LNG brake valve

A gate valve and valve stem technology, applied in the field of LNG gate valve, can solve the problems of difficult safety control, inability to seal in both directions, and inability to conduct bidirectional conduction, and achieve the effects of low processing and manufacturing cost, prevention of leakage, and easy backflow control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

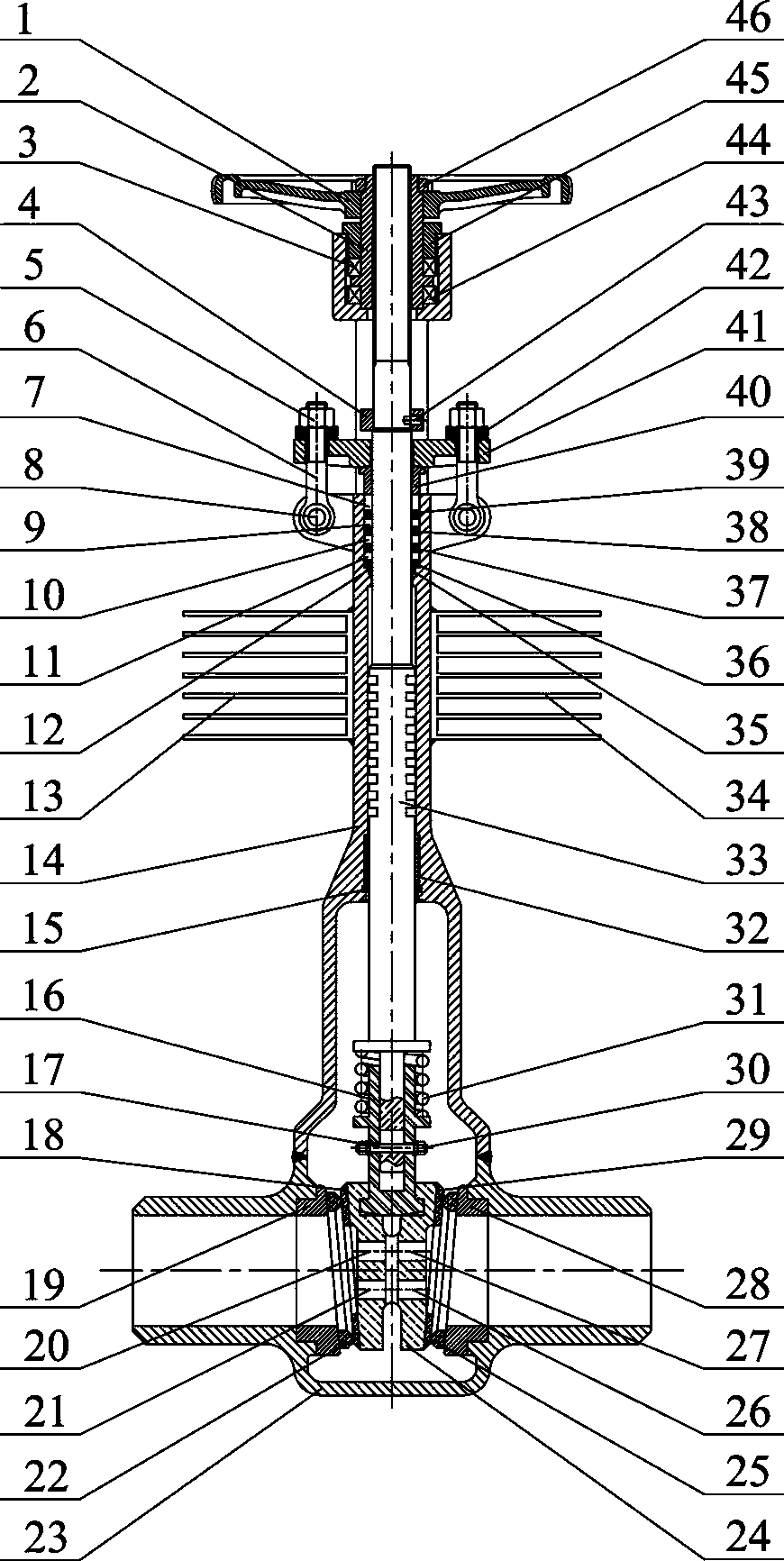

[0020] Processing and manufacturing of main components of LNG gate valve, including hand wheel (1), stem nut (2), upper bearing (3), anti-rotation ring (4), compression nut (5), compression screw (6), first Sealing ring (7), compression pin (8), second sealing ring (9), third sealing ring (10), fourth sealing ring (11), elastic sealing ring (12), left cooling fin ( 13), upper valve body (14), sixth sealing retaining ring (15), lower valve stem (16), valve stem bolt (17), seventh sealing ring (18), left valve seat (19), first Pressure regulating valve (20), second pressure regulating valve (21), eighth sealing ring (22), lower valve body (23), gate (24), ninth sealing ring (25), third pressure regulating valve (26), the fourth pressure regulating valve (27), the right valve seat (28), the tenth sealing ring (29), the valve stem bolt nut (30), the valve stem spring (31), the sixth sealing ring (32) , upper valve stem (33), right cooling fin (34), elastic sealing support ring (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com