Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Tryptic hydrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

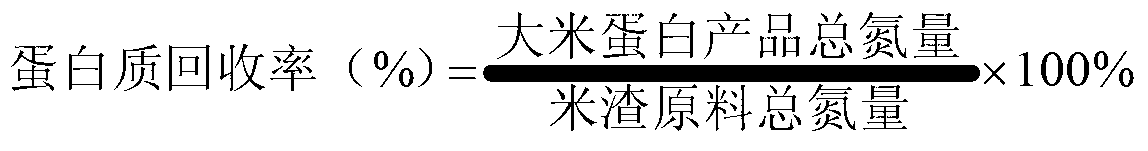

Preparation method of high-purity rice protein

InactiveCN103283934AHigh dissolution rateHigh extraction rateVegetable proteins working-upSolubilityDissolution

Owner:ANHUI AGRICULTURAL UNIVERSITY

Dendrobe beauty fluid and preparation method thereof

The invention discloses a dendrobe beauty fluid and a preparation method thereof. The dendrobe beauty fluid comprises a dendrobe extract, a tremella extract and a hydrolysis product of defatted milk, wherein the dendrobe extract is an aqueous extract of the dendrobe; the tremella extract is an aqueous extract of tremella; the hydrolysis product of defatted milk is a product obtained by hydrolyzing defatted milk by trypsin; the ratio of the dendrobe to the tremella to the defatted milk which are taken as raw materials is (1-5g) to (0.3-1g) to (5-12ml). The composition provided by the invention has good whitening, moisturizing and anti-ageing effects on skin to enable the skin to be mild and fine, and full of elasticity and gloss.

Owner:郑州蓬泽生物科技开发研究院

Method for preparing spirulina polypeptide-chitosan nano particles

InactiveCN103110585APromote development and utilizationHas inhibitory effectPowder deliveryPeptide/protein ingredientsUltrafiltrationSpirulina sp.

The invention provides a method for preparing spirulina polypeptide-chitosan nano particles. The method mainly comprises the following steps: extracting spirulina proteins by employing a method of combining multigelation and ultrasonication, hydrolyzing the spirulina proteins through trypsin, separating and purifying by a sephadex column, filtering through an ultrafiltration centrifugation tube, and preparing the spirulina polypeptide-chitosan nano particles by employing a sodium tripolyphosphate ion exchange method. The obtained spirulina polypeptide-chitosan nano particles Y2-CS have the following antitumor activities that the spirulina polypeptide-chitosan nano particles Y2-CS have a certain function of inhibiting in-vitro growth of human breast cancer cell MCF-7 and have a certain dose relationship; and when the concentration is 250mug / mL, the highest inhibition rate can be 26.05 percent. Therefore, the spirulina polypeptide-chitosan nano particles contribute to developing and utilizing antitumor health-care foods and medical products.

Owner:SOUTH CHINA UNIV OF TECH

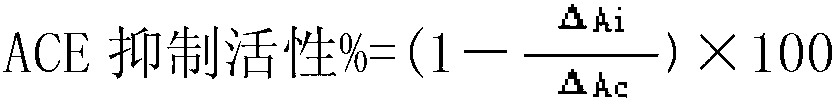

Preparation method of yak milk casein antihypertensive peptide

ActiveCN102787155AHigh protein contentLow priceFermentationCardiovascular disorderSide effectFiltration

The invention relates to a preparation method of yak milk casein antihypertensive peptide. The method comprises main technical schemes as follows: (1) dissolving yak milk casein; (2) adding trypsin for hydrolysis; (3) inactivating the trypsin; (4) precipitating casein; (5) centrifuging and removing the precipitant; (6) performing ultra-filtration; (7) performing nano-filtration; and (8) performing spray drying. Raw materials for the method provided by the invention are unique; the process is scientific and reasonable, simple and feasible; the product is the casein antihypertensive peptide with rather high purity with the ACE (angiotensin converting enzyme) inhibition activity higher than 70%; the product is safe and free from toxic side effects, has nutritional and assistant medical treatment functions, and can be used as an additive widely applied in the fields of food, healthcare products and medicines and the like.

Owner:甘肃华羚生物技术研究中心

Rice bran immune peptide and preparing method thereof

ActiveCN101210043AFunctional properties are not affectedHas immunomodulatory activityPeptide preparation methodsFermentationTryptic hydrolysisProteolytic enzymes

The invention discloses a rice bran immune peptide and a preparation method thereof. The invention uses fall-fat rice bran as raw material, adopts a low alkali method to extract rice bran protein and uses tryptic enzyme to hydrolyze rice bran protein so as to obtain the rice bran peptide. By adopting the low alkali method to extract the rice bran protein and animal proteolytic enzyme to hydrolyze the rice bran protein, the products obtained not only have no bitterness, taste good, but also have immunoregulatory activity.

Owner:深圳市腾泰农业科技有限公司

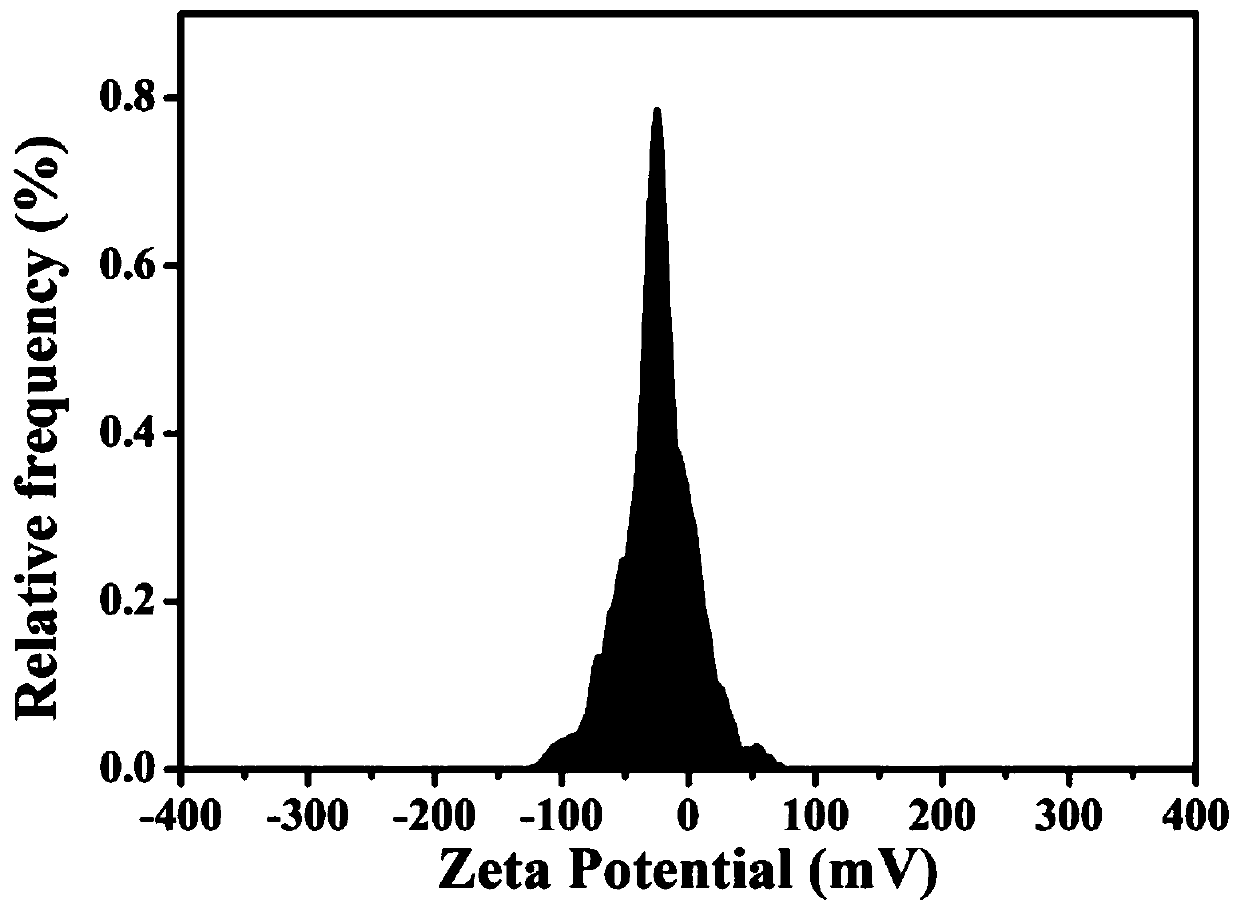

Novel chitosan nanoparticles and preparation method thereof

InactiveCN101838467AImprove stabilityAvoid degradationFermentationFood preparationCross-linkChitosan nanoparticles

The invention discloses a method capable of being used for preparing novel chitosan-casein phosphopeptide nanoparticles in the food industry. At present, the chitosan nanoparticles are generally prepared by a method using sodium tripolyphosphate cross-linked chitosan. However, as oral delivery carriers, the chitosan nanoparticles are not resistant to strong acid and cause that delivered nutriments are damaged in gastric acid and cannot be delivered to intestinal tracts in a targeted mode for absorption. In the method, a product obtained by using trypsase to hydrolyze casein is separated and purified to obtain casein phosphopeptide, and the casein phosphopeptide and chitosan are cross-linked with each other to from a 'core-shell' nanoparticle structure through condition optimization. Underthe action of negative charges of a surface phosphate group, the chitosan-casein phosphopeptide nanoparticles can avoid acidic and enzymatic degradations in vivo to have very strong stability, have certain targeting and controlled-release characteristics, and solve the problem that the current chitosan-sodium tripolyphosphate nanoparticles serving as the oral delivery carriers can be degraded by the gastric acid easily.

Owner:NANJING AGRICULTURAL UNIVERSITY

Probiotic fermentation milk drink with bowel relaxing and blood fat reduction assisting functions and making method thereof

The invention relates to a probiotic fermentation milk drink with the bowel relaxing and blood fat reduction assisting functions and a making method thereof. The method comprises the steps that on the basis that trypsin is utilized for hydrolyzing reconstituted skimmed milk to obtain skimmed milk enzymatic hydrolysate, whey powder conditioning fluid, beer, banana jam, sweet potato jam, fructo-oligosaccharide and xylitol are added, and hawthorns, roots of red-rooted salvia and a traditional Chinese medicine extract of roots of kudzu vine are added to prepare a mixed nutrient solution; after heat treatment cooling is performed, inoculation of a mixed probiotic leavening agent is performed, and the probiotic fermentation milk drink with the bowel relaxing and blood fat reduction assisting functions is obtained after fermentation is performed for 24-72 h. The probiotic fermentation milk drink with the bowel relaxing and blood fat reduction assisting functions can remarkably lower the TC, TG, LDL-C content in rat serum, remarkably increase the HDL-C and ApoAI content, remarkably lower the ALT and AST levels of the rat serum, remarkably improve the SOD activity of liver tissue and effectively relieve liver injuries caused by lipid peroxidation, and has the good bowel relaxing and blood fat reduction assisting functions.

Owner:YANGZHOU UNIV

Preparation method of yak milk casein antibacterial peptide

InactiveCN102876764AHigh nutritional valueHigh protein contentPeptide preparation methodsFermentationEscherichia coliMinimum inhibitory concentration

The invention relates to a preparation method of a yak milk casein antibacterial peptide and belongs to the technical field of biology. The preparation method includes steps of dissolving yak milk casein, adding trypsin for hydrolysis, inactivating the trypsin, precipitating casein, performing centrifugation to remove precipitation, subjecting yak milk casein to sephadex column chromatography seperation, determining molecular weight by mass spectra, performing ultrafiltration and performing spray drying, wherein ultrafiltration membranes with interception of 1000Da and 2500Da are used for collecting peptide fragments with the molecular weight range of 1000Da to 2500Da. According to the yak milk casein antibacterial peptide prepared by the method, peptide molecular weight distribution is concentrated, bacteriostatic activity is high, the minimum inhibition concentration of staphylococcus aureus is 270 mu g / mL, and the minimum inhibition concentration of Escherichia coli is 980 mu g / mL.

Owner:甘肃华羚生物技术研究中心

Preparation method for chlorella antitumor polypeptide

InactiveCN102851345AHas antitumor activityHas inhibitory effectFermentationAntineoplastic agentsUltrafiltrationTryptic hydrolysis

The invention provides a preparation method for chlorella antitumor polypeptide. The preparation method is characterized in that chlorella protein is extracted by using a low temperature ultrahigh pressure continuous flow cell crusher, then is hydrolyzed by trypsin and finally filtered with an ultrafiltration centrifuge tube so as to obtain chlorella polypeptide with a molecular weight in ranges of 0 to 3 KD, 3 to 5 KD, 5 to 10 KD and more than 10 KD. The chlorella polypeptide prepared in the invention has antitumor activity, e.g., the chlorella polypeptide has inhibitory effects on in vitro growth of human hepatoma carcinoma cells HepG2 and inhibition rates of chlorella polypeptide with a concentration of 1 mg / mL and in ranges of 0 to 3 KD, 3 to 5 KD and 5 to 10 KD on in vitro growth of hepatoma carcinoma cells (HepG-2) respectively reach 7%, 14% and 10%. Therefore, the chlorella antitumor polypeptide prepared in the invention is beneficial for development and utilization of antitumor health food and medicinal products.

Owner:SOUTH CHINA UNIV OF TECH

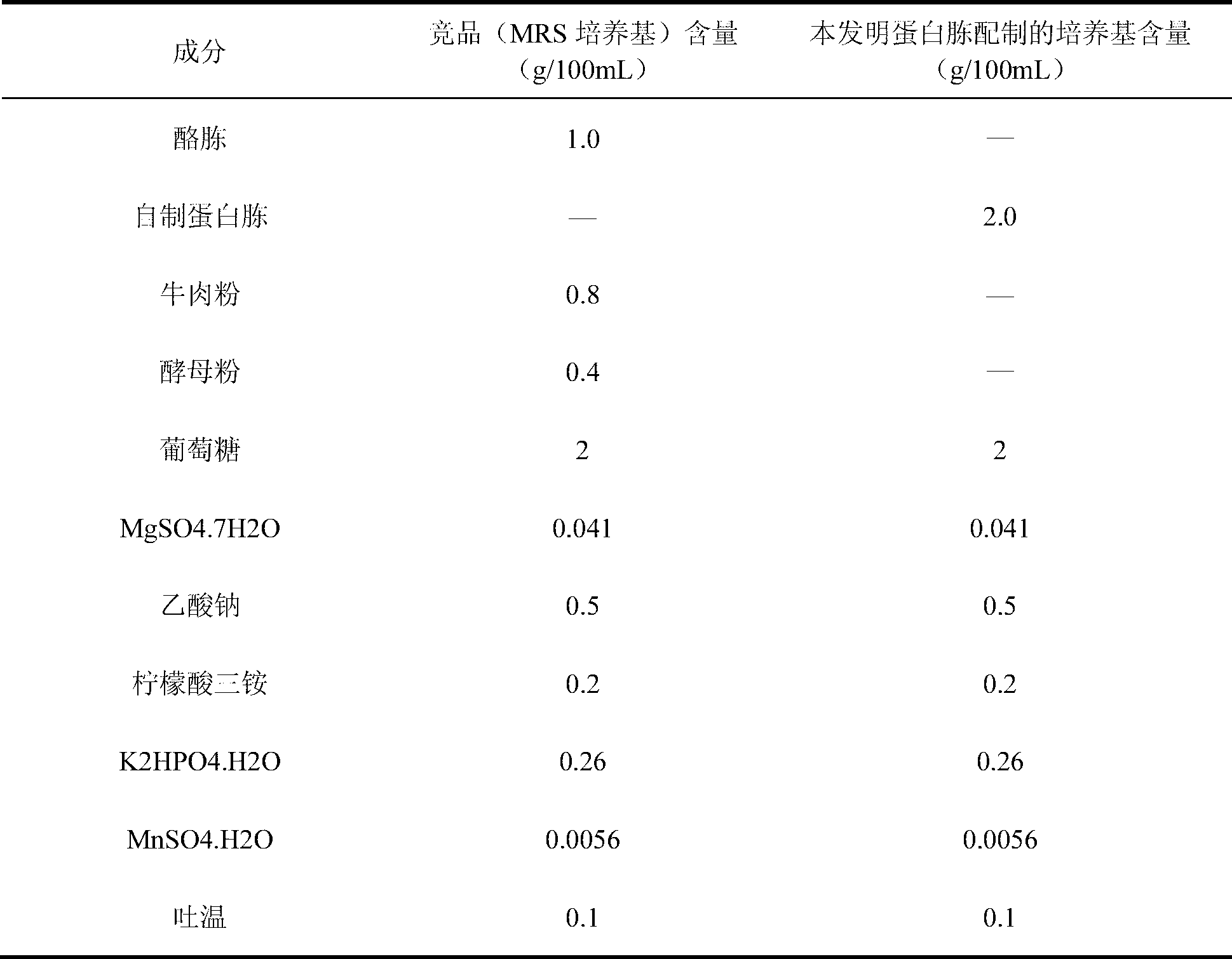

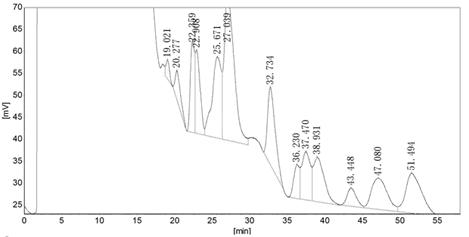

Method for preparing peptone by hydrolyzing lactalbumin with compound enzymes and peptone obtained by using same

ActiveCN103014109AHigh oligopeptide contentHigh nutritional valueBacteriaFermentationNutritive valuesFlavor

The invention provides a method for preparing peptone by hydrolyzing lactalbumin with compound enzymes and peptone obtained by using the same. The method comprises the following steps: preparing a lactalbumin water solution, and carrying out heat treatment to implement protein denaturation; adding proteinase into the lactalbumin water solution subjected to protein denaturation to carry out hydrolysis, wherein trypsin is firstly added for hydrolysis until the degree of hydrolysis reaches 40-50%, flavor proteinase is then added for common hydrolysis until the degree of hydrolysis reaches higher than 70%, and hydrolysis is terminated; and ultrafiltering the solution after terminating hydrolysis through an ultrafiltration membrane, concentrating, and drying to obtain the peptone. The peptone prepared by hydrolyzing lactalbumin with specific compound enzymes has the advantages of high yield, low oligopeptide content and high nutritive value, and can be used for culturing lactobacillus as the unique nitrogen source instead of the routine culture medium MRS (Man, Rogosa and Sharpe).

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Refining process of Ganoderma lucidum polysaccharide

The present invention relates to a refining process of Ganoderma lucidum polysaccharide, which is prepared from dried Ganoderma lucidum by pulverizing and sieving, ultrasonic extracting polysaccharide, trypsin hydrolyzing protein impurities, cation exchange resin deenzyme, forward osmotic membrane treatment, spray drying and other technological steps, so as to obtain refined Ganoderma lucidum polysaccharide. Protein impurities in Ganoderma polysaccharide extract are hydrolyzed with single trypsin, the isoelectric point of trypsin is high than that optimum reaction pH, and after enzymatic hydrolysis, a cation exchange resin is directly used to deenzyme, thus eliminating the need to adjust pH value again, and the process is simple. The deenzymatic polysaccharide extract is filled with 100-fold water-absorbent grafted starch and treated with forward osmotic membrane with molecular weight cut-off of 5000Da. The proteolytic peptides are removed at the same time of concentration. The separation efficiency is high and the energy consumption is low. The trypsin enzymatic hydrolysis, cation exchange resin deenzyme and forward osmosis membrane treatment are carried out in series, which can not only completely remove protein impurities and achieve high purity of polysaccharide, but also mild deproteinization conditions and stable structure of polysaccharide can be achieved.

Owner:HEFEI UNIV OF TECH +1

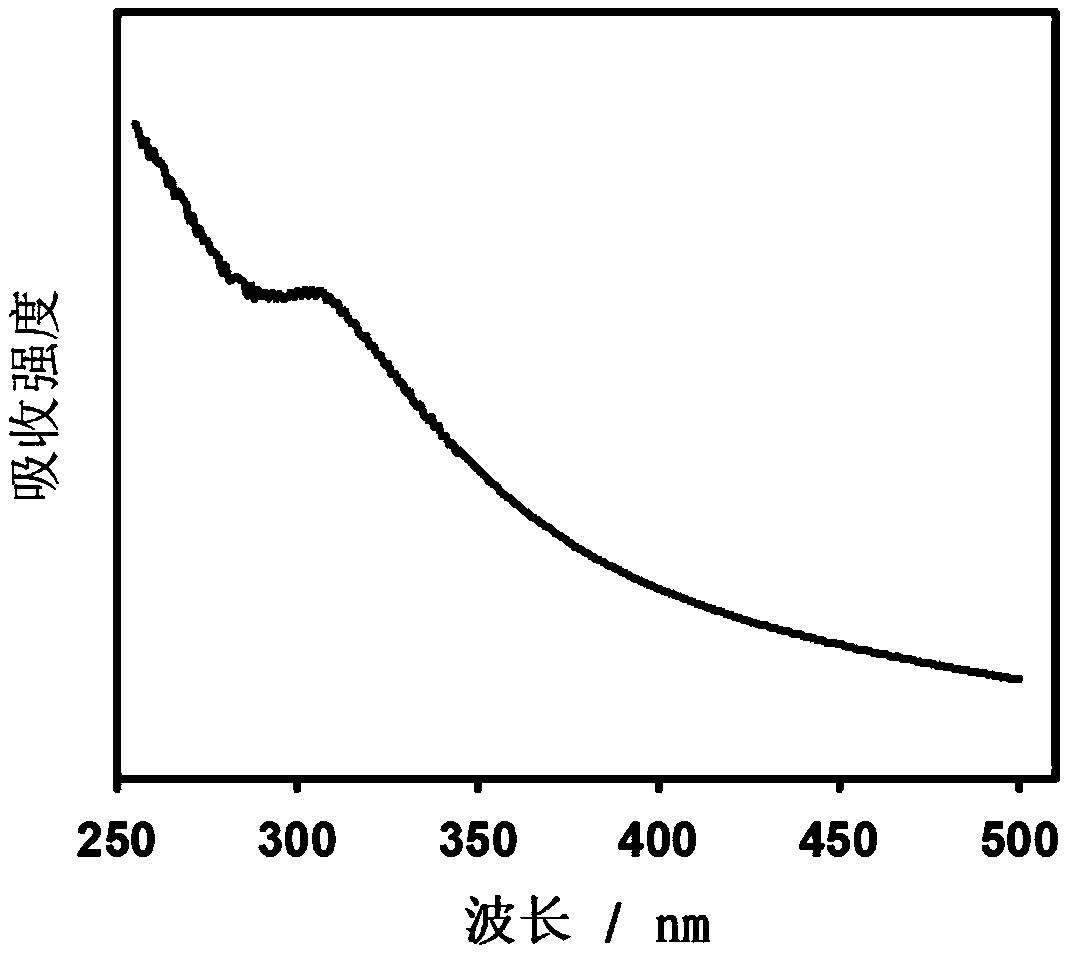

Kit for detecting trypsin and inhibitor thereof based on platinum nanoclusters

InactiveCN109781719AQuick checkHigh detection specificityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsMethylanilineUltraviolet absorption

The invention discloses a kit for detecting trypsin and the inhibitor thereof based on platinum nanoclusters. The kit is characterized in that synthesized platinum nanocluster simulated oxidase is utilized to catalyze the color development of the coupling product of 3-Methyl-2-benzothiazolinone hydrazone hydrochloride monohydrate and N-ethyl-N-(2-hydroxy-3-sulfopropyl)-3-methylaniline sodium salt;protamine makes platinum nanoclusters aggregate by means of an electrostatic effect, so that the catalytic activity of the nanoclusters is decreased; the protamine is hydrolyzed by trypsin, and so that the trypsin can effectively inhibit the effect of the protamine on the aggregation of the platinum nanoclusters. Therefore, on the basis of solution color change and ultraviolet absorption spectrumfeature change, the kit can be directly used for the determination of the trypsin and the content of the inhibitor of the trypsin. The rapid detection method provided by the invention does not need complicated chemical modification or signal labeling, has strong anti-interference capacity, can quickly and accurately realize the rapid detection of the trypsin, and is suitable for clinical application, for example the diagnosis of diseases such as pancreatitis.

Owner:FUJIAN MEDICAL UNIV

Method for detecting trypsin and inhibitor of trypsin on basis of phosphorescence copper nano-cluster

ActiveCN108760696ADetect Green FastGreen Rapid Quantitative DetectionFluorescence/phosphorescenceCopper sulfateTryptic hydrolysis

The invention relates to a method for detecting trypsin and an inhibitor of the trypsin on the basis of a phosphorescence copper nano-cluster, and belongs to the technical field of nanometer biosensing. Glutathione (GSH) and copper sulfate (CuSO4) are added in a mixed solvent of DMF (Dimethyl Formamide) and deionized water to prepare a copper nano-cluster having a phosphorescent property. Throughthe electrostatic interaction of cytochrome C (Cyt c), the fluorescence intensity of Cu NCs is reduced. The Cyt c incubated trypsin is added in the prepared Cu NCs. The Cyt c is hydrolyzed by the trypsin, the existence of the trypsin effectively inhibits the quenching effect of Cyt c on Cu NCs. Therefore, the trypsin is quantitatively detected through the change of the fluorescence intensity. A phosphorescence copper nano-cluster probe has the characteristics that the reaction is simple and fast, the detection of the trypsin is highly sensitive, and the chemical stability and the biological compatibility are good.

Owner:NANJING UNIV OF TECH

Infant milk protein partial hydrolysis formula food for special medical use

The present application provides an infant milk protein partially hydrolyzed formula for special medical use comprising hydrolyzed whey protein prepared from alkaline protease or trypsin hydrolyzed whey protein. According to the formula food disclosed by the invention, good flavor is maintained through moderate hydrolysis, and meanwhile, the sensitization of beta-lactoglobulin is effectively reduced.

Owner:青岛圣桐营养食品有限公司

Preparation method of urechis unicinctus viscera glycosaminoglycan and application thereof

InactiveCN105085694AHigh purityGood anti-lipid peroxidation activityMetabolism disorderAntinoxious agentsFreeze-dryingHydrolysate

The invention relates to a preparation method of urechis unicinctus viscera glycosaminoglycan. The method comprises the following steps: using urechis unicinctus viscera, rubbing and homogenizing, degreasing and performing pumping filtration to obtain the urechis unicinctus viscera dry powder, then hydrolyzing the viscera dry powder by papain and trypsin, extracting a viscera glycosaminoglycan crude product from a hydrolysate, and performing dialysis and freeze drying to obtain the viscera glycosaminoglycan. The invention also relates to an application of the viscera glycosaminoglycan in preparation of food, health product and medicine for preventing and adjusting blood fat. The extraction method is simple, yield can reach 6-7%, protein content of viscera glycosaminoglycan can be greatly reduced, purity of glycosaminoglycan is increased, and the method provides a novel approach for preventing and adjusting blood fat.

Owner:ZHEJIANG OCEAN UNIV

Method for preparing ACE (Angiotensin Converting Enzyme) inhibitory peptides through substep enzymatic hydrolysis of feta protein

The invention provides a method for preparing ACE (Angiotensin Converting Enzyme) inhibitory peptides through substep enzymatic hydrolysis of feta protein. The method comprises the following steps of: cooling and centrifuging recovered feta for degreasing to obtain skimmed milk, using the skimmed mild for preparing casein by isoelectric precipitation, firstly hydrolyzing the casein with Alcalase to obtain hydrolysate containing the ACE inhibitory peptides through optimization of hydrolysis condition, and performing optimization of neutral protease and trypsin hydrolysis conditions by taking the hydrolysate as a substrate to obtain small-molecule peptides with high ACE inhibitory activity through. The inhibitory proportion of an ACE inhibitory peptide product prepared by the method can reach above 90%; and the ACE inhibitory peptide product has the characteristics of being diversified in variety of the ACE inhibitory peptides, having small fragments, being beneficial to the separation and purification of the small-molecule peptides and being high in inhibitory proportion.

Owner:SHAANXI UNIV OF SCI & TECH

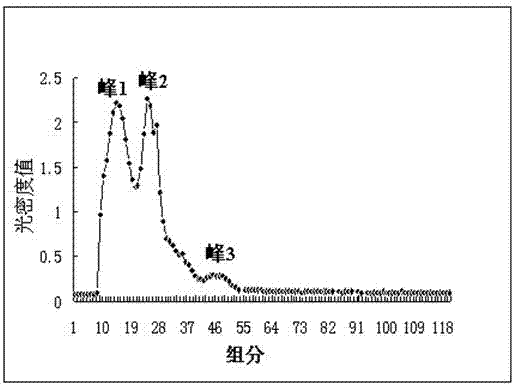

Preparation method of yak milk casein anticoagulant peptide

ActiveCN103388015AHigh nutritional valueHigh protein contentPeptide preparation methodsFermentationHydrolysateReaction temperature

The invention relates to a method for preparing, separating and purifying anticoagulant peptide by hydrolyzing yak milk casein with trypsin. The method comprises the following steps: (1), adjusting the reaction temperature at 30-50 DEG C and pH at 5.5-7.5, and stirring to dissolve yak milk casein; (2) hydrolyzing by adding trypsin, maintaining the reaction temperature at 30 DEG C and pH at 5.5-7.5, and hydrolyzing for 1-4 hours; (3) heating to 80-100 DEG C, maintaining for 5-15 minutes, and inactivating trypsin; (4) adjusting pH to 4.6 with 5mol / L edible grade hydrochloric acid to separate out casein at an isoelectric point thereof; (5) centrifugalizing for 5-10 minutes by a centrifugal force at 4000-10000g to remove precipitates and reserving supernate; (6) spraying and drying the supernate; (7) separating and purifying hydrolysates by a glucan column; (8) detecting the activities of the components by an agarose-fibrous protein flat band method; and (9) detecting an amino acid sequence: detecting the amino acid sequence of the yak milk casein anticoagulant peptide by an N-terminal sequencing method.

Owner:甘肃华羚生物技术研究中心 +2

Method for preparing exorphins from soybean protein isolate by fractional hydrolysis

The invention provides a method for preparing exorphins from soybean protein isolate by fractional hydrolysis, which relates to a method for preparing exorphins. The invention solves the problem that the traditional exorphins preparing method has high preparing cost and is easy to produce harmful substances in the preparing process. The method 1: after being hydrolyzed, the pepsin is hydrolyzed by trypsin, acid protease, alkaline protease or neutral protease; the method 2, after being hydrolyzed, the trypsin is hydrolyzed by pepsin, acid protease, alkaline protease or neutral protease; the method 3, after being hydrolyzed, the alkaline protease is hydrolyzed by pepsin, trypsin, acid protease or neutral protease; the method 4, after being hydrolyzed, the neutral protease is hydrolyzed by pepsin, trypsin, acid protease or alkaline protease; and the method 5, after being hydrolyzed, the acid protease is hydrolyzed by pepsin, trypsin, alkaline protease or neutral protease. The invention has low cost, and does not produce harmful substances in the preparing process.

Owner:HARBIN UNIV OF COMMERCE

Preparation method of whey protein peptide with antibacterial activity

InactiveCN104673866AHas antibacterial activityHigh antibacterial activityPeptide preparation methodsFermentationChromatographic separationBiotechnology

The invention discloses a preparation method of a whey protein peptide with antibacterial activity, and relates to the technical field of biology. The preparation method comprises steps of preprocessing, enzymolysis, separation and purification, wherein the purification step adopts a simulated mobile chromatography separation method for industrial production of the coarse whey protein peptide after separation, and the whey protein peptide with antibacterial activity is obtained. According to the preparation method, trypsin is adopted to hydrolyze the whey protein to prepare the peptide with antibacterial activity, so that deep processing of the whey protein is realized; the process of the preparation method is simple, the antibacterial activity of the hydrolysis product is high, and the preparation method is suitable for industrial popularization and production; the method is high in automation degree, low in production cost and high in extraction efficiency, and the antibacterial peptide prepared with the method not only has more remarkable bacteriostatic effect, but also is safe and nutritional, provides a reliable base material or ingredient for development of a natural preservative agent, can increase the weight of preservative products of China and improve the safety of the preservative products of China, and meets the requirement of market development of natural food additives.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

Preparing method for transparent wood frog skin

InactiveCN105349711AEfficient use ofPromote environmental protectionTanning treatmentHydrolysisProcess design

The invention provides a preparing method for transparent wood frog skin. According to the preparing method, the wood frog skin serves as a raw material, a trypsin hydrolysis method is adopted, the black green on the surface of the wood frog skin is effectively removed, and the wood frog skin which is transparent in character and retains original special textures is obtained; the wood frog skin becomes a novel leather raw material convenient to dye; and meanwhile a new material is provided for process design. By means of the preparing method, effective utilization of the wood frog skin is achieved; and in addition, the preparing process is beneficial to environmental protection and has a wide application prospect.

Owner:JILIN UNIV

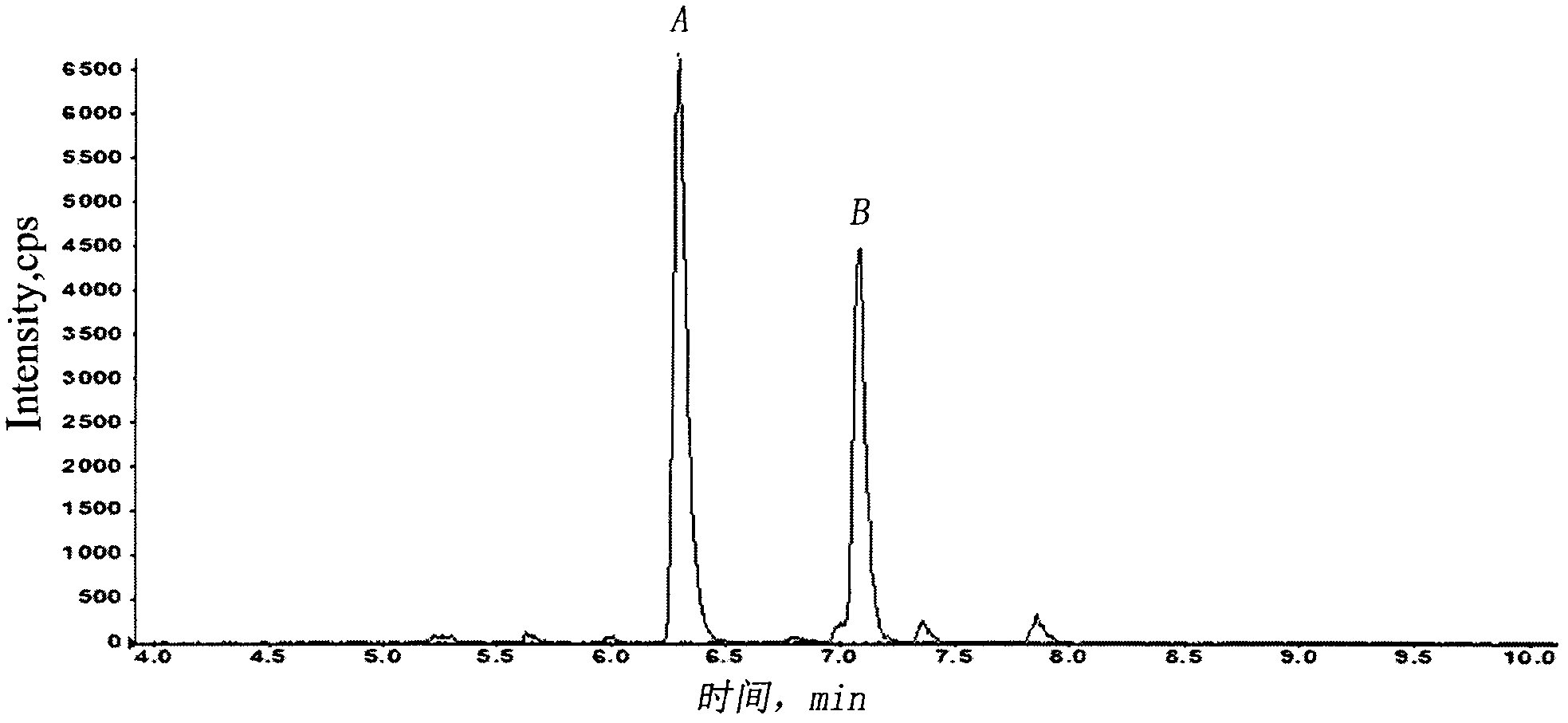

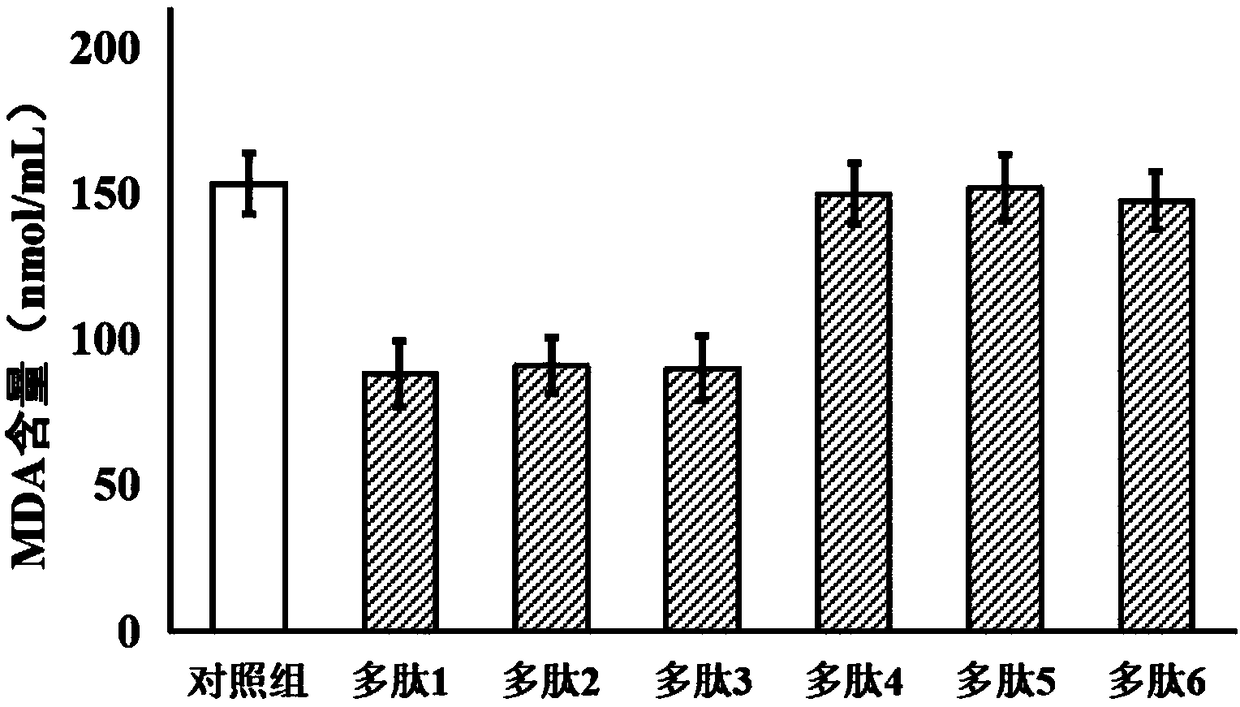

Preparation method and applications of camel milk antioxidant polypeptides

ActiveCN109180788AEnhance humoral immunityFunction increaseDepsipeptidesPeptide preparation methodsFreeze-dryingWhole body

The invention relates to a preparation method and applications of camel milk antioxidant polypeptides. According to the preparation method, fresh camel milk is taken as a raw material, is subjected tocentrifugation at 4 DEG C to remove cream, is subjected conventional isoelectric precipitation, dialysis bag method, concentration, and freeze drying so as to obtain total casein, trypsin is adoptedfor hydrolysis, freeze drying is adopted for refining so as to obtain antioxidant polypeptides; and then ultrafilter membrane method, gel column treatment, and high efficiency liquid phase separationpurification are adopted so as to obtain three camel milk antioxidant polypeptides with relatively high antioxidant activities. It is determined that an obtained product comprises three polypeptides including RLDGQGRPRVWLGR (1665.94Da), TPDNIDIWLGGIAEPQVKR (2122.13Da), and VAYSDDGENWTEYRDQGAVEGK (2489.09Da) based on high resolution mass spectrum and liquid mass tandem chromatography analysis of the amino acid primary structures. The camel milk antioxidant polypeptides are capable of enhancing humoral immunity and whole body immunity, are rich in pure natural proteins and 18 amino acids which can be easily absorbed and digested by human body, and are suitable to be taken as ideal dairies of old people and infants.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

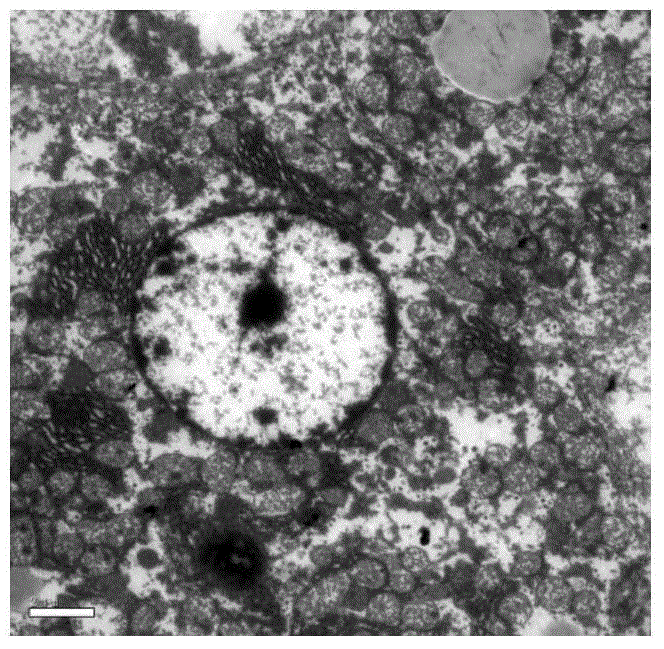

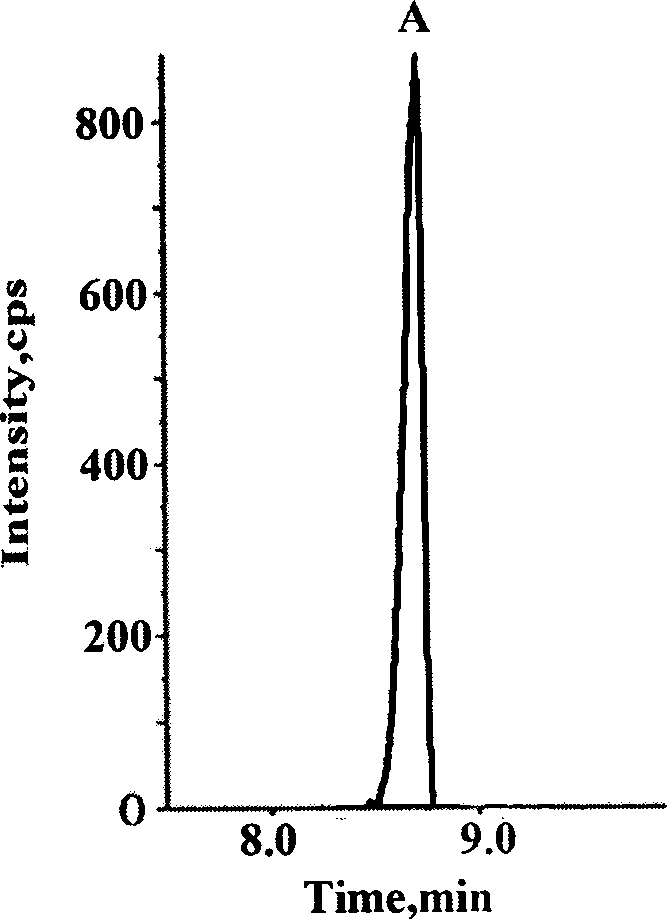

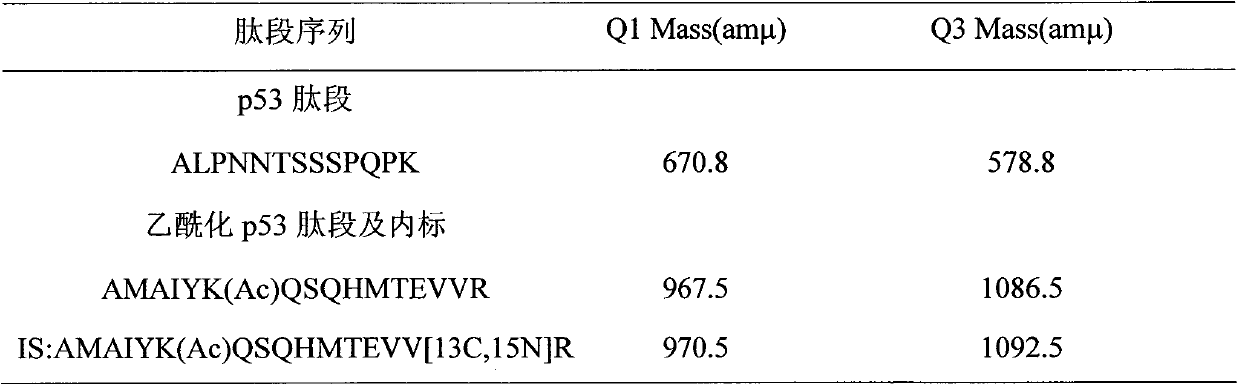

Human breast cancer cell acetylation p53 protein isotope labeling quantitative method

The invention belongs to the field of analysis and relates to breast cancer cell endogenous biological macromolecule acetylation p53 protein isotope quantitative analysis. The acetylation p53 protein in a complex cell matrix sample is extracted, separated and purified by utilizing the technical means such as co-immunoprecipitation and gel electrophoresis. The method comprises the following steps: by utilizing a strategy for performing qualitative and quantitative analysis on specific peptide fragments generated by performing trypsin hydrolysis on recombinant human p53 proteins and p53 proteins in breast cancer cells, by taking synthetic peptide fragments generated by performing stable carbon 13 and nitrogen 15 isotope labeling on amino acids in the specific peptide fragment sequence as interior labels, realizing quantitative analysis of acetylation p53 proteins on specific sites in a DNA binding domain in a breast cancer cell sample. The method mainly comprises a sample extraction and gel electrophoresis method, an Obitrap measurement method, preparation of a standard curve and measurement of precision and density. The method is good in linear relationship, high in accuracy and high in reproducibility and can be used for quantitative analysis of acetylation p53 proteins in cells.

Owner:CHINA PHARM UNIV

Preparation method for chlorella antitumor polypeptide

InactiveCN102851345BHas antitumor activityHas inhibitory effectFermentationAntineoplastic agentsUltrafiltrationBiochemistry

The invention provides a preparation method of chlorella anti-tumor polypeptide, which is characterized in that firstly, the chlorella protein is extracted by using a low-temperature ultra-high pressure continuous flow cell crusher, and then the chlorella protein is hydrolyzed by trypsin, filtered by an ultrafiltration centrifuge tube, and obtained Chlorella polypeptides with molecular weights ranging from 0-3KD, 3-5KD, 5-10KD and greater than 10KD. The chlorella polypeptide prepared by the present invention has anti-tumor activity, for example, it has a certain inhibitory effect on the growth of human liver cancer cell HepG2 in vitro. The cell (HepG-2) growth inhibition rates in vitro reached 7%, 14% and 10%, respectively, which is conducive to the development and utilization of anti-tumor health food and pharmaceutical products.

Owner:SOUTH CHINA UNIV OF TECH

Processing method of donkey-hide gelatin and ginger tea

InactiveCN107712157AImprove solubilityAchieve continuous extractionPre-extraction tea treatmentCavitationPancreas

The invention discloses a processing method of donkey-hide gelatin and ginger tea. The processing method is characterized in that crude trypsin is extracted by processing pig pancreas, so that the activity is better and the benefit for reducing the production cost is achieved; the donkey-hide gelatin is hydrolyzed by the crude trypsin to obtain small-molecular peptides with certain physiological activity, so that the digestion and the absorption by a human body are easier and the effects are exerted more easily; and continuous extraction of effective components of fresh ginger is realized by asubcritical water extraction mode, and the cavitation effect of ultrasonic wave is utilized to generate an enhancing action for extracting subcritical water.

Owner:安徽华健生物科技有限公司

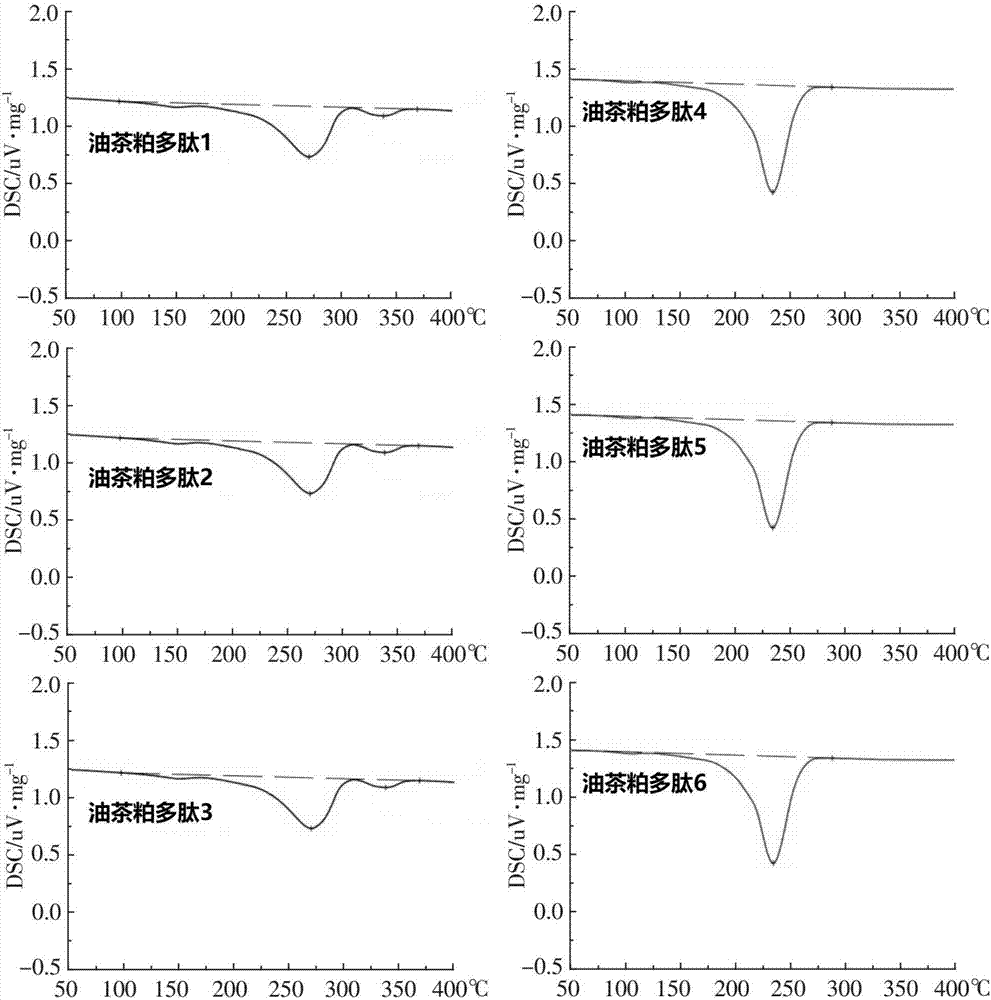

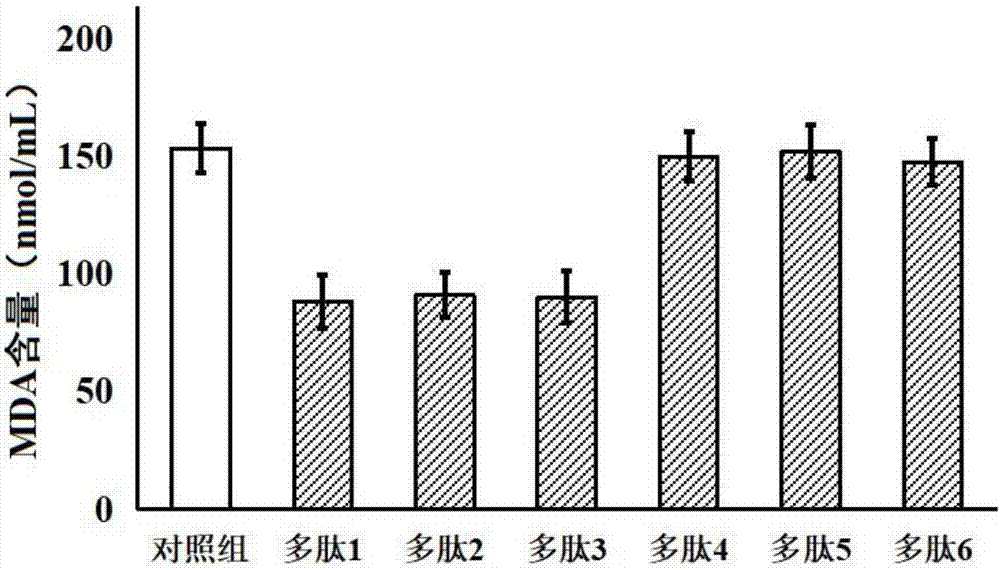

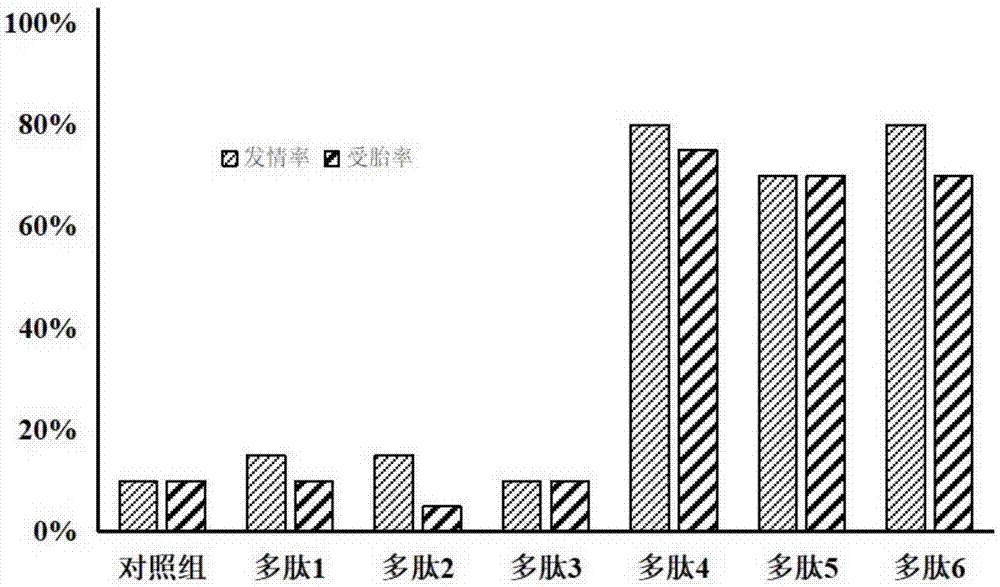

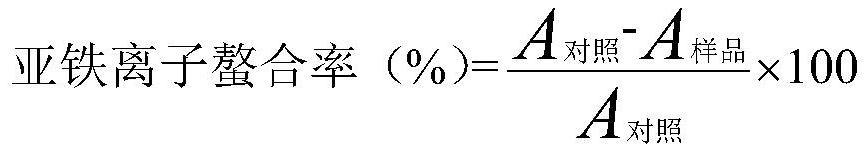

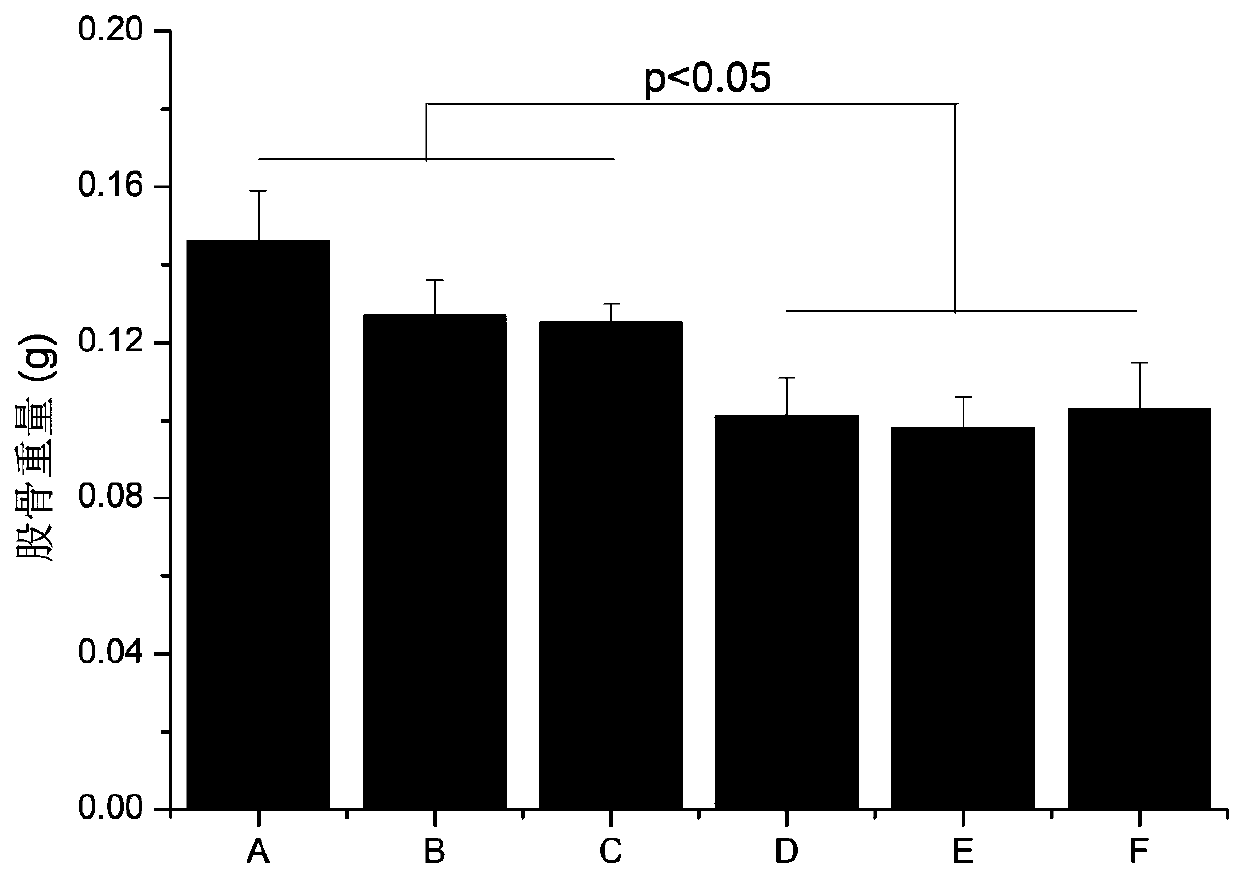

Oil tea meal polypeptide, and preparation method and application thereof in cryopreservation of bovine semen

ActiveCN107964033AImprove antioxidant capacityPromote estrusDead animal preservationPeptide preparation methodsPregnancyUltrafiltration

The invention discloses an oil tea meal polypeptide, and a preparation method and an application thereof in cryopreservation of bovine semen. The oil tea meal hydrolytic polypeptide has a variety of activities, and the activities of the hydrolytic polypeptide are affected by proteolytic sites in the oil tea meal: the polypeptide produced by trypsin hydrolysis and having the molecular weight of [5000 u, 3000 u] has the effect of improving the antioxidant ability of the bovine cryopreserved semen, and can be used as a bovine semen cryopreservation protection agent for reducing oxidative damage;and the polypeptide produced by alkaline protease hydrolysis and having the molecular weight of [5000 u, 3000 u] can promote empathema and pregnancy of anestrus cows. Moreover, the preparation methodof the hydrolytic polypeptide is simple, only simple crushing, enzymatic hydrolysis, ultrafiltration and freeze drying are used, and all the steps can be realized in a factory with mass production andare easy to implement. Waste reuse of camellia meiocarpa hu. meal is realized, and the economic added value of the camellia meiocarpa hu. meal can be increased.

Owner:盐城新咏投资发展有限公司

Composite ACE inhibitory peptide as well as preparation method and application thereof

ActiveCN114164247AImprove antioxidant capacityHigh activityHydrolysed protein ingredientsAntinoxious agentsMeat pasteHydrolysis

The invention discloses a composite ACE inhibitory peptide and a preparation method and application thereof.The method comprises the following steps that soybean protein isolate is mixed with water, the mixture is mixed through a colloid mill, the temperature is increased to 90-95 DEG C, heat preservation is conducted for 1.0-1.5 hours, then alkaline protease, papain and trypsin are added for hydrolysis for 4-6 hours, then blue round meat paste is added, and the mixture is stirred to be uniform; adding glutamine transaminase, continuing hydrolysis for 3-5 hours, and then performing enzyme deactivation and separation to obtain a water system layer containing the composite ACE inhibitory peptide. Animal protein (blue circle) and vegetable protein (soybean protein isolate) are used as raw materials, on the premise that protease is used for preliminarily degrading soybean protein, blue circle is added for enzymolysis, glutamine transaminase is added at the same time, and when the protease degrades the soybean protein and the blue circle protein to release functional peptide and amino acid, the amino acid content of the protein is increased. Part of peptide and amino acid are recombined to form new functional peptide, so that the oxidation resistance and ACE inhibitory activity of the enzymolysis product are further improved.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for absolutely quantifying mass spectrum of histidine tag-containing recombinant human endostatin

The invention belongs to the technical field of analysis, and relates to a method for absolutely quantifying mass spectrum of histidine tag-containing recombinant human endostatin. The method is based on LC-MS / MS, and extracts histidine tag-containing recombinant human endostatin from a plasma sample through utilizing Ni<2+> sepharose gel resin, and realizes absolute quantification of histidine tag-containing recombinant human endostatin in the plasma sample through utilizing a quantifying strategy for a specific peptide generated during hydrolysis of recombinant human endostatin with trypsin and taking a synthetic peptide having a sequence similar to that of the specific peptide as an interior label. The invention mainly includes a biological sample preparation method, an LC-MS / MS measuring method, standard curve preparation and precision degree measurement. The method has good linear relation, high accuracy degree and excellent reproducibility, and can be used for measuring the blood concentration of histidine tag-containing recombinant human endostatin and studying the pharmacokinetics.

Owner:CHINA PHARM UNIV

Method for monitoring preparation of codfish immunoactive peptide on line

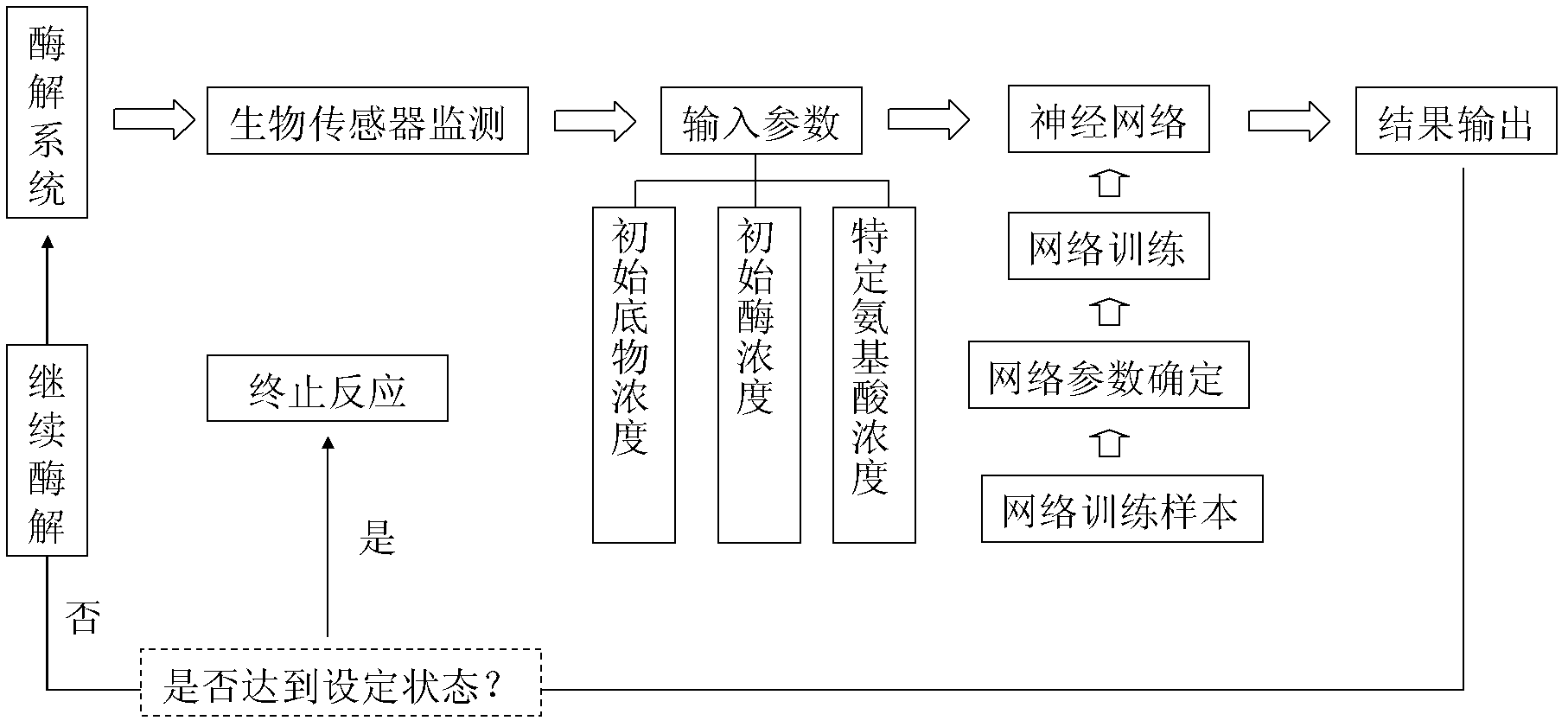

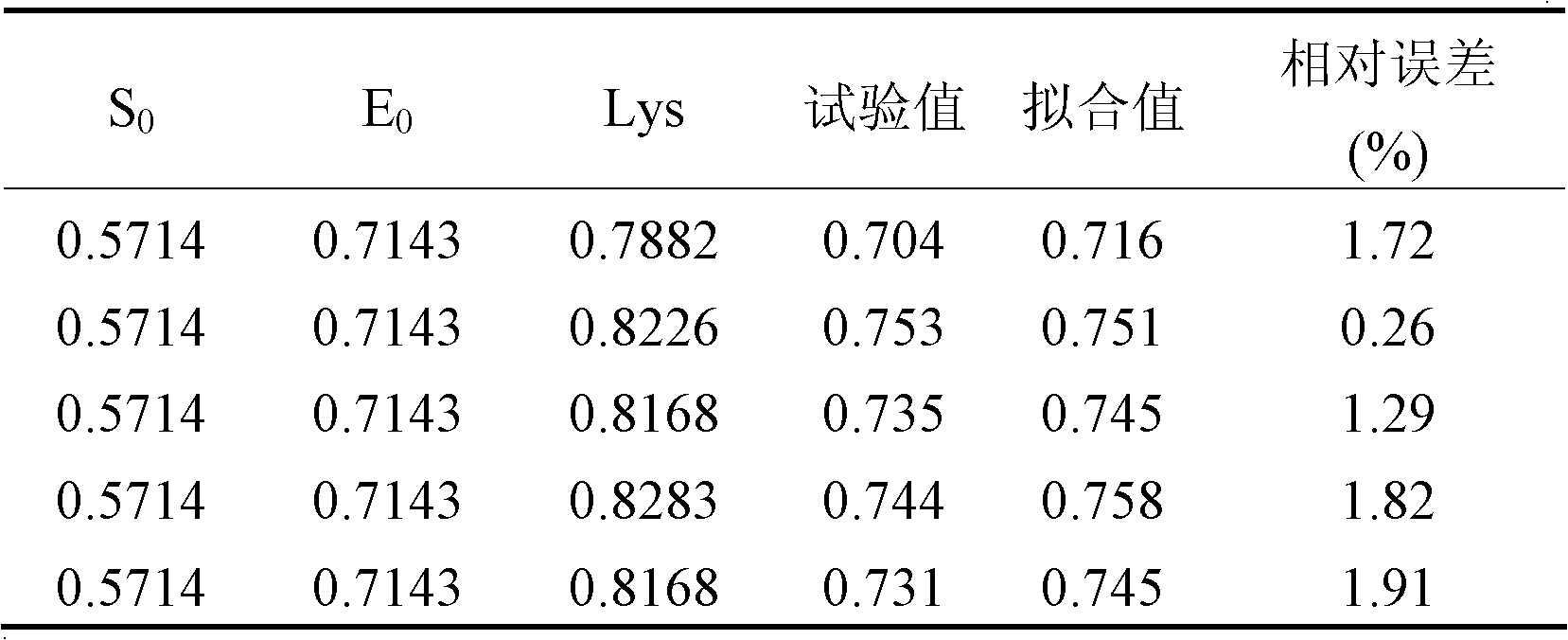

InactiveCN102559822AOptimum degree of hydrolysisOn-line monitoring of hydrolysis reaction degreeMaterial analysis by electric/magnetic meansBiological neural network modelsImmune effectsArtificial neural network model

The invention relates to codfish immunoactive peptide and a method for monitoring preparation of the codfish immunoactive peptide on line. A preparation method for the codfish immunoactive peptide comprises the following steps: hydrolyzing codfish protein by using trypsin; and stopping hydrolysis when the hydrolysis degree is 16 to 17 percent. GLU-BP-ANNs and LYS-BP-ANNs network modes are established, so that the method for monitoring preparation of the codfish immunoactive peptide on line is provided. The optimum hydrolysis degree of the codfish protein is determined, so that basis is laid for achieving the codfish immunoactive peptide with the optimum immune effect. After the optimum hydrolysis degree is determined, the on-line monitoring method is established, so the hydrolysis reaction degree can be monitored on line through a biosensor-artificial neural network model. Even if the hydrolysis conditions are fluctuated, for example temperature, pH value, stirring speed and the like are changed, the hydrolysis reaction degree can still be monitored accurately. Therefore, the method has a good popularization and application prospect.

Owner:OCEAN UNIV OF CHINA

Camellia meal polypeptides, preparation method and application in promoting oestrus and conception of anestrus cows

ActiveCN108060196AImprove antioxidant capacityPromote estrusHydrolysed protein ingredientsAccessory food factorsCamellia oleiferaUltrafiltration

The invention discloses camellia meal polypeptides, a preparation method and application in promoting oestrus and conception of anestrus cows. The hydrolyzed polypeptides of camellia meal have variousactivities, and the activities of the hydrolyzed polypeptides are affected by proteolytic sites in the camellia meal: the polypeptide which is produced by hydrolysis of trypsin and has a molecular weight of (5,000 mu, 3,000 mu) has the effect of improving the oxidation resistance performance of bovine cryopreserved semen, and can be used as a bovine semen cryoprotective agent to reduce oxidativeinjury; the polypeptide which is produced by hydrolysis of alkaline protease and has a molecular weight of (5,000 mu, 3,000 mu) can promote the oestrus and the conception of the anestrus cows. Furthermore, the preparation method of the hydrolyzed polypeptides is simple, and only simple smashing, enzymolysis, ultrafiltration and lyophilization are used. The steps all can realize mass production ina factory and are easy to implement. According to the camellia meal polypeptides, the preparation method and the application in promoting the oestrus and the conception of the anestrus cows, waste reuse of small-fruit camellia meal is realized, and the economical additional value of the small-fruit camellia meal can be increased.

Owner:CP UNITED ANIMAL PHARMA TECH JIANGSU

Preparing method of calcium nutrient supplement

ActiveCN110353272APromotes anabolismGood water solubilityProtein food ingredientsFood additivePhosphate

The invention discloses a preparing method of a calcium nutrient supplement, and belongs to the field of biochemical engineering and food additives. The method includes the steps of hydrolyzing caseinas the raw material through trypsin to obtain casein phosphoeptide, making the casein phosphoeptide react with octacosanol and calcium phosphate under the effect of acid phosphatase, and conducting phosphate esterification to form the calcium nutrient supplement (casein phosphoeptide-octacosanol ester-calcium phosphate CPP-OOL-ACP). The prepared calcium nutrient supplement (CPP-OOL-ACP) has the calcium content of 0.7% or above and the casein phosphoeptide and calcium chelating rate of 96%, is solid-state light yellow powder at normal temperature, is odorless, can be dissolved in water, and can effectively promote the calcium absorption and calcium deposition in bones, improve the bone density and increase the bone strength.

Owner:NANTONG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com