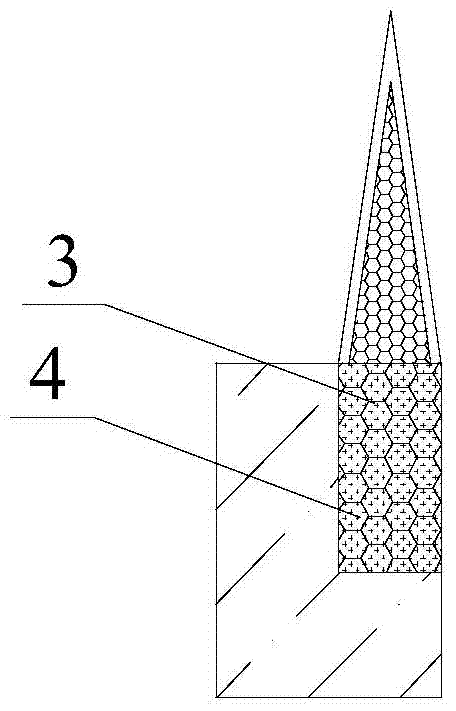

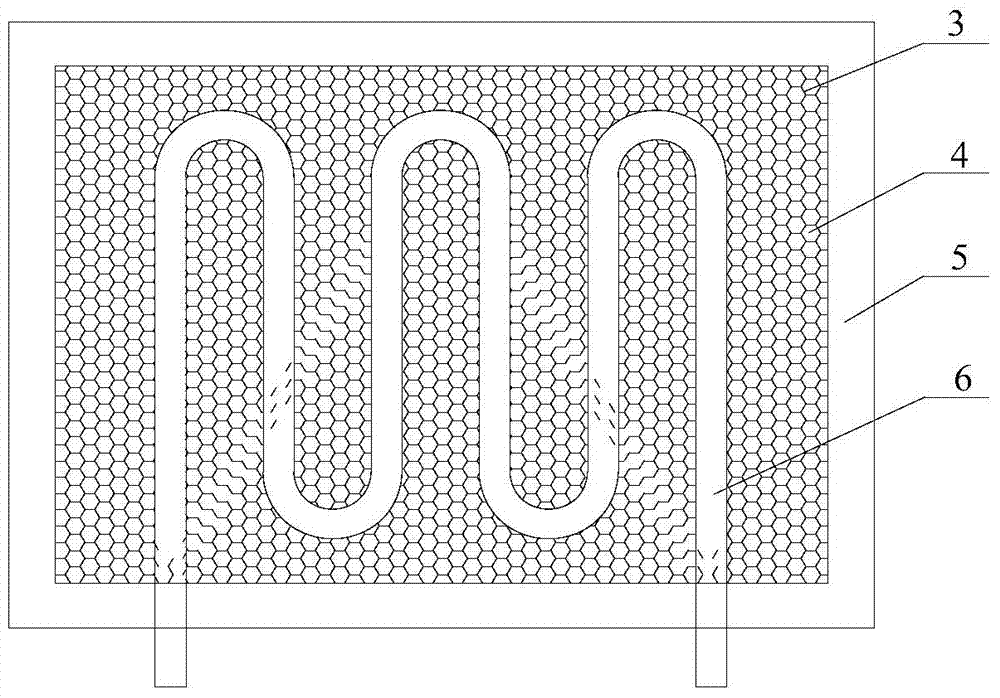

Solar heat collector with film hole structure

ActiveCN104121709AAvoid heat lossImprove energy storage capacitySolar heat devicesSolar thermal energy generationPhase-change materialTransmitted light

A solar heat collector with a film hole structure comprises a heat preservation box with the upper end open, a phase-change material layer is arranged in the heat preservation box, a coiled pipe is arranged in the phase-change material layer, a conical metal foam layer is arranged at the top of the phase-change material layer, the outer wall of the conical metal foam layer is wrapped by a transparent outer layer which can transmit light, and metal foam is added into the phase-change material layer. The content of air in a heat collecting area is greatly increased due to the metal foam structure, an air layer is divided into parts with small volumes, and therefore heat loss caused by convection is prevented. Sunlight can illuminate the conical metal foam layer through the transparent outer layer, the conical metal foam layer has the function of a heat absorber and converts light energy into heat energy, and the transparent outer layer has the function of a heat insulating layer and prevents heat in the heat absorber from being dissipated to the outside. The solar heat collector can effectively absorb solar radiation and fast store the energy and can be widely used for drying, food processing, household heat supplying , cooking and the like.

Owner:XI AN JIAOTONG UNIV

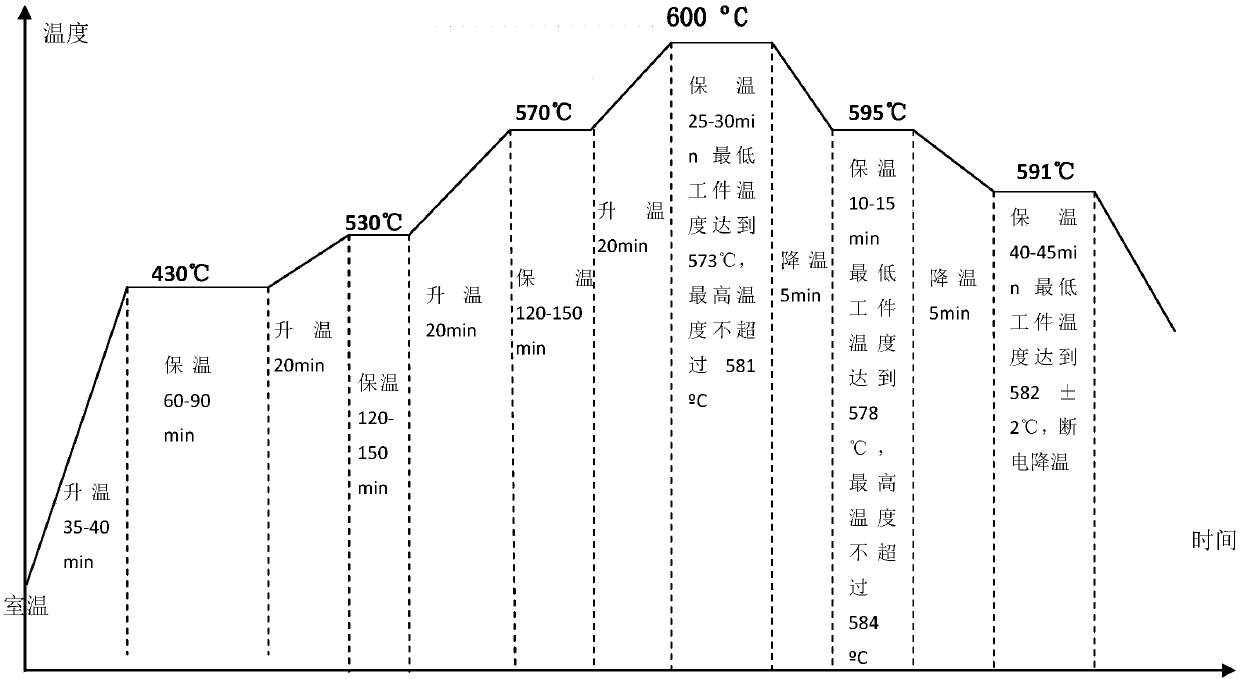

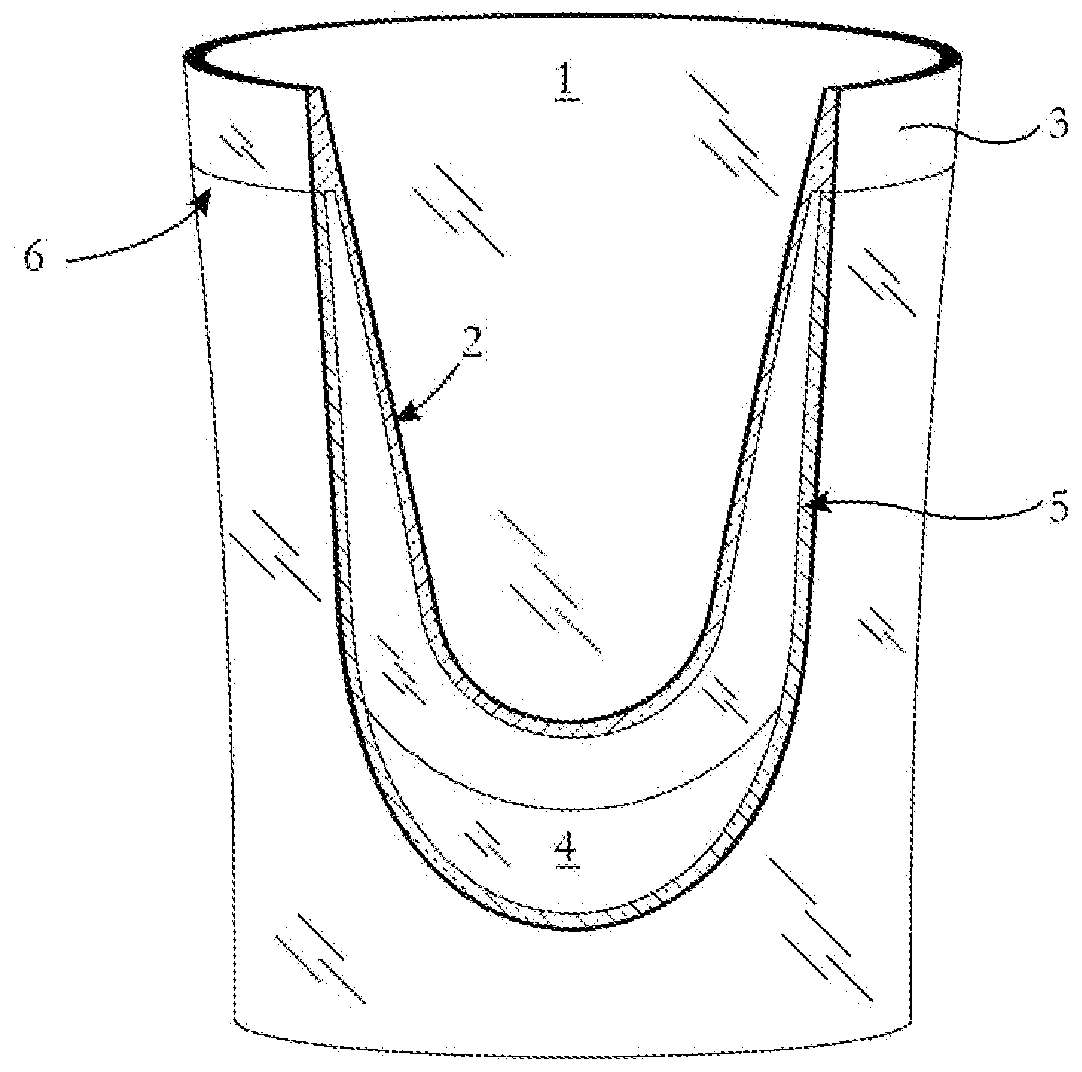

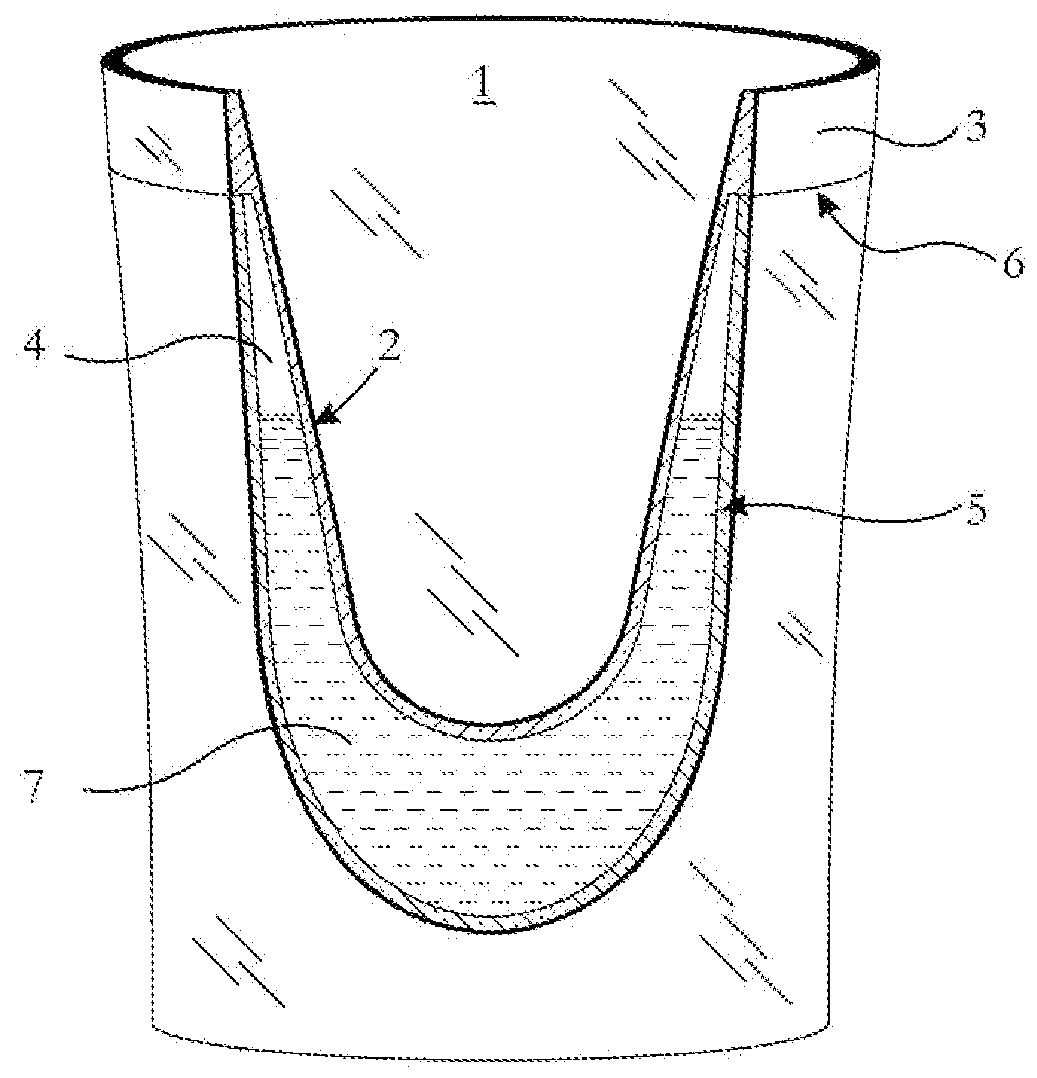

Process method for reducing vacuum brazing defects of 6061 aluminum alloy and clamp

ActiveCN107598318ALarge boardPrevent thinningWelding/cutting auxillary devicesAuxillary welding devices6061 aluminium alloySteel plates

The invention discloses a process method for reducing vacuum brazing defects of a 6061 aluminum alloy and a clamp. The clamp comprises an upper cover plate (2) and a lower cover plate (1) connected through a vertical rod (7); an upper stainless steel plate (4), a spring (5) and a gasket (3) are successively arranged below the upper cover plate (2); and a lower stainless steel plate (6) is arrangedabove the lower cover plate (1). According to the process method and clamp disclosed by the invention, curves of temperature-raising, insulating and cooling processes are adjusted during brazing. Thecold plates can be domesticated by adopting the processing method and the clamp, the vacuum brazing defects of the 6061 aluminum alloy are reduced greatly, the product quality is improved, and meanwhile the international image of an enterprise is enhanced.

Owner:贵州永红换热冷却技术有限公司

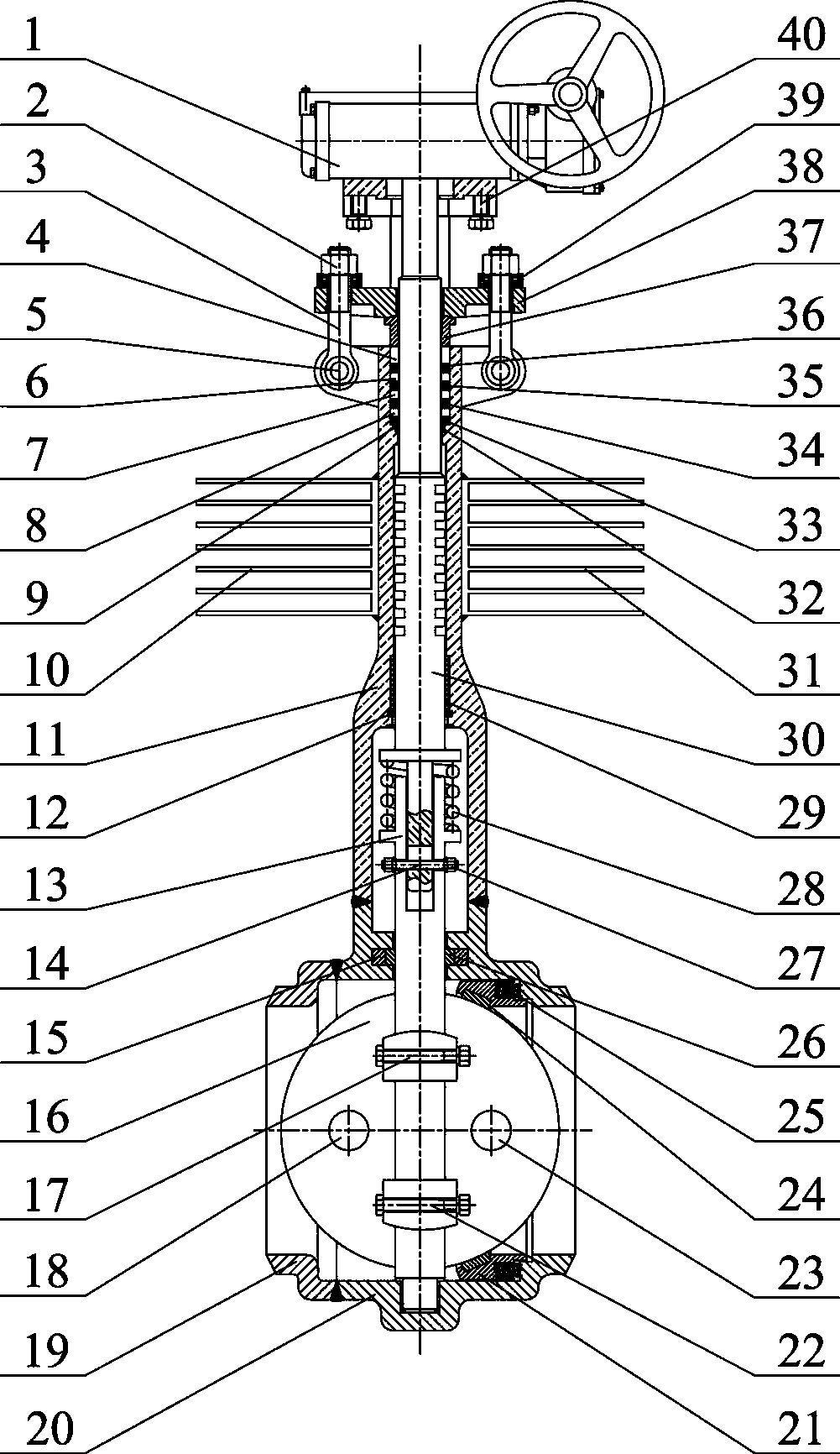

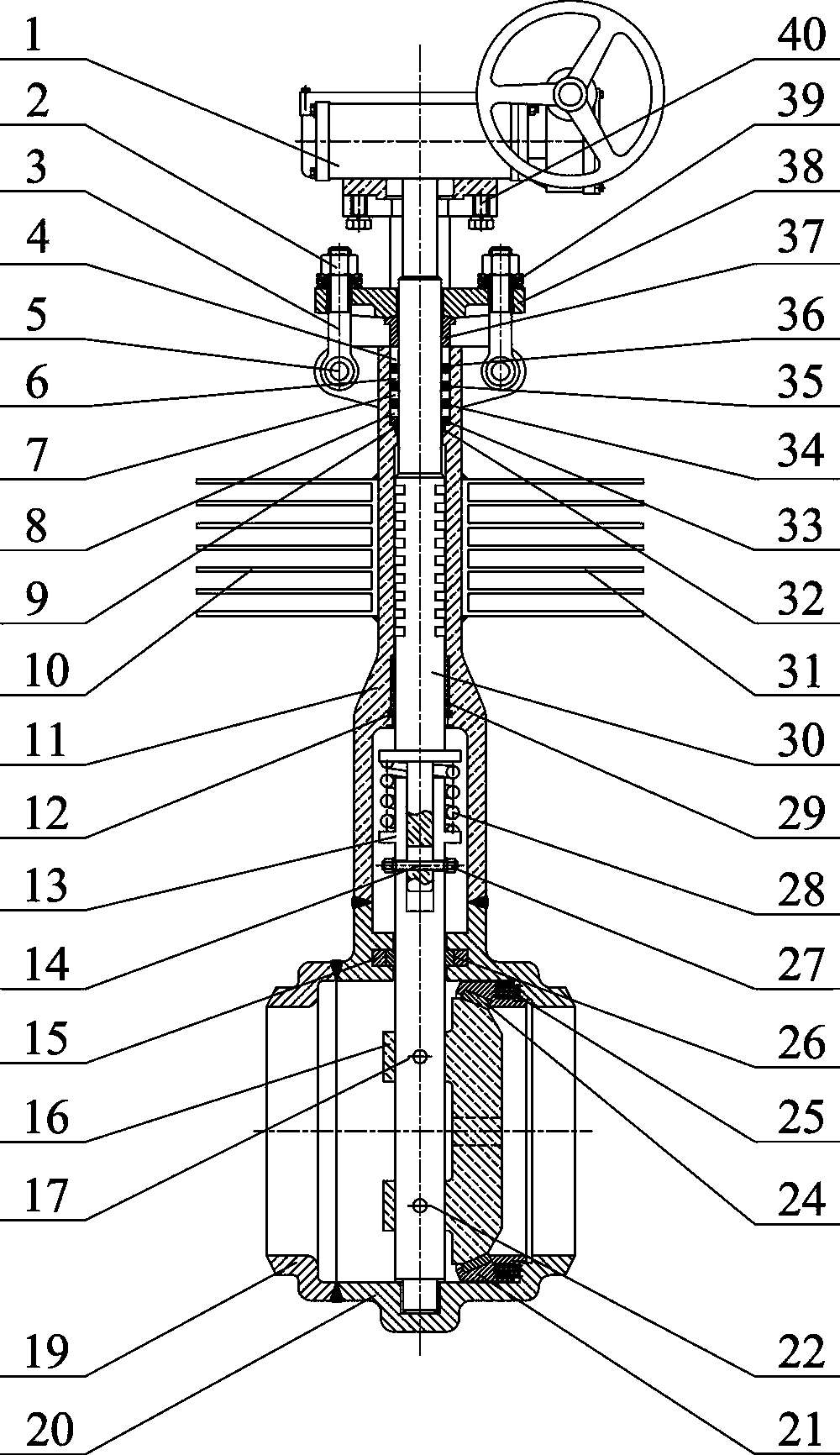

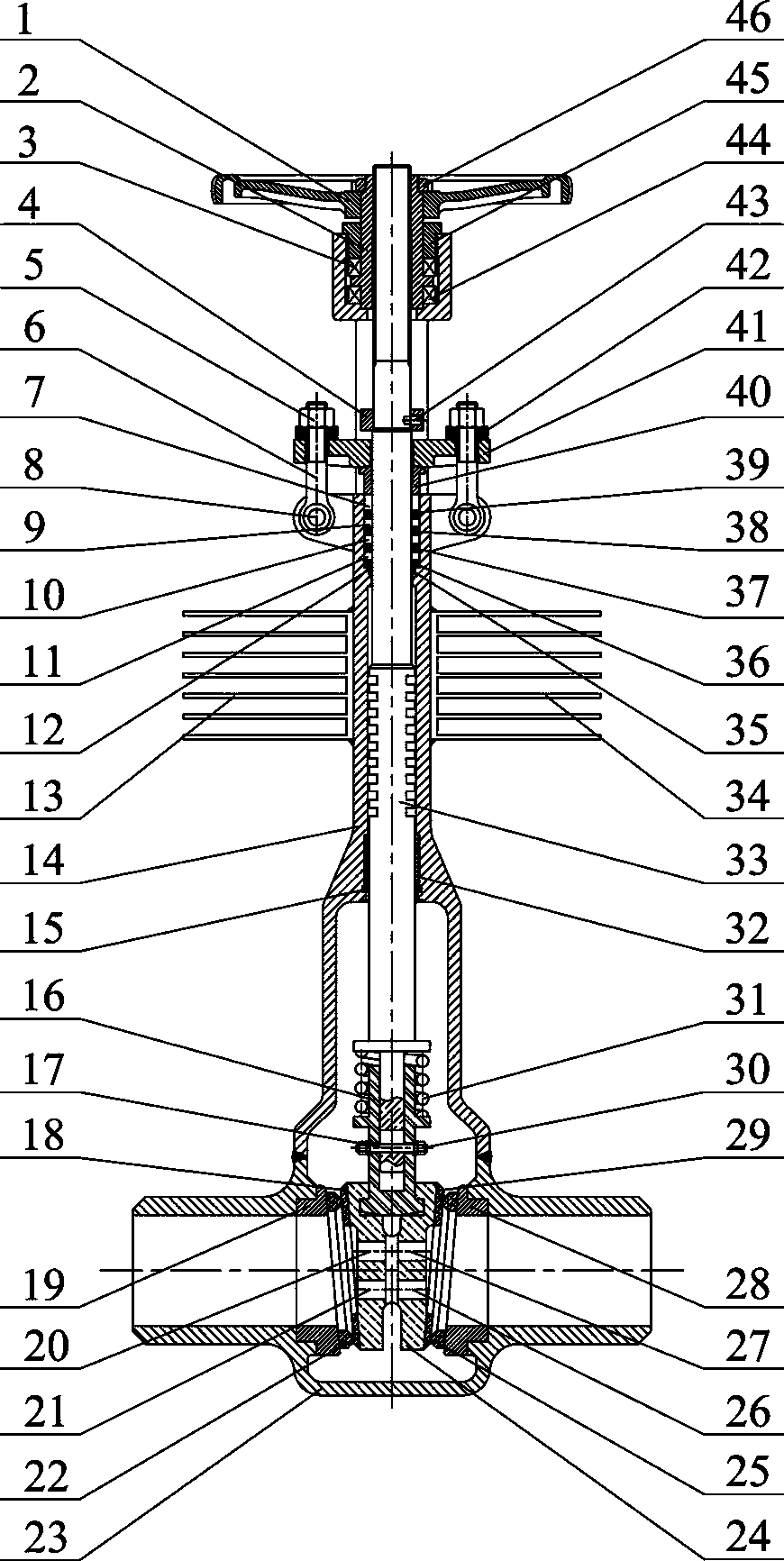

LNG stop valve

InactiveCN103791104ALower the altitudeExtend your lifeSpindle sealingsValve members for heating/coolingTemperature differenceEngineering

The invention relates to a 162-degree LNG stop valve. The technology of a shrinkable elastic valve rod provided with a prestress spring, the maze sealing technology, the multi-sealing all-welded valve technology and the like are adopted, the LNG stop valve can freely shrink according to the temperature difference stress of a low-temperature valve body so as to adapt to changes of temperature of the valve body, stress required by the sealing face of the valve can be maintained, and leakage caused by temperature difference strain can be prevented. The height of the whole valve rod can be effectively reduced, the whole size of the LNG stop valve can be reduced, and the dual functions of LNG stopping and safety are achieved; the design pressure of the valve and the design pressure of an LNG conveying system can be effectively reduced, the size of the valve can be smaller, the safety is higher, and the machining and manufacturing cost is lower.

Owner:张周卫

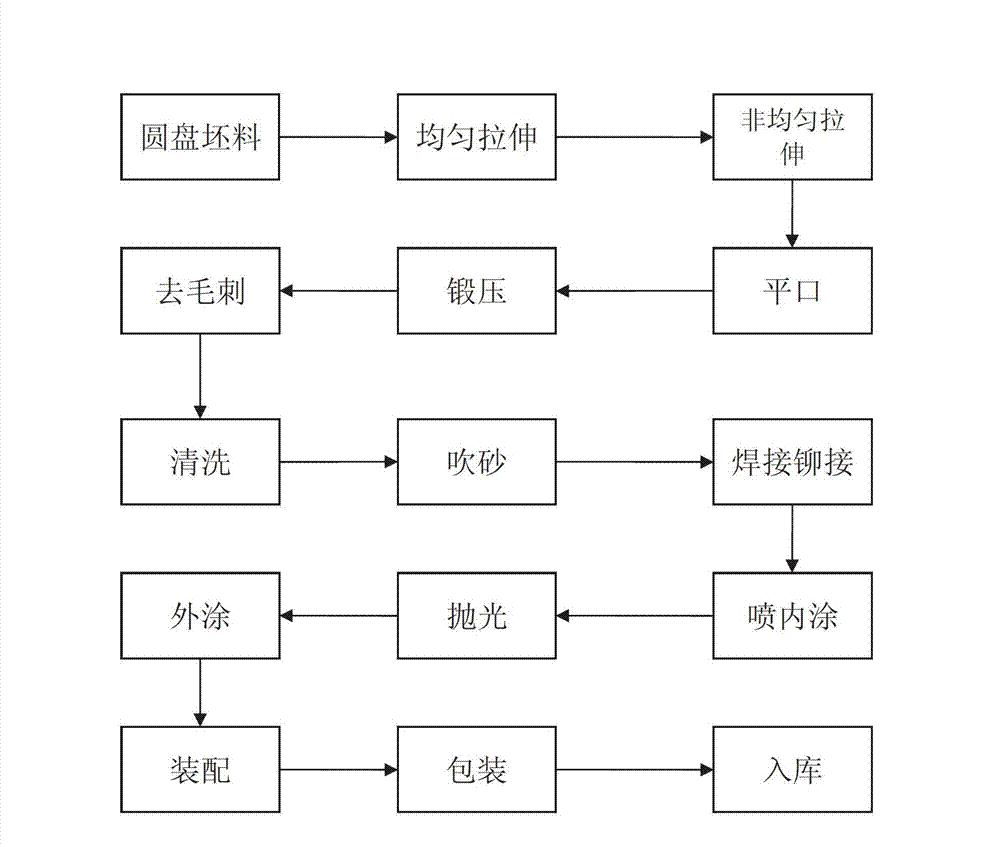

Preparation method for aluminum pot

The invention discloses a preparation method for an aluminum pot, which comprises the following steps in turn: preparing materials; uniformly stretching; non-uniformly stretching; and forging and pressing. The preparation method for the aluminum pot has the advantages that the prepared pot meets the use habit of people, the cooking effect is good, the preparation technology is simple and the cost is lower.

Owner:杭州皓鸿电力科技有限公司

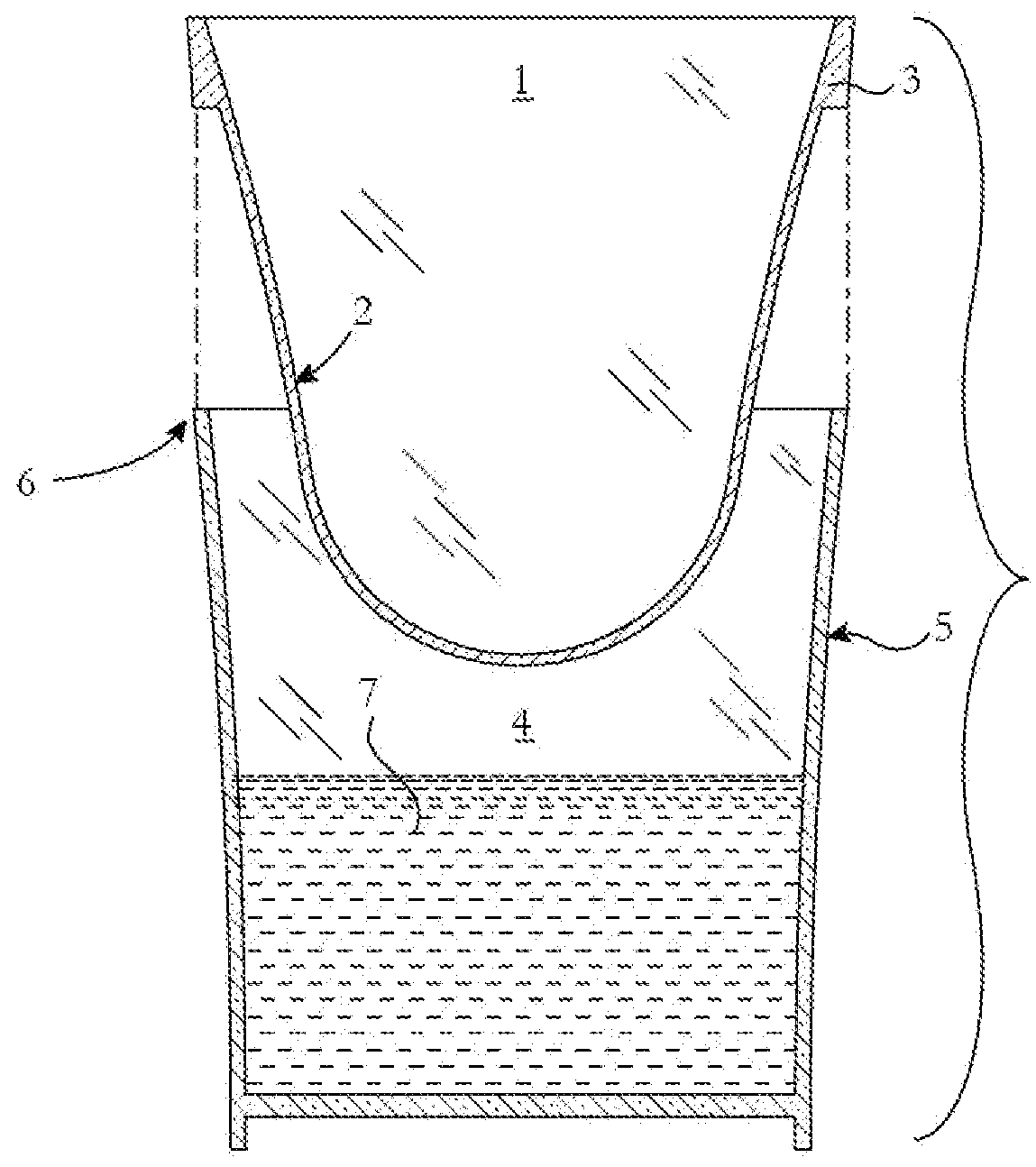

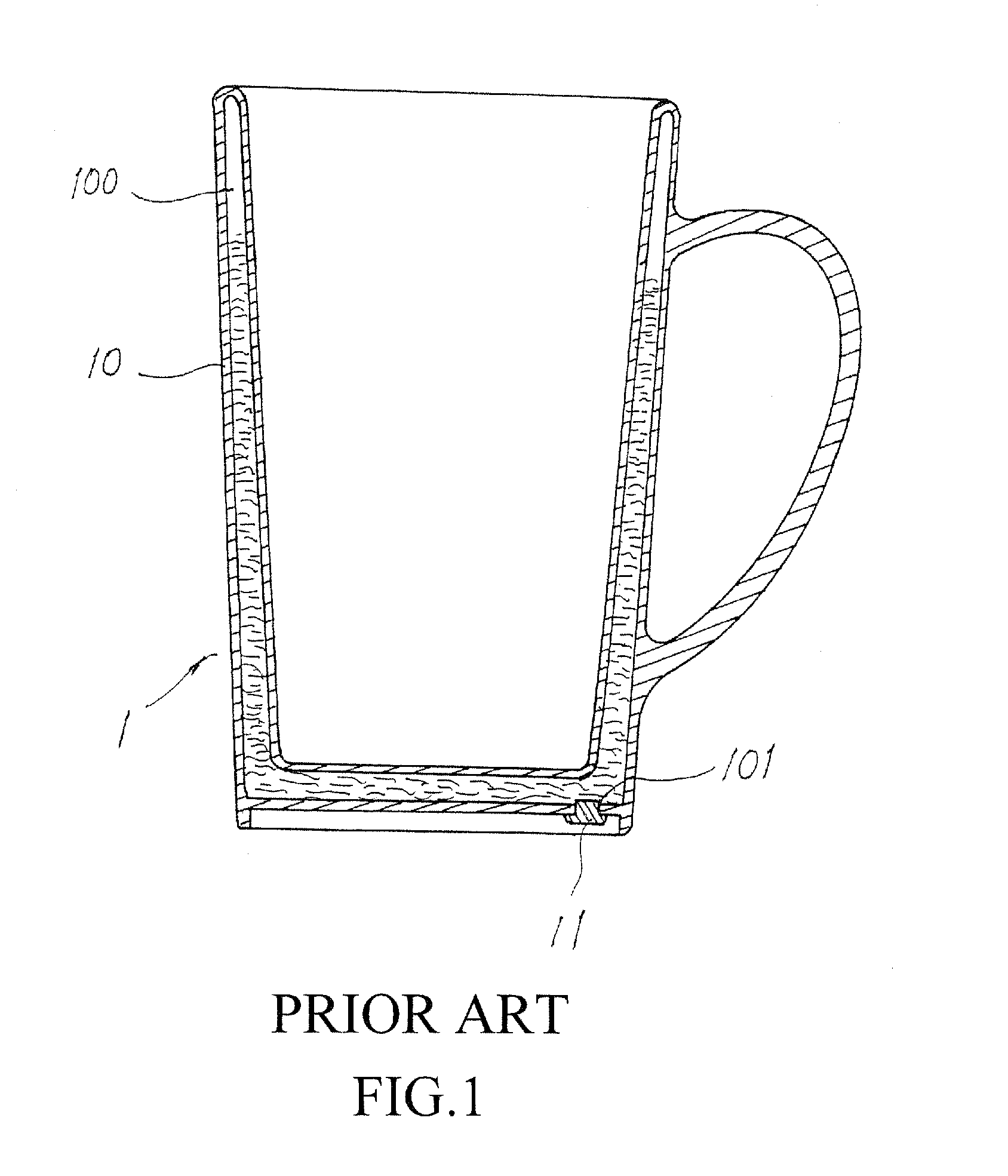

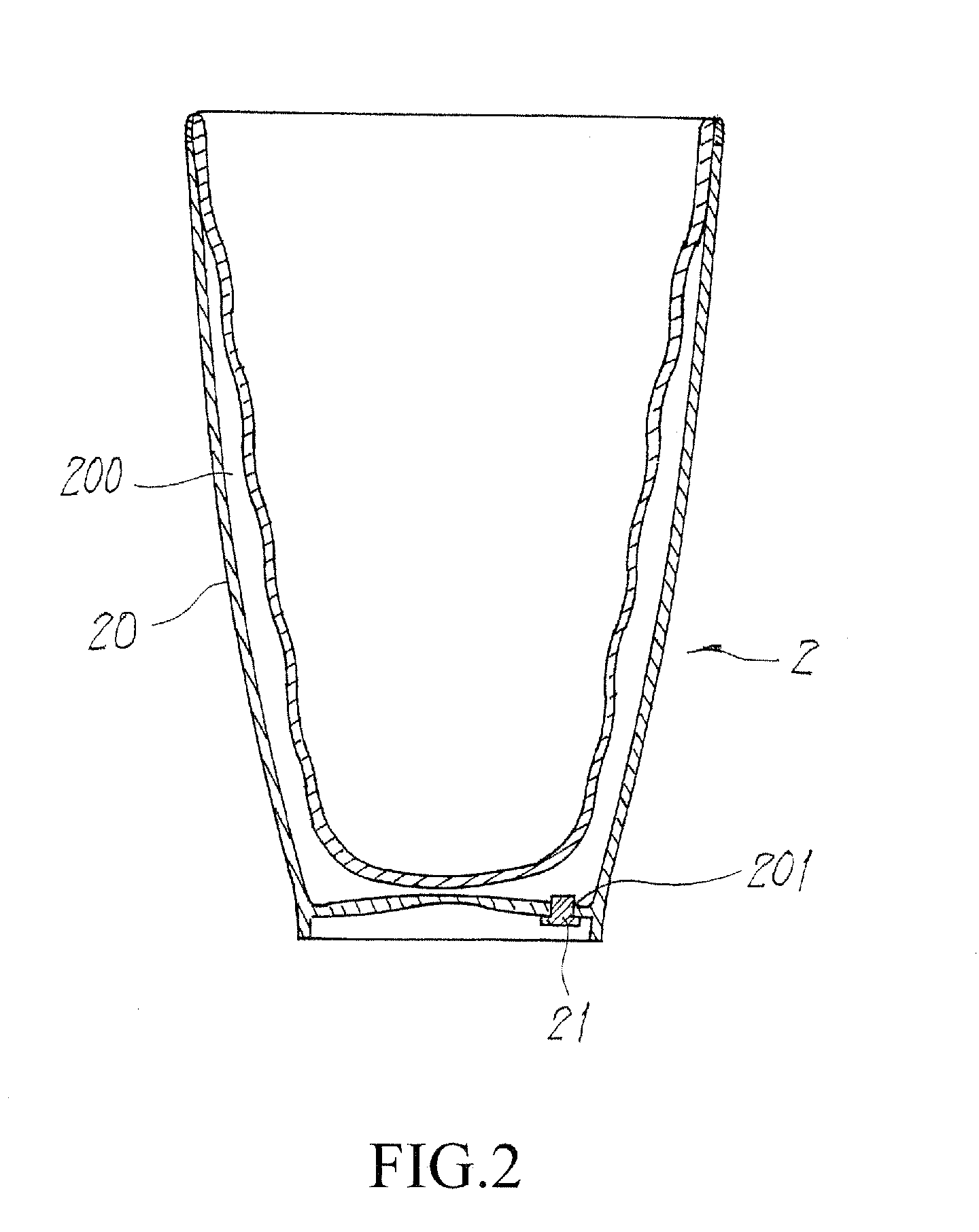

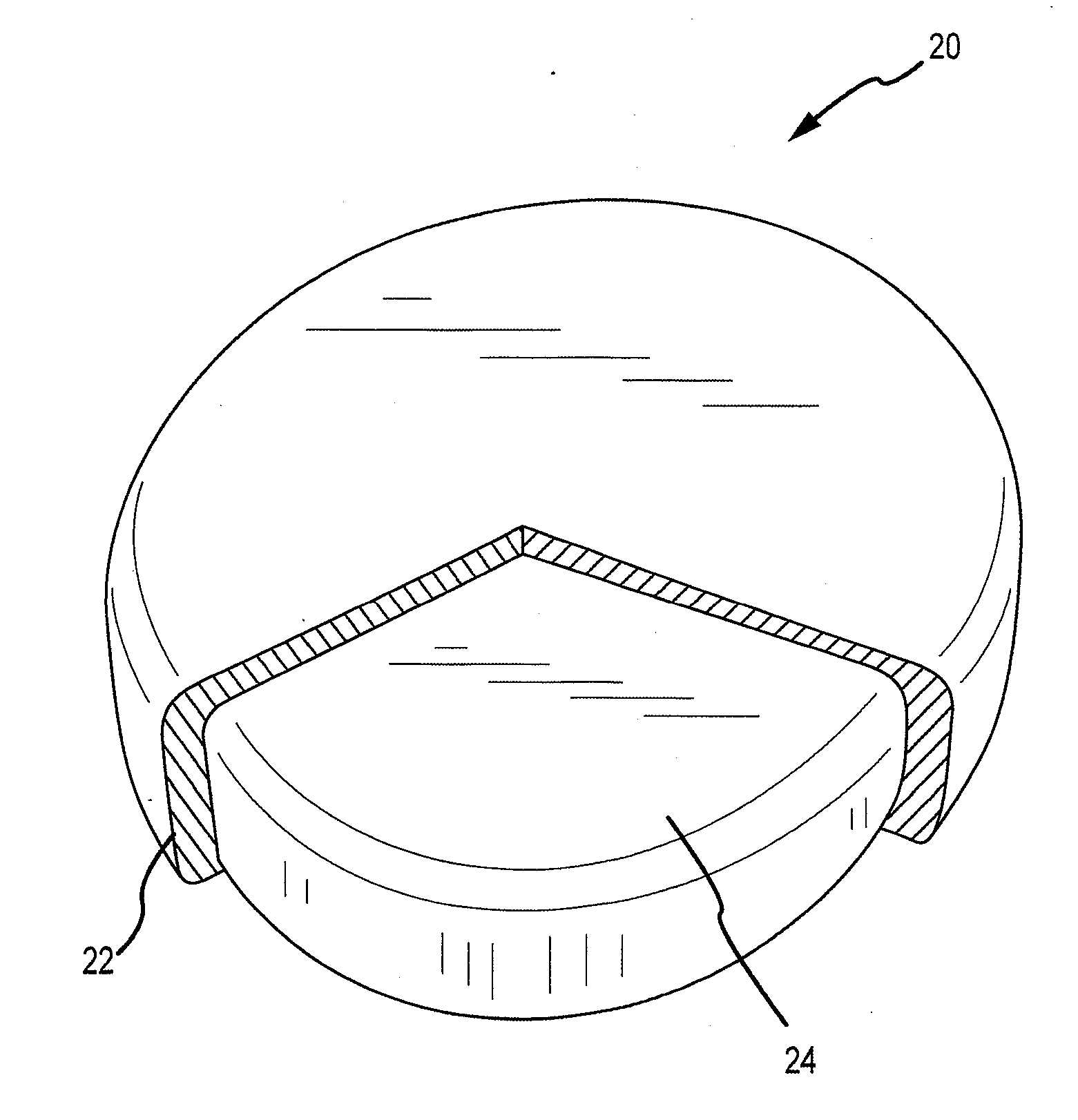

Insulating Vessel

InactiveUS20160031630A1Less discomfortLong holding timeDomestic cooling apparatusLighting and heating apparatusEngineeringBiomedical engineering

A self-contained insulated vessel having a storage area defined by an inner wall and an outer wall which are spaced apart and dosed off to define a cavity therebetween. An insulating substance is contained within at least part of the cavity in order to maintain a stored item at a predetermined temperature for an extended period of time or cool a stored item with a temperature higher than the predetermined temperature of the insulating substance. The insulating vessel can include a user engagement interface for shielding a user from at least part of an exterior surface of said vessel.

Owner:TRUE FABTIONS

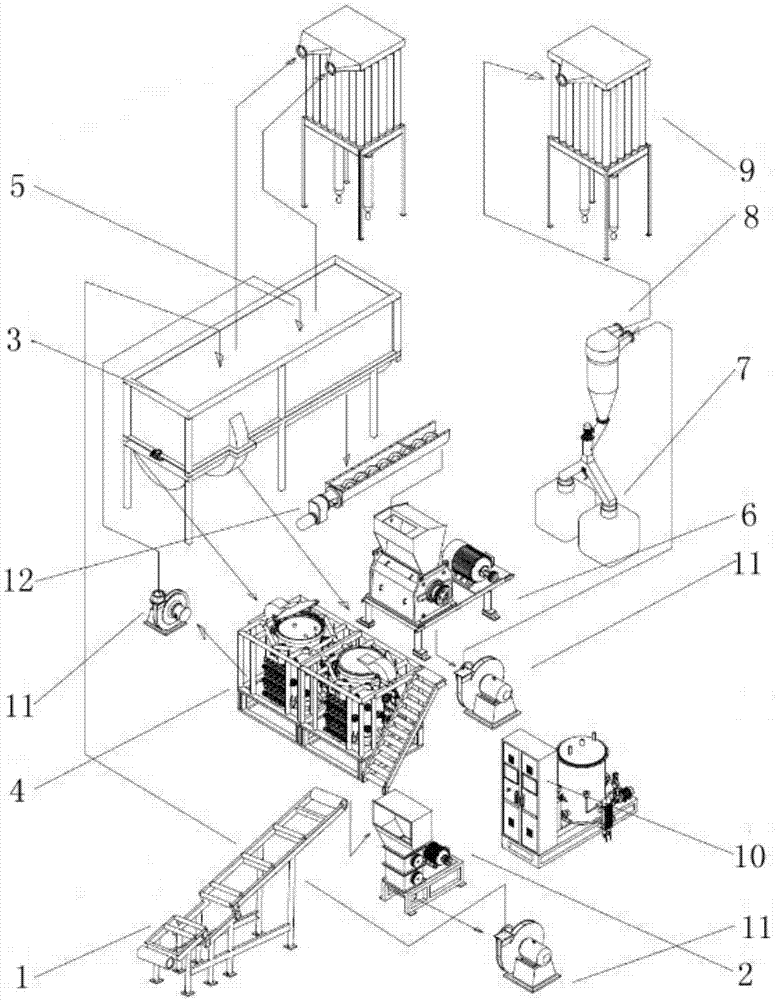

Method for recycling waste terylene fibers to obtain polyester raw materials as well as device system and microwave purifying equipment

ActiveCN104842473ASlow heat transferAvoid overheating and oxidationPlastic recyclingPolyesterMicrowave

The invention discloses a method for recycling waste terylene fibers. The method comprises the following steps of primarily crushing the waste terylene fibers to obtain staple fiber pompons; purifying and degrading on the staple fiber pompons by dense microwave fields with high-frequency rotation; performing vacuum pumping on water and oil; finally, grinding and crushing to obtain finely-ground terephthalate (BHET) polymer powder; meanwhile, the invention provides a device system and microwave purifying equipment for realizing the method. The method, the device system and the microwave purifying equipment disclosed by the invention have the advantages that the waste terylene fibers are recycled by adopting microwave purification degradation to obtain the BHET polymer powder which can be used as the polyester raw materials; an original recovery mode of obtaining bubble powder is thoroughly changed, and closed circulating recovery of the waste terylene fibers is realized; the method is green and environment-friendly, high in economy and resource-saving; the device system and the equipment provide hardware guarantee for realizing the method.

Owner:镇江宝利玛机械有限公司

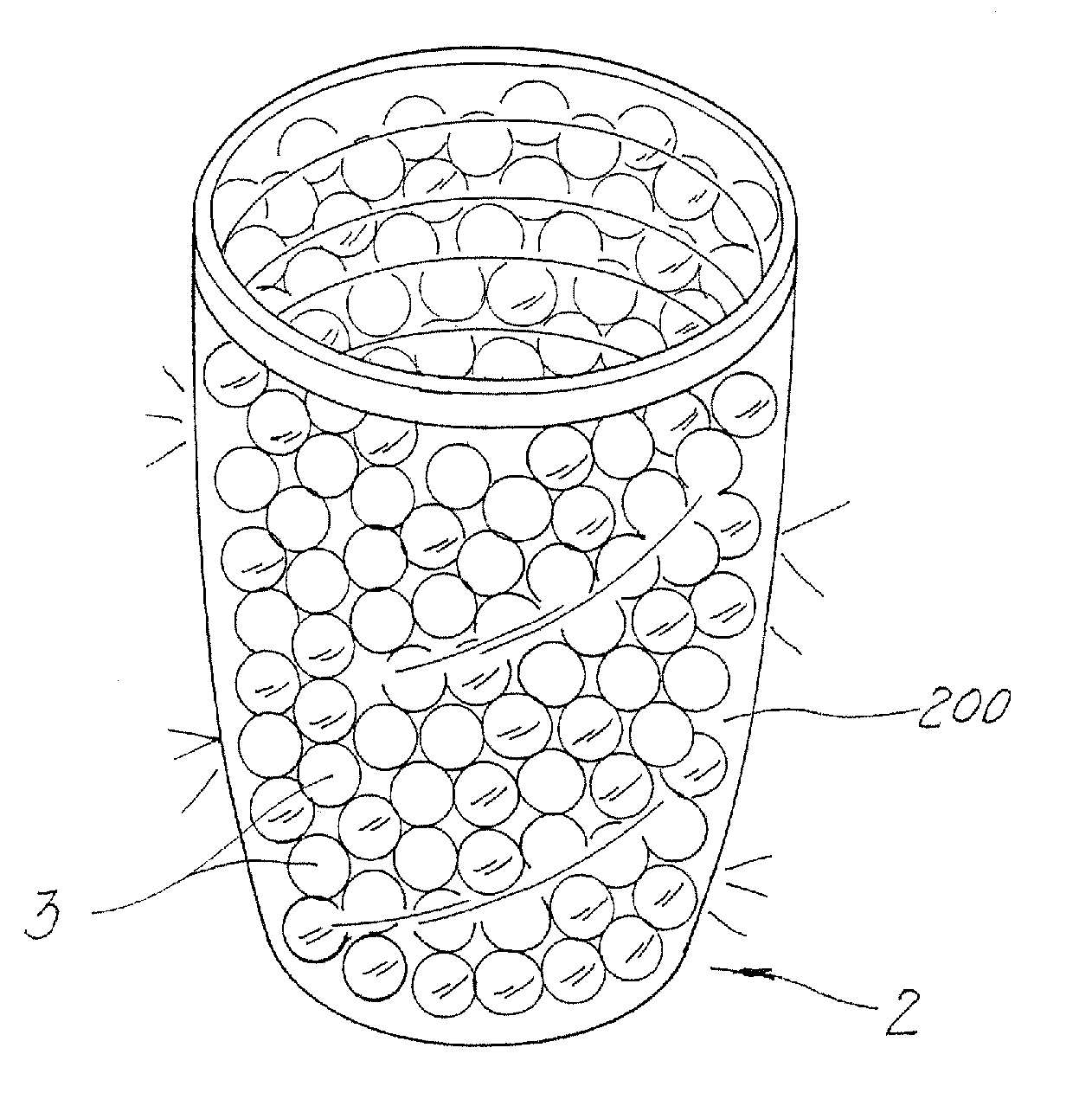

Structure of crystal-bead-contained glass

InactiveUS20110155744A1Colorful visionShorten the timeDomestic cooling apparatusLighting and heating apparatusEngineeringToughness

A crystal-bead-contained glass has a circumferential wall in which a hermetical hollow chamber is formed. The glass forms a filling opening in communication with the hollow chamber for receiving crystal beads and water that are mixed according to a given ratio into the hollow chamber. The crystal beads, after mixed with water, expand and fill up the hollow chamber to form a sparkling visual effect. The crystal beads are mixed with water in a ratio of 7 gram of crystal beads added with 240 cc water, which provides the best resiliency and toughness. The crystal beads can be made with various colors to provide a colorful vision after mixed with water to attract the attention of consumers. The glass can be deposited in a freezer chamber to freeze the crystal beads so as to extend the time period of cold-keeping in using the glass to enjoy beverages.

Owner:SU YEN PIN

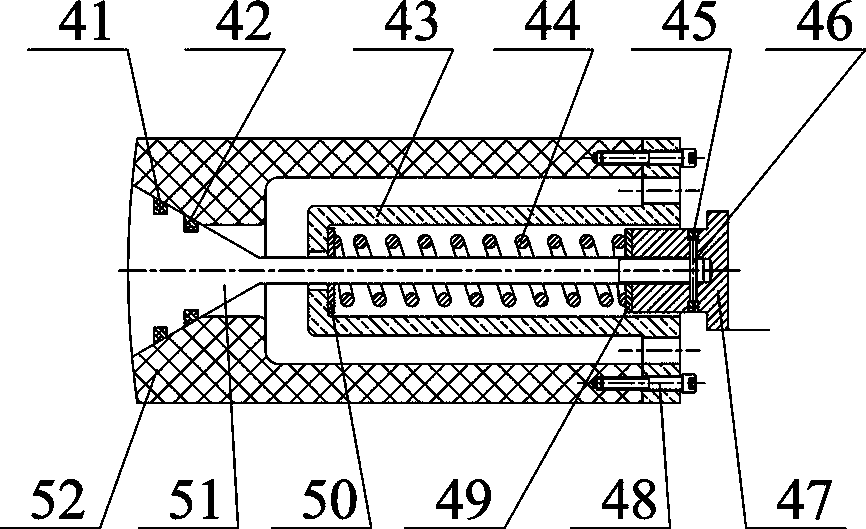

LNG butterfly valve

InactiveCN103807452ASmall sizeReduce volumeSpindle sealingsValve members for heating/coolingSafety controlEngineering

The invention relates to a -162 DEG C LNG butterfly valve. In order to embody the characteristics that the LNG butterfly valve is communicated in two directions and has a safety function, a butterfly plate is axially provided with two pressure adjustment valves which are respectively communicated in a single direction, the pressure adjustment valves can be set according to specific requirements of LNG pipeline flow paths together with control pressure of each pressure adjustment valve, the two portions, on the two sides of a pipeline, of the LNG butterfly valve can be automatically communicated in two directions, pressure balance of the two sides of the valve is effectively controlled, backflow control is easy, and both opening and closing and safety control can be achieved. Meanwhile, due to the adoption of the technology that a telescopic elastic valve rod provided with a prestressed spring is adopted, the all-welded ball valve technology of the labyrinth seal technology and the like, valve design pressure and design pressure of an LNG conveying system can be effectively reduced, the size of the valve is smaller, safety is higher, and machining and manufacturing cost is lower.

Owner:张周卫

High comfort hot or cold thermal therapy pad

InactiveUS20120215293A1Safely comfortably rapidly deliveringHighly effectiveTherapeutic coolingTherapeutic heatingPhysical therapyPain relief

A comfortably, yet highly efficient therapy pad that is effective in delivering cold or hot thermal therapy for the relief of pain, inflammation, swelling, and muscle stiffness.

Owner:FRUITMAN CLINTON O

Puncture resistant boot sole material

The invention relates to a material for making a boot sole, and concretely relates to a puncture resistant boot sole material. The puncture resistant boot sole material comprises, by weight, 20-60 parts of natural rubber, 40-20 parts of chloroprene rubber, 40-20 parts of styrene butadiene rubber, 1.2-2.0 parts of sulfur, 0.3-0.8 parts of an accelerant DM, 0.3-1.0 part of an accelerant M, 5.0-7.0 parts of zinc oxide, 1.0-2.5 parts of stearic acid, 25-35 parts of high-wear-resistance carbon black, 0.8-1.5 parts of an antioxidant D, 1.0-2.0 parts of an antioxidant 4010 and 1.5-2.5 parts of magnesium oxide. The puncture resistant boot sole material has a reasonable design, and is designed through a ternary combination method of the chloroprene rubber, the natural rubber and the styrene butadiene rubber, so the molecular chain slip and fracture phenomena of the sole material are difficult when a sole meets a sharp object, thereby the puncture resistance of the boot sole is substantially improved.

Owner:SHANXI XINHUA CHEM

LNG brake valve

InactiveCN103836221AControl pressure balanceExtend your lifeSpindle sealingsEqualizing valvesCounter flowEngineering

The invention relates to a -162 DEG C LNG brake valve. According to the characteristic that the LNG brake valve needs two-way sealing and two-way brake, four one-way connecting pressure adjusting valves are arranged along the axis of a wedge disc, control pressure of the pressure adjusting valves can be set and adjusted respectively according to the specific requirement for the LNG pipeline process, LNG in a dead zone can be automatically guided out in a two-way mode, pressure of the two sides of the valves can be effectively controlled to be balanced, counter flow control is facilitated, and the safety functions of two-way brake, two-way sealing and two-way connecting of LNG are achieved. Meanwhile, by the adoption of the technology of retractable elastic valve rods provided with prestress springs, the labyrinth sealing technology, the multi-sealing all-welded valve technology and the like, design pressure of the valve and design pressure of an LNG conveying system can be effectively reduced, the size of the valve is smaller, safety is higher, and machining and manufacturing cost is lower.

Owner:张周卫

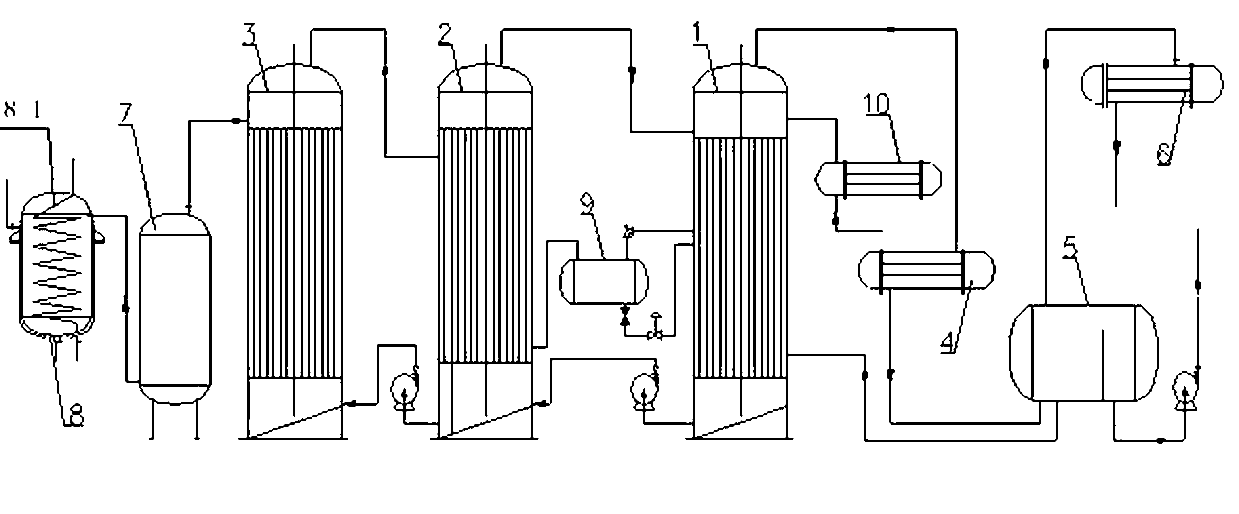

Method and device for triple-effect separation of methylbenzene and polyethylene

InactiveCN103007565AReduce liquiditySlow heat transferDistillation purification/separationDistillation separationDistillationPositive pressure

The invention relates to a method for the triple-effect separation of methylbenzene and polyethylene and a device used for the method. The method comprises the following step: separating a polyethylene-containing methylbenzene waste liquid sequentially through primary reduced-pressure distillation, primary normal-pressure distillation and primary positive-pressure distillation, wherein methylbenzene steam serves as a heat source which is used repeatedly. The device comprises a waste liquid preheater, a negative-pressure evaporator, a methylbenzene condenser, a decanter, a tail gas condenser, a normal-pressure evaporator, a positive-pressure evaporator, a positive-pressure methylbenzene intermediate tank, a methylbenzene residue storage tank and a residue evaporation tank. The device provided by the invention is an energy-saving and emission-reducing device. According to the method provided by the invention, based on the distillation range difference of one liquid under different pressures, the material is concentrated by using secondary steam, thereby greatly saving the production cost.

Owner:张瑞烟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com