Method for preparing spirulina polypeptide-chitosan nano particles

A technology of chitosan nanoparticles and spirulina polypeptides, which can be applied to medical preparations without active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc., can solve problems such as human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

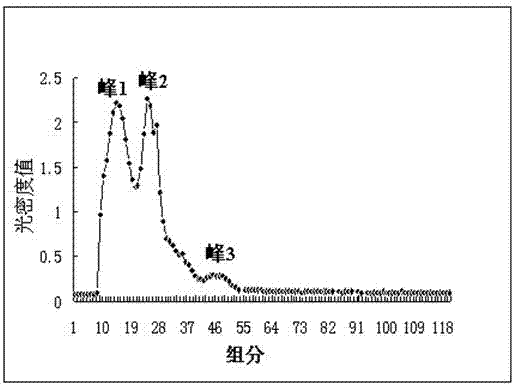

Image

Examples

Embodiment 1

[0032] The preparation method of spirulina polypeptide-chitosan nanoparticle, the steps are as follows:

[0033] (1) Dissolve 20 g of spirulina powder in 300 mL of Milli-Q water, and stir magnetically for 30 min at room temperature. After it was completely dissolved, it was frozen in a -20 °C refrigerator for 80 min, and then thawed in a 4 °C refrigerator, and the freezing and thawing was repeated three times. Then, the Spirulina wall was disrupted by ultrasonication for 300 times at 100 W ultrasonic power at intervals of 10 s for 5 s, so that the protein was freed. To prevent protein denaturation from the heat generated during sonication, samples were placed in an ice bath. Finally, the obtained solution was centrifuged at 4 °C and 8000 r / min for 30 min to remove the precipitate to obtain the protein supernatant, and then rapidly freeze-dried in vacuum to obtain the Spirulina protein powder.

[0034] (2) Based on the spirulina protein powder obtained in step (1), configure ...

Embodiment 2

[0042] The preparation method of spirulina polypeptide-chitosan nanoparticle, the steps are as follows:

[0043] (1) Dissolve 10 g of spirulina powder in 200 mL of Milli-Q water, and stir magnetically for 20 min at room temperature. After it was completely dissolved, it was frozen in a -20 °C refrigerator for 80 min, and then thawed in a 4 °C refrigerator, and the freezing and thawing was repeated three times. Then, the Spirulina wall was broken by sonicating 100 times at an ultrasonic power of 50 W at intervals of 5 s and 4 s, so that the protein was freed. To prevent protein denaturation from the heat generated during sonication, samples were placed in an ice bath. Finally, the obtained solution was centrifuged at 4 °C and 6000 r / min for 25 min to remove the precipitate to obtain the protein supernatant, and then quickly freeze-dried in vacuum to obtain the Spirulina protein powder.

[0044] (2) Based on the spirulina protein powder obtained in step (1), configure a 2% spi...

Embodiment 3

[0048] The preparation method of spirulina polypeptide-chitosan nanoparticle, the steps are as follows:

[0049] (1) 30 g of spirulina powder was dissolved in 500 mL of Milli-Q water, and magnetically stirred for 40 min at room temperature. After it was completely dissolved, it was frozen in a -20 °C refrigerator for 80 min, and then thawed in a 4 °C refrigerator, and the freezing and thawing was repeated three times. Then, the Spirulina wall was broken by sonicating 200 times at 150 W ultrasonic power at intervals of 10 s for 6 s, so that the protein was freed. To prevent protein denaturation from the heat generated during sonication, samples were placed in an ice bath. Finally, the obtained solution was centrifuged at a temperature of 4 °C and a speed of 5000 r / min for 40 min to remove the precipitate to obtain a protein supernatant, and then rapidly freeze-dried in a vacuum to obtain Spirulina protein powder.

[0050] (2) Based on the spirulina protein powder obtained in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com