Gas sensor apparatus for automotive exhaust gas applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]The particular values and configurations discussed in these non-limiting examples can be varied and are cited merely to illustrate at least one embodiment and are not intended to limit the scope thereof.

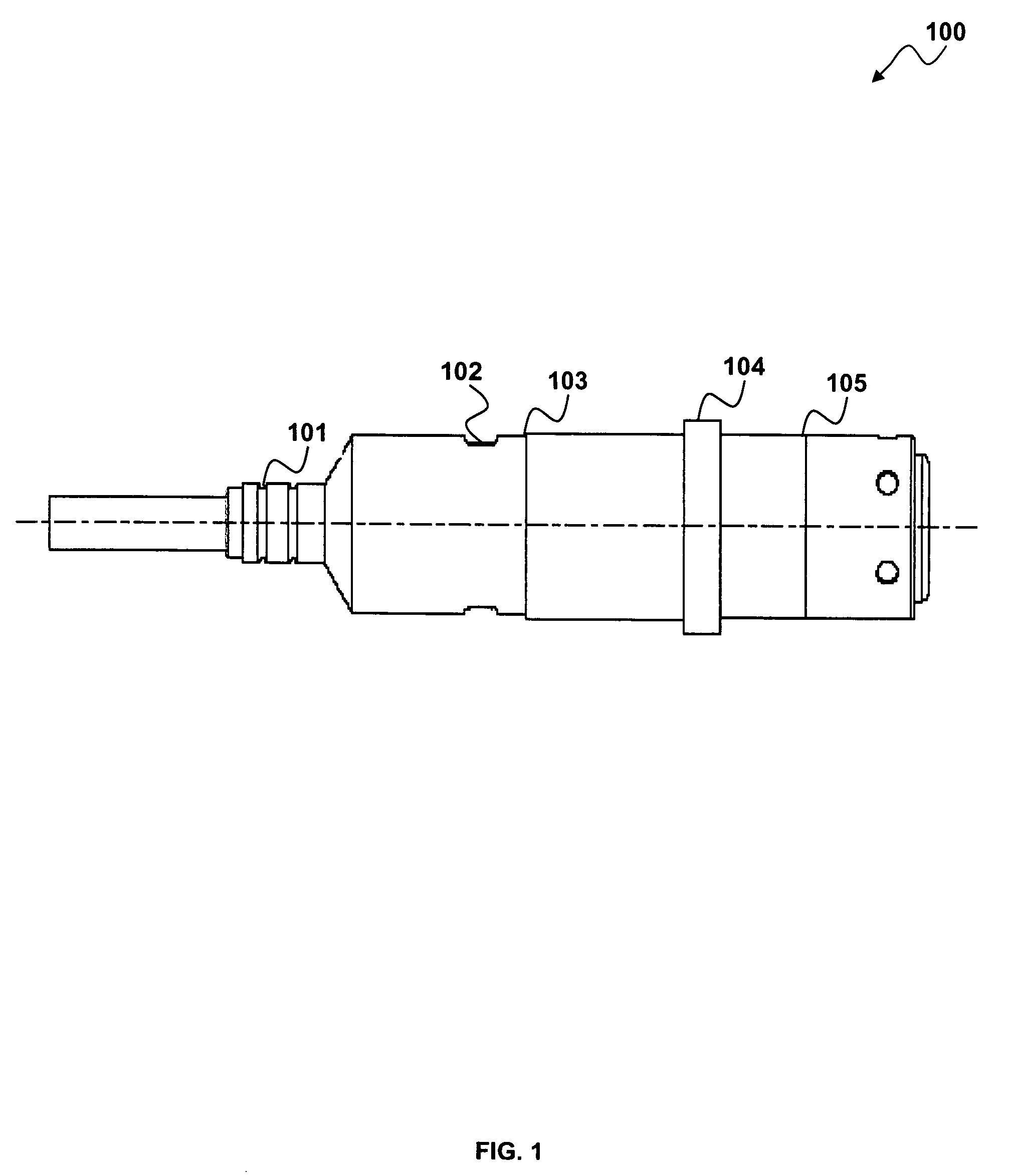

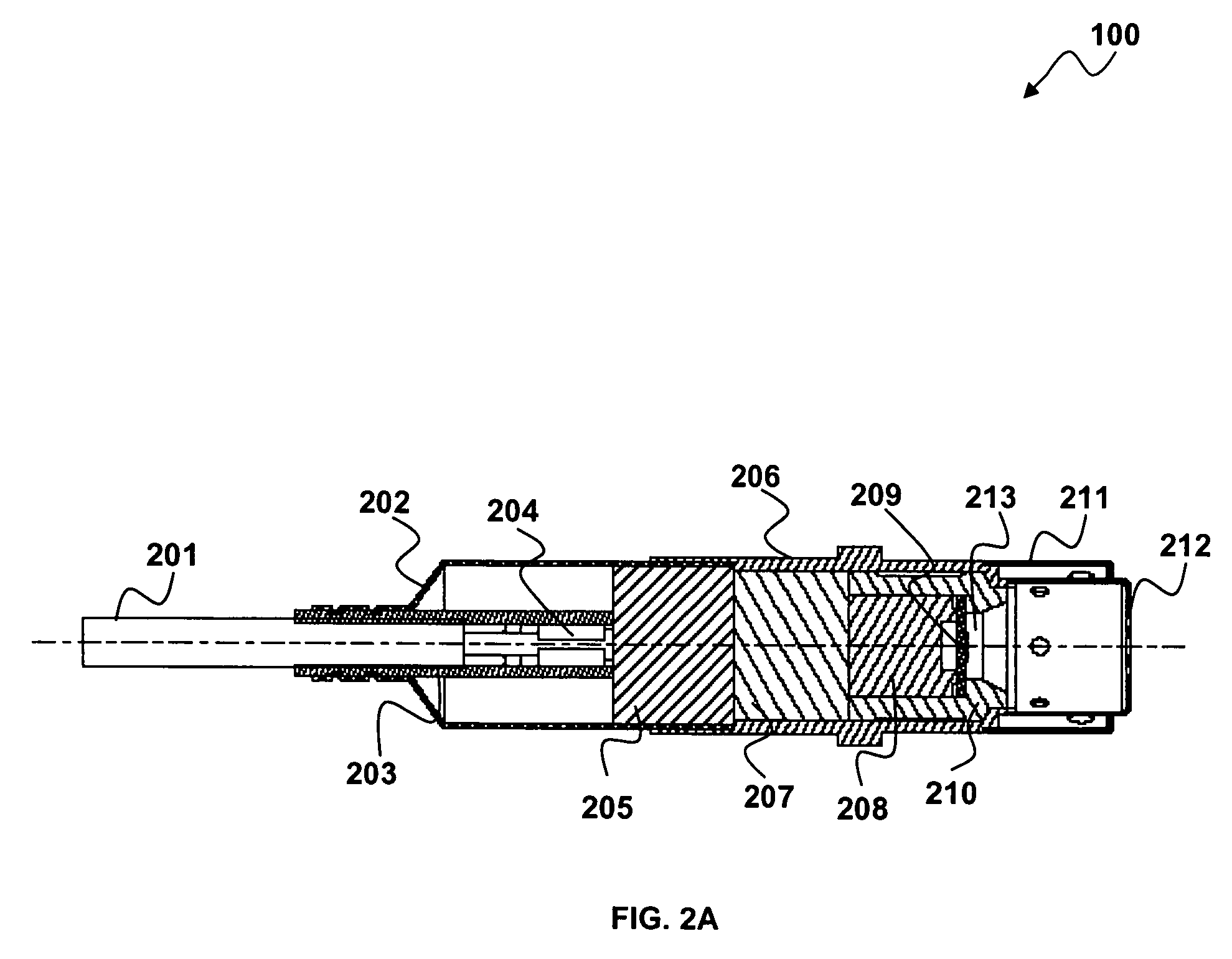

[0028]FIG. 1 illustrates a side view of a gas sensor apparatus 100, which can be implemented in accordance with a preferred embodiment. FIG. 2A illustrates a longitudinal cross-sectional view of the gas sensor apparatus 100 as depicted in FIG. 1, in accordance with a preferred embodiment. The gas sensor apparatus 100 generally includes an embossing 102, a laser welding 103, a collar 104, and a welding 105. The gas sensor apparatus 100 includes a crimping 101 to seal the cable 201 as depicted in FIG. 2A, and an embossing 102 to retain a ceramic insulator 205 as also depicted in FIG. 2A and laser welding 103 of a rear cover 202 with a main shell 206 as further depicted in FIG. 2A. The gas sensor apparatus 100 also includes a collar 104 located in a portion of the main shell 206 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Electrical conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com