Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146results about How to "Reduce heat transfer rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

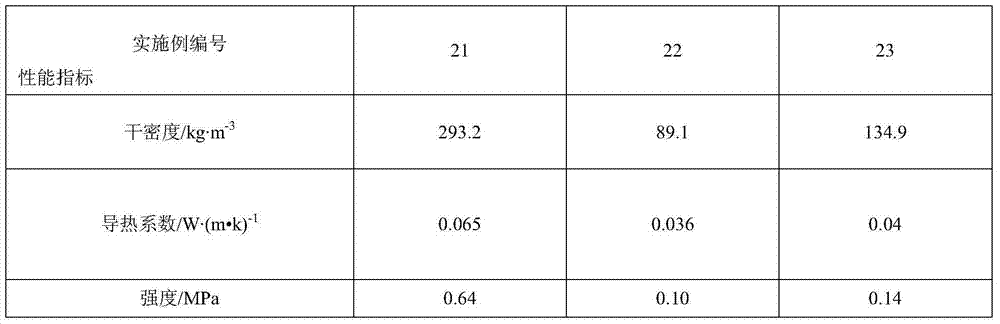

Heat-preservation sound-proof low-density foamed concrete

The invention discloses heat-preservation sound-proof low-density foamed concrete. The heat-preservation sound-proof low-density foamed concrete is characterized by being prepared from, by weight, 40-100 parts of cement, 5-40 parts of carbide slags, 5-40 parts of active powder, 1-20 parts of foaming agents, 0.1-8 parts of foam stabilizers, 0-8 parts of water reducing agents, 0-8 parts of coagulation accelerator, 0-25 parts of waterproof agents, 0.1-5 parts of anti-cracking agents and 25-150 parts of water, and the foamed concrete is prepared from the materials through mixing, foam molding and maintenance. The heat-preservation sound-proof low-density foamed concrete has the advantages of being low in dry density, low in heat conductivity coefficient, high in strength, wide in raw material source, low in cost, simple in preparation technology, convenient to prefabricate in factories or pour on site and the like; the heat-preservation sound-proof low-density foamed concrete is suitable for building exterior wall heat-preservation engineering, roof heat-preservation engineering, floor heating heat-preservation engineering, composite heat-preservation wall engineering, backfilling engineering, retaining wall slab engineering and the like.

Owner:株洲大禹恒基新材料有限公司

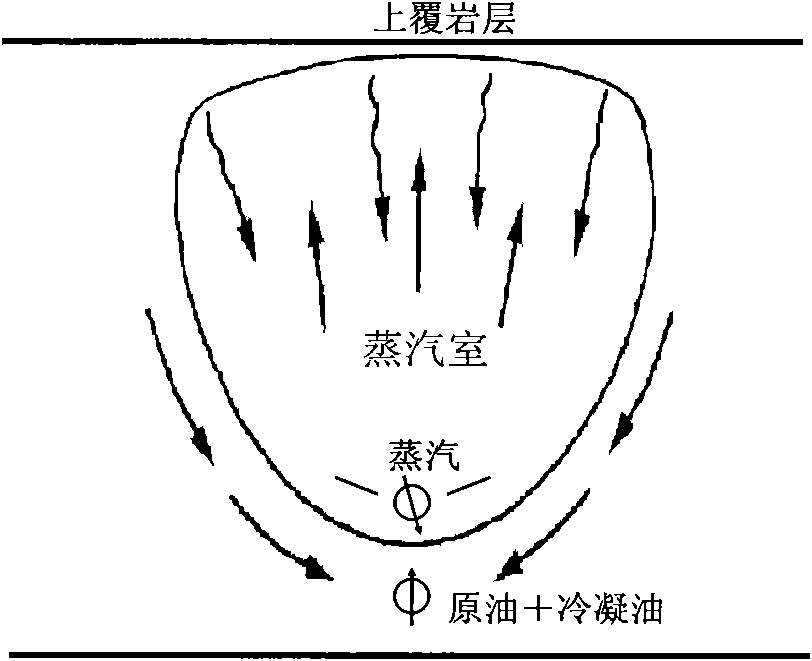

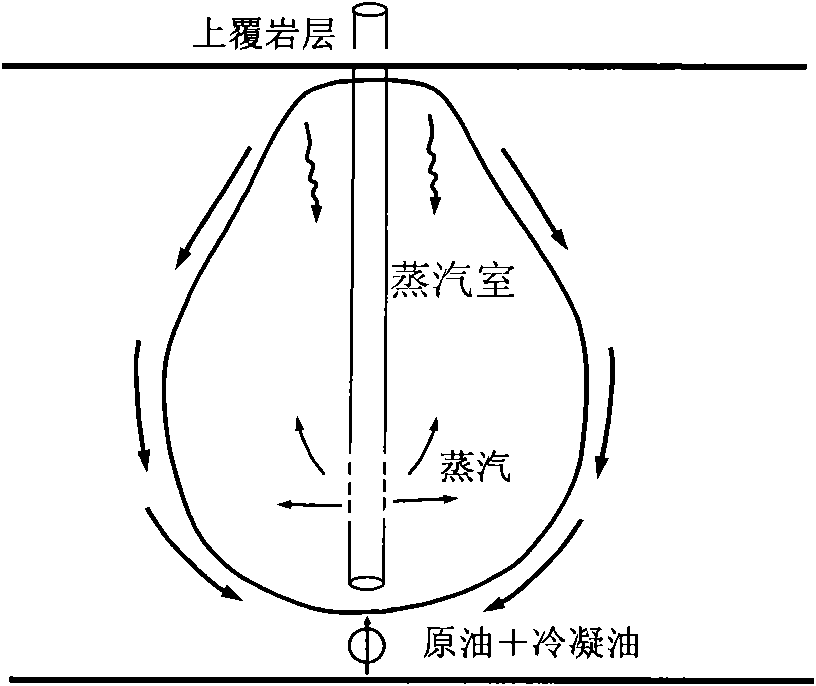

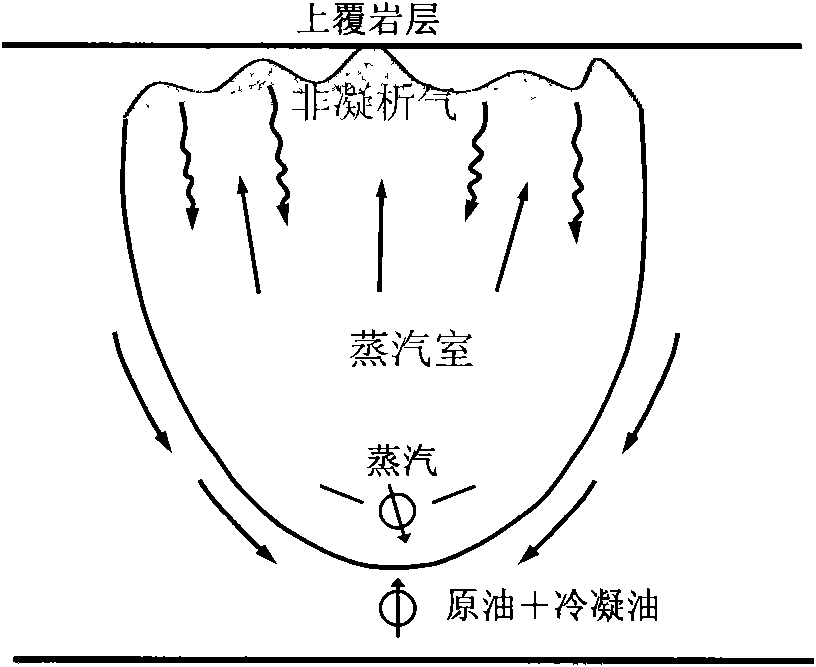

Gas-assisted SAGD method for exploiting super heavy oil

The invention relates to a gas-assisted SAGD method for exploiting super heavy oil; the selecting layer thickness is 530m, remaining oil saturation is more than 0.50, oil layer thickness is more than 10.0m, horizontal permeability is more than 250md, the ratio of the vertical permeability to the horizontal permeability is more than 0.1, the oil layer porosity is more than 0.20, continuous distributed impermeable clay and intercalated shale oil pools do not exist in the oil layer; a horizontal well is drilled between soaking vertical wells, the well spacing is 35m or a pair of horizontal wells are drilled at the bottom of the oil layer, the vertical distance is 6m; swallowing is carried out for 3 stages, when the hot communication is formed between the wells, the vertical wells is used to inject steam continuously, the production of horizontal wells is 3 years, then the vertical wells is used to inject nitrogen and steam until the underground volume ratio is 0.5 and the total injection rate of nitrogen is 0.10PV, then the steam is injected continuously, the steam injection rate is 1.4m / d.ha.m, the dryness of steam at the bottom of wells is 70%, the production-injection ratio is maintained at 1.2; the recovery percent is increased by 6.0-9.0% and the oil-steam ratio is improved by 0.02-0.05.

Owner:PETROCHINA CO LTD

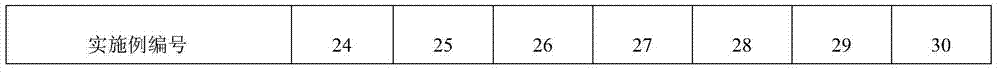

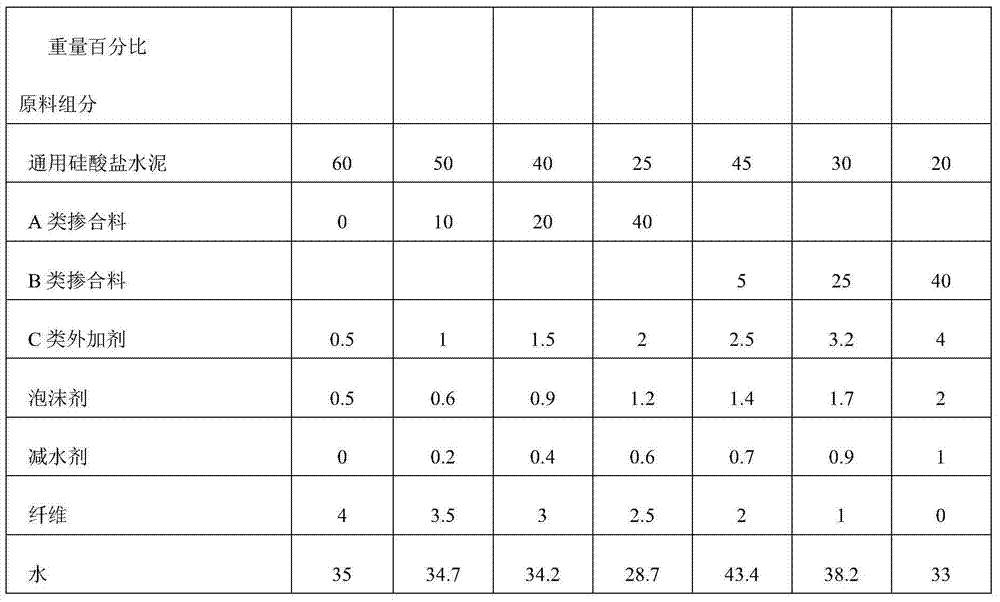

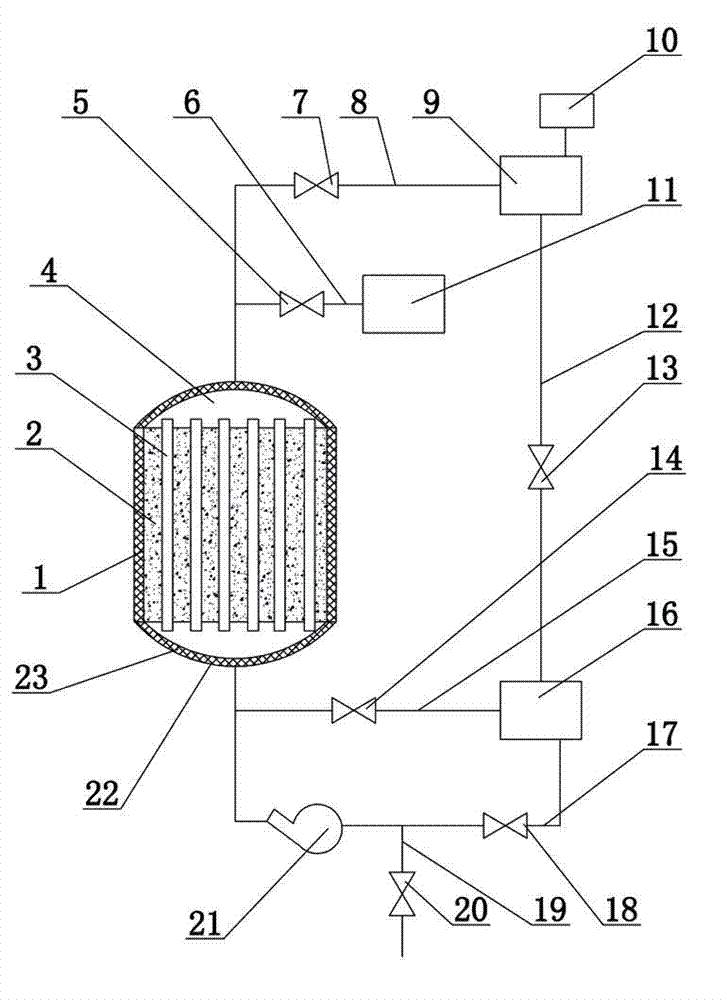

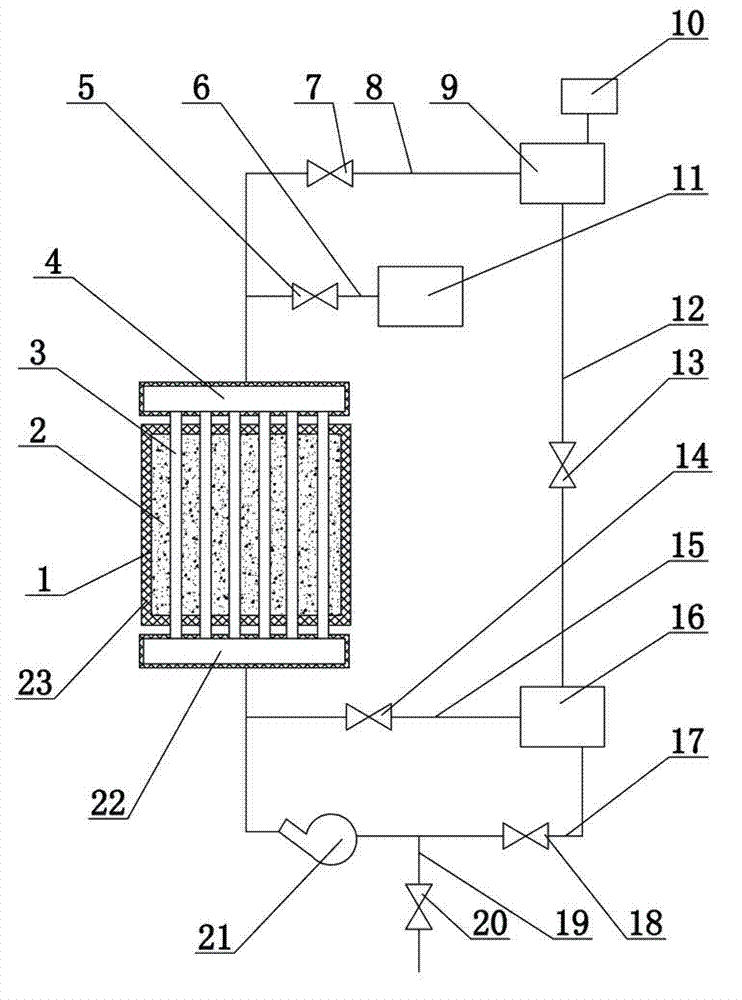

General purpose Portland cement based ultra-light physical foamed concrete

ActiveCN104774033AReduce raw material usageReduce resource consumptionCeramicwareCushionPortland cement

The invention discloses general purpose Portland cement based ultra-light physical foamed concrete which is characterized by being prepared by mixing, forming and maintaining the following components in percentage by weight: 20-70% of general purpose Portland cement, 0-40% of a type A admixture or / and 0-40% of a type B admixture, 0.5-4% of a type C additive, 0.3-2% of a foaming agent, 0-1% of a water reducing agent, 0-4% of fibers and 25-60% of water. The general purpose Portland cement based ultra-light physical foamed concrete disclosed by the invention has the characteristics of ultra-low dry density, low thermal conductivity, relatively high strength, wide raw material source, low cost, simple preparation process, easy maintenance process selection and the like, is suitable to serve as an earthquake-proof and energy-absorbing material, a lightweight cushion course and a catalyst carrier material in a thermal insulation project, a floor heating project and a back filling project, and is particularly suitable for a building exterior wall external thermal insulation system, a roof thermal insulation system, a composite thermal insulation wall body and a buffer energy absorbing system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

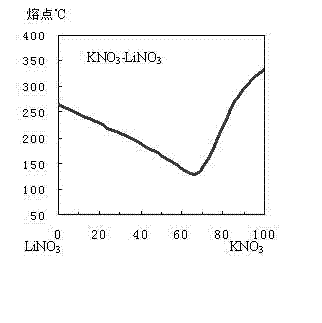

Phase change heat accumulation system for generating steam directly and preparation method of phase change heat accumulation agent

InactiveCN102777874AImprove efficiencyImprove heat transfer coefficientHeat storage plantsChemical industryPorous mediumToxic industrial waste

The invention relates to a phase change heat accumulation system for generating steam directly and a preparation method of a phase change heat accumulation agent. A phase change material is enhanced with graphite foam, and is absorbed in a porous medium of the graphite foam, so that a binary eutectic salt / graphite foam material is prepared and is used as a composite phase change material of a heat accumulation device, the composite phase change material is high in heat conduction coefficient, therefore under the same design condition, the phase change heat accumulation system provided by the invention is applied to systems of a focusing type solar thermal power generation system, an industrial waste heat recovery system and the like, and has the characteristics of high heat transfer efficiency, small volume, low cost and the like. In addition, the phase change heat accumulation system for generating steam directly can flexibly adopt a parallel connection or serial connection mode according to the temperature of high-temperature waste heat steam and the requirement of a steam user; and during serial connection, the binary eutectic salt / graphite foam composite phase change material can be combined in a cascaded manner according to a melting point, thus the efficiency of an energy accumulation system is increased, and the energy can be greatly accumulated.

Owner:ZHENGZHOU UNIV

Biomass spiral pyrolysis device and pyrolysis process

InactiveCN101709224AControl dwell timePrevent slippingLiquid hydrocarbon mixture productionCollection systemPropeller

The invention relates to a biomass pyrolysis device and a process thereof. The device comprises a charging system, a spiral pyrolysis reactor and a product collection system, wherein a rotating shaft which is communicated with a variable-frequency motor and provided with a spiral propeller is arranged in center holes on two end covers of a cylinder body of the reactor; the side wall of the cylinder body is provided with a biomass feed pipe and a pyrolysis product outlet pipe; the outlet pipe is vertically extended into a coke collection tank; and the coke collection tank are communicated with a condenser, a bio-oil collection tank and a tail gas discharge pipe in turn through an air outlet pipe on the side wall. The process comprises the following technological processes: firstly, starting an external heating system to ensure that the temperature in a reactor is between 500 and 550 DEG C; secondly, putting biomass granular raw materials into the reactor through an inlet pipe, simultaneously starting the variable-frequency motor, and determining the rotating speed n of the variable-frequency motor according to the set residence time t, and the axial length L and the screw pitch l of the spiral propeller; and finally, starting the pyrolysis product collection system. The biomass pyrolysis device can accurately control the pyrolysis time and control the pyrolysis temperature in a partitioning mode so that the obtained bio-oil components are controllable and are easy to extract chemical products.

Owner:UNIV OF SCI & TECH OF CHINA

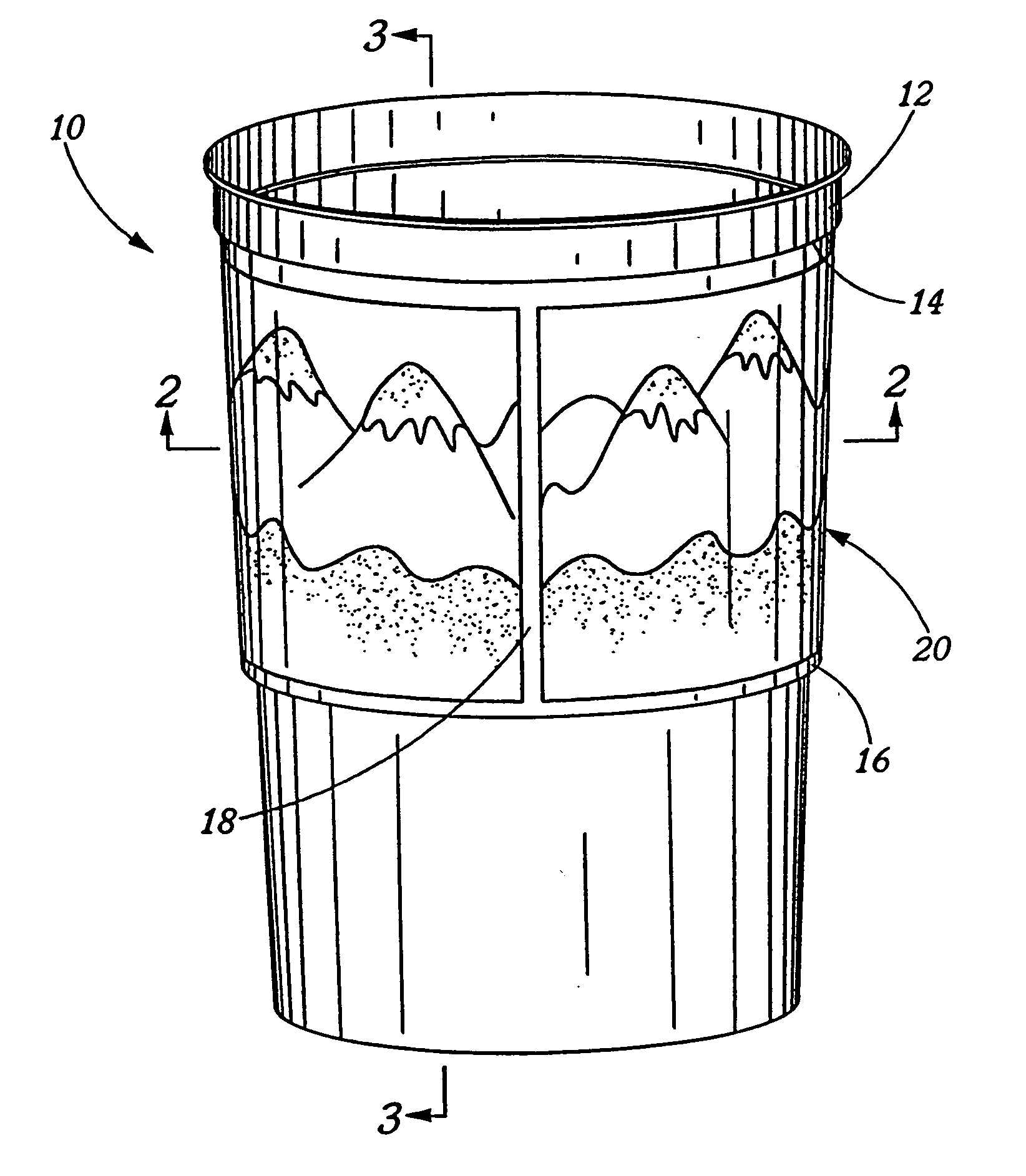

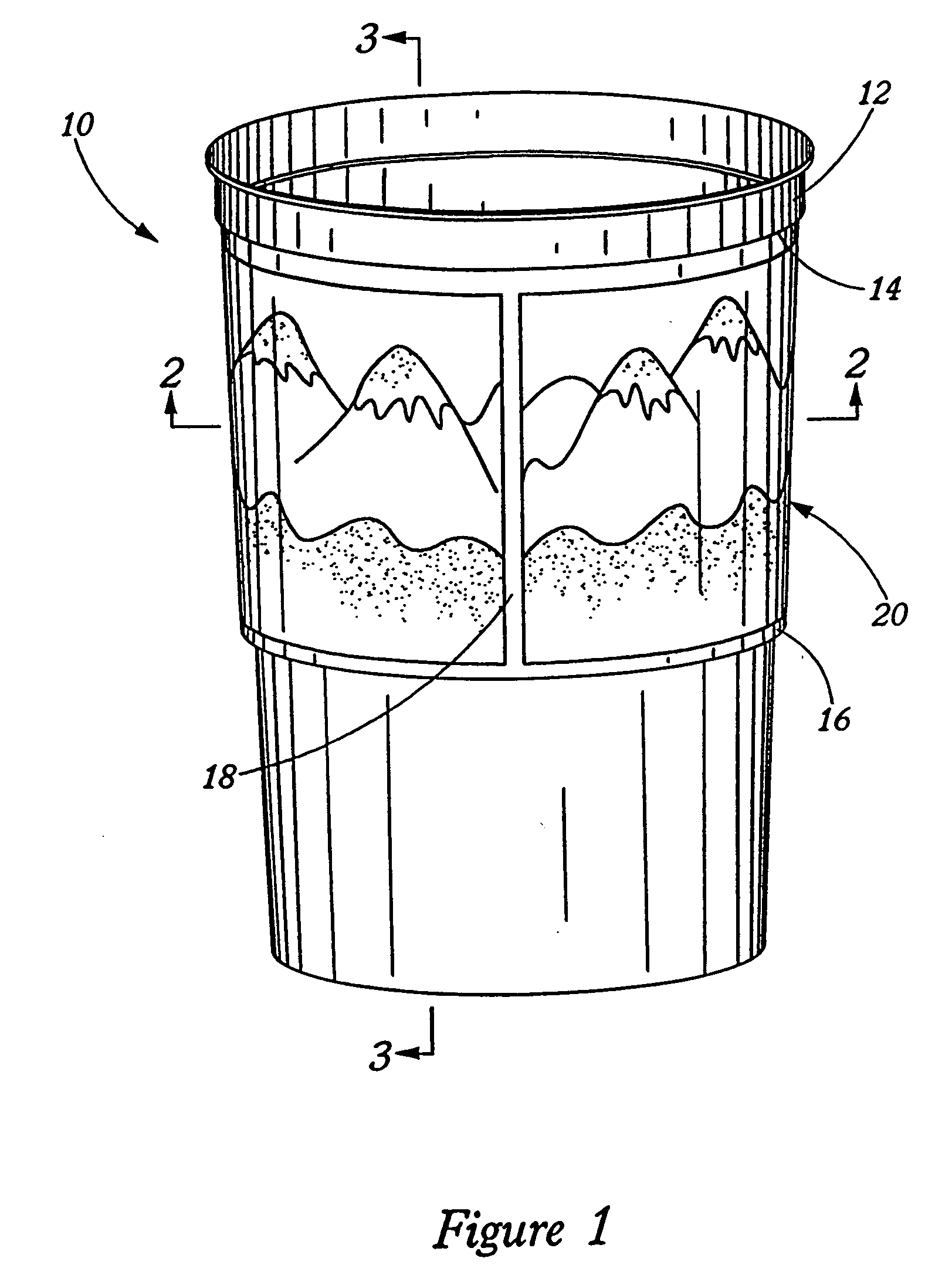

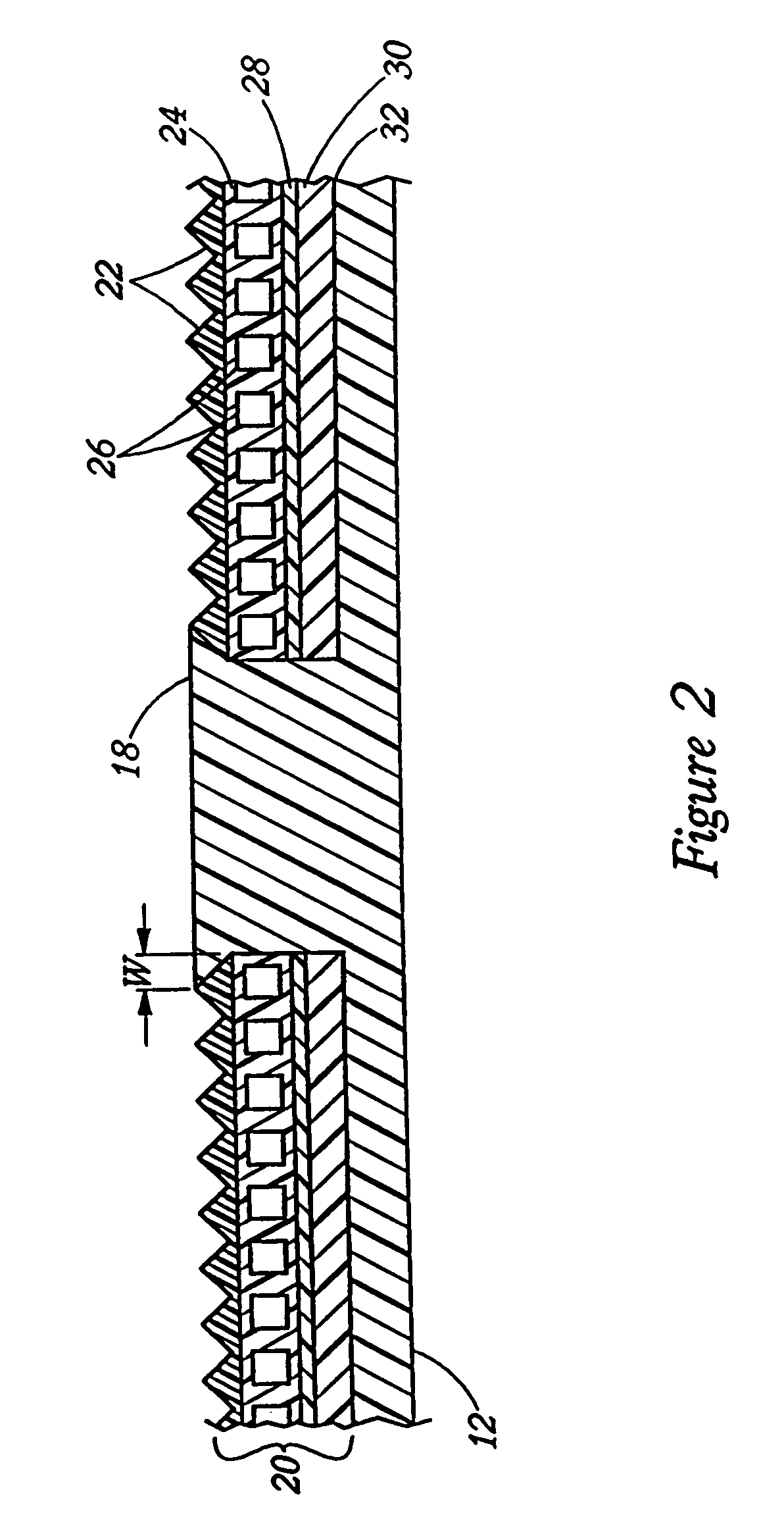

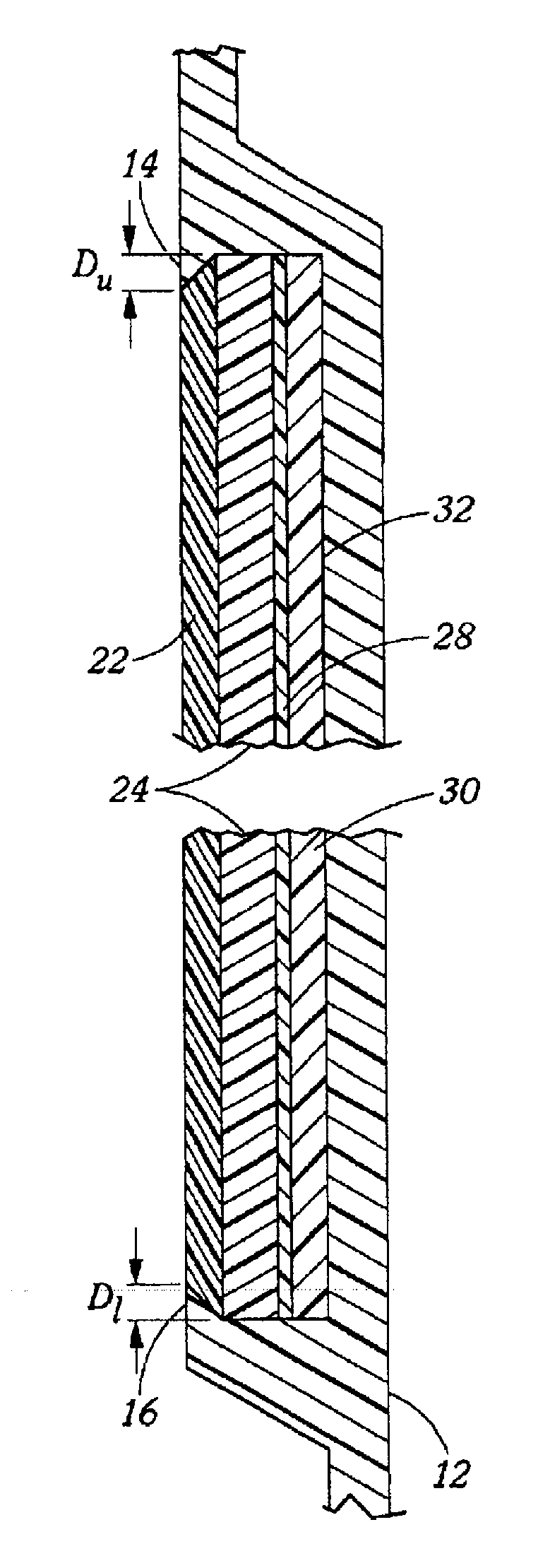

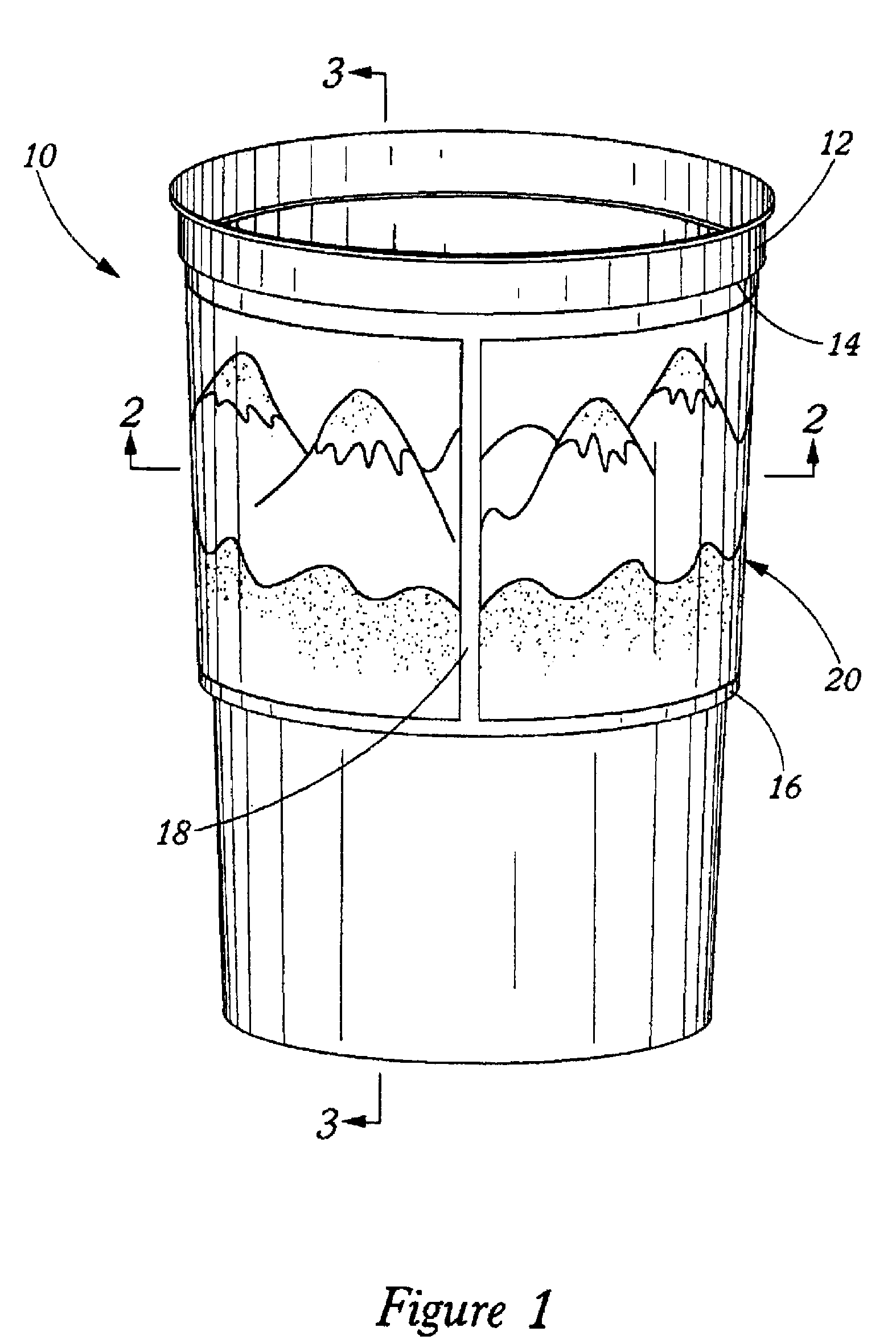

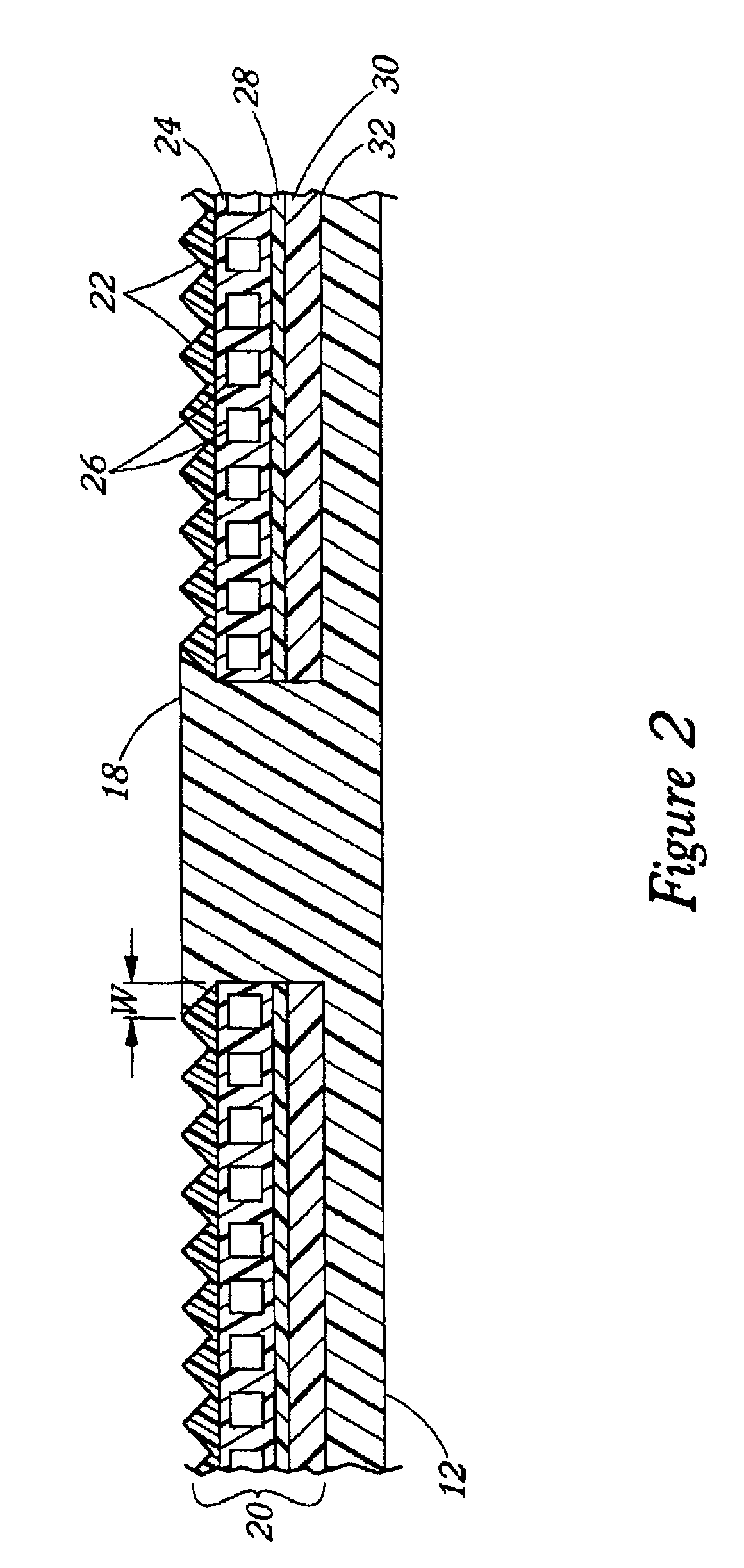

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20050053737A1Efficient and economicalQuality improvementEnvelopes/bags making machineryContainer decorationsPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

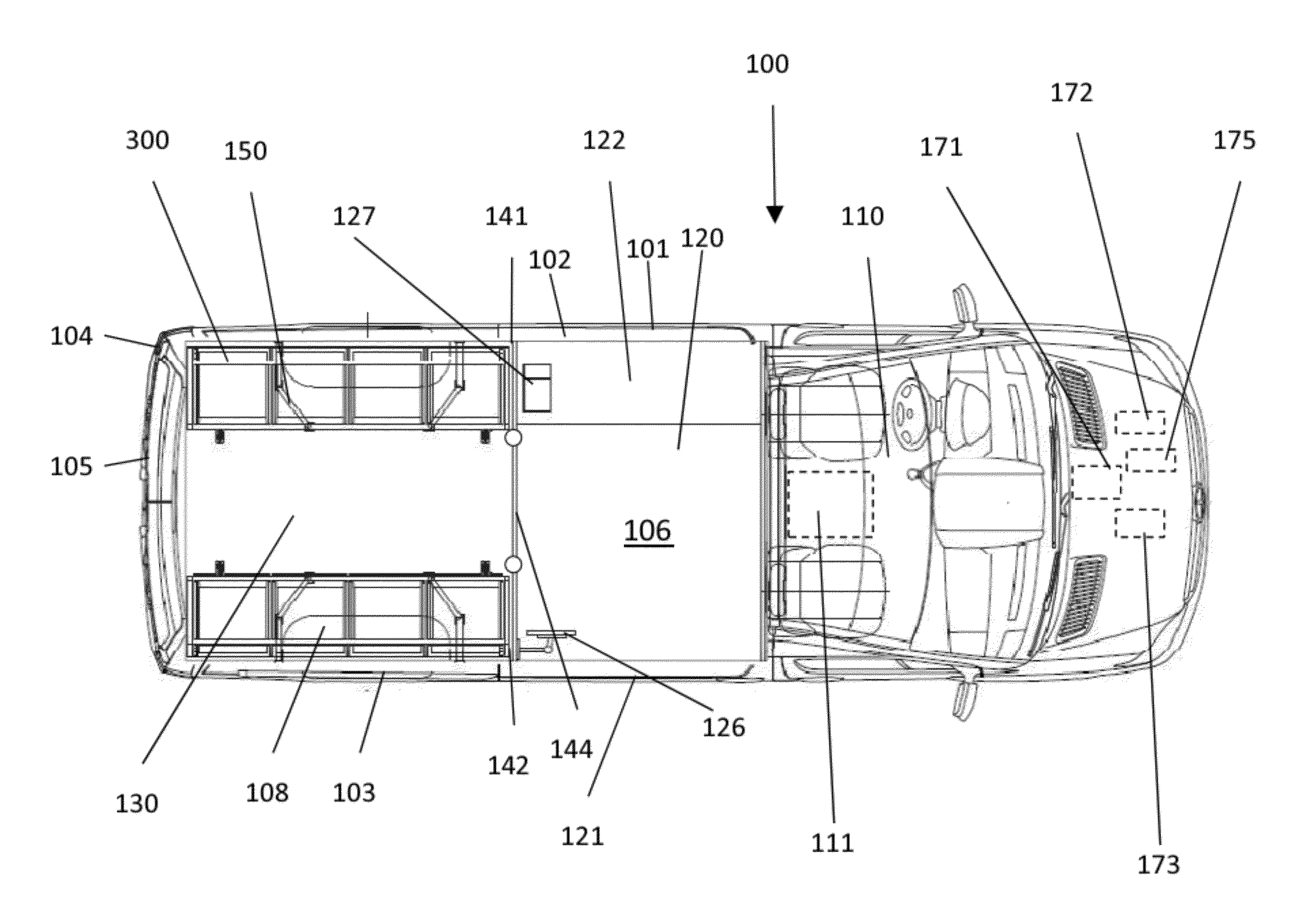

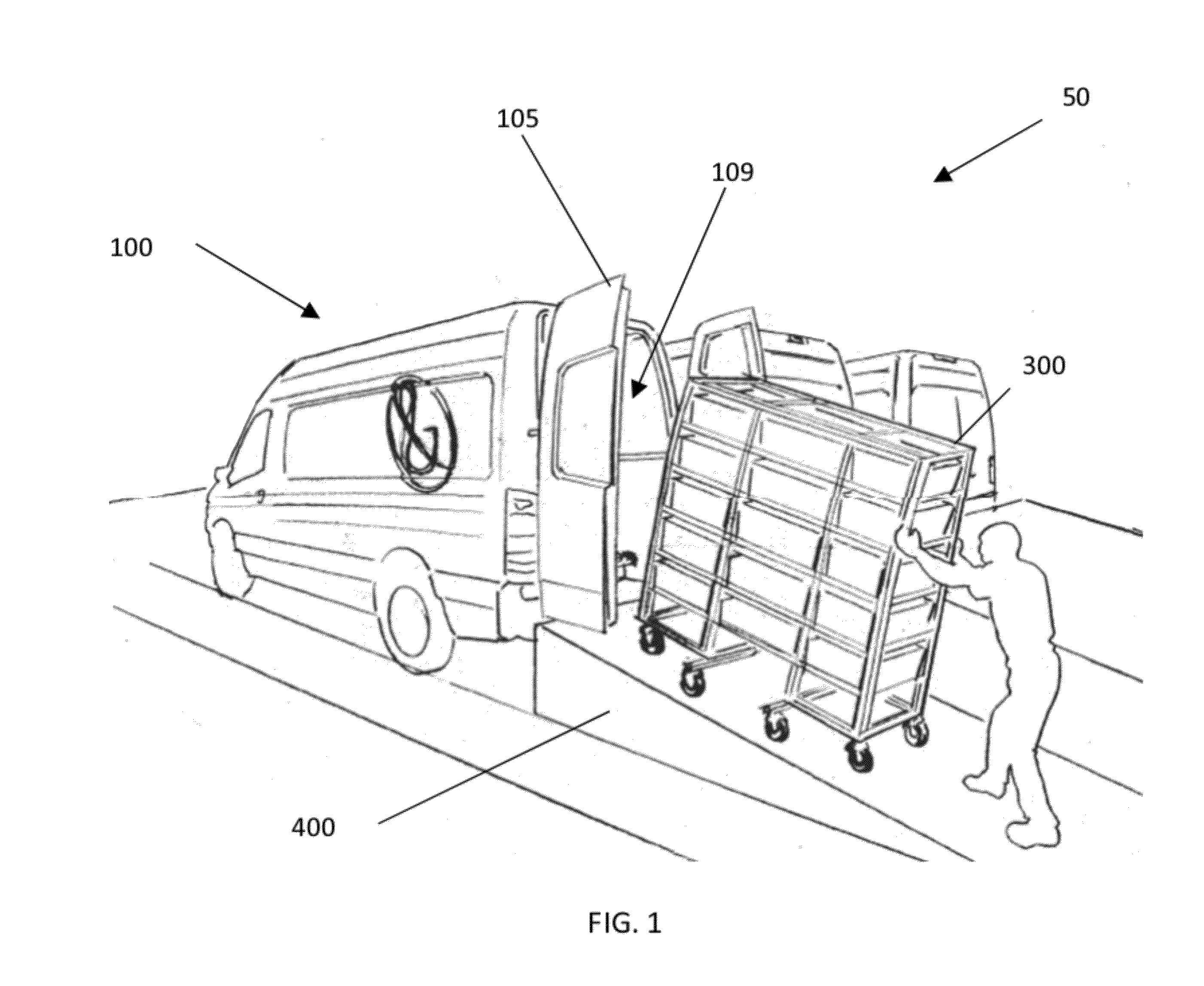

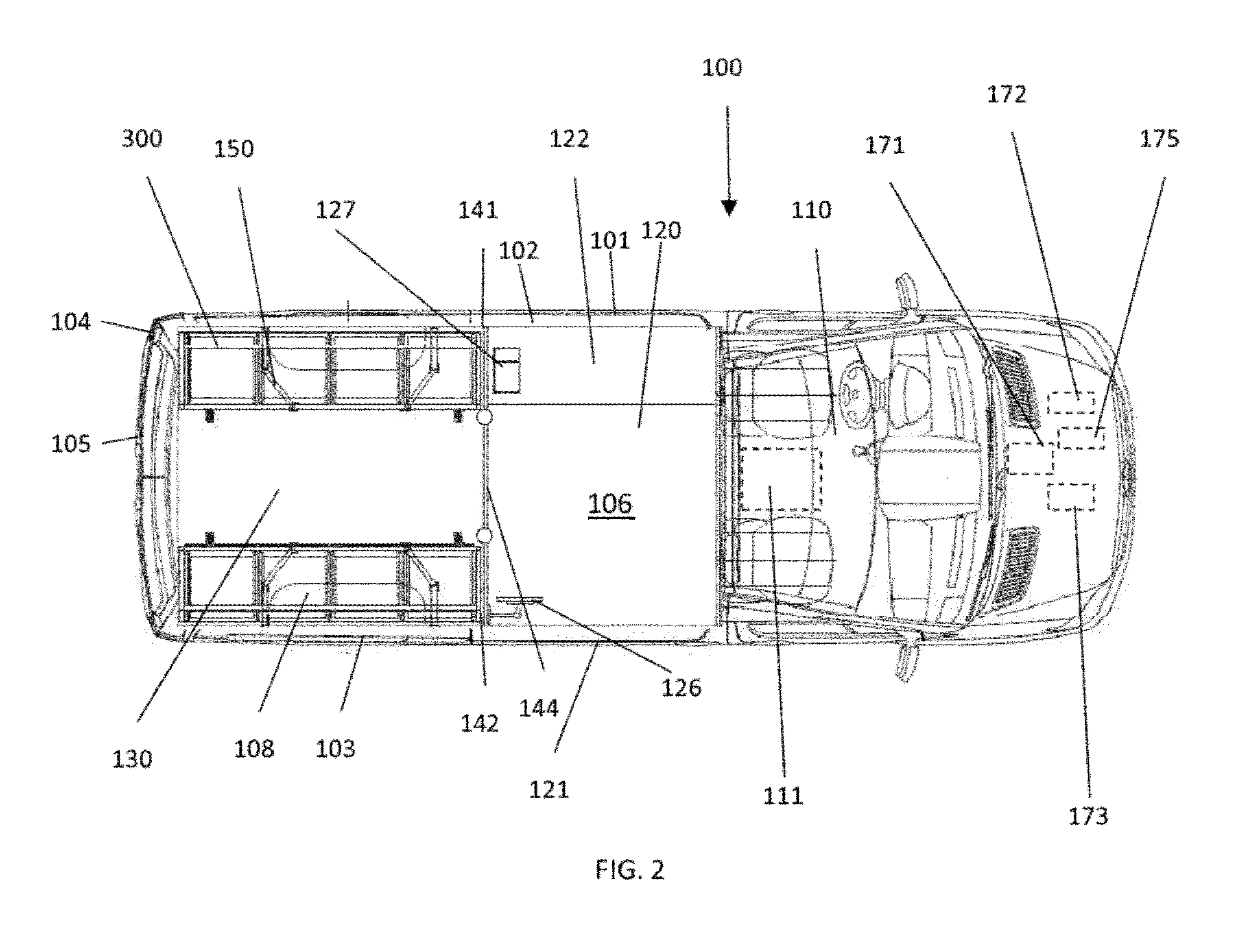

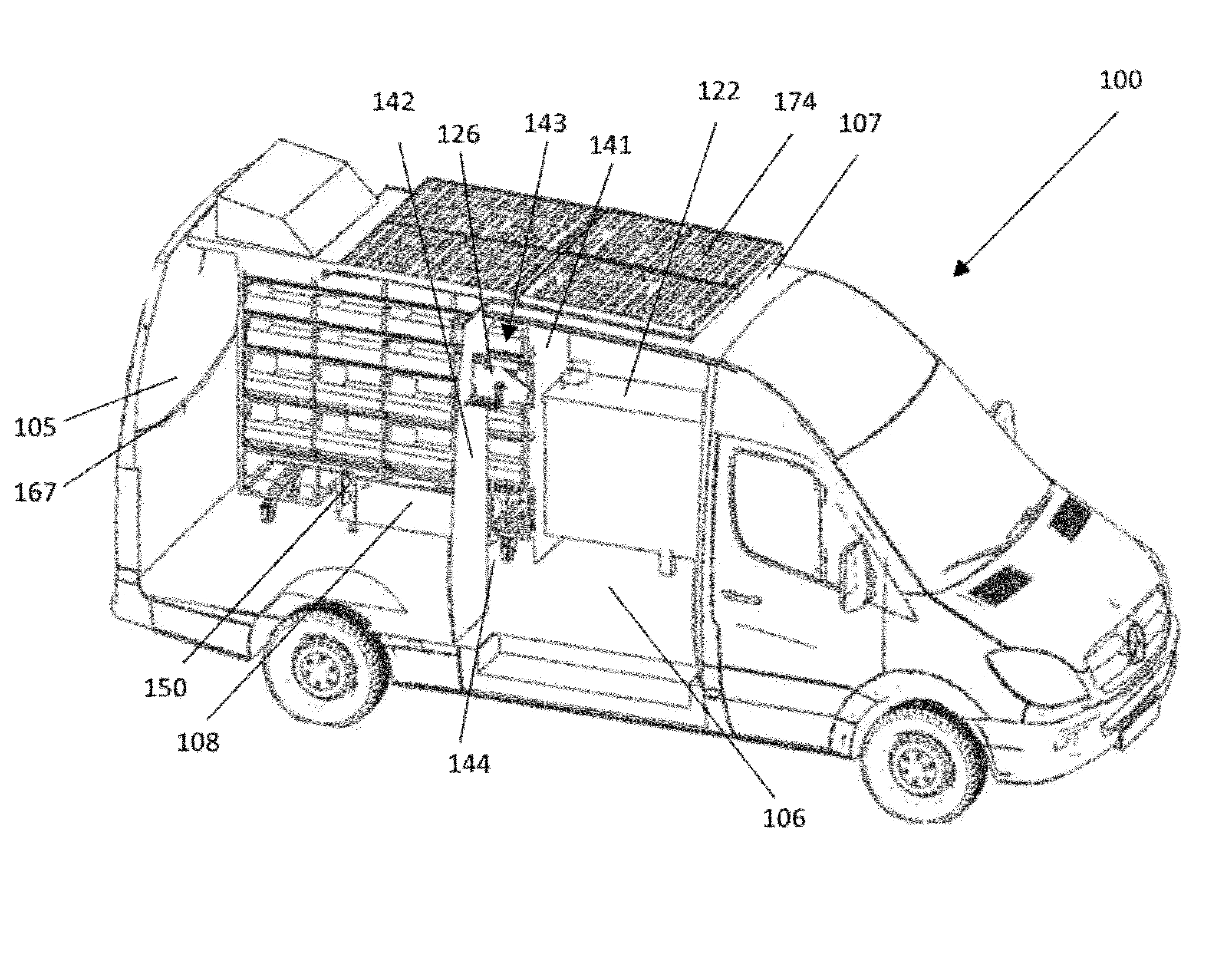

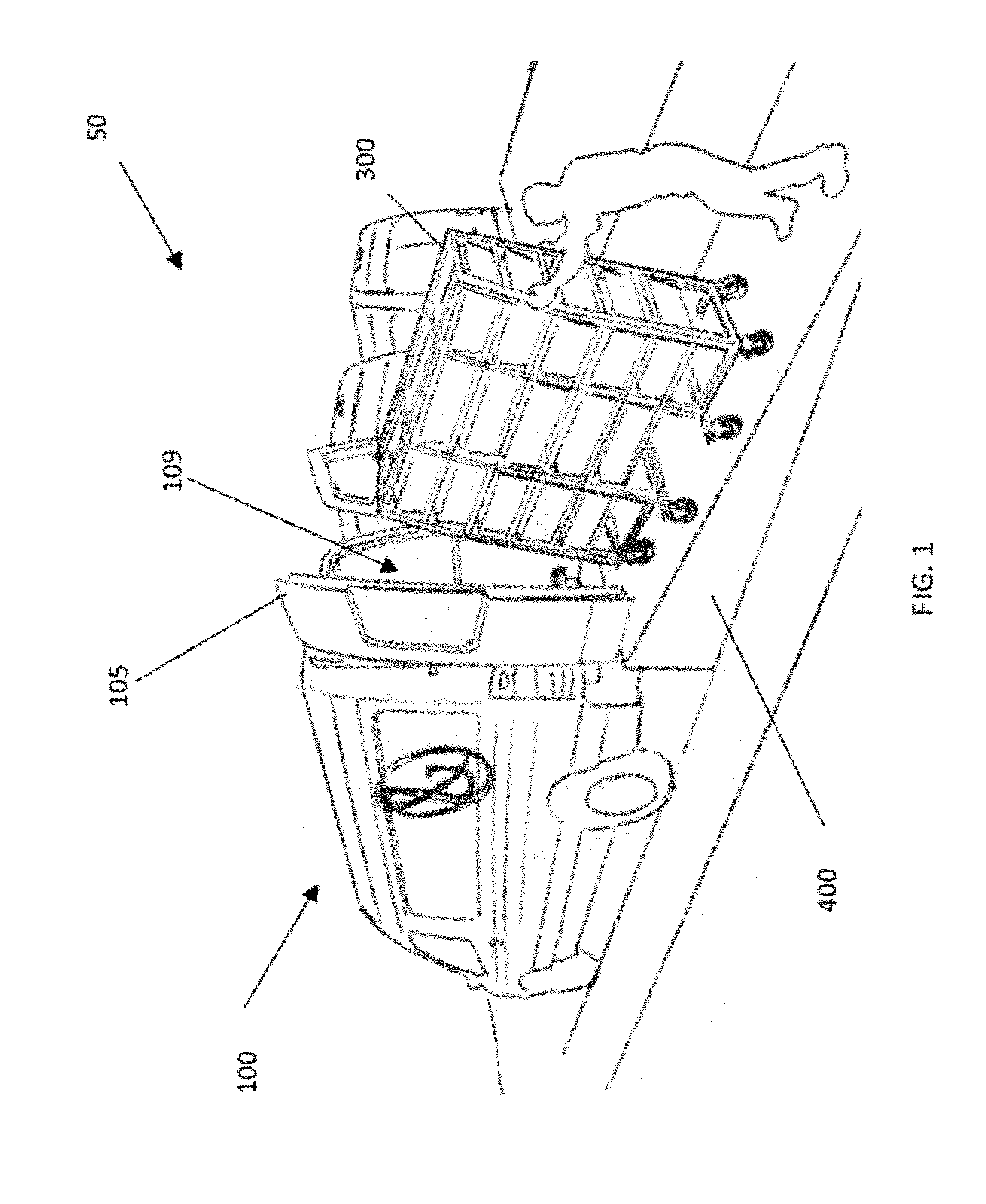

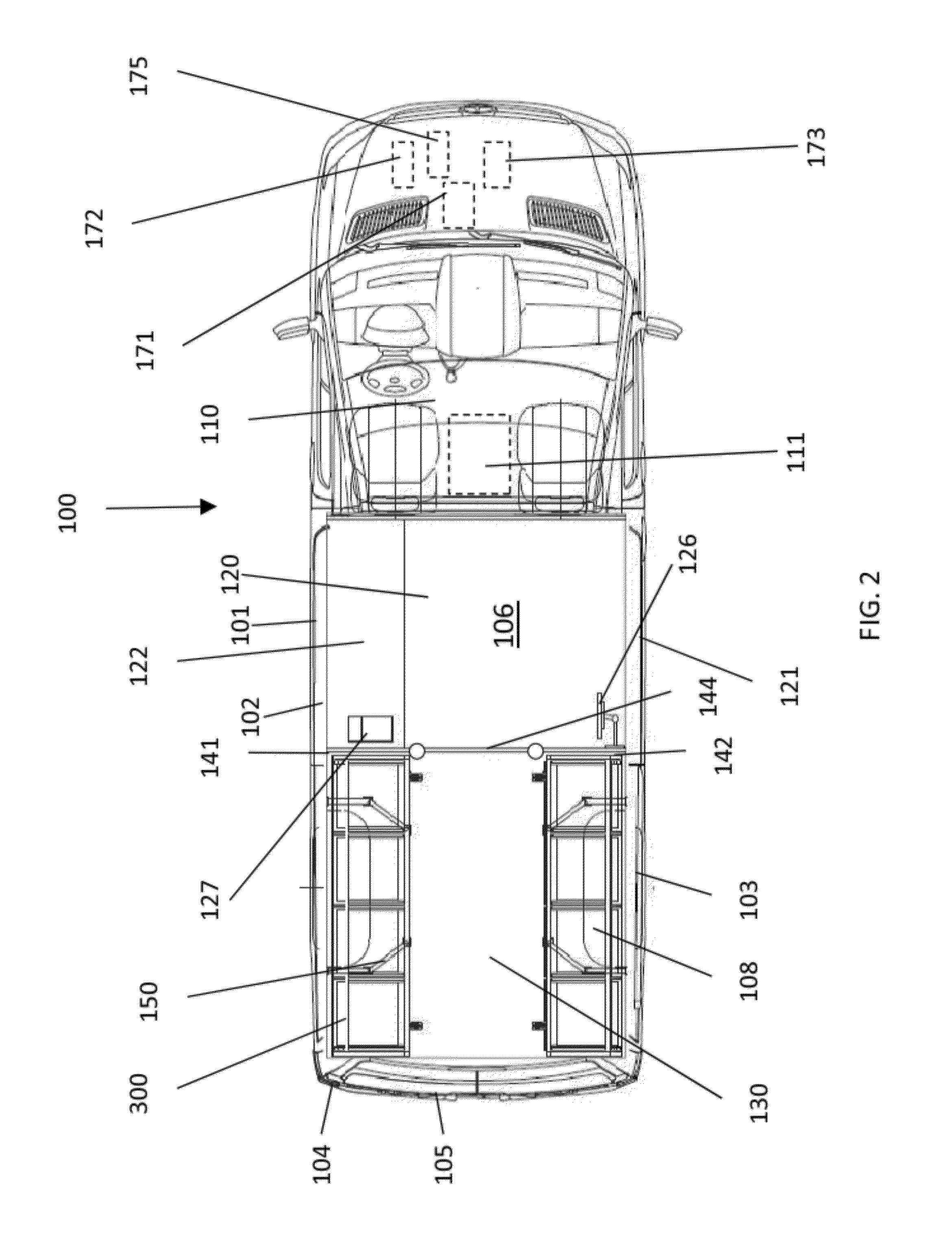

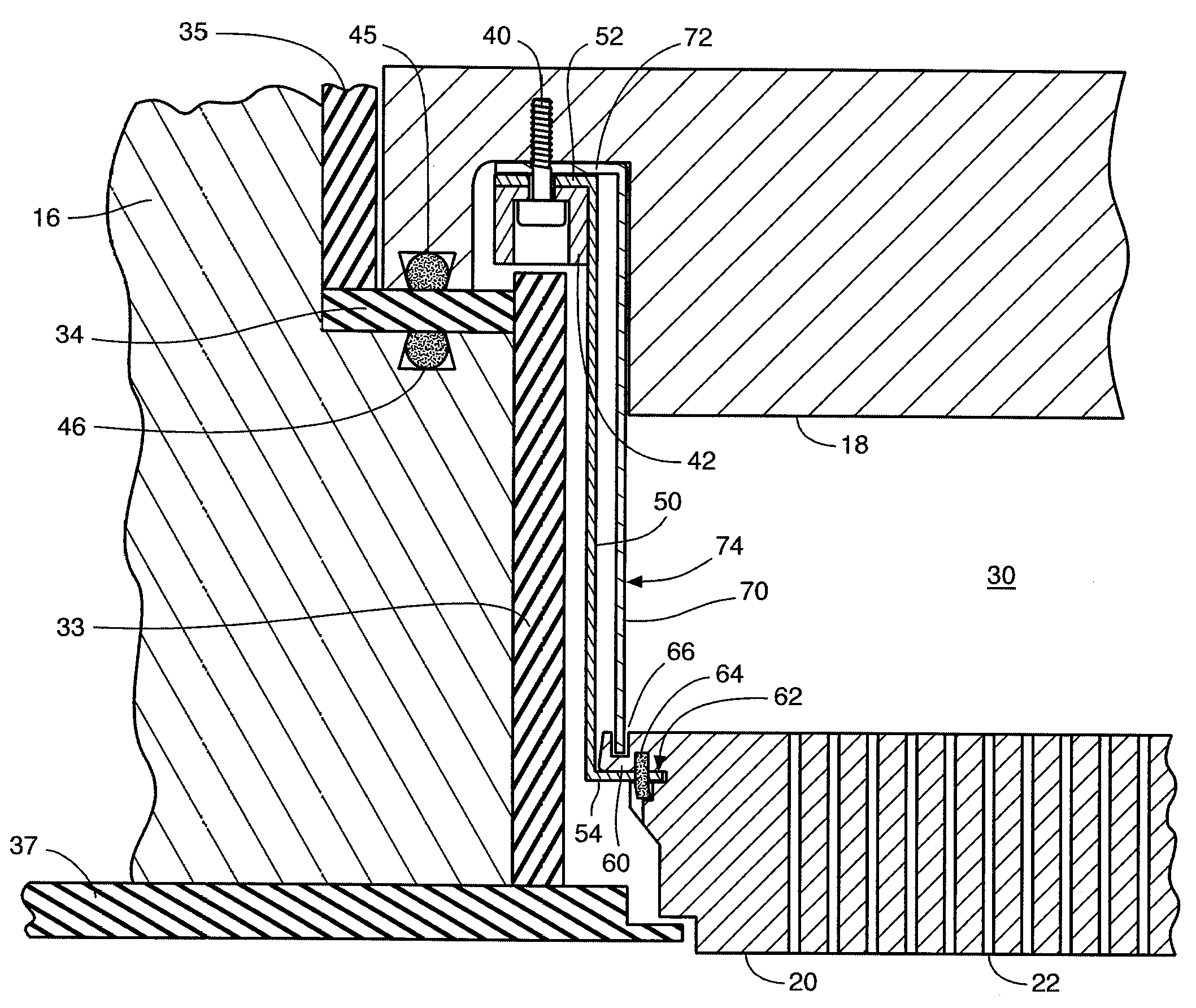

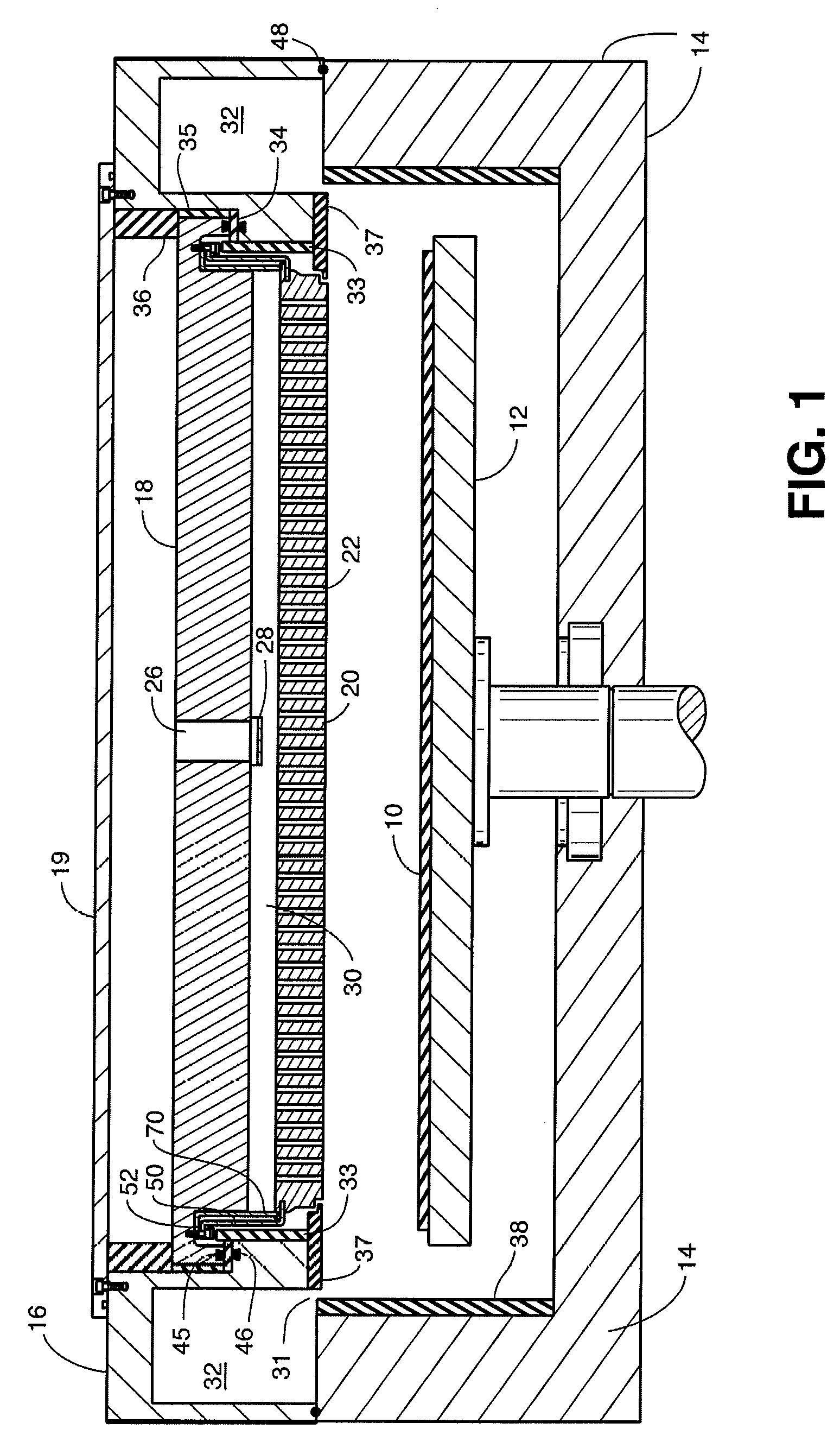

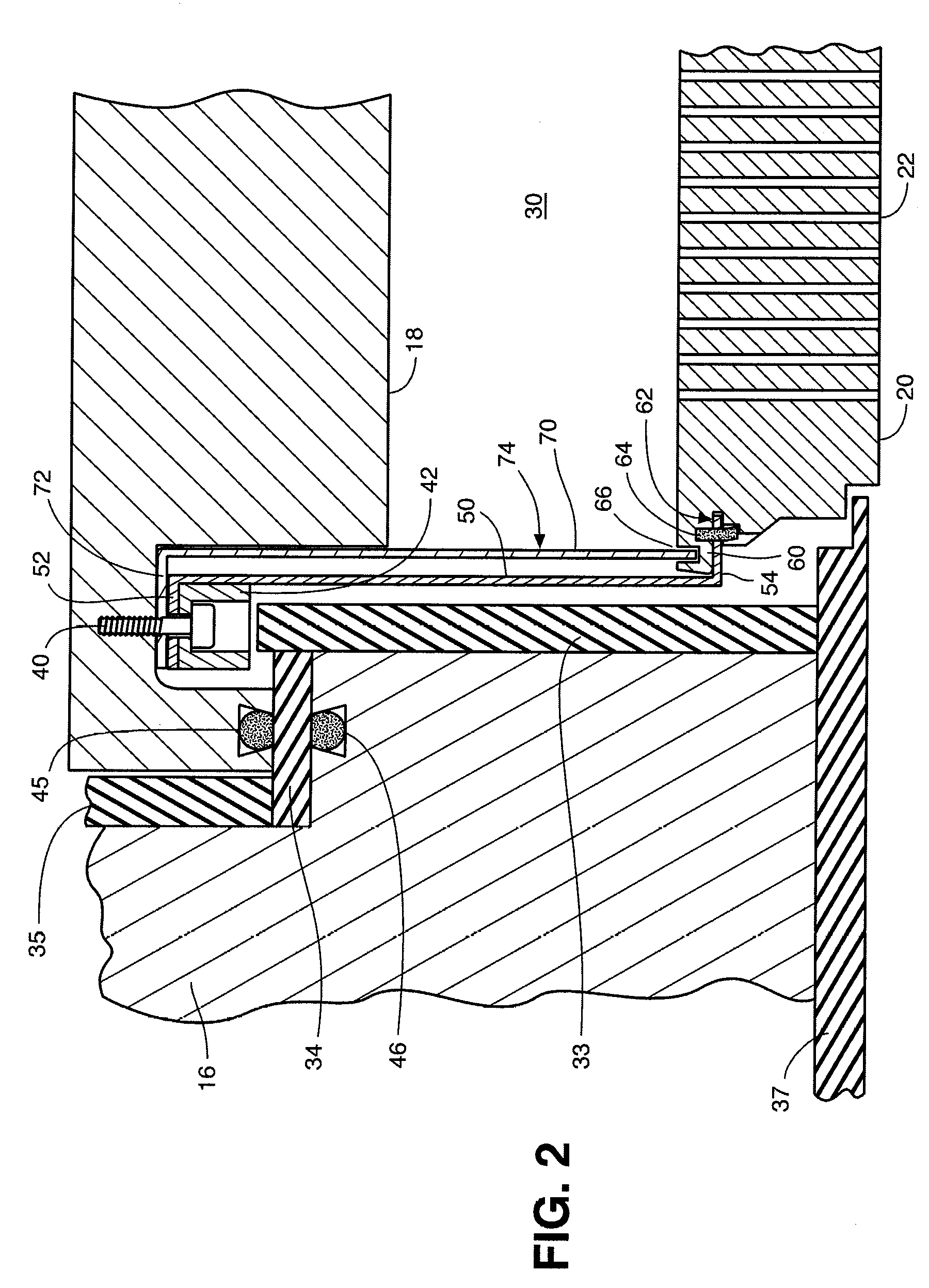

Mobile Product Retail System and Methods Thereof

InactiveUS20120031686A1Reduce heat transfer rateMaintain temperatureAuxillary drivesRefrigerated goods vehicleElectricityTemperature control

The present disclosure pertains to a vehicle for transporting or vending refrigerated product having a peripheral body extending vertically from the supporting surface, the peripheral body having a driver area, retail area, and cooling area, a bulk head for dividing the retail area from the cooling area, and an auxiliary power system for powering at least one electrical component, having a battery bank and a charging mechanism, the charging mechanism having a vehicle charging system, shore power charging system, and solar array charging system, the charging mechanism imparting electrical charge to the battery bank, where the electrical component is a temperature control system for maintaining the temperature of the cooling area within a desired temperature range.

Owner:FERRIGNI MAX

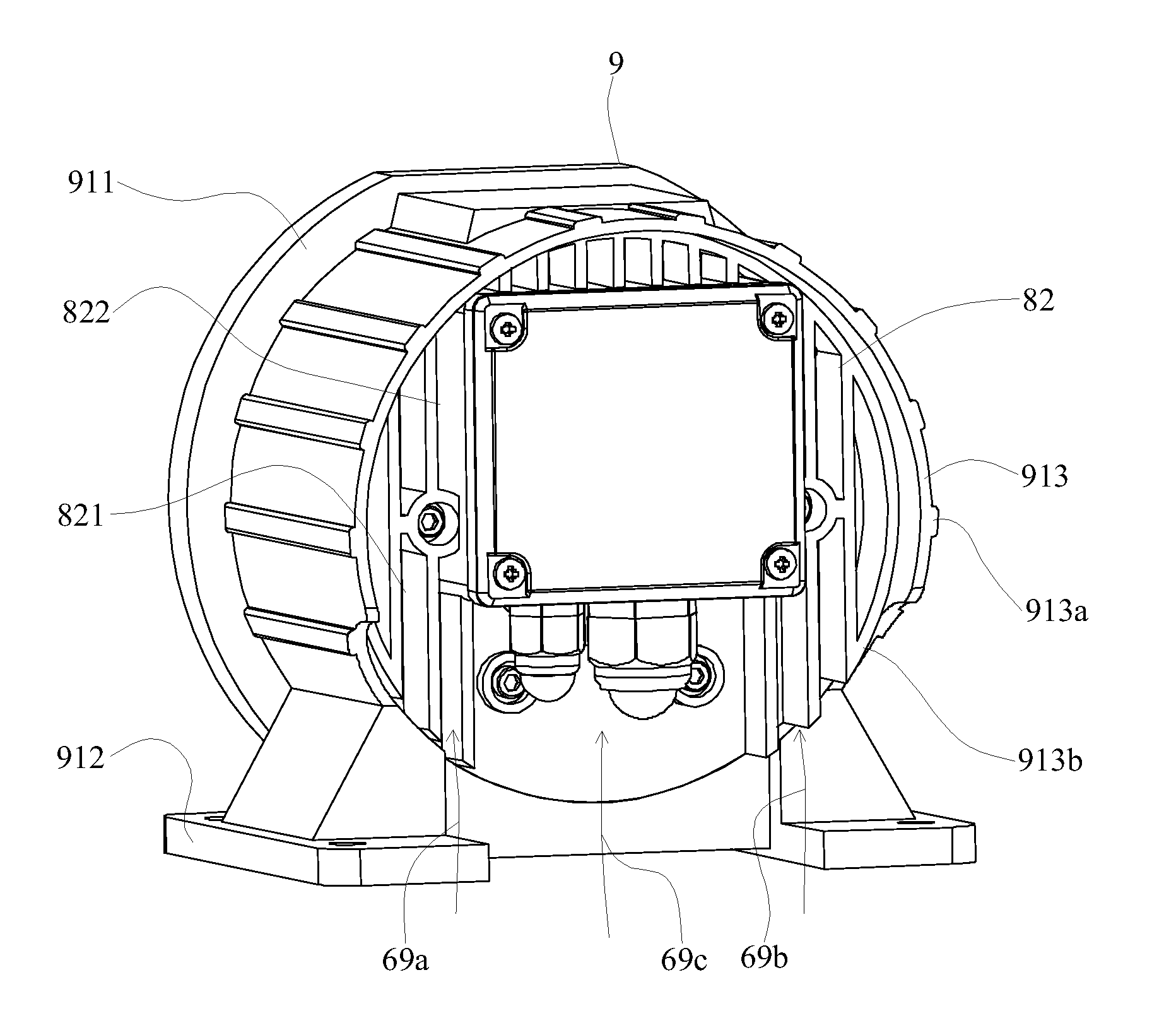

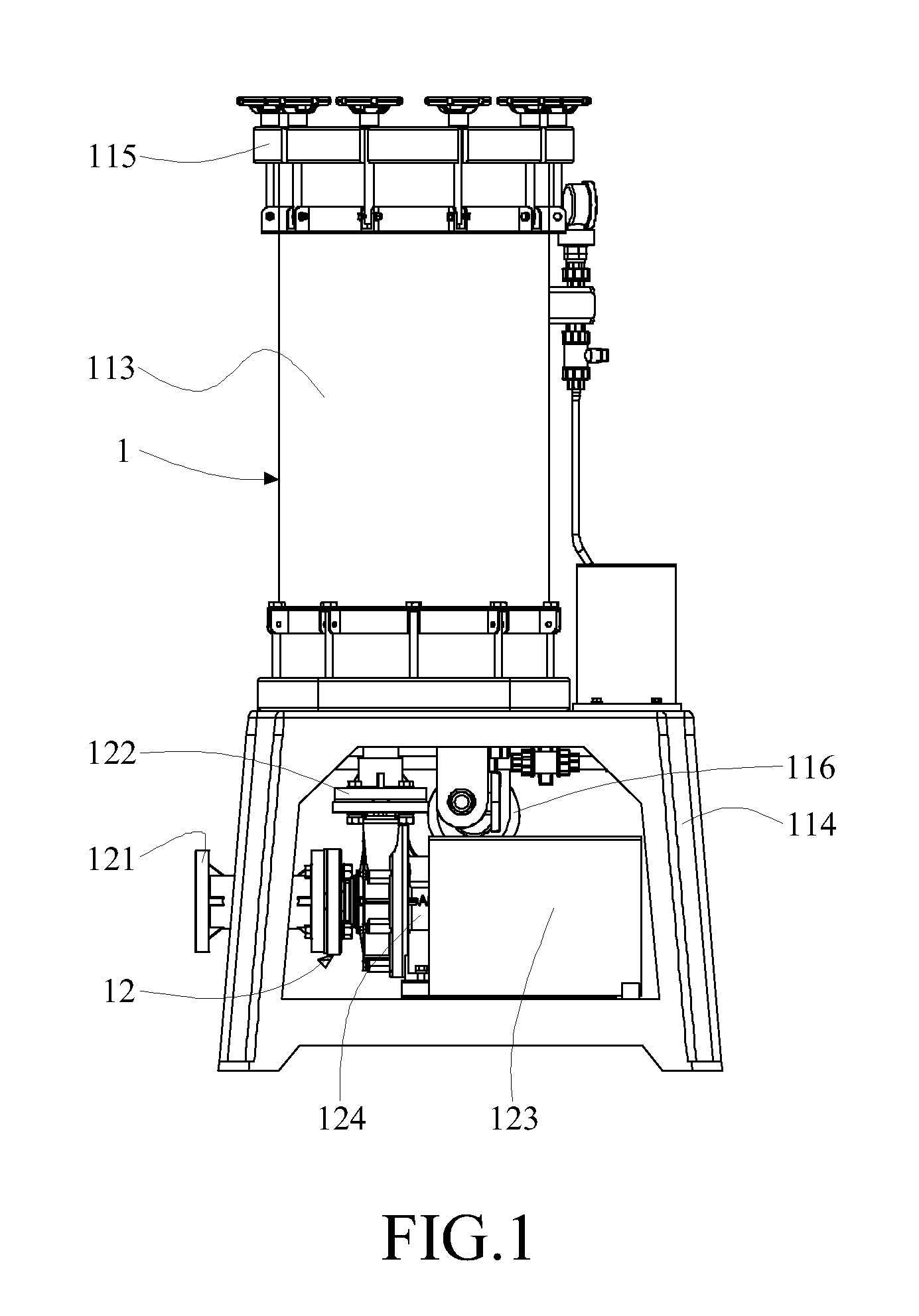

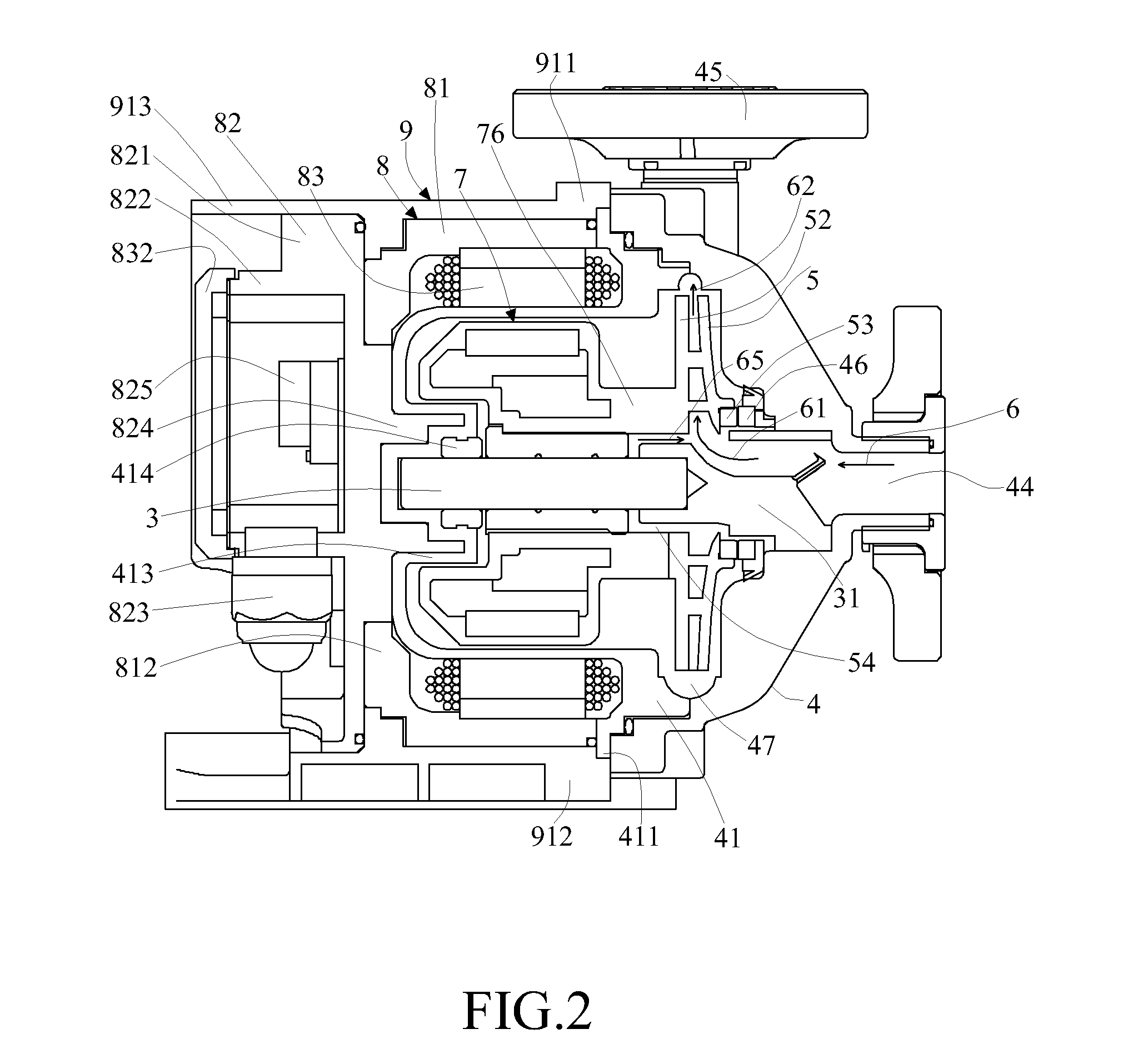

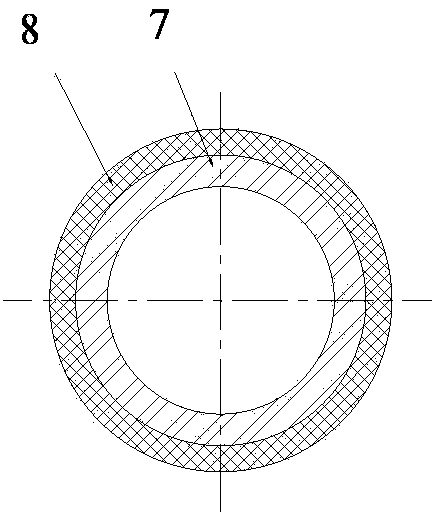

Permanent magnet canned motor pump with corrosion-protection housing

ActiveUS20130115118A1Avoid corrosionPrevent leakagePump componentsEngine fuctionsCompound (substance)Engineering

A permanent magnet canned motor pump features in its corrosion-protection housing which comprises a reinforced bracket, motor casing and a motor rear casing. The reinforced bracket is made of corrosion-resistance plastic and the motor casing and the motor rear casing are made of aluminum alloy. Accordingly, the corrosion-protection housing is capable of preventing the corrosion of the chemical liquid to the aluminum alloy components. Beside, the permanent magnet canned motor pump provides a heat dissipation mechanism while meets the structural need of the corrosion-protection housing, so that the motor can dissipate heat in a sufficient rate.

Owner:ASSOMA

Mobile product retail system and methods thereof

InactiveUS8485285B2Reduce heat transfer rateMaintain temperatureAuxillary drivesRefrigerated goods vehicleElectricityTemperature control

A vehicle for transporting or vending refrigerated product having a peripheral body extending vertically from the supporting surface, the peripheral body having a driver area, retail area, and cooling area, a bulk head for dividing the retail area from the cooling area, an auxiliary power system for powering at least one electrical component, having a battery bank and a charging mechanism, the charging mechanism having a vehicle charging system, shore power charging system, and solar array charging system, the charging mechanism imparting electrical charge to the battery bank, where the electrical component is a temperature control system for maintaining the temperature of the cooling area within a desired temperature range.

Owner:FERRIGNI MAX

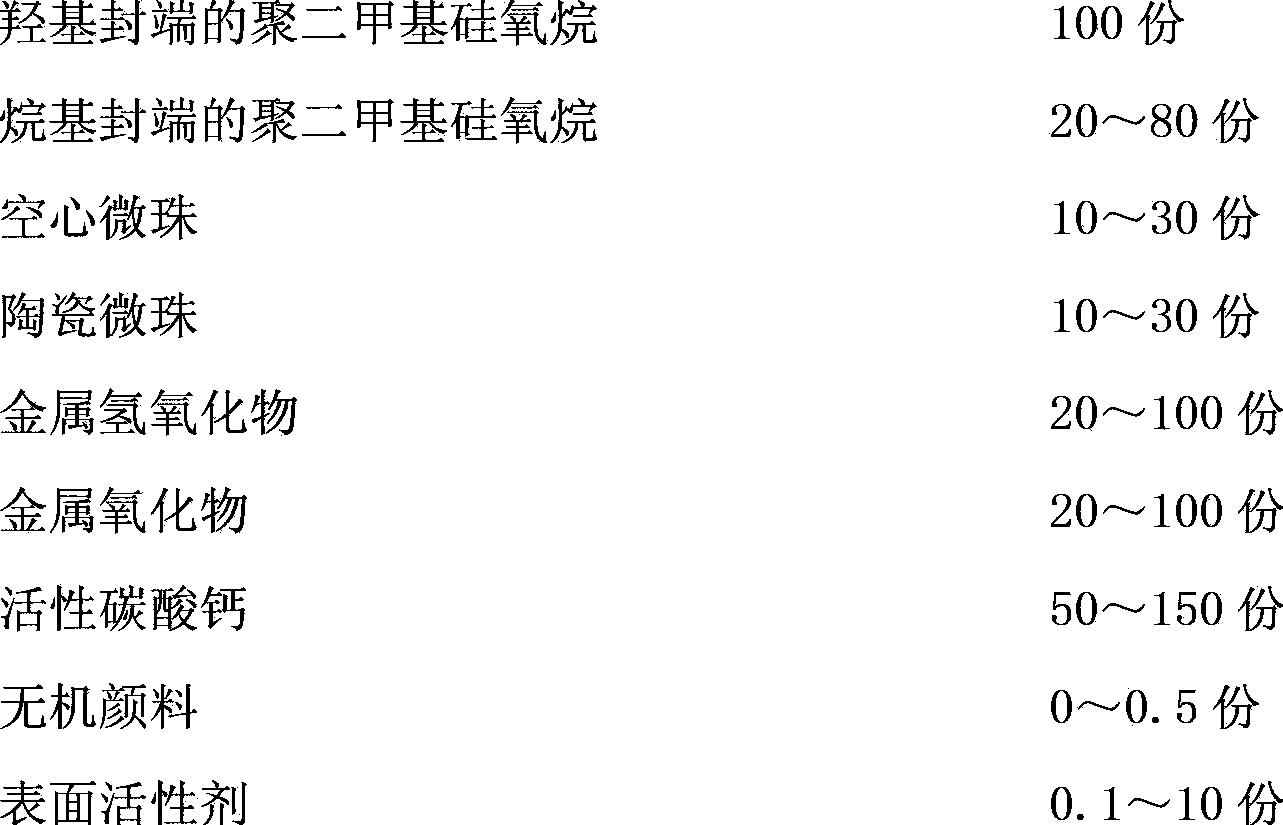

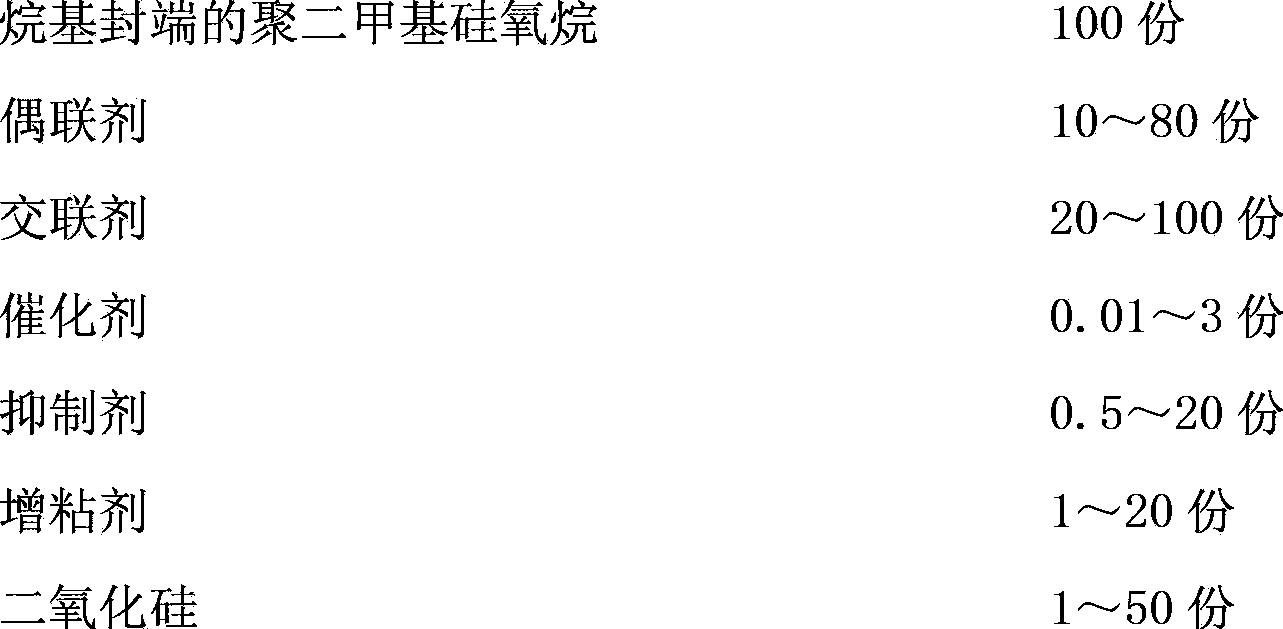

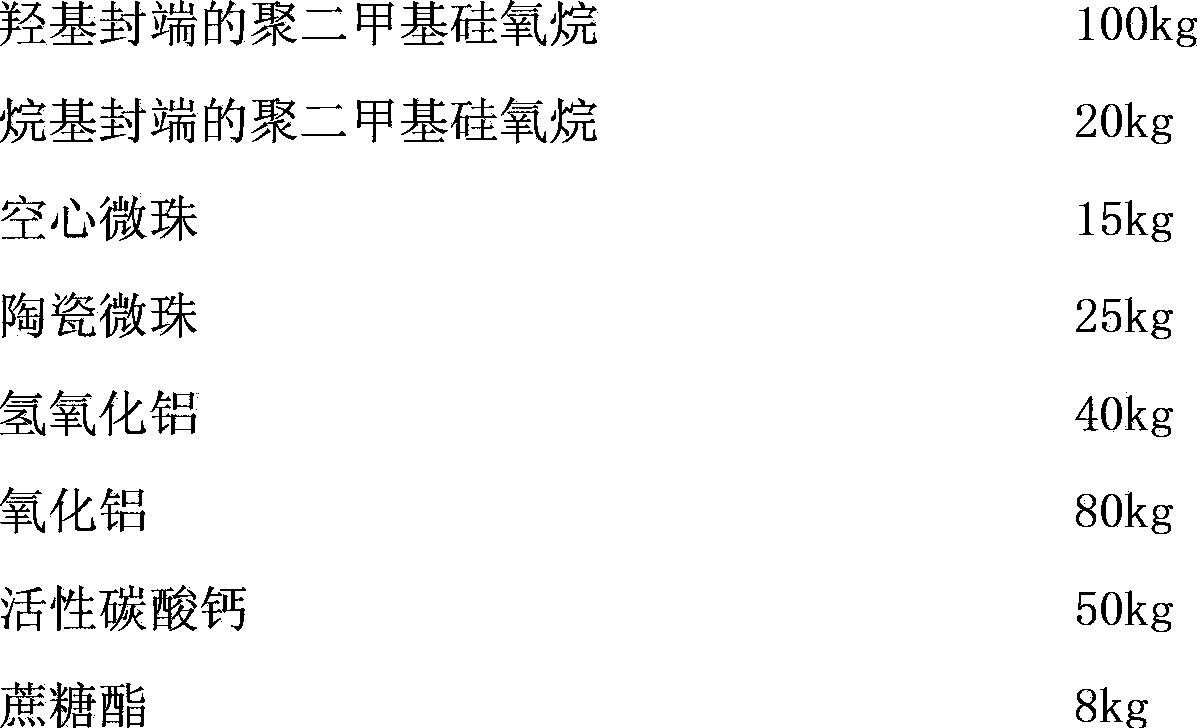

Double-component silicone structural sealant for heat mirror hollow glass and preparation method thereof

ActiveCN103820072AIncreased crosslink depthFast bondingNon-macromolecular adhesive additivesCross-linkMicrosphere

The invention discloses a double-component silicone structural sealant for heat mirror hollow glass and a preparation method of the sealant. The sealant comprises a component A and a component B, wherein the component A comprises hydroxyl-terminated polydimethylsiloxane, alkyl-terminated polydimethylsiloxane, hollow microsphere, ceramic microbead, metal hydroxide, metal oxide, activated calcium carbonate, inorganic pigment and a surfactant; the component B comprises alkyl-terminated polydimethylsiloxane, a coupling agent, a cross-linking agent, a catalyst, an inhibitor, a thickening agent, and silicon dioxide. The preparation method of the sealant comprises the following steps: 1) taking each ingredient in the component A to be mixed uniformly under the vacuum condition; 2) taking each ingredient in the component B to be mixed uniformly under the vacuum condition; 3) mixing the component A and the component B at room temperature according to the weight ratio of (8:1) to (20:1), and at last obtaining the sealant. The double-component silicone structural sealant is good in adhesiveness, high in curing speed, good in sealing performance, high in hardness and modulus, and excellent in thermal barrier effect, and suitable for sealing and bonding of heat mirror film, glass and metal materials etc.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

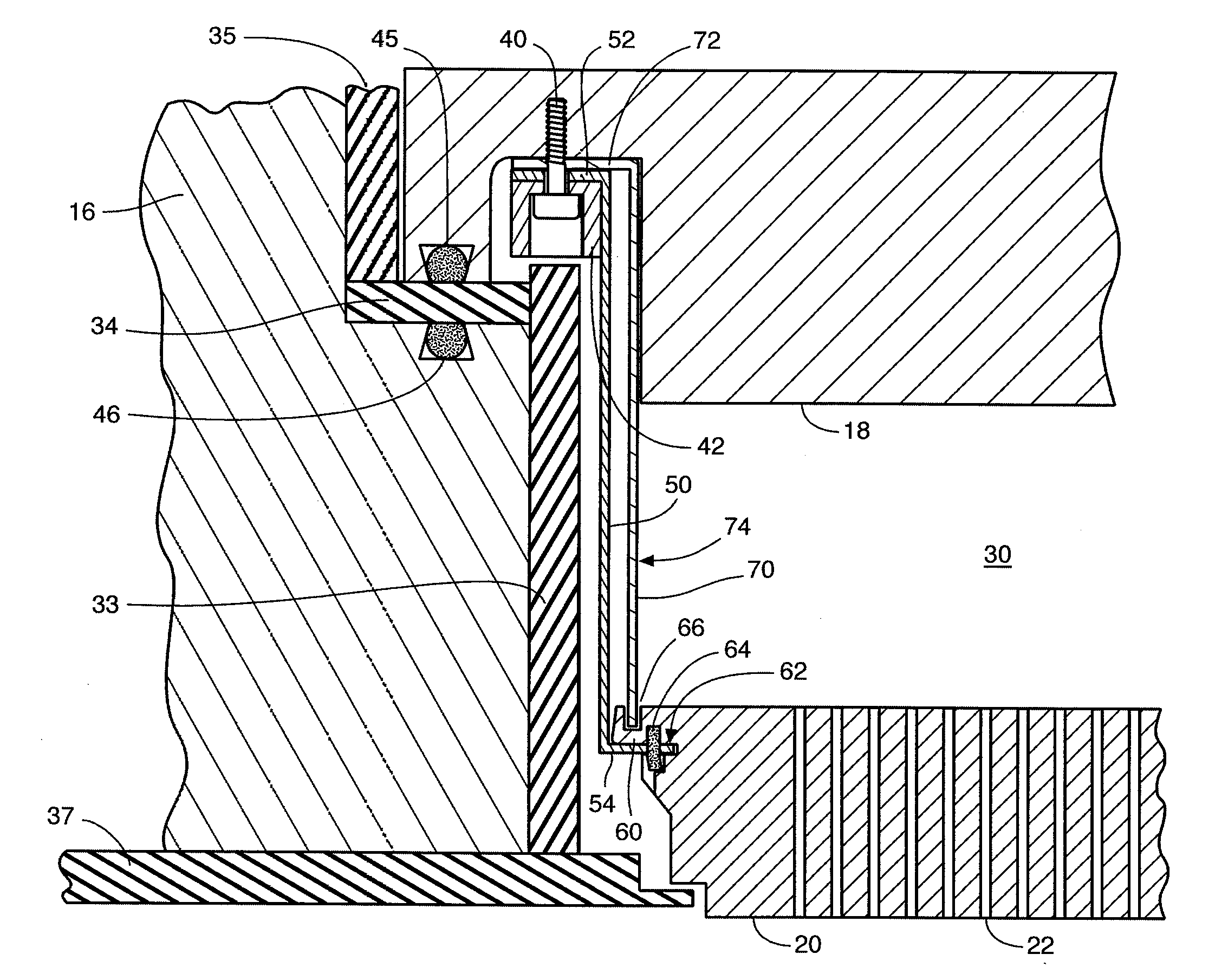

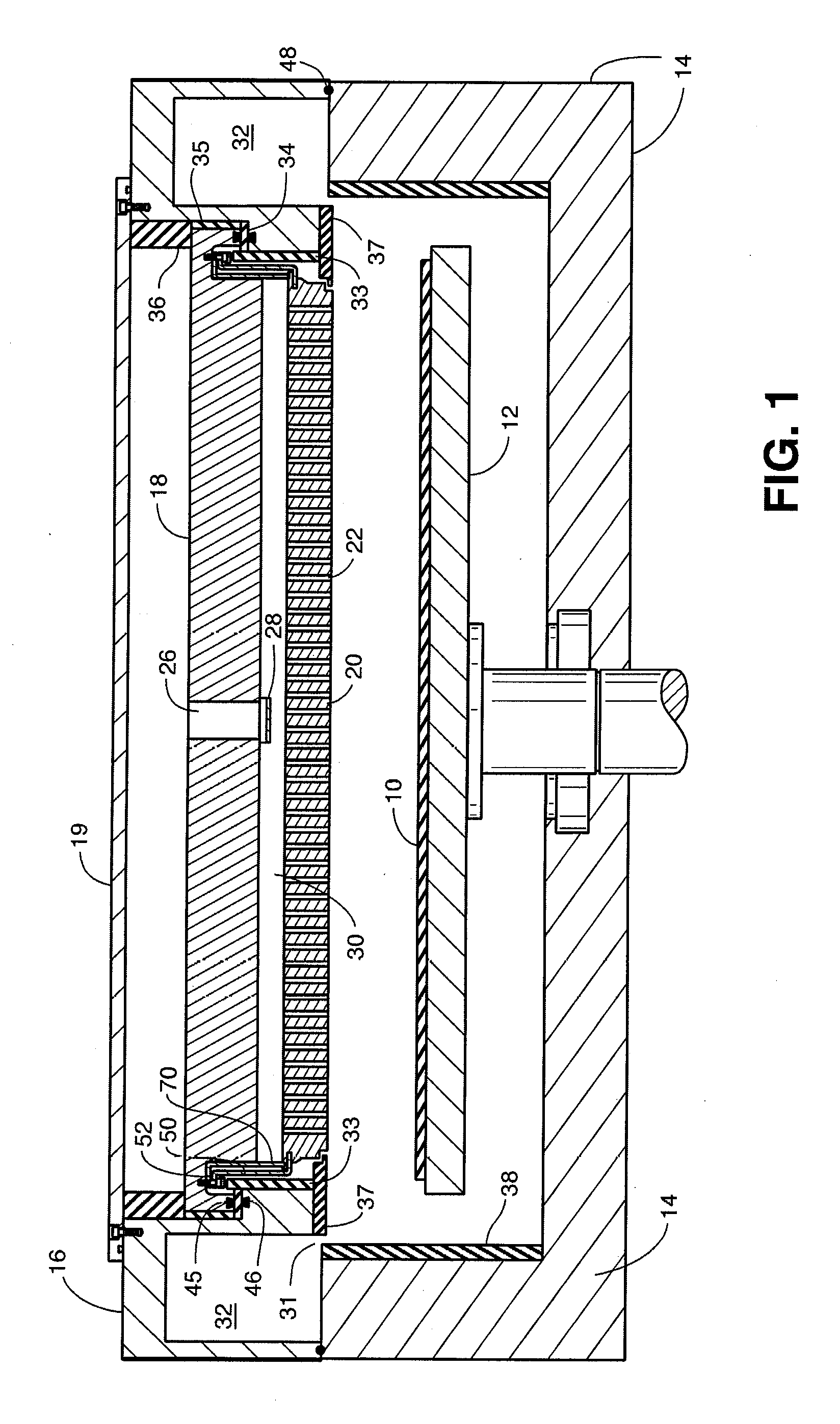

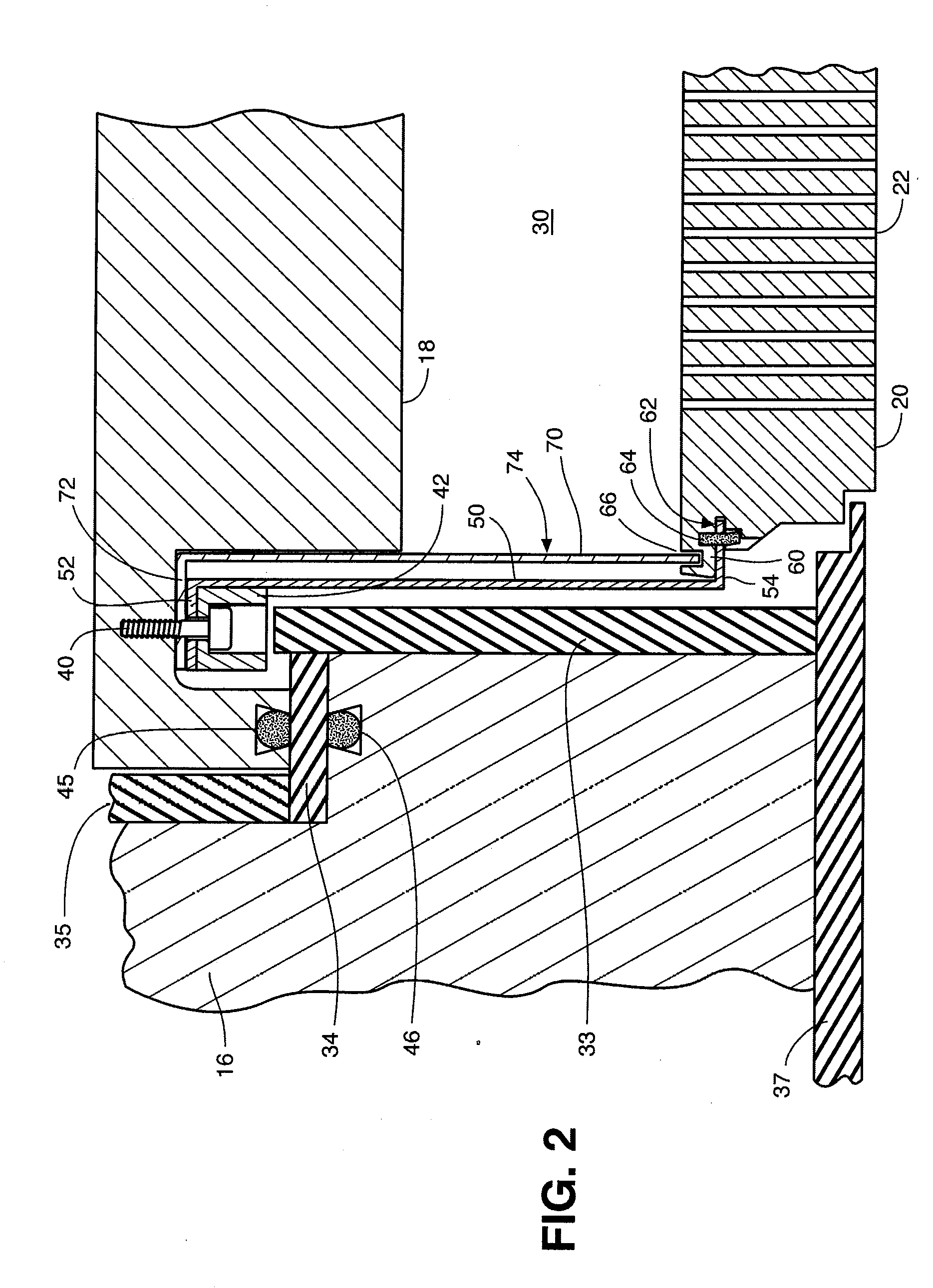

Suspension for showerhead in process chamber

ActiveUS20080099146A1Reduce thermal stressReduce heat transfer rateElectric discharge tubesSemiconductor/solid-state device manufacturingHermetic sealEngineering

Stress within a suspension wall for suspending a showerhead in a process chamber is ameliorated by one or more of: (1) Openings in the suspension wall that reduce exposure of the suspension wall to process gas or ambient atmosphere when the chamber lid is opened.(2) A substantially vertical arrangement of one or more rifts in the suspension wall which facilitate horizontal buckling or flexing of the suspension wall. (3) A plurality of suspension walls whose respective central portions are coplanar. (4) A gas sealing skirt that helps protect the suspension wall from direct contact with process gas. The gas sealing skirt is connected to either the chamber wall or the showerhead but is not connected to both.

Owner:APPLIED MATERIALS INC

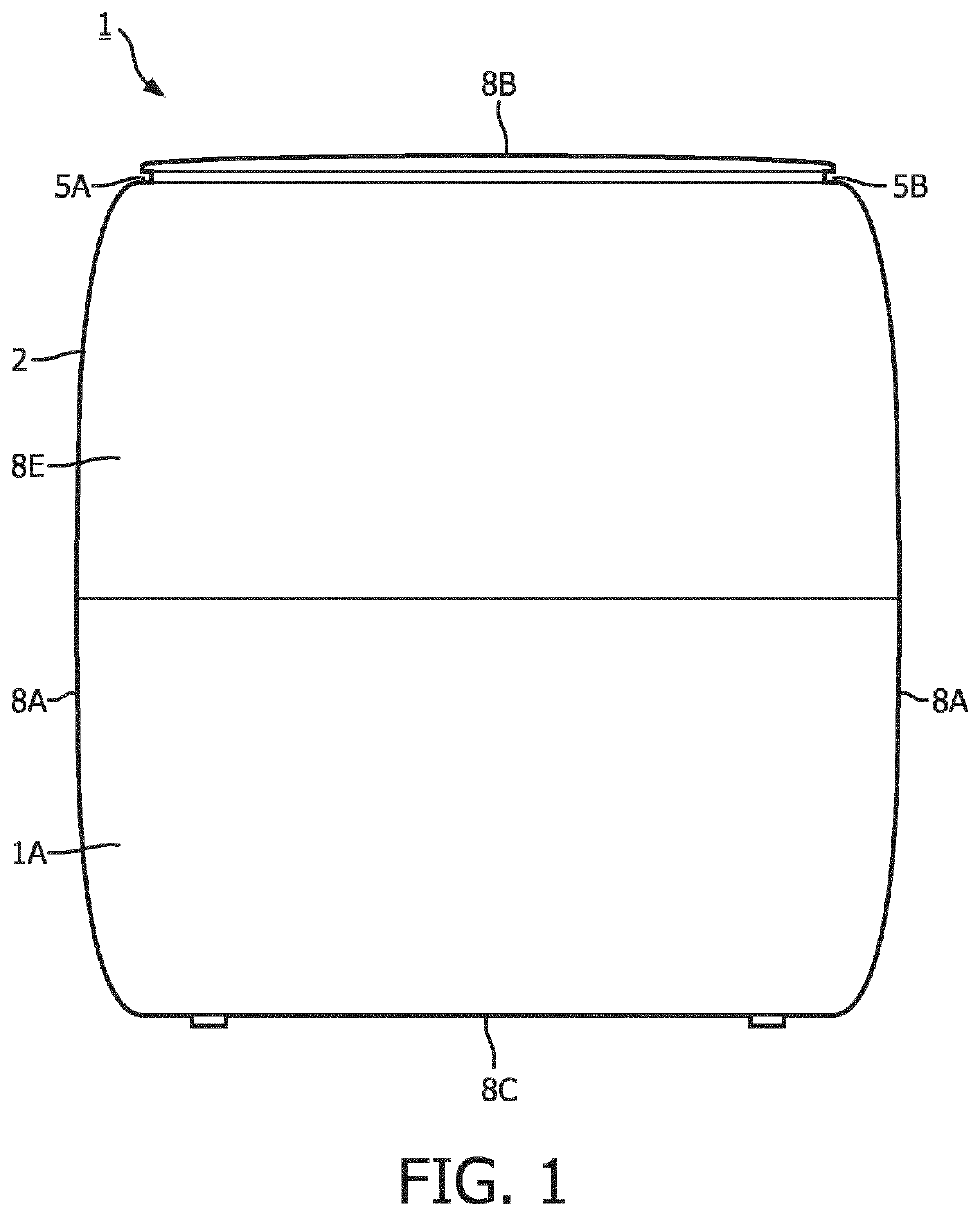

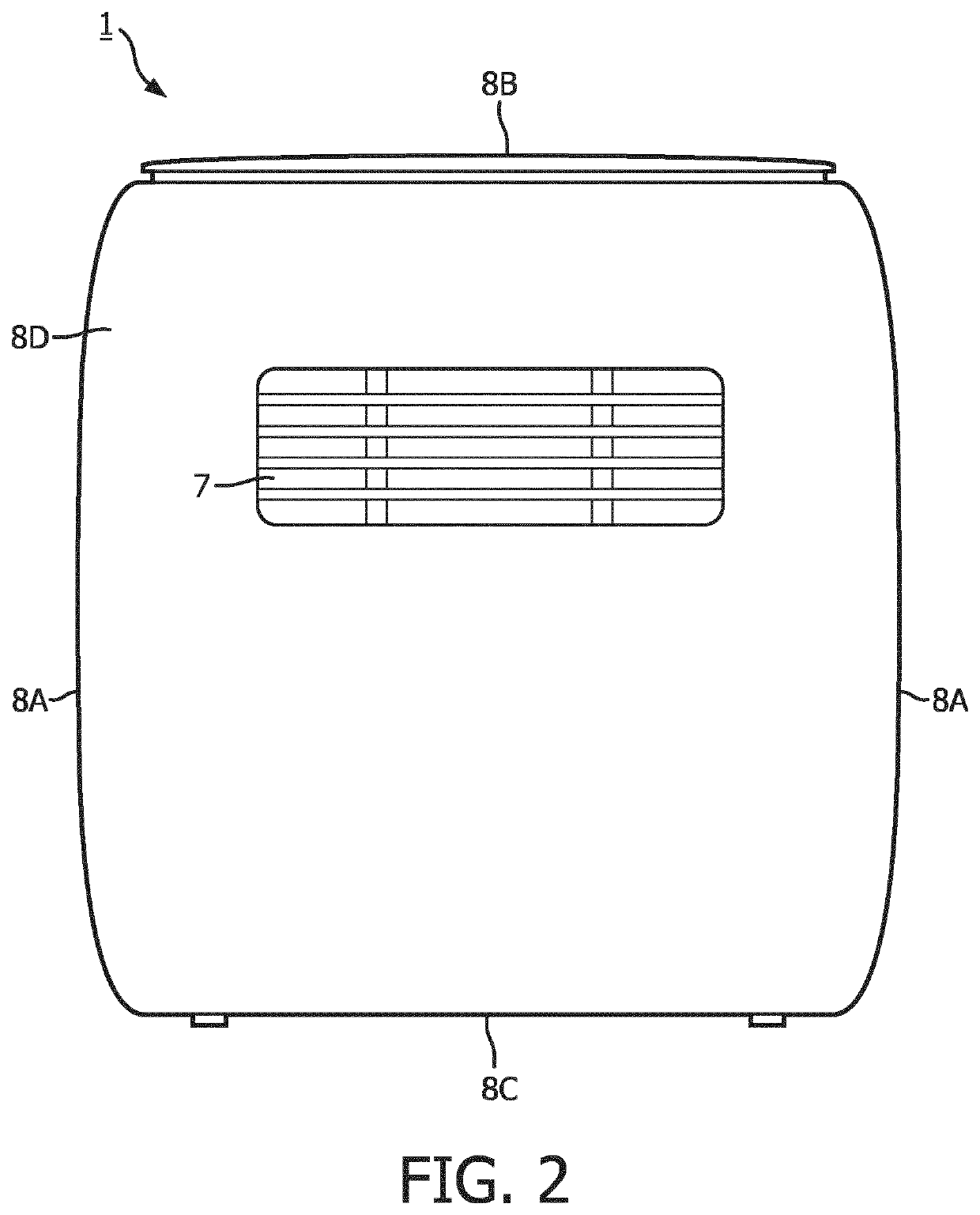

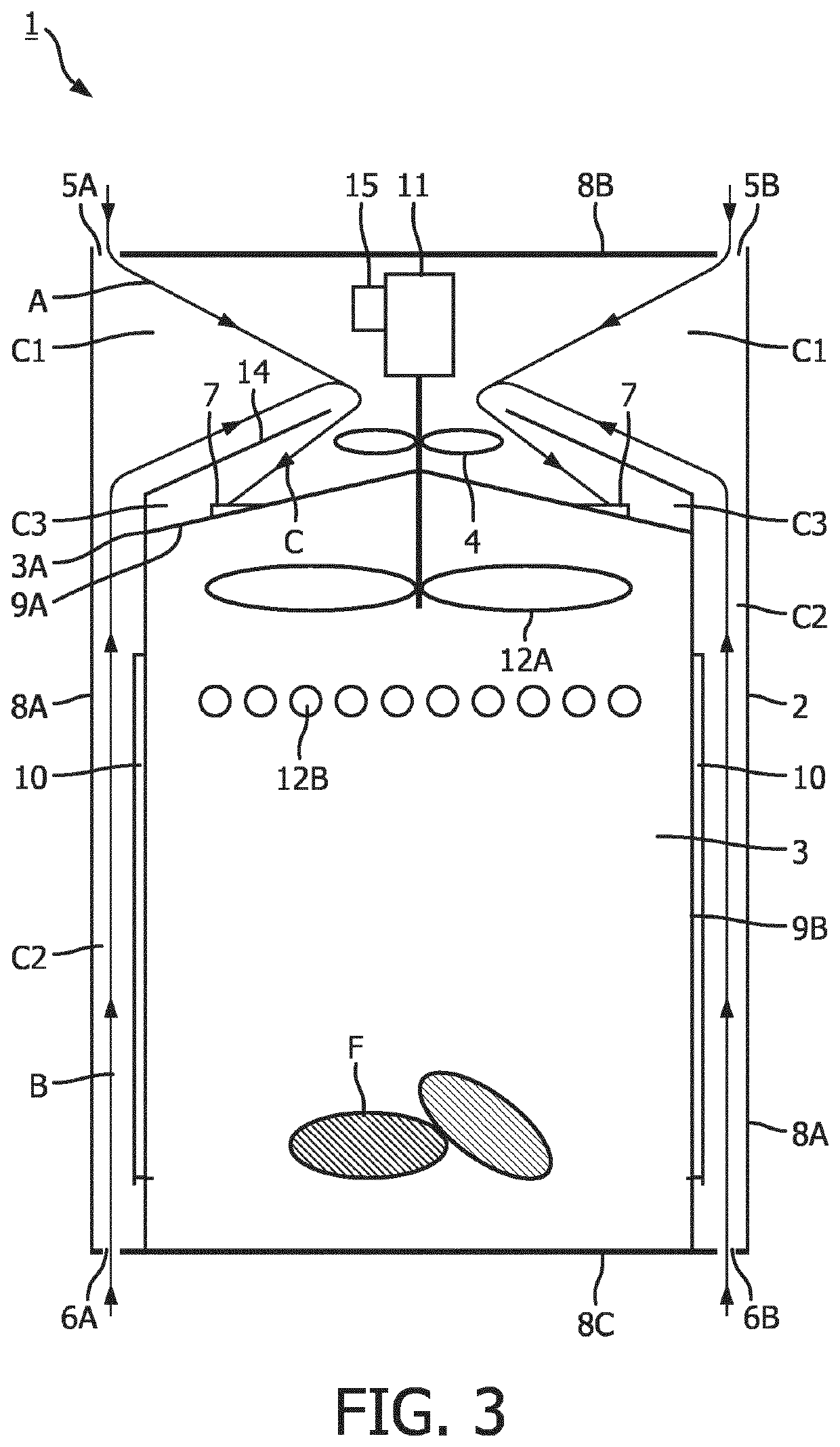

Apparatus for preparing food and comprising an air cooling system

ActiveUS10729282B2Reduce distanceReduce the cross-sectional areaFood scienceThermodynamicsEngineering

The present application relates to an apparatus (1) for preparing food. The apparatus (1) comprises a housing (2), and a food preparation chamber (3) arranged in the housing (2) and having an outer wall (3A). The apparatus (1) further comprises an air cooling system comprising a fan (4), a first air inlet (5A, 5B) arranged at an upper part of the housing (2), a second air inlet (6A, 6B) arranged at a lower part of the housing (2), and an air outlet (7). A first air channel (C1) is formed between said housing (2) and said outer wall (3 A) for fluidly connecting said first air inlet (5A, 5B) and said fan (4). A second air channel (C2) is formed between said housing (2) and said outer wall (3A) for fluidly connecting said second air inlet (6A, 6B) and said fan (4). A third air channel (C3) fluidly connects said fan (4) and said air outlet (7). The fan (4) is arranged to convey air through said first air channel (C1) between said first air inlet (5 A, 5B) and said fan (4), to convey air through said second air channel (C2) between said second air inlet (6A, 6B) and said fan (4), and to convey air through said third air channel (C3) between said fan (4) and said air outlet (7). The third air channel (C3) is arranged such that air passing through said third air channel (C3) is directed onto said outer wall (3 A) of the food preparation chamber (3) before being vented from said air outlet (7).

Owner:VERSUNI HLDG BV

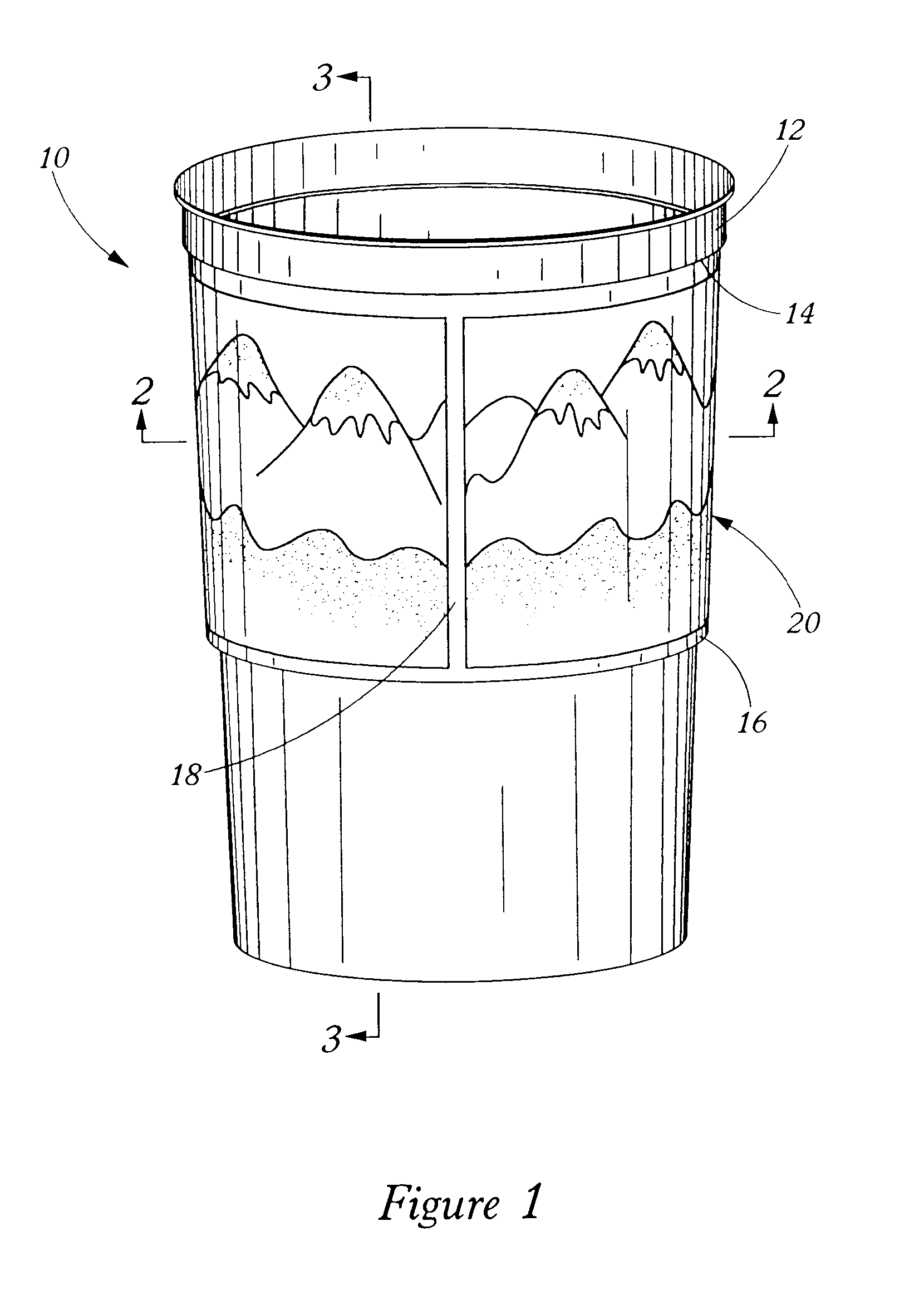

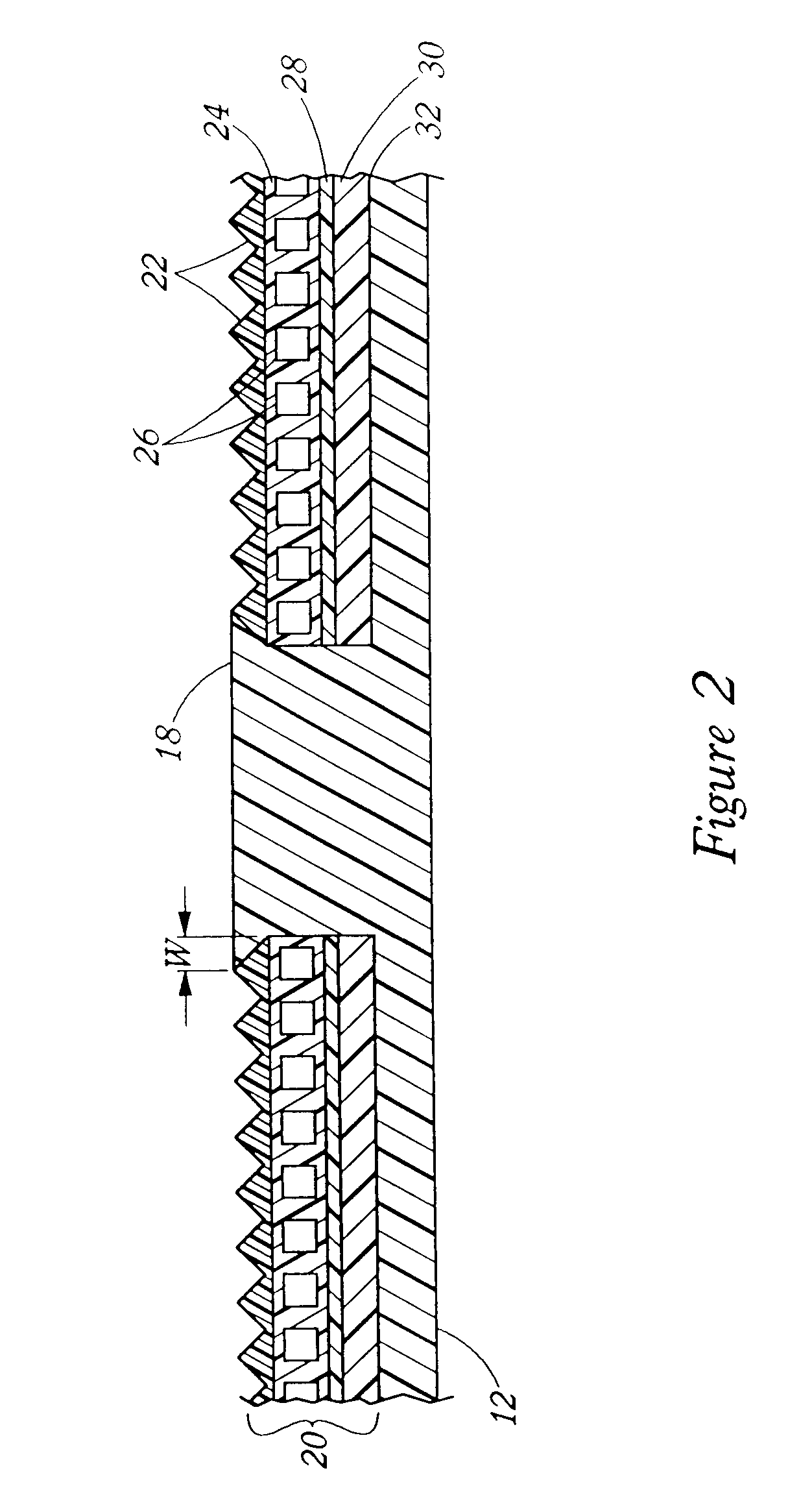

Method of bonding a lenticular lens sheet to plastic objects and objects made from same

InactiveUS20040157011A1Efficient and economicalHigh qualityEnvelopes/bags making machineryWrappers shrinkageLens materialsPolyester

Abstract of the Disclosure A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:REIL JENNIFER +4

High temperature-distributed load thermal strength test device for plane structure of high-speed missile aerobat

InactiveCN102721612AGuaranteed to workReduce heat transfer rateMaterial strength using tensile/compressive forcesSafety designTemperature load

The invention discloses a high temperature-distributed load thermal strength test device for a plane structure of a high-speed missile aerobat, which comprises a plane high-temperature heating unit, a high-speed missile plane test piece, a thermostability insulation thin layer, a temperature thermocouple, a computer, a water sac loader, flexible heat insulation materials, a steel stressing plate, a hydraulic pressure actuator, a loading link rod, a ceramic frame and a force transducer, a thermal environment with a temperature above 1,000 DEG C is generated by the plane high-temperature heating unit, and a flexible heat separation is carried out between the water sac loader which can generate distributed load and a heat source. According to the thermal strength test device, uniform high-temperature distributed load is implemented to the plane structure of the high-speed missile in the thermal environment with a temperature above 1,000 DEG C, and a high temperature load test method closer to the actual stressing state is provided for a safe design of the high-speed missile structure. The device has important application values on military engineering.

Owner:BEIHANG UNIV

Heat insulation super-weather-proof powder coating and preparation method and application thereof

ActiveCN103131294AHigh infrared reflectivityReduce heat transfer ratePowdery paintsEpoxy resin coatingsEpoxyFluorocarbon

The invention relates to a heat insulation super-weather-proof powder coating which comprises an epoxy resin particle system and a fluorocarbon resin particle system, wherein the epoxy resin particle system contains epoxy resin and a curing agent A, the fluorocarbon resin particle system contains fluorocarbon resin, a curing agent B and a heat insulation material. The ratio of parts by weight for the epoxy resin particle system and the fluorocarbon resin particle system is 6-4:4-6. The heat insulation super-weather-proof powder coating not only has good heat insulation, weather-proof and corrosion-resistant performance, but also can achieve self-layering after one-time coating, and is simple to construct.

Owner:NINGBO SOUTH SEA CHEM

Methods of manufacturing plastic objects having bonded lenticular lens-sheets

InactiveUS20070132122A1Quality improvementEfficient and economicalOptical articlesContainer/bottle contructionPolyesterBond interface

A method of fabricating plastic objects having an insert of Lenticular lens material integrally bonded or otherwise attached therein. In one embodiment, the method is used to fabricate a container, such as a conical cup, by first manufacturing or providing a sheet of Lenticular material comprising layers of lens material and optical ridges and grooves and an ink layer printed on the flat side of the lens material. To protect the ink from the heat of molten or moldable plastic during later plastic processing, a thermally protective substrate is attached or bonded to the ink layer by using adhesives to attach a plastic substrate or by coating the ink with coating materials that thermally protect the ink from high temperatures. In one embodiment, the protective substrate is applied in a two step process of first placing a plastic hot melt onto a polyester or other material release liner and, after cooling of the hot melt, using heat and pressure to laminate or bond the hot melt plastic to the ink and then removing the liner. Lenticular inserts are cut out of the Lenticular material sheets and the inserts are positioned within a mold where the container is formed by injection, blow, or other molding process. In this step, the substrate acts as a bonding surface as it contacts the molten plastic, melts, and then cools forming a bonding interface with the plastic used to form the container.

Owner:TRAVEL TAGS

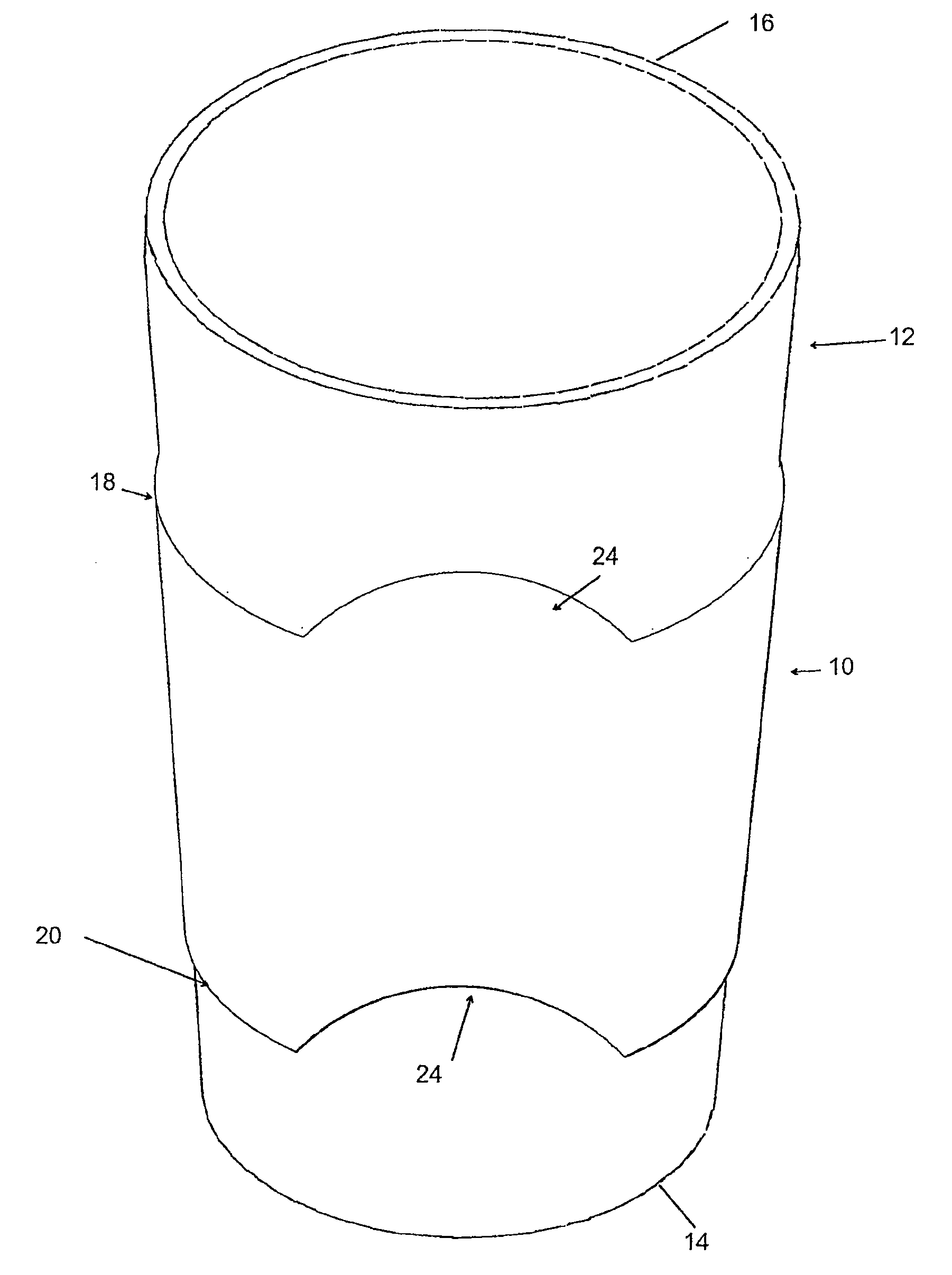

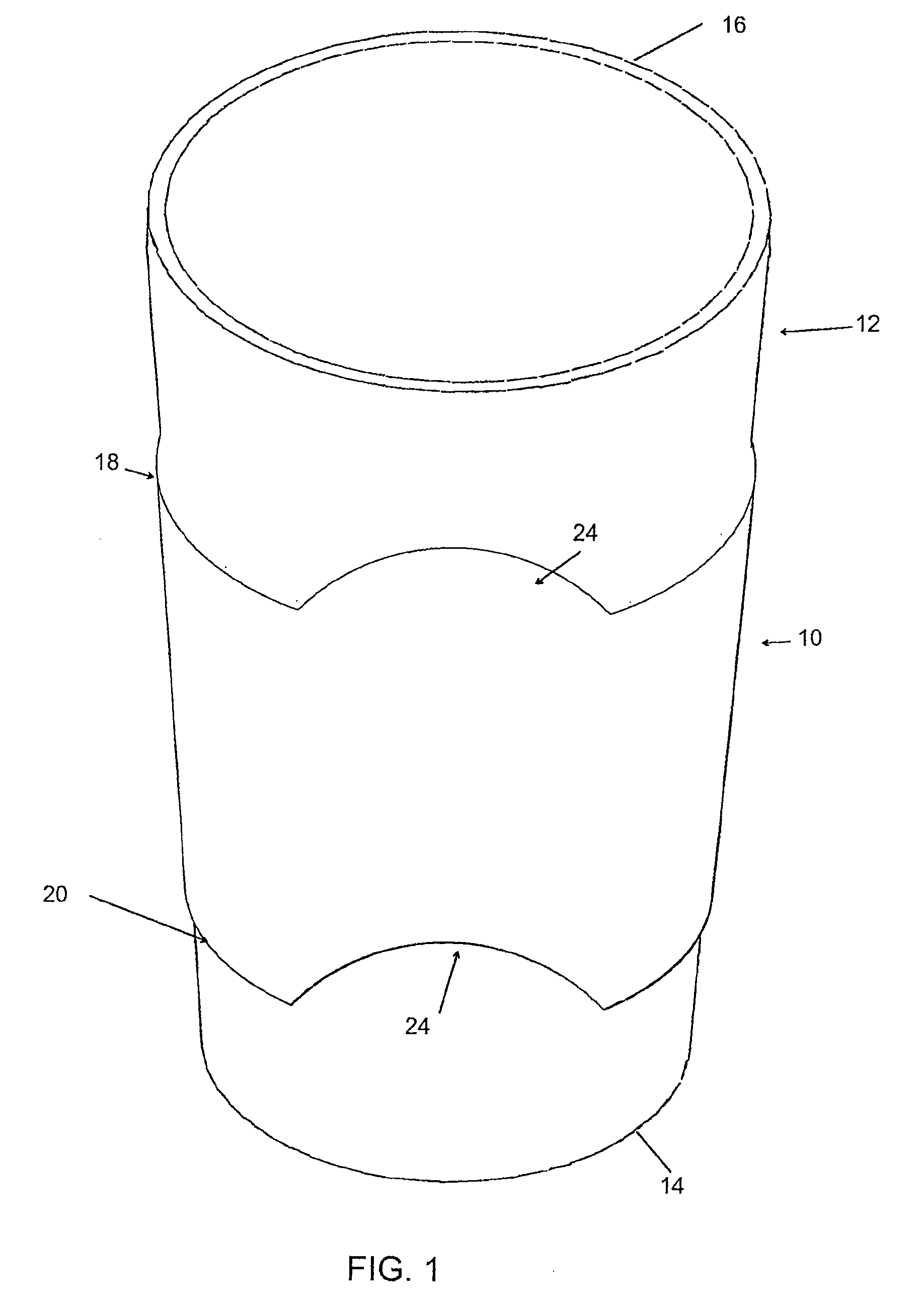

Protective sleeve

InactiveUS20100019023A1Supplement thermal insulating propertyReduce heat transfer rateMechanical working/deformationBoxes/cartons making machineryManufactured materialEngineering

A sleeve is disclosed having a unique arch-like shape that facilitates manufacturing material efficiency and therefore reduces material costs and environmental waste. A blank for a sleeve and a method of making a sleeve are also disclosed. The sleeve, when unassembled and laid flat, is a blank with top and bottom edges. The top and bottom edges have an arch-like formation created by peaks and troughs.

Owner:LBP MANUFACTURING INC

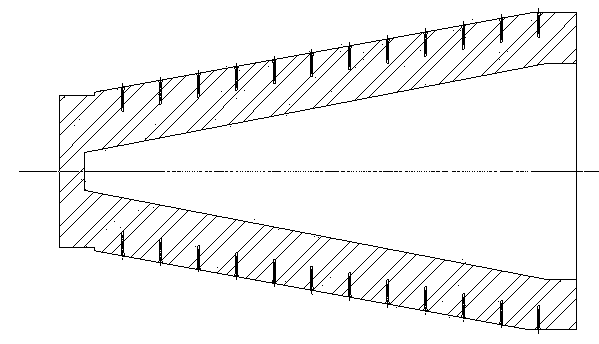

Conical cavity type high-energy laser total-absorption energy meter

ActiveCN103630236AReduce heat transfer rateReduce laser power densityPhotometry using electric radiation detectorsData acquisitionConical cavity

The invention provides a conical cavity type high-energy laser total-absorption energy meter. The energy meter comprises an absorber, a thermocouple sensor, an absorber support, a barrel-shaped insulator, a data acquiring system and a shell, wherein the absorber is made of a high-purity graphite material and has a cone structure; a conical hollow cavity is formed in the absorber; the absorber support is fixedly connected with the shell in a threaded manner; the middle and the bottom of a cone of the absorber are arranged on the support; the insulator is arranged in the shell; the thermocouple sensor is adhered to counter bores in the surface of the absorber; the distance between the bottom of each counter bore in the absorber and the outer surface of the absorber is 40% of the thickness of the wall of the absorber; the counter bores are equidistantly formed along the cone busbar direction and the direction perpendicular to a busbar; and the distance between two optional counter bores along the cone busbar direction is smaller than the length of the cone busbar of the absorber by 10%. By using the conical cavity type high-energy laser total-absorption energy meter, the high-energy laser energy measuring precision can be obviously improved; and the testing capability of the high-energy laser total-absorption energy meter is improved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

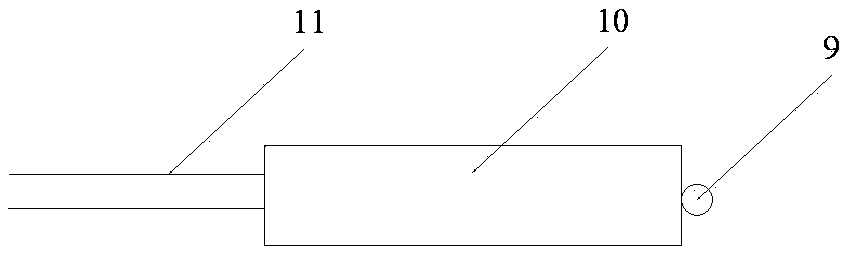

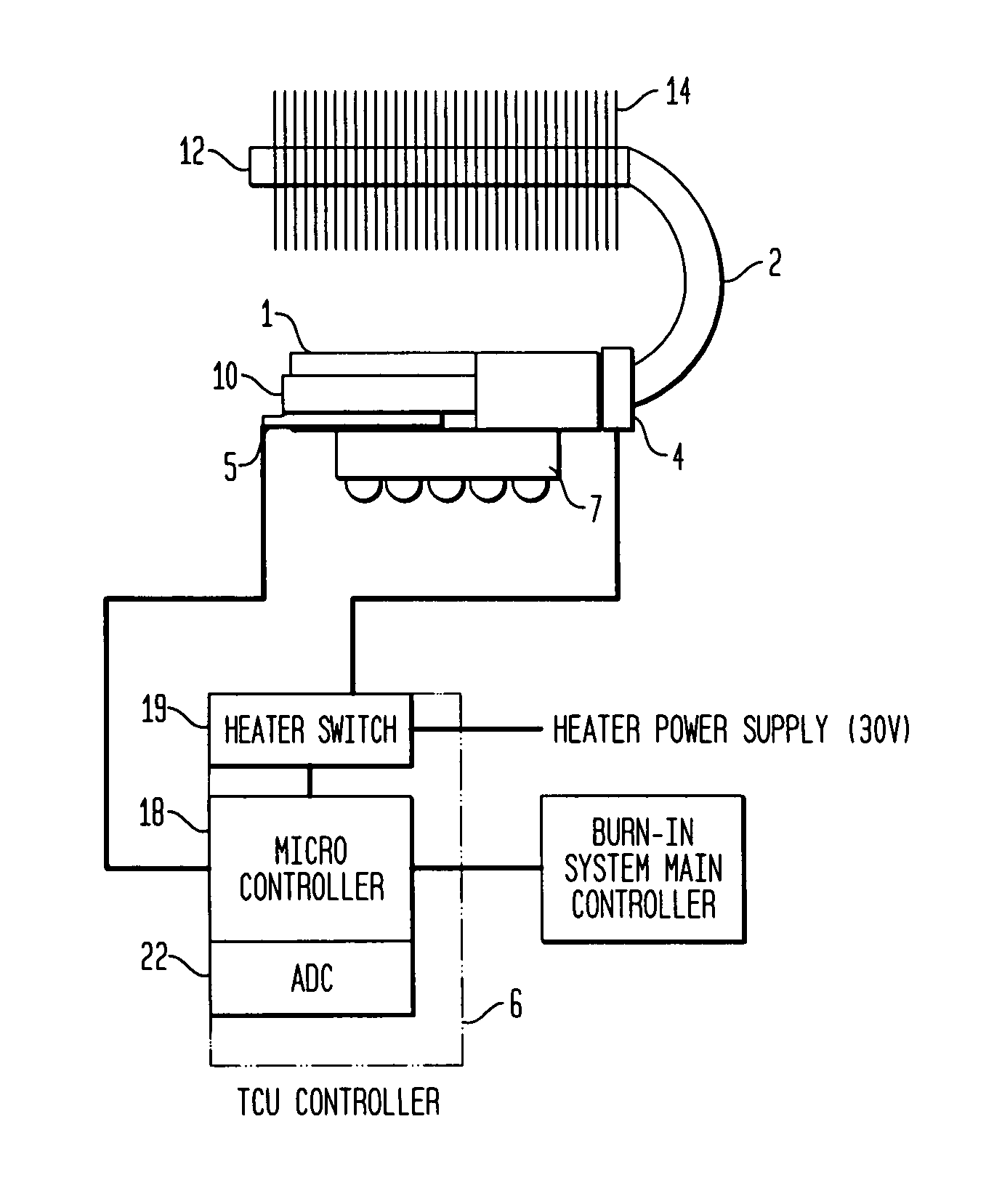

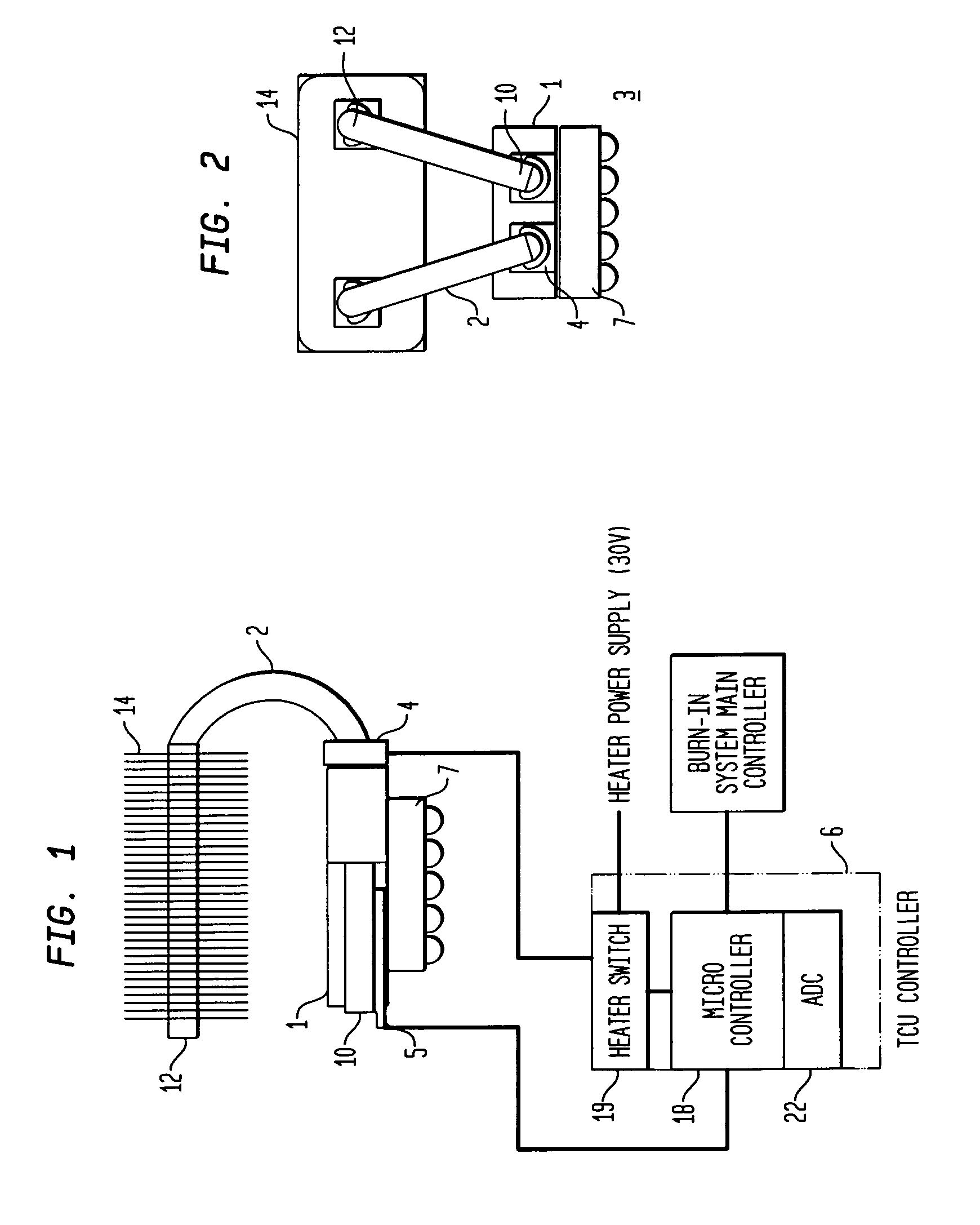

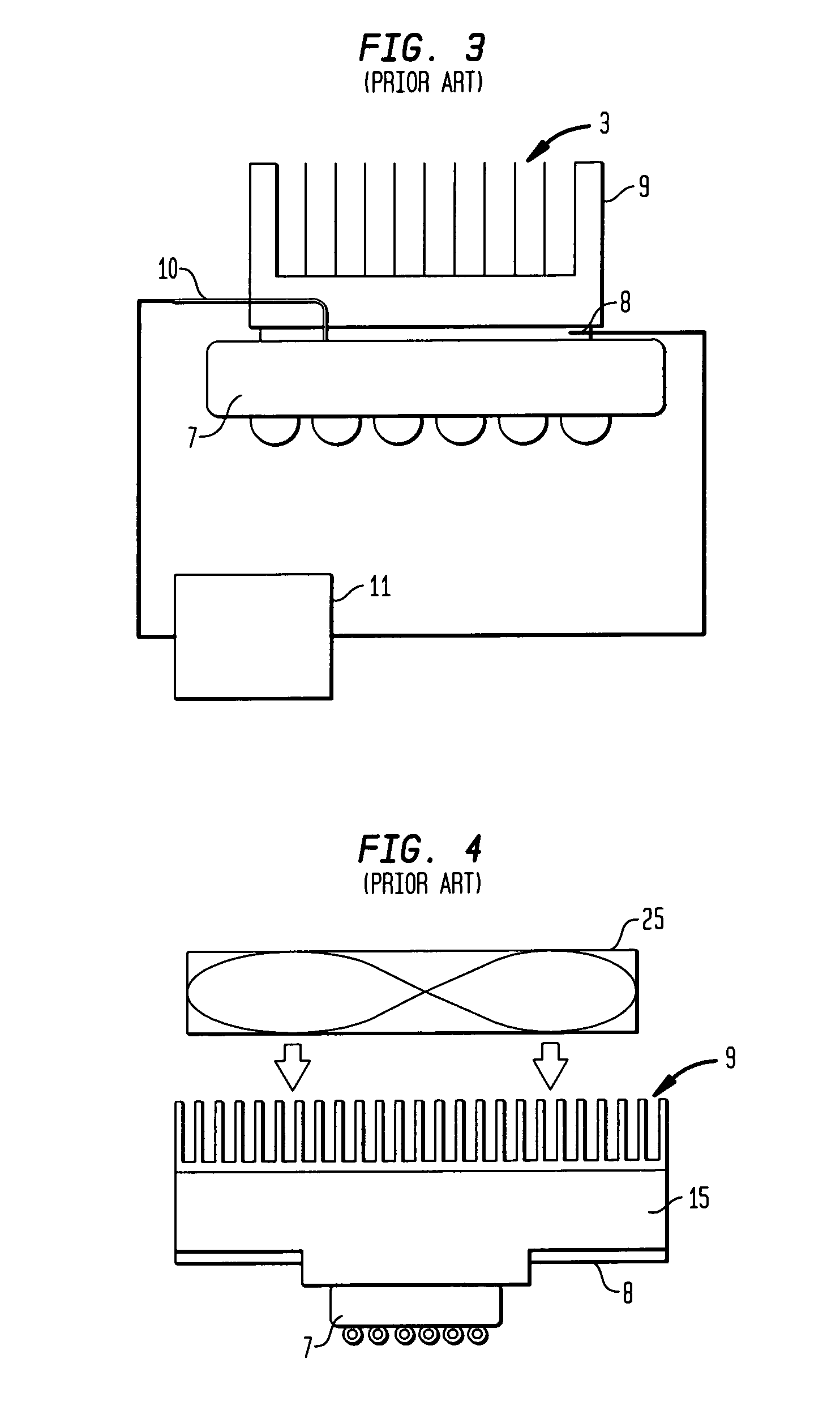

Thermal control unit for semiconductor testing

InactiveUS8274300B2Reduce probabilityReduce heat transfer rateSpace heating and ventilation safety systemsLighting and heating apparatusEngineeringSemiconductor

A thermal control unit with a heat pipe that conducts heat away from a device under test during burn-in. The heat pipe has a heater that allows control of the rate at which heat is transferred from the DUT to the heat pipe. A sensor and controller are provided to control the heat in response to the measured temperature of the DUT. The sensor and controller control the heater to maintain the surface temperature of the DUT within a specified range.

Owner:KES SYST & SERVICE 1993 PTE

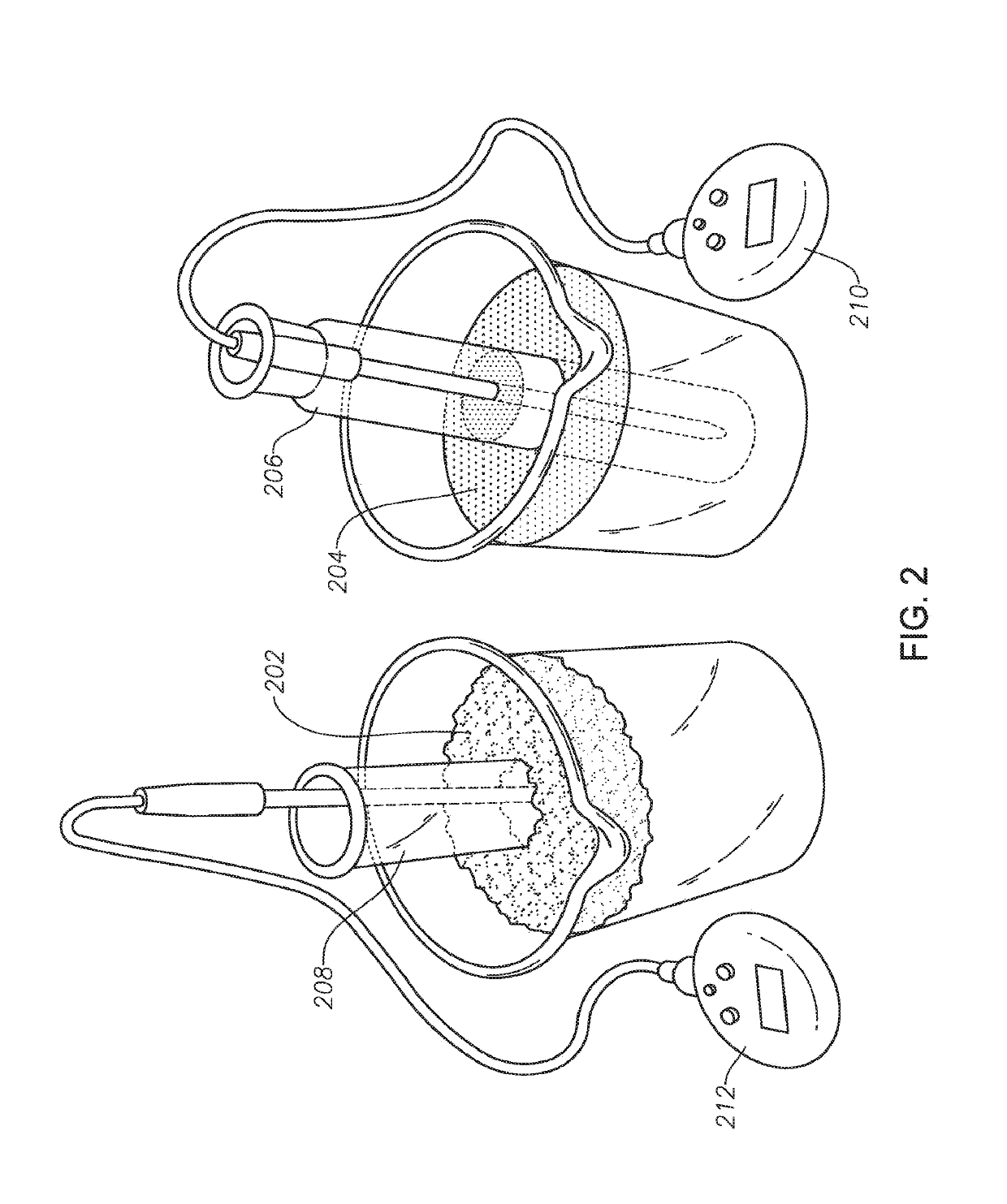

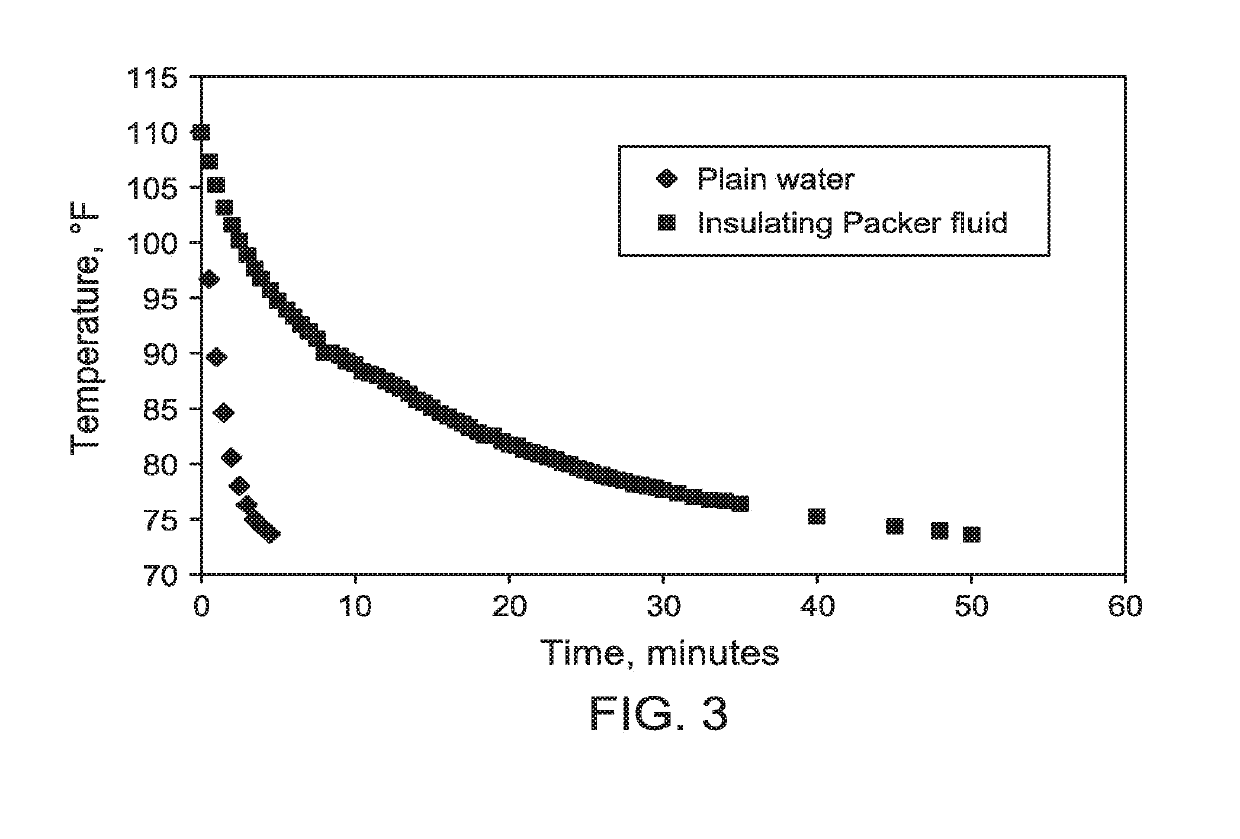

Nanosilica Dispersion for Thermally Insulating Packer Fluid

ActiveUS20190249067A1Low inherent thermal conductivityEasy to handleInsulationDrilling compositionEngineeringSilicon dioxide

A method to control a heat transfer profile in a defined space, the method comprising the steps of introducing a thermally insulating packer fluid into the defined space such that the thermally insulating packer fluid forms a gelled solid and reduces a rate of heat transfer through the defined space as compared to a prior rate of heat transfer through the defined space before introducing the thermally insulating packer fluid, where the thermally insulating packer fluid comprises an acidic nanosilica dispersion and a polyamine.

Owner:SAUDI ARABIAN OIL CO

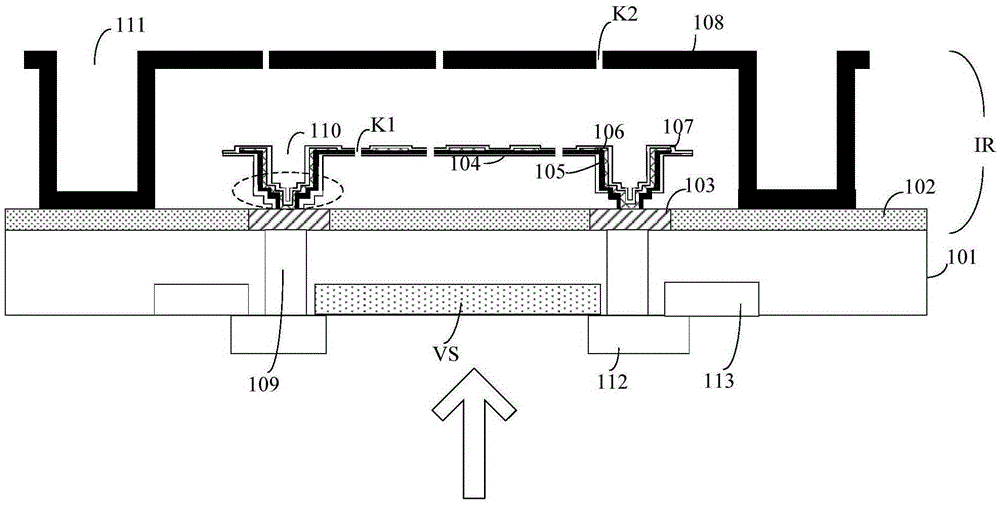

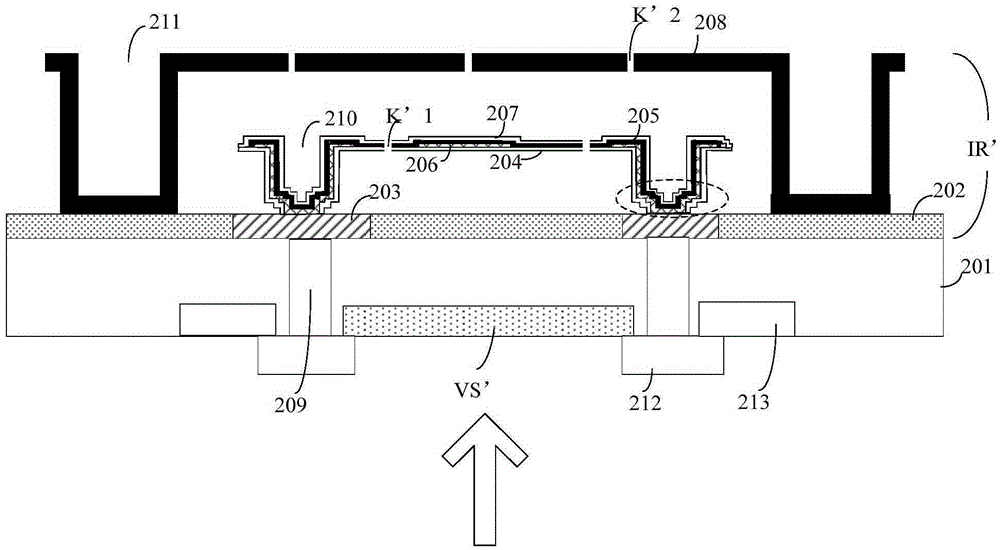

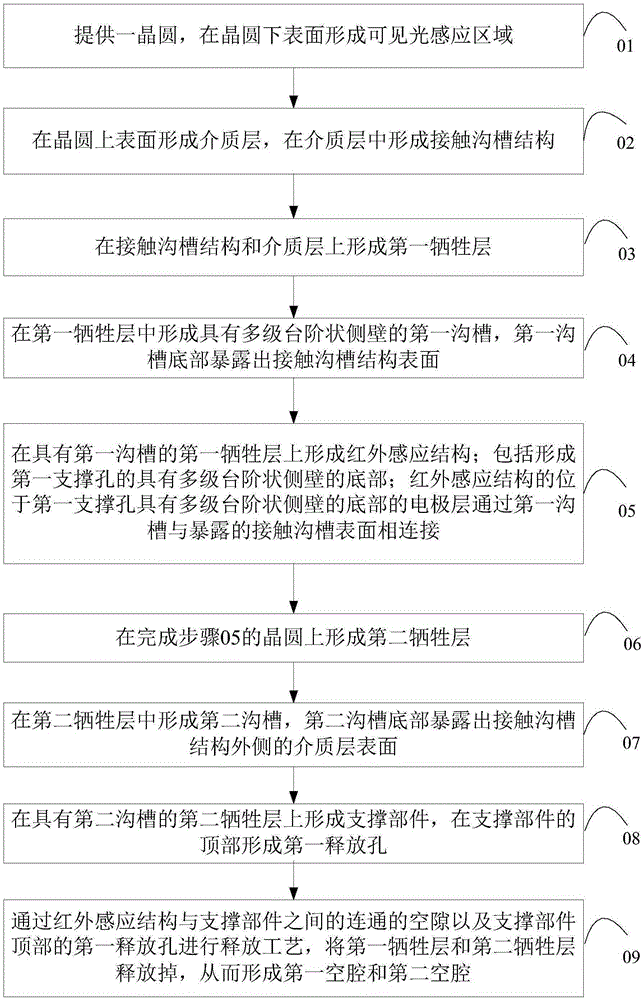

Hybrid imaging detector pixel structure with step supports and preparation method of hybrid imaging detector pixel structure

ActiveCN105206637AQuality improvementReduce volumeRadiation controlled devicesPhysicsVisible light sensing

The invention provides a hybrid imaging detector pixel structure with step supports and a preparation method of the hybrid imaging detector pixel structure. The hybrid imaging detector pixel structure comprises a wafer, a visible light induction region located at the lower surface of the wafer, an infrared induction region located at the upper surface of the wafer and a conversion unit which is used for calculating electric signals outputted by the visible light induction region and the infrared induction region and converting the electric signals into an image; the infrared induction region includes contact trench structures which are located in a dielectric layer, infrared induction structures which are provided with multiple-step-shaped side walls, and a supporting component which is located at around the infrared induction structures and does not contact with the infrared induction structures; a first cavity is formed between the infrared induction structures and the upper surface of the dielectric layer; the bottom of the supporting component is connected with the dielectric layer; release holes are formed in the top of the supporting component; the inner surface of the supporting component is provided with an infrared reflective material or the whole supporting component is made of an infrared reflective material; and a second cavity is formed between the support component and the infrared induction structures.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

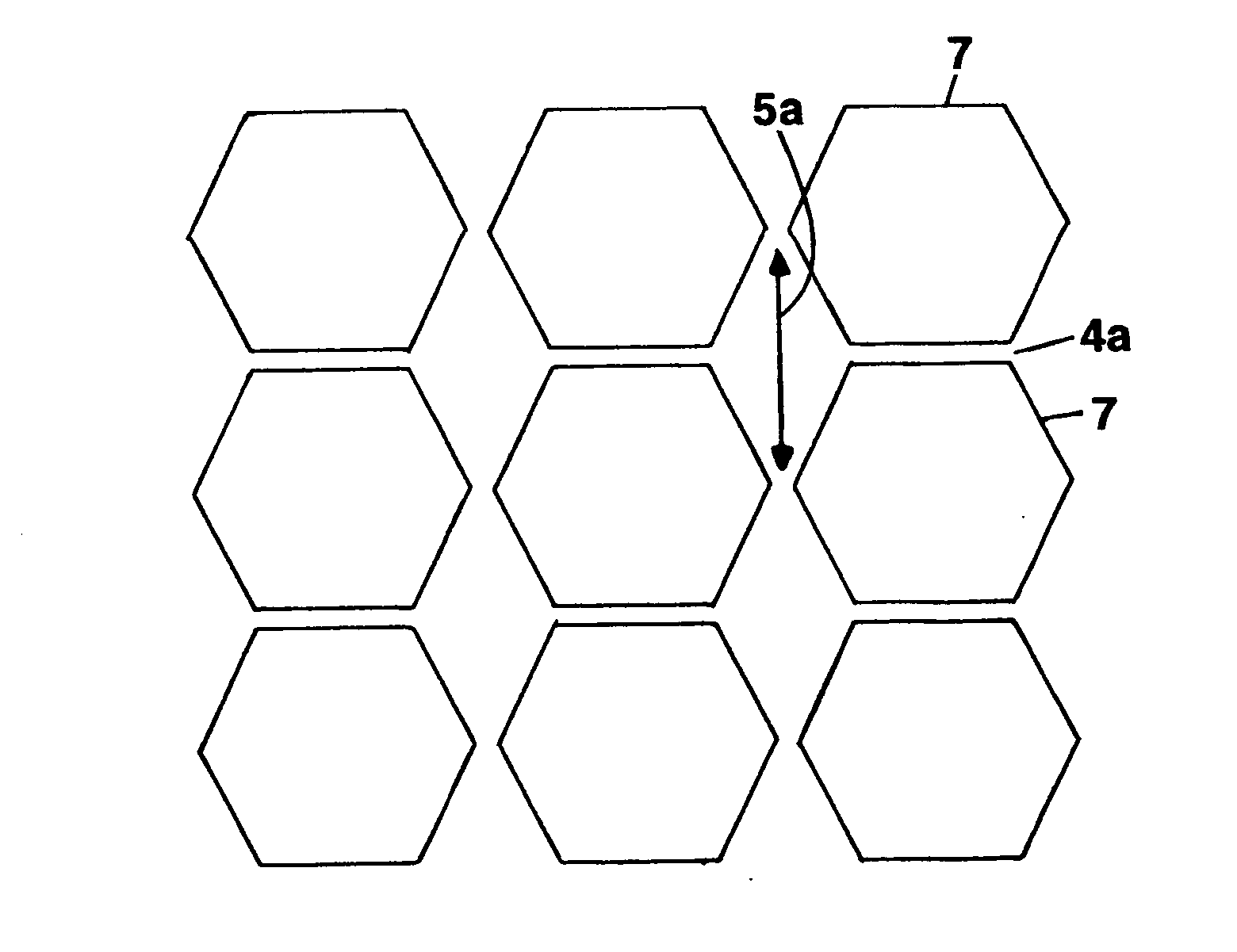

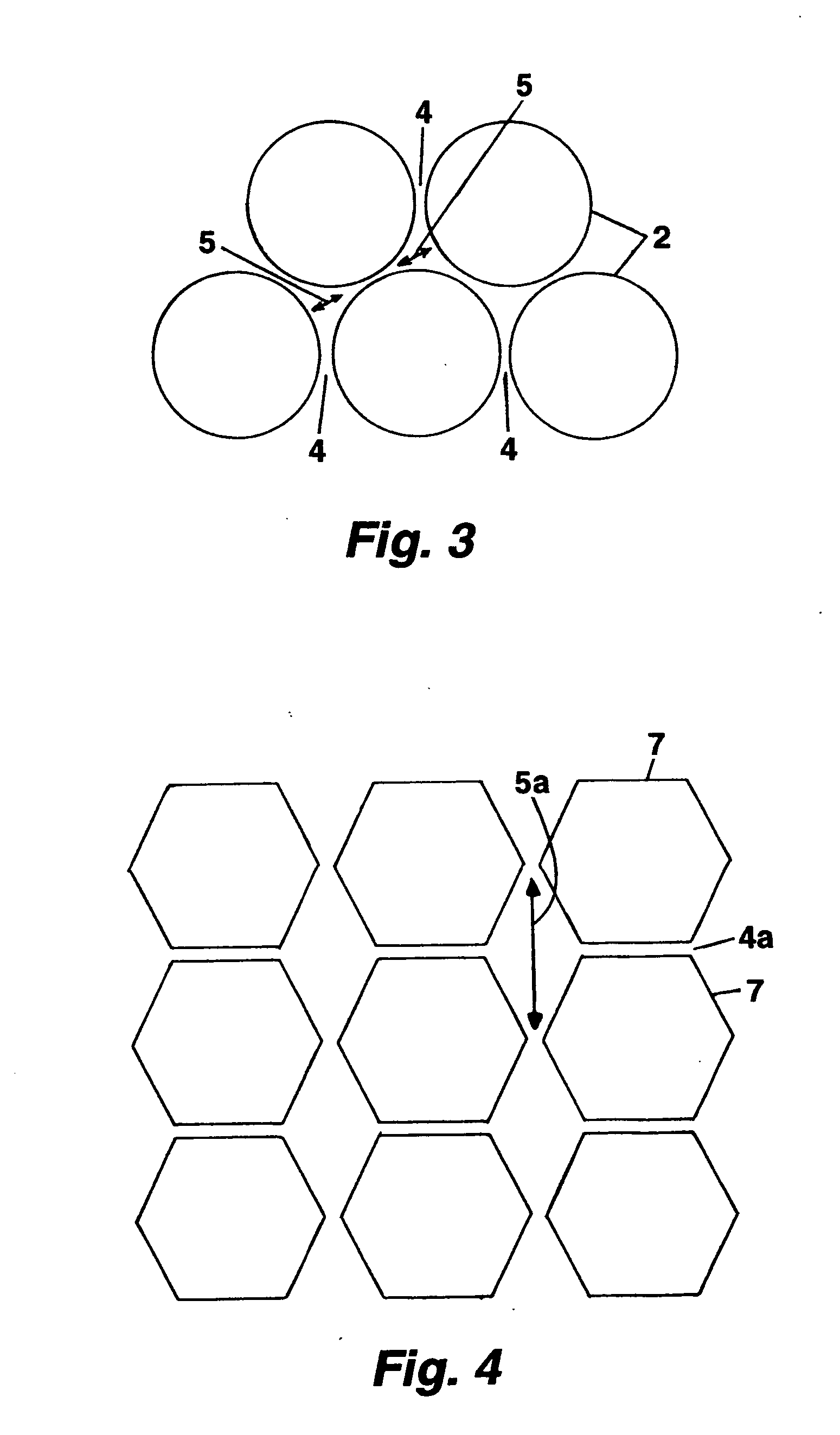

Energy saving honeycomb having enhanced strength

InactiveUS20110033655A1Low densityReduce heat transfer rateSynthetic resin layered productsCeramic shaping apparatusHoneycomb structureFiber

An injection molding method of producing a honeycomb body involves introducing an injection moldable polymer into a mold having a two-dimensional array of parallel pins separated from each other in a manner forming inter-cell reinforcement volumes between honeycomb cells being molded for strengthening the honeycomb. The pins can be cylindrical or have hexagonal shapes, trapezoidal shapes, and diamond shapes. Reinforcement fibers can be introduced into the polymer for even further strengthening the honeycomb body. Foaming agents can be added to the molten polymer with or without the fibers to decrease the density of the honeycomb and reduce heat transfer through the honeycomb for saving energy. Roughening, or producing textured surfaces of the honeycomb product can reduce glare due to sunshine that is detrimental should the honeycomb be used in the construction of buildings and the like. Foaming agents introduced into the polymer during molding can also produce such textured surfaces.

Owner:GRIFFIN THERMOPLASTICS

Gas sealing skirt for suspended showerhead in process chamber

InactiveUS7641762B2Reduce thermal stressReduce heat transfer rateElectric discharge tubesSemiconductor/solid-state device manufacturingHermetic sealEngineering

Stress within a suspension wall for suspending a showerhead in a process chamber is ameliorated by one or more of: (1) A gas sealing skirt that helps protect the suspension wall from direct contact with process gas. The gas sealing skirt is connected to either the chamber wall or the showerhead but is not connected to both. (2) Openings in the suspension wall that reduce exposure of the suspension wall to process gas or ambient atmosphere when the chamber lid is opened. (3) A substantially vertical arrangement of one or more rifts in the suspension wall which facilitate horizontal buckling or flexing of the suspension wall. (4) A plurality of suspension walls whose respective central portions are coplanar.

Owner:APPLIED MATERIALS INC

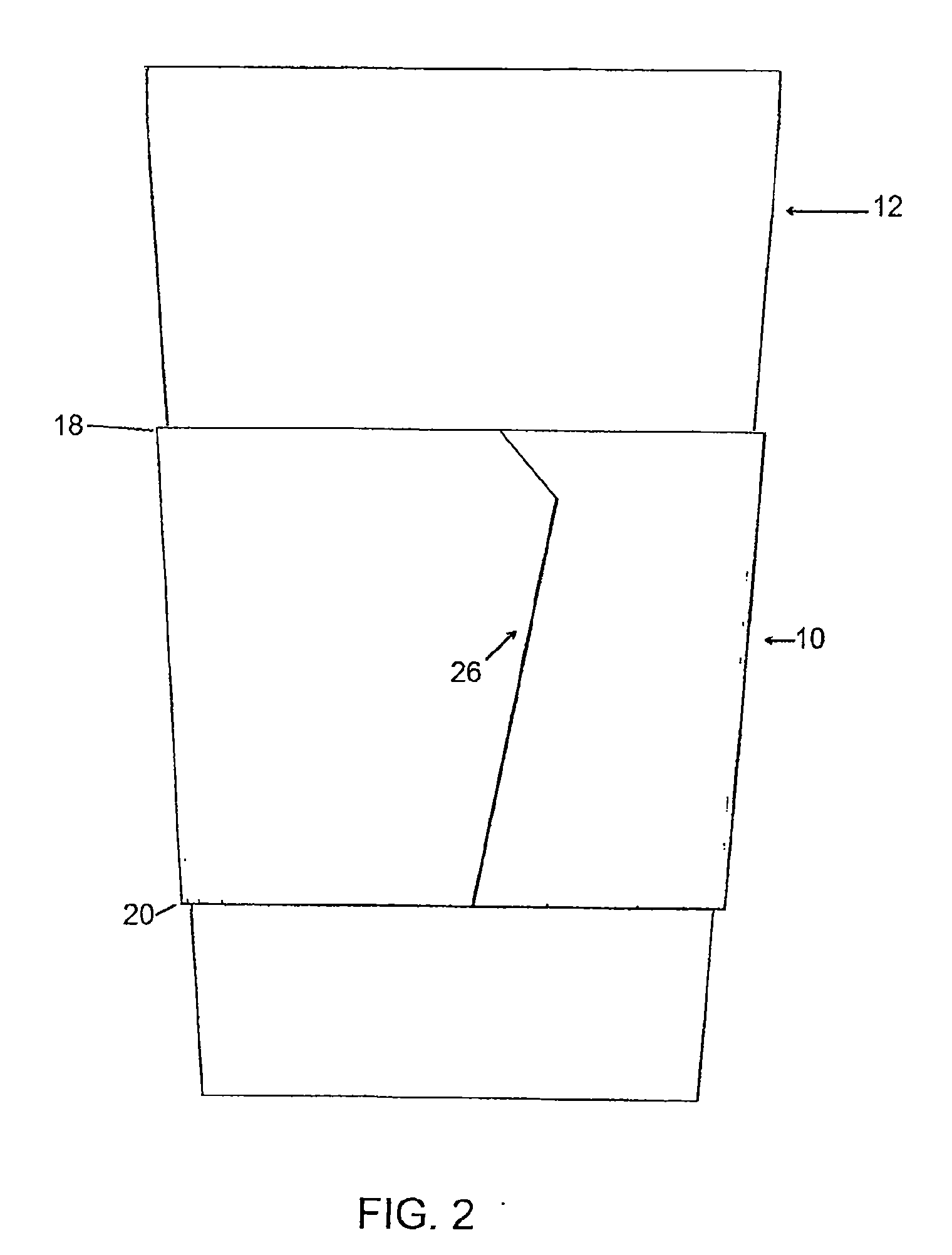

Extreme environment heat exchanger

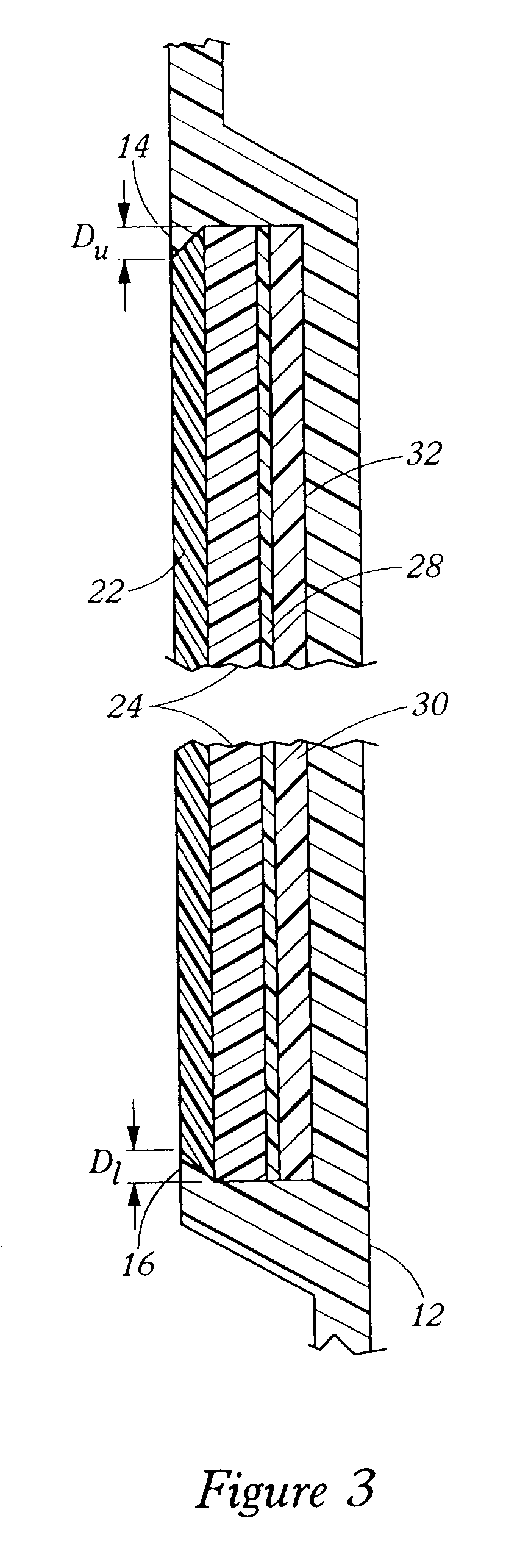

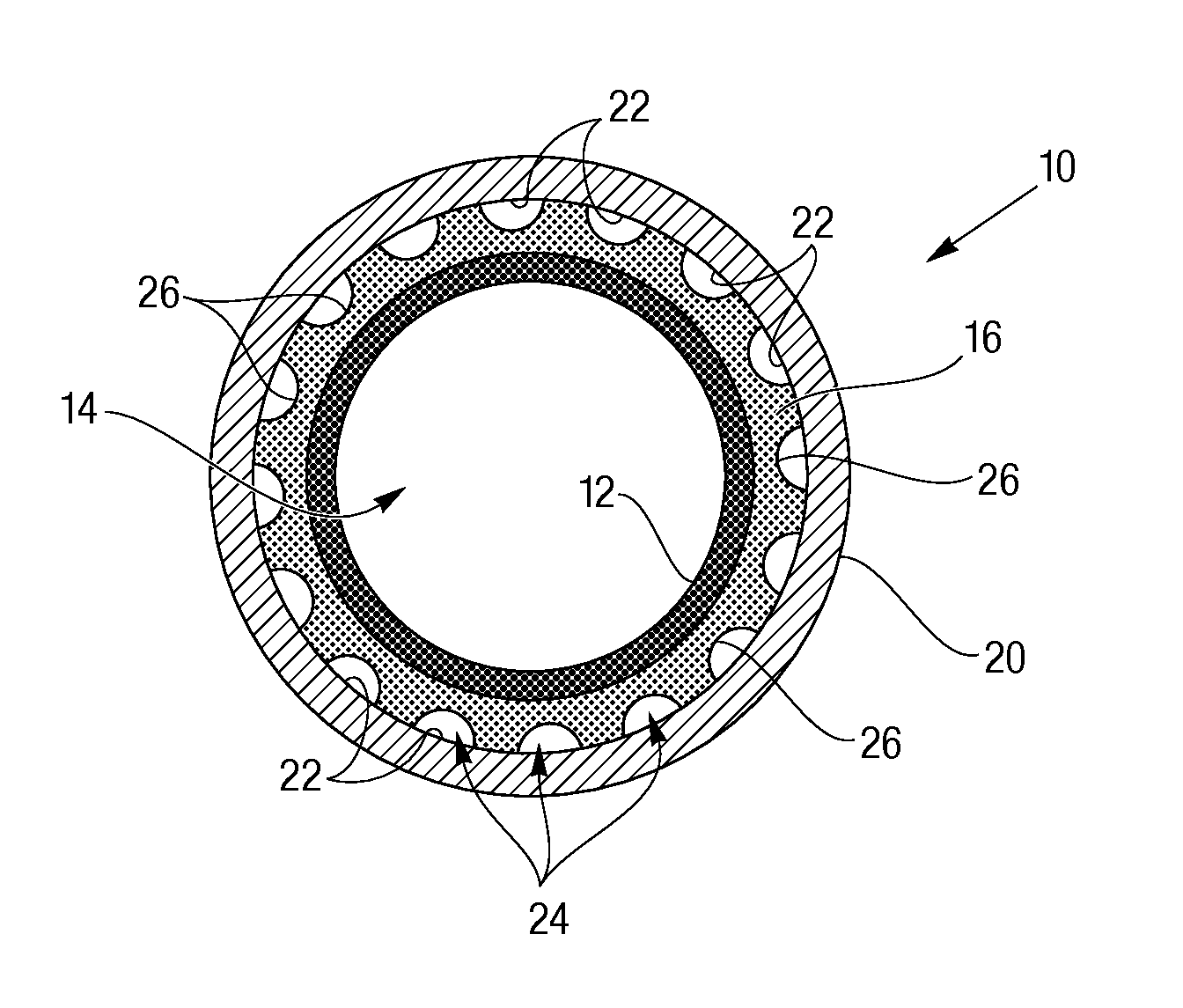

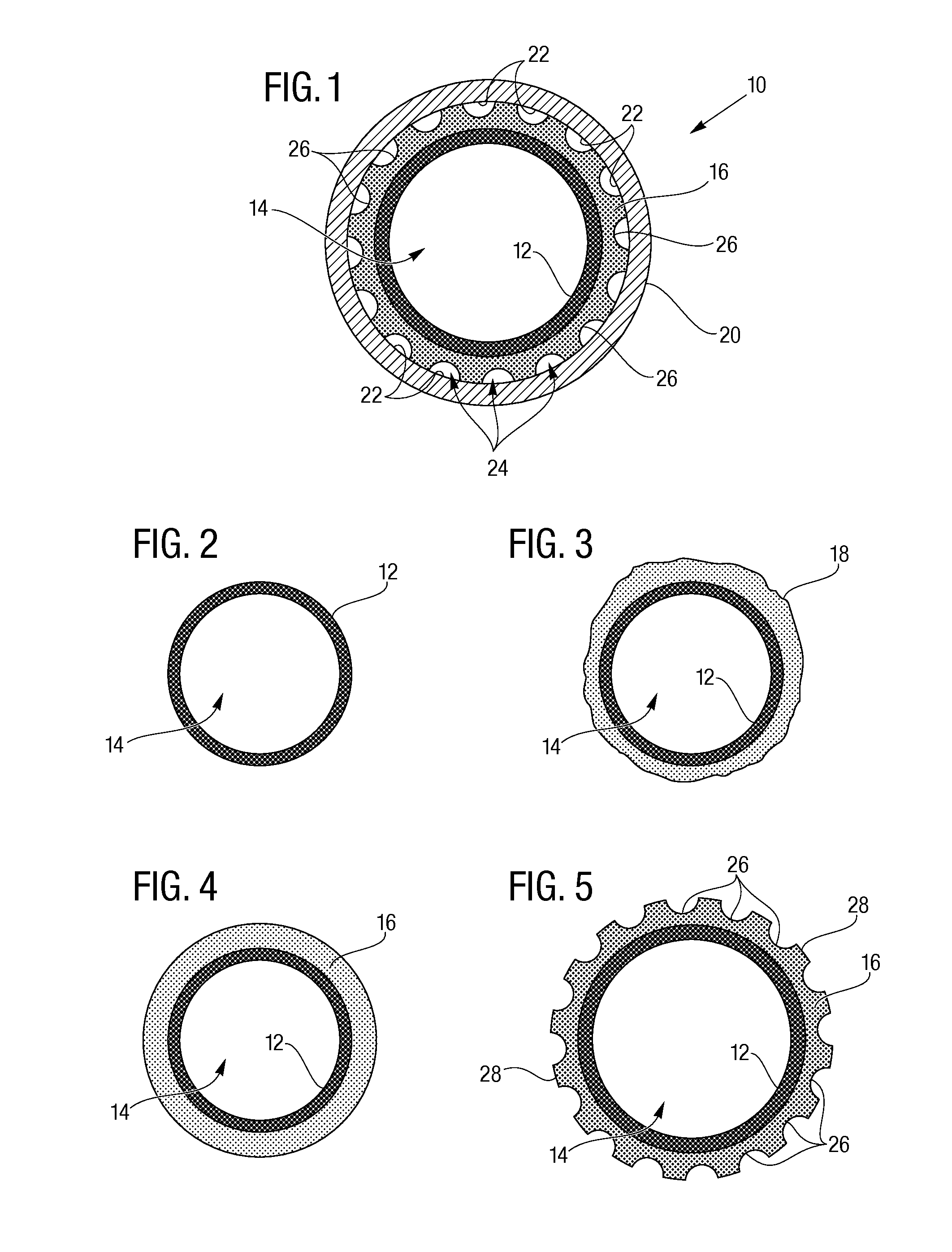

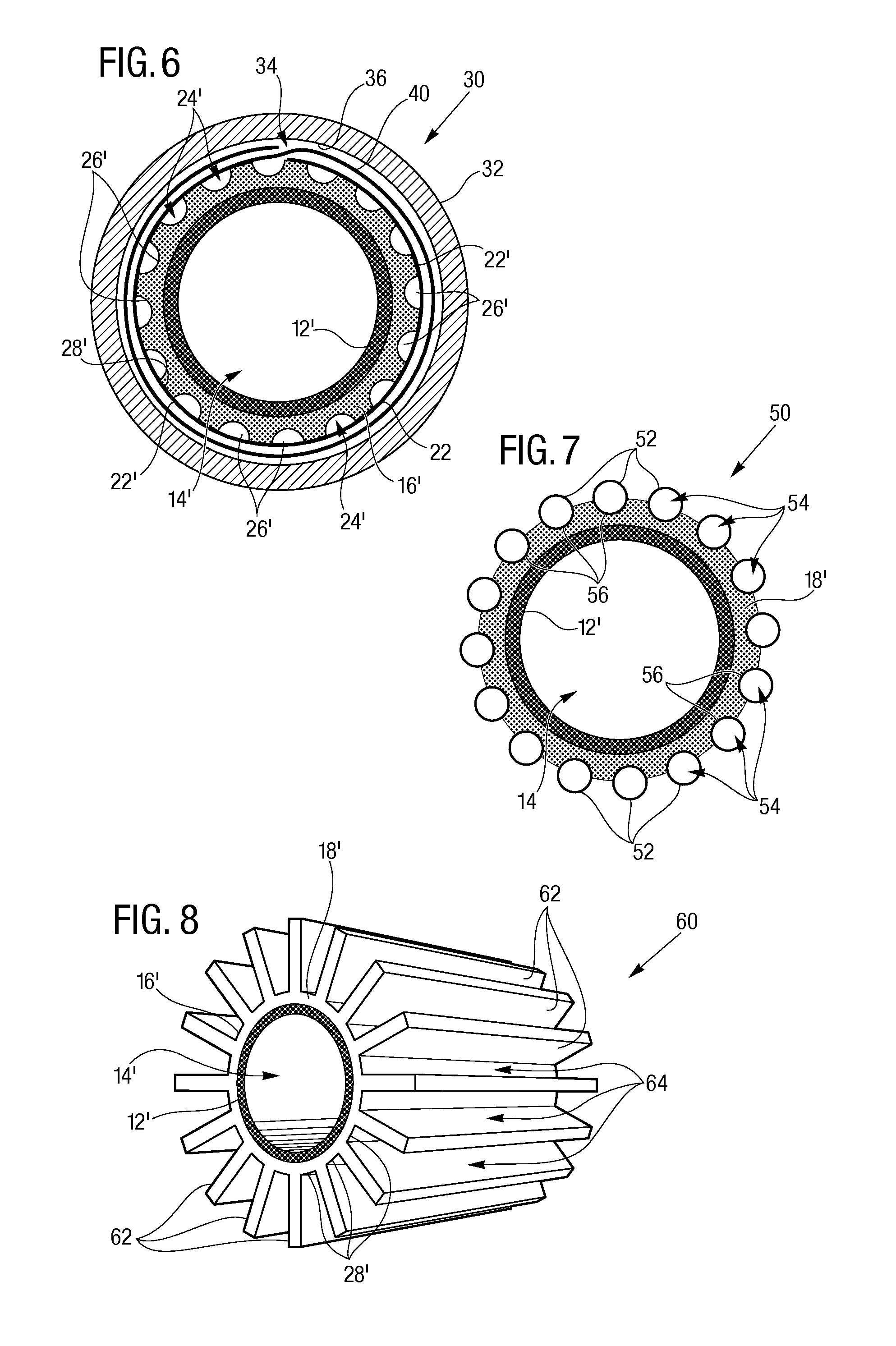

ActiveUS20140332191A1Minimize thermal expansionReduce heat transfer rateSafety devices for heat exchange apparatusMetal-working apparatusCooling fluidExtreme environment

The heat exchanger (10) includes a ceramic matrix composite (12) (stable at temperatures up to 1,650° C.) surrounding and defining a hot fluid conduit (14). A hardenable material (18) having a high thermal conductivity is formed into a heat transfer layer (16) surrounding the ceramic matrix composite (12). A metal pipe (20) is coextensive with the heat transfer layer (16) and defines at least a portion (22) of at least one cool fluid passage (24, 34, 54) defined adjacent to and in heat exchange relationship with the heat transfer layer (16) so that a fluid passing through the cool fluid passage (24, 34, 54) absorbs heat passing through the heat transfer layer (16) from the hot fluid passing through the hot fluid conduit (14).

Owner:RTX CORP

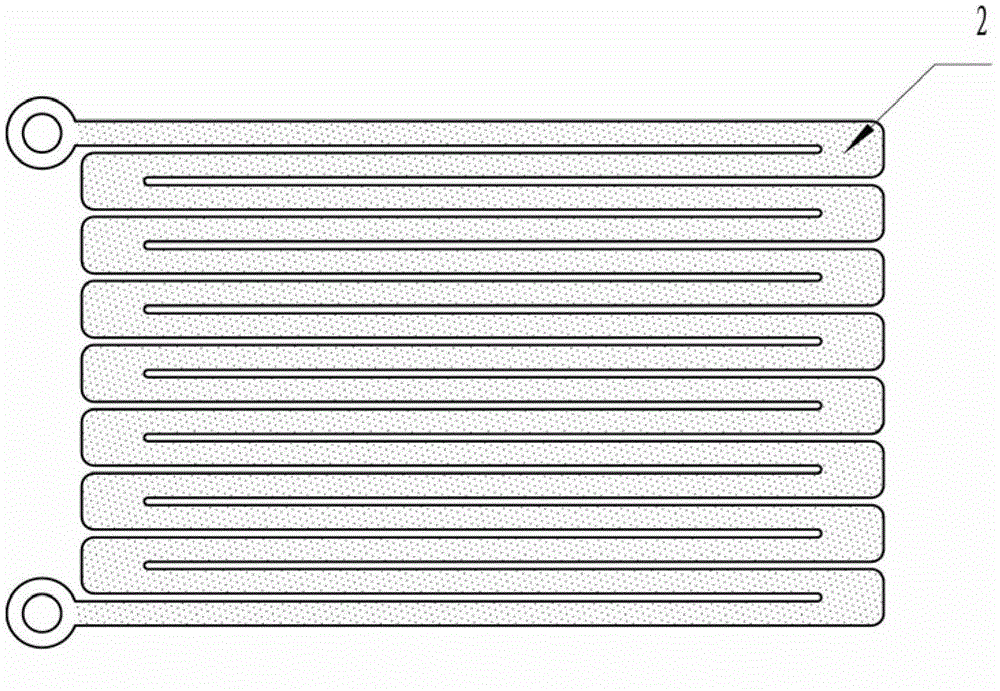

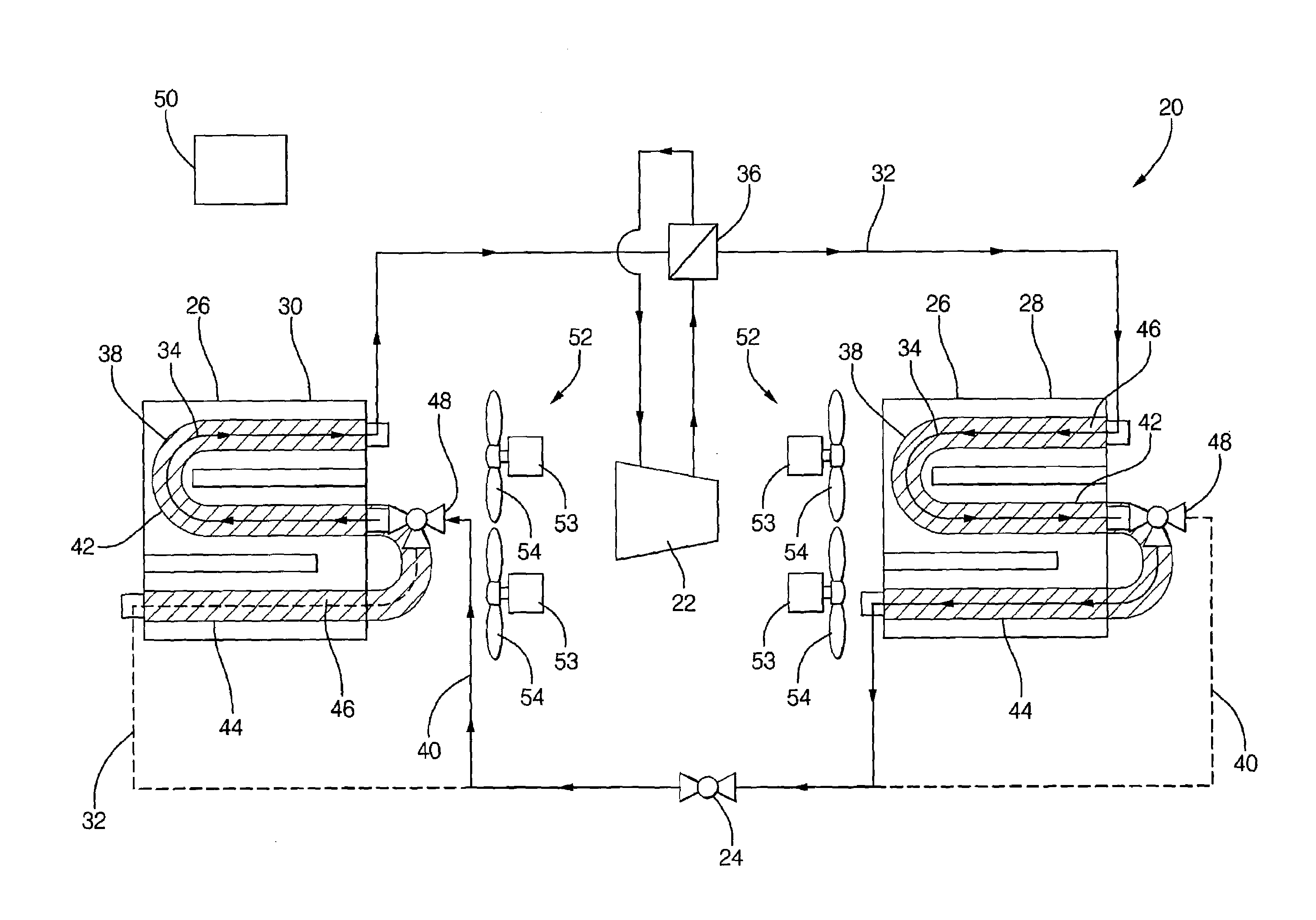

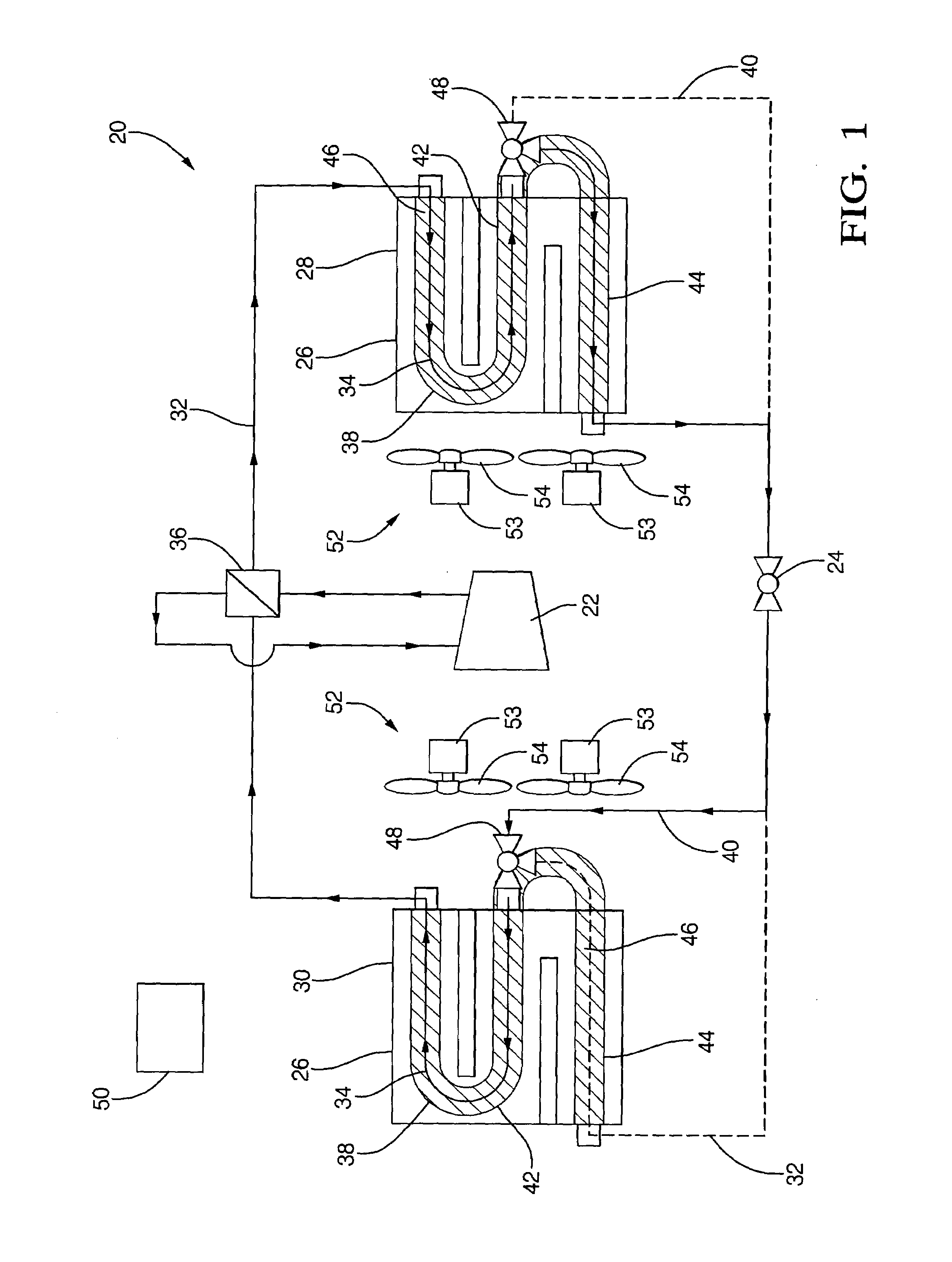

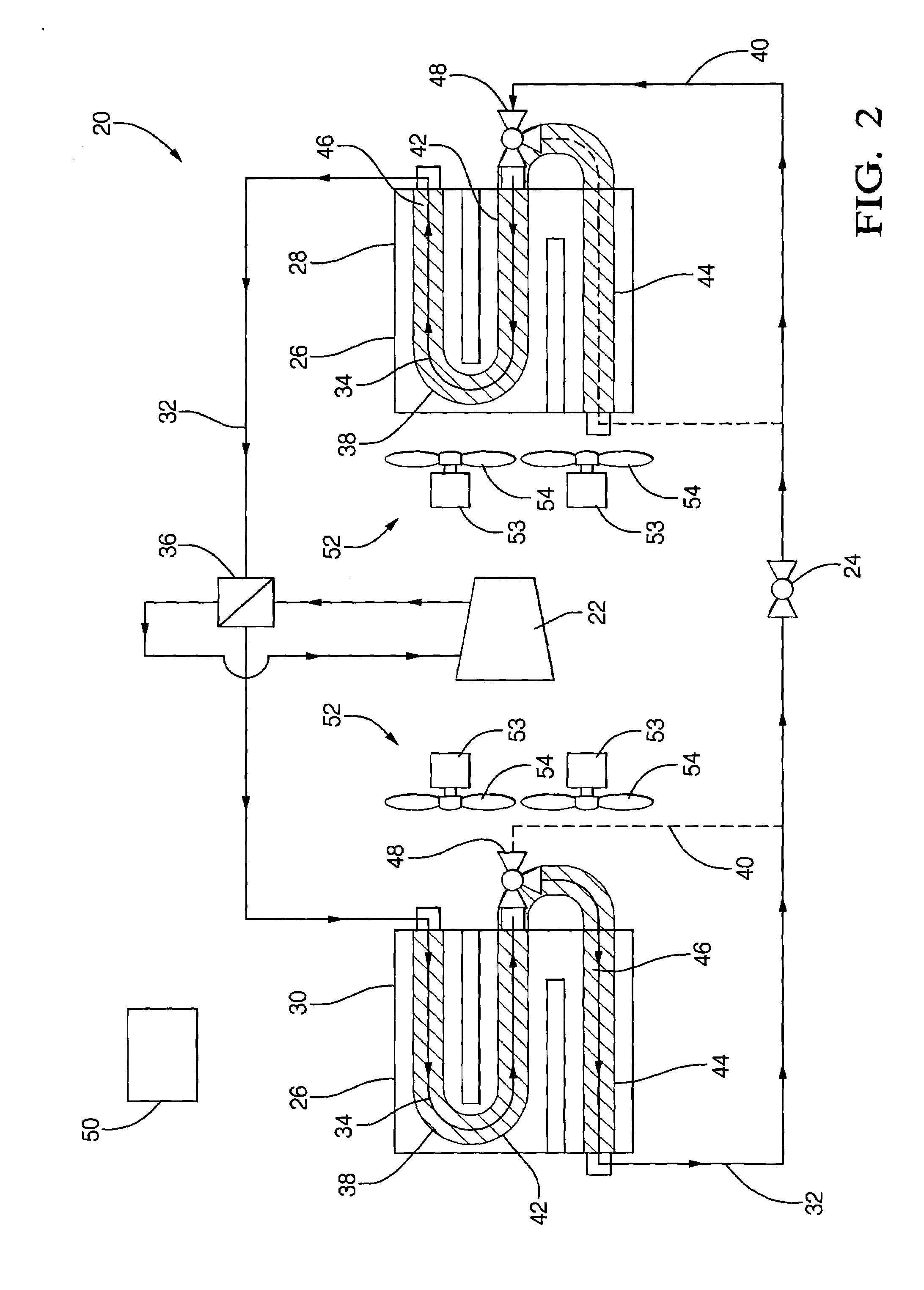

Heat pump system

ActiveUS7263848B2Reduce heat transfer rateEffective maintenanceEvaporators/condensersCompression machines with reversible cycleEngineeringRefrigerant

A heat pump is operable in a heating mode and a cooling mode and includes two identical heat exchangers. The heat exchangers alternate between operating as a condenser and an evaporator as the heat pump switches between the heating mode and the cooling mode. The heat exchangers include a fluid passageway for directing a refrigerant therethrough and a bypass bisecting the fluid passageway into a first portion and a second portion. A valve interconnects the first portion and the second portion of the fluid passageway and the bypass for directing the refrigerant through the first portion of the fluid passageway and into the bypass to prevent refrigerant flow through the second portion of the fluid passageway when the heat exchanger is operable as the evaporator.

Owner:MAHLE INT GMBH

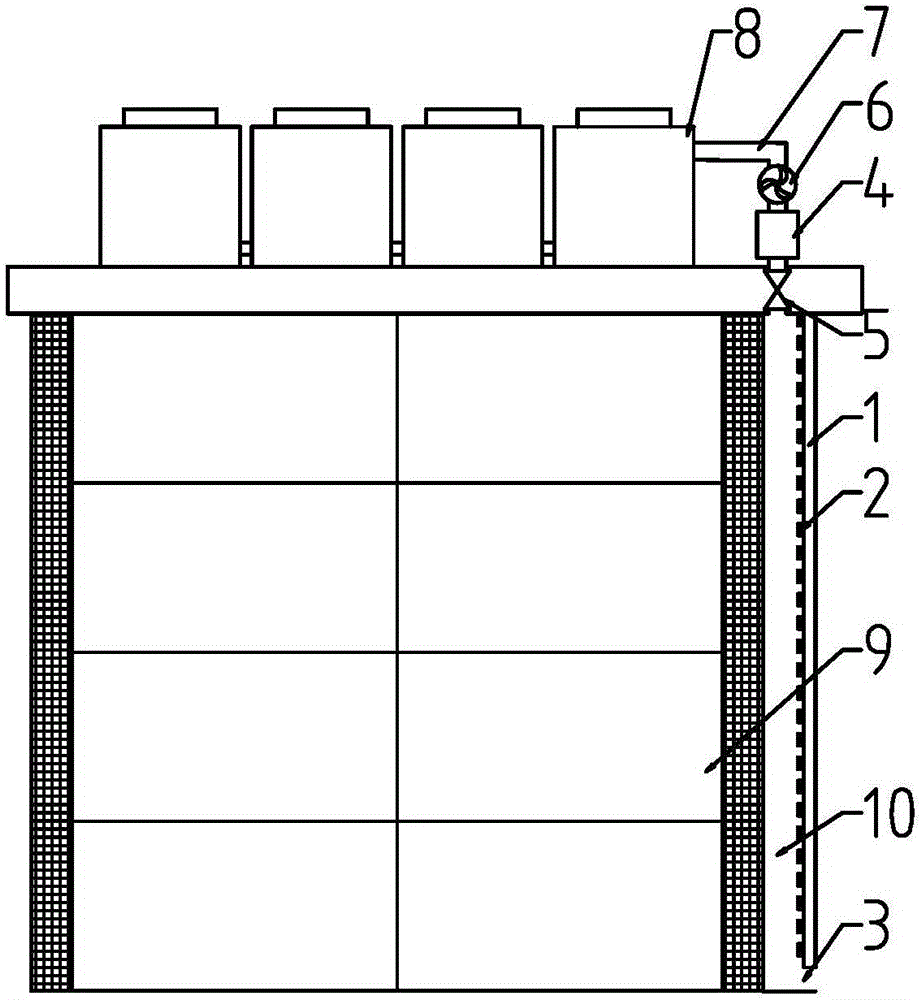

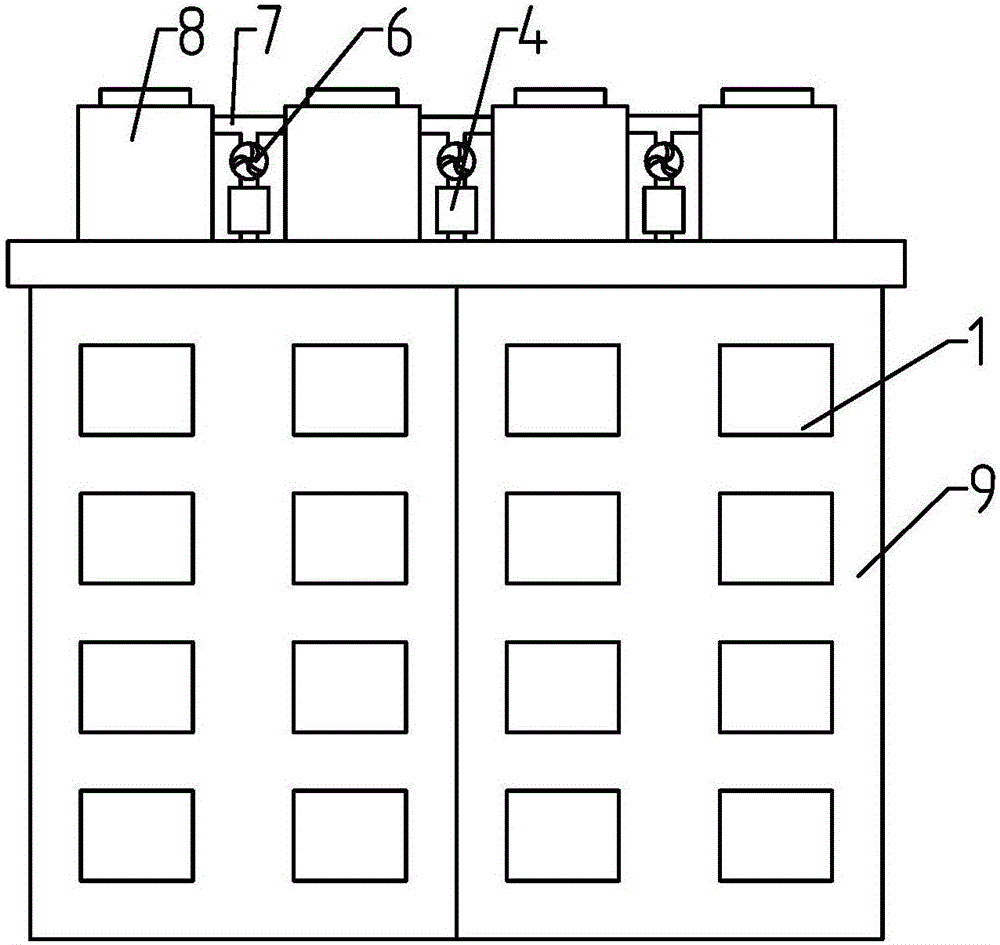

Photovoltaic curtain wall and waste-heat heat pump utilization system based on building envelope structure

InactiveCN106091478AReduce energy loadReduce heat transfer rateMechanical apparatusHeat pumpsExcess heatAir source heat pumps

The invention discloses a photovoltaic curtain wall and waste-heat heat pump utilization system based on a building envelope structure. The system comprises a wall support arranged on the outer layer of the building. An air source heat pump is arranged on the top of the building. A gap is formed between the wall support and the outer layer of the building. A photovoltaic curtain wall is laid on the inner side face of the wall support. A plurality of air inlets lead to the gap are formed below the photovoltaic curtain wall, and therefore an air partition layer is formed between the photovoltaic curtain wall and the outer layer of the building. A pipeline communicated with the air partition layer is arranged at the upper end of the photovoltaic curtain wall. The other end of the pipeline is connected to an air source heat pump. A valve, a temperature measuring control system and a drainage fan are arranged on the pipeline. The temperature measuring control system is connected with a valve. According to the photovoltaic curtain wall and waste-heat heat pump utilization system, a building envelope is added for the building, working efficiency of the photovoltaic curtain wall is kept, excessive heat generated in the photovoltaic conversion process of the photovoltaic curtain wall is sufficiently utilized and supplied to the air source heat pump through air, and the higher heat pump heating working efficiency can be obtained.

Owner:TIANJIN UNIV

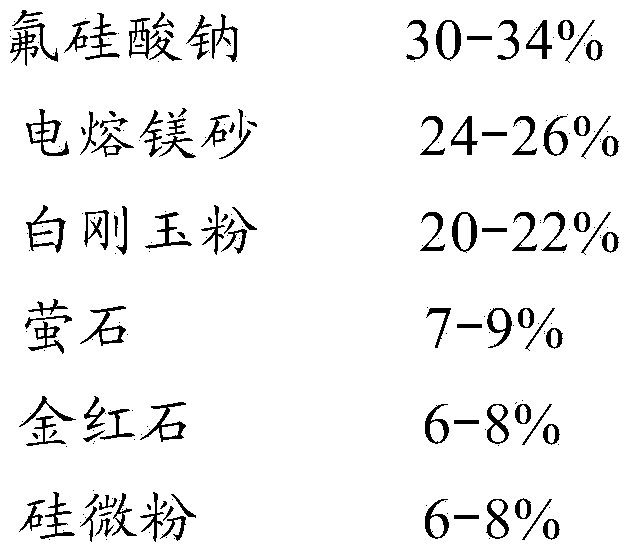

Aluminum alloy sheet laser welding auxiliary weld-joint forming material and preparation method thereof

ActiveCN103506770AReduce heat transfer rateChange viscosityWelding/cutting media/materialsSoldering mediaPorosityRutile

The invention provides an aluminum alloy sheet laser welding auxiliary weld-joint forming material and a preparation method of the material. The aluminum alloy sheet laser welding auxiliary weld-joint forming material is formed by mixing a powder material and a binding agent, and then pressing and baking the mixture. The powder material comprises, by weight, 30-34% of sodium fluosilicate, 24-26% of fused magnesite, 20-22% of white emery powder, 7-9% of fluorite, 6-8% of rutile and 6-8% of silica powder. The aluminum alloy sheet laser welding auxiliary weld-joint forming material is easy to obtain, and the obtained aluminum alloy sheet laser welding auxiliary weld-joint forming material is small in porosity and can effectively overcome the defects generated in the welding process of aluminum alloy sheets.

Owner:武汉光谷机电科技有限公司

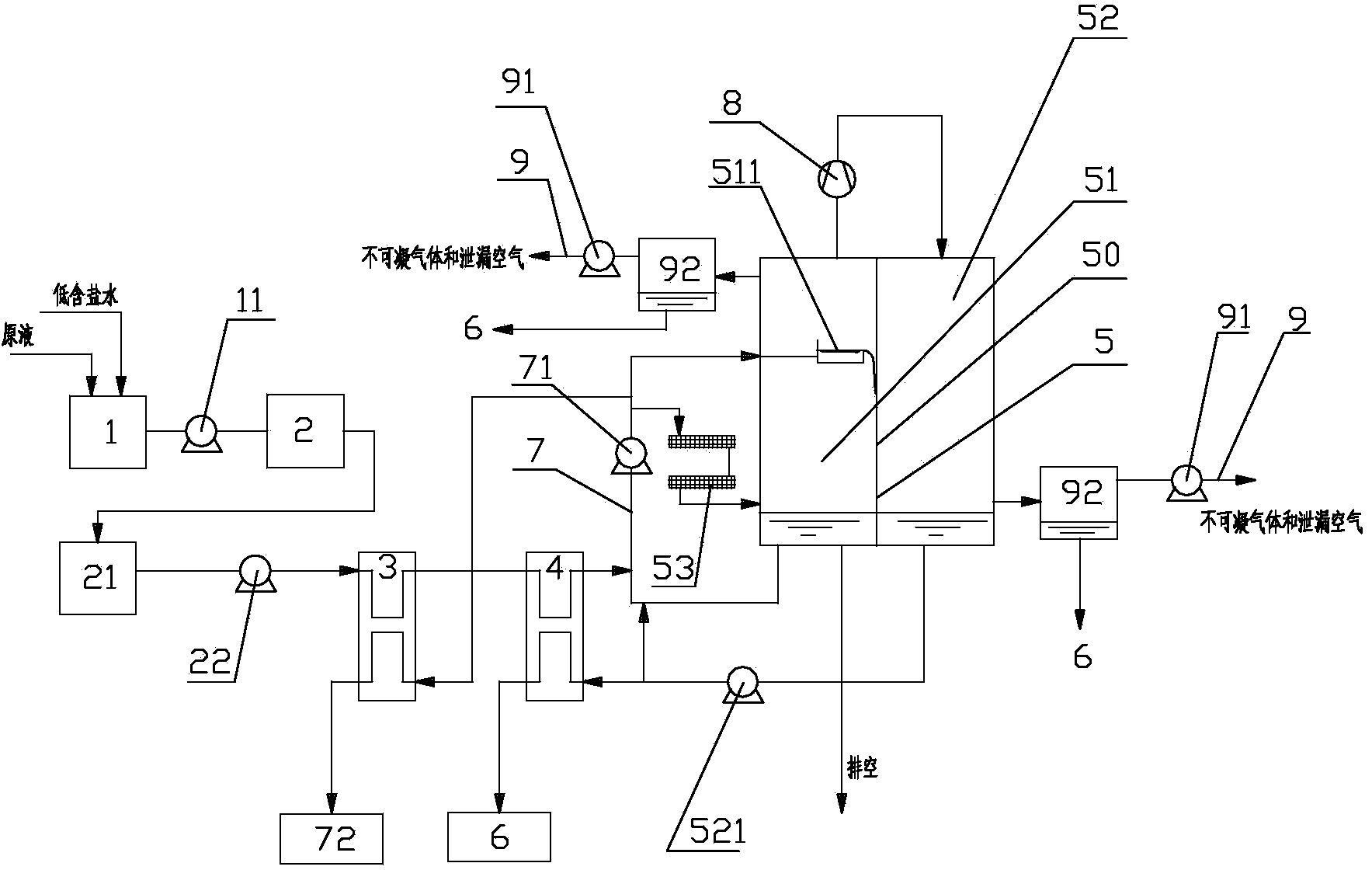

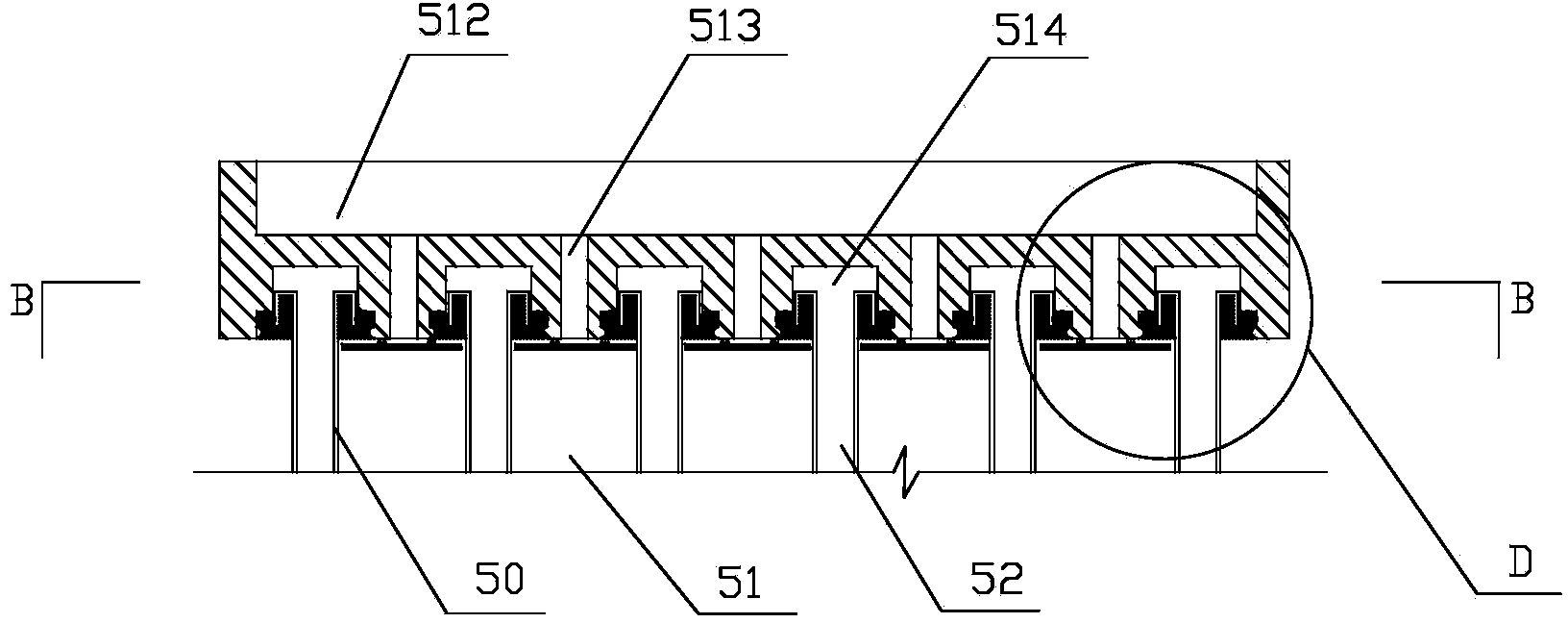

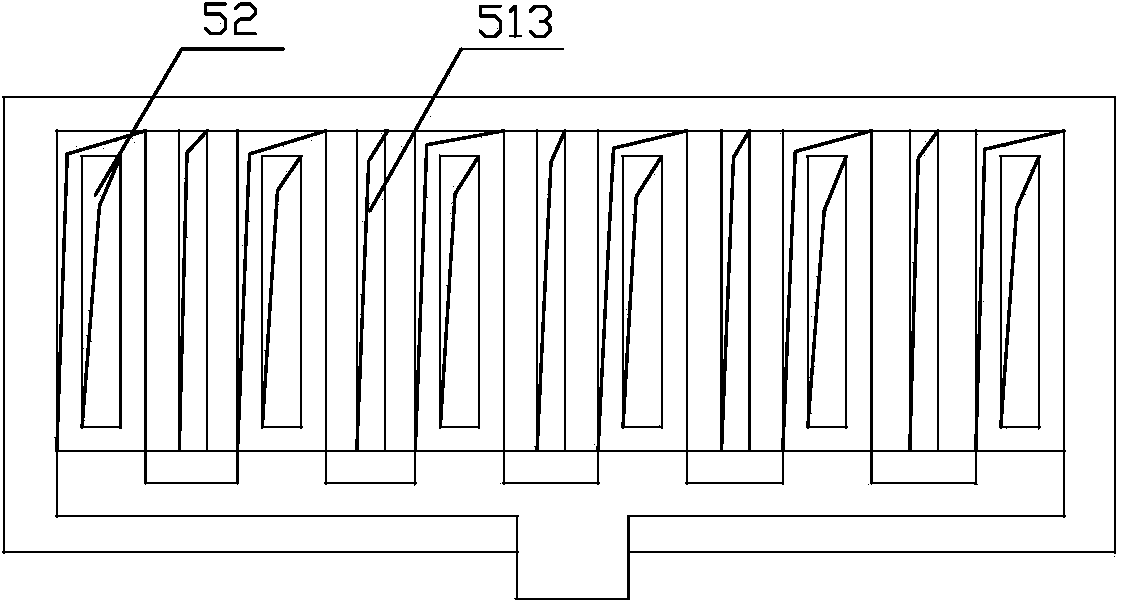

Mechanical steam recompressing evaporation system and energy saving method

ActiveCN104027993ASolve corrosiveAvoid badEvaporation with vapour compressionEvaporator accessoriesEvaporationEngineering

The invention discloses a mechanical steam recompressing evaporation system and an energy saving method, and belongs to the technical fields of evaporation and energy conservation. The mechanical steam recompressing evaporation system is designed for solving the problems that an existing MVR system forms scales, corrodes, and is high in manufacturing cost and energy consumption in the industrial wastewater treatment and recover processes. The evaporation system comprises a stock solution storage tank, a pretreater, a heat exchange device, an evaporation and condensation device and a condensed water recovery pond, wherein the stock solution storage tank, the pretreater, the heat exchange device, the evaporation and condensation device and the condensed water recovery pond are sequentially connected in the flowing direction of liquid. The evaporation and condensation device comprises a plurality of evaporators, a plurality of condensers and an electromagnetic induction heater, the evaporators and the condensers are arranged in a separated mode through a plurality of thin polymer films; the heat exchange device is connected with the evaporators through a circulating liquid system, the evaporators are connected with the condensers through fans, and the condensers are connected with the condensed water recovery pond through the heat exchange device. The invention further provides the energy-saving method of the evaporation system. The thin polymer films are used for replacing metal films of the existing MVR system to manufacture the evaporation and condensation device, the evaporation and condensation device has the equivalent heat transfer effect as the metal-film evaporation and condensation device, and the problems of corrosion and scale forming on the surfaces of the evaporators are solved.

Owner:BEIJING OTC ENERGY & ENVIRONMENT ENGINEERING PUBLIC LIMITED COMPANY

Thermal ink jet ink composition

ActiveUS8632630B2Keep for a long timeReduce rateCosmetic preparationsToilet preparationsDrop weightOrganic solvent

A thermal ink jet ink composition includes one or more volatile organic solvents, wherein the one or more volatile organic solvents are selected from C1-C4 alcohols, C3-C6 ketones, C3-C6 esters, C4-C8 ethers, and mixtures thereof; one or more humectants, wherein the humectants are present in an amount not more than 30% by weight of the ink composition; one or more binder resins; and one or more dyes. The ink composition is suitable for use in a thermal ink jet printer and the ink composition has a slow rate of kogation such that it is capable of being printed at least 10 million drops per nozzle from the thermal ink jet printer before drop weight of the ink composition is reduced by more than 10%.

Owner:VIDEOJET TECH INC

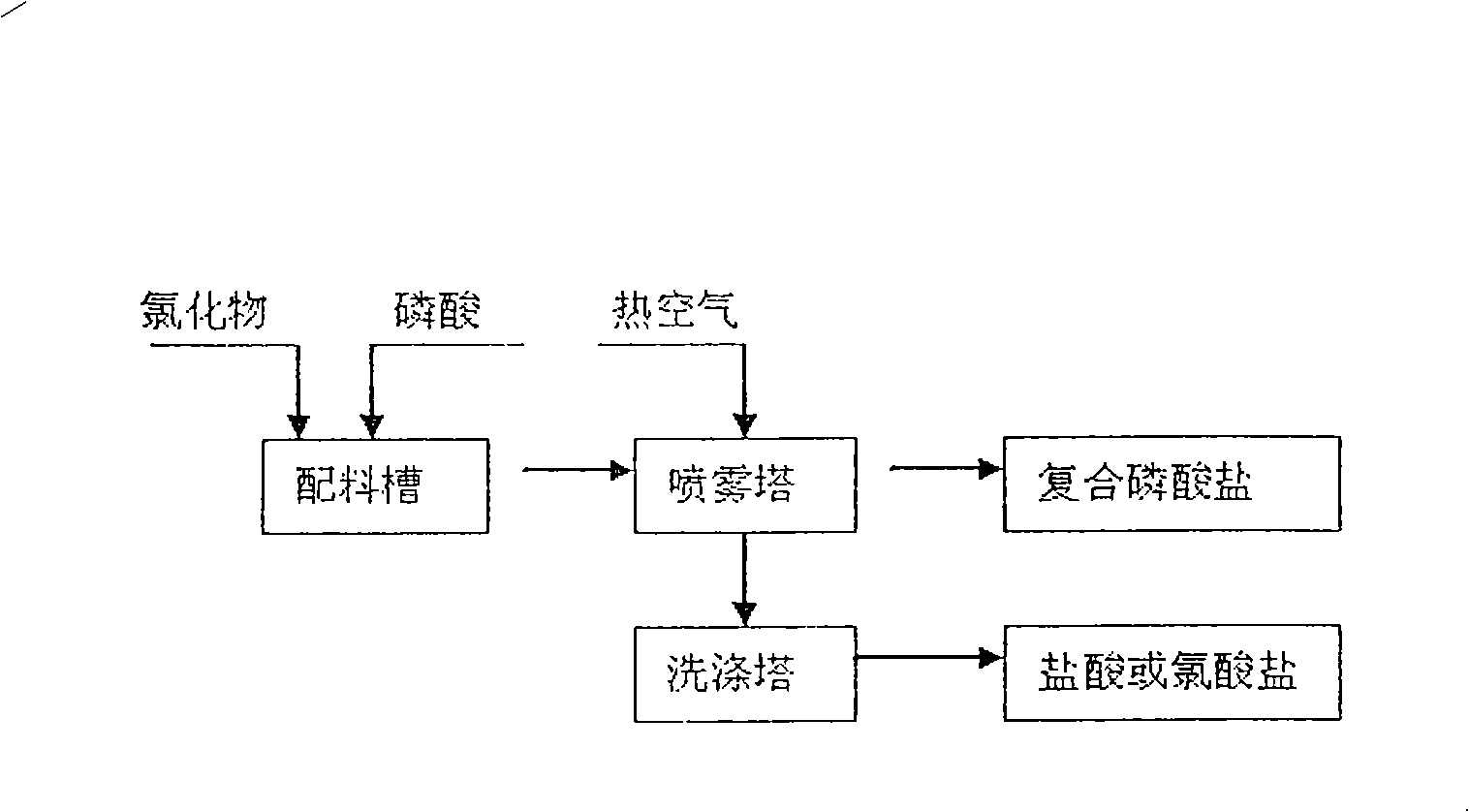

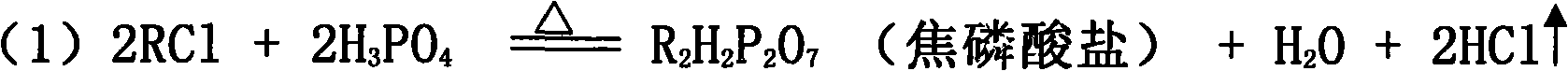

Method for preparing composite phosphate

ActiveCN101343053AReduce heat transfer rateLow mass transfer efficiencyPhosphatesState of artSmall droplet

The invention discloses a production method of composite phosphate, which essentially comprises steps as follows: firstly, chloride is mixed with excessive phosphoric acid in order to obtain material liquid; secondly, the material liquid is added into the spray dryer to atomize into tiny droplets; thirdly, the droplets are instantaneously contacted and heated with as much hot air as is sufficient to enable double decomposition reaction between chloride and phosphoric acid to happen, so that hydrogen chloride gas escapes, and the remaining things are reacted to obtain a compound phosphate product. The production method has technical advantages that the shortcomings of prior art can be overcome, the spray dryer is adopted as a core reactor to atomize the material liquid into small droplets to be contacted with the high-temperature hot air, the specific surface area of evaporation is maximum, so that the escaping time of HCl and the water vapor is 3 to 8 seconds only, the reaction conversion rate reaches up to 97 percent, the material liquid continues to be in and out, and large-scale industrialization production can be achieved.

Owner:GUIZHOU CHANHEN CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com