Method and device for triple-effect separation of methylbenzene and polyethylene

A polyethylene and toluene technology, applied in the field of devices used in the method, can solve problems such as affecting the quality of recovered toluene, no longer satisfying production expansion, bumping and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

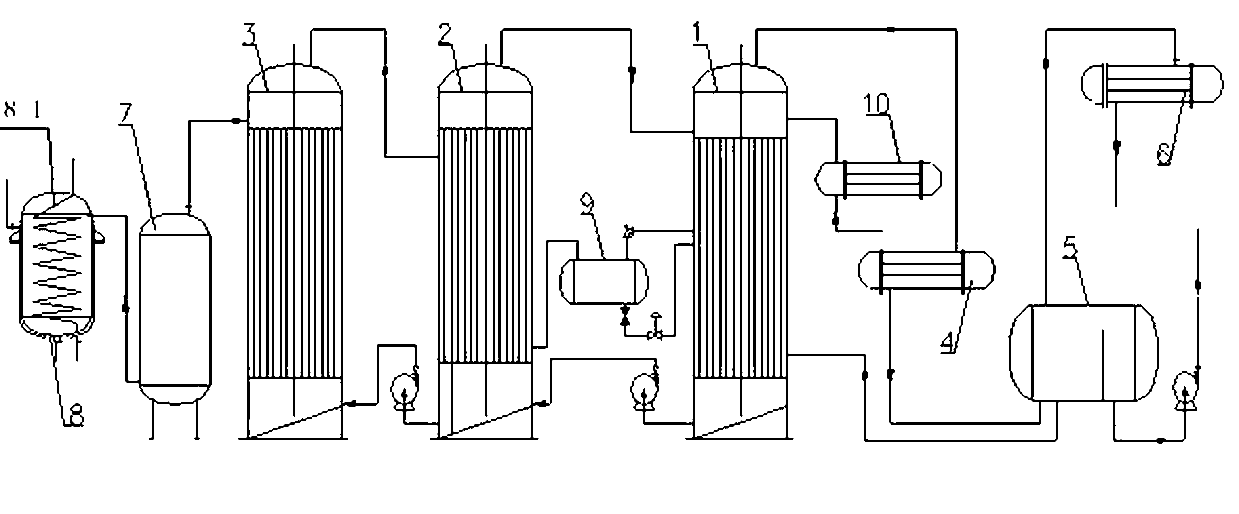

[0018] Such as figure 1 As shown, the device of this embodiment includes a waste liquid preheater 10, a negative pressure evaporator 1, a toluene condenser 4, a decanter 5, a tail gas condenser 6, a normal pressure evaporator 2, a positive pressure toluene evaporator 3, Positive pressure toluene intermediate tank 9, toluene residue storage tank 7 and residue evaporation pot 8;

[0019] The waste liquid preheater 10 is connected to the upper part of the negative pressure evaporator 1, the inlet of the toluene condenser 4 is connected to the toluene vapor outlet at the top of the negative pressure evaporator 1, and the outlet of the toluene condenser 4 is connected to the decanter 5, decanting The gas outlet of the evaporator 5 is connected to the tail gas condenser 6; the bottom of the negative pressure evaporator 1 is connected to the bottom of the atmospheric pressure evaporator 2 through a pump; the toluene vapor outlet at the top of the atmospheric evaporator 2 is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com