Solar heat collector with film hole structure

A technology of solar heat collectors and film holes, which is applied in the field of solar energy, can solve the problems of thermal conductivity of discontinuous phase change materials, failure to solve high-efficiency absorption of solar energy, and failure of heat collectors to work normally, so as to achieve continuous and stable supply , prevent heat loss, slow heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

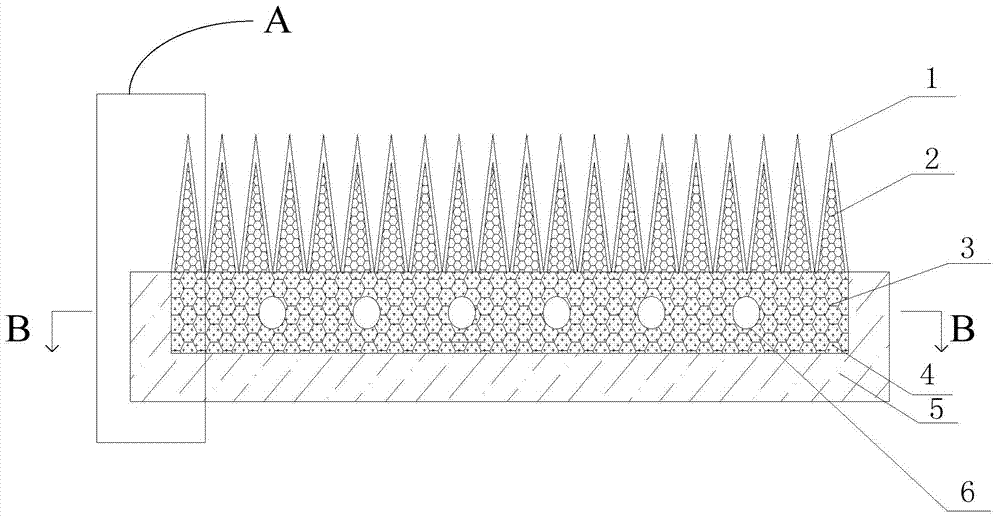

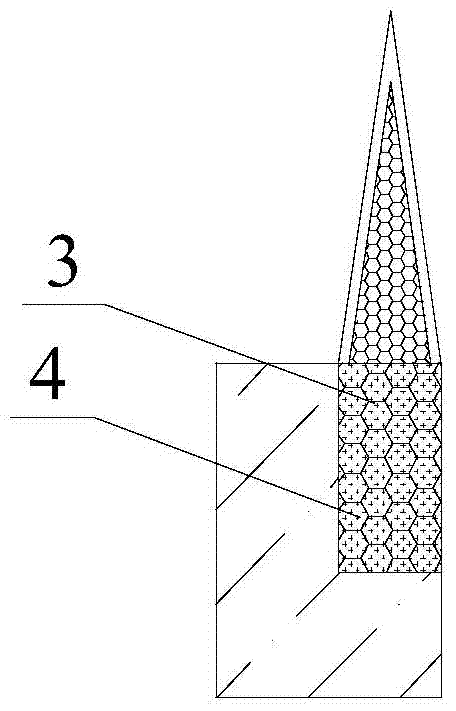

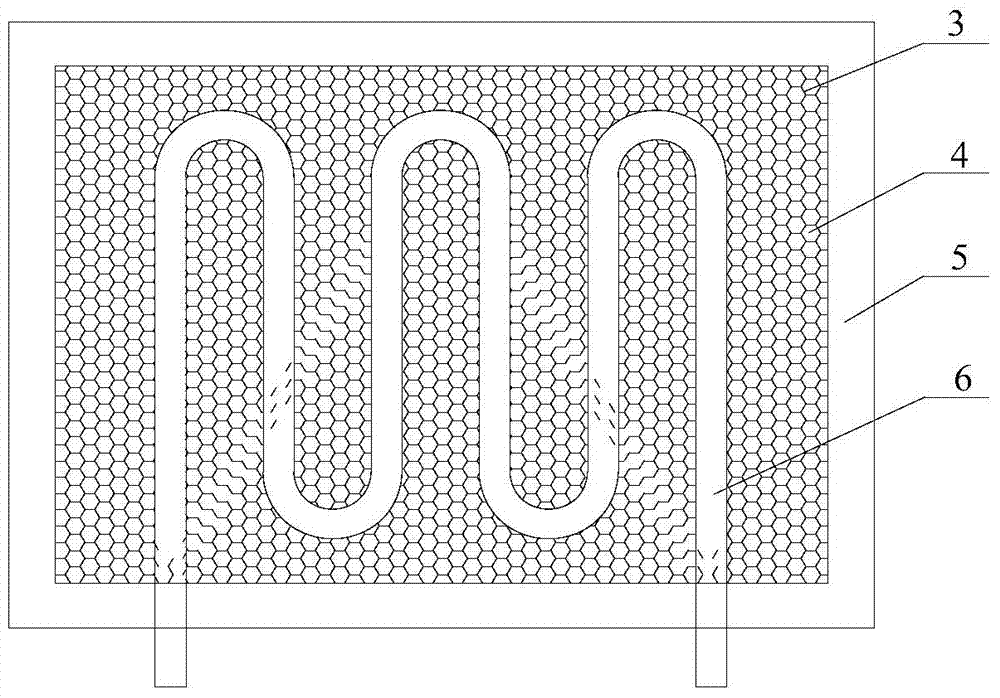

[0020] like figure 1 and figure 2 As shown, the present invention includes an incubator 5 with an open upper end, the incubator is made of insulating material, a phase change material layer 3 in contact with the inner wall of the incubator is provided in the incubator 5, and a snake is arranged inside the phase change material layer 3. shaped tube 6 and metal foam 4 with large pore diameter, the porosity of the metal foam 4 with large pore diameter is 0.3-0.9, and the pore diameter is 200-2000 μm. The top of the phase change material layer 3 is provided with a conical metal foam layer 2, and the outer wall of the conical metal foam layer 2 is wrapped with a transparent outer layer 1. The transparent outer layer 1 is wrapped on the conical metal foam layer 2 and can pass through sunlight. film of transparent material. Wherein, the metal foam layer 2 includes sever...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com