Method for preparing peptone by hydrolyzing lactalbumin with compound enzymes and peptone obtained by using same

A technology for compound enzymatic hydrolysis and whey protein, applied in the field of peptone and its preparation, can solve the problems of description of the degree of hydrolysis of soybean raw materials, complicated process, etc., and achieve the effects of being conducive to rapid growth and reproduction, high nutritional value and high oligopeptide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

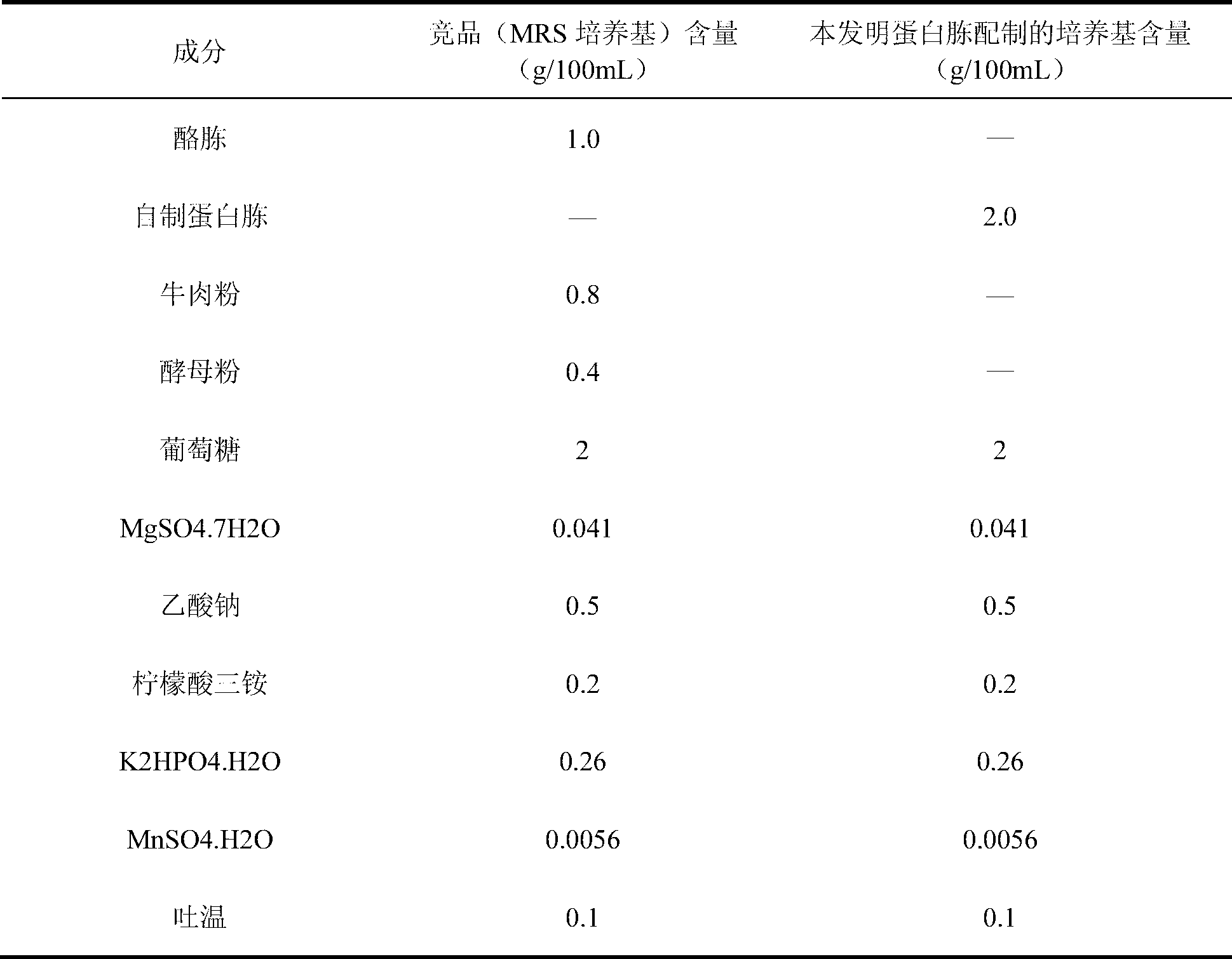

Embodiment 1

[0037] see figure 1 Process, prepare whey protein into a 5% solution with water, and centrifuge the solution to degrease (5000r / min, 55°C). Incubate in medium for 20 minutes to denature the protein, and adjust the pH value of the defatted and denatured solution to 8.0 with 1 mol / L aqueous sodium hydroxide solution. Then put the whey protein solution in a 55°C water bath to keep warm, add trypsin accounting for about 1.66% of the raw whey protein to the whey protein solution, hydrolyze it for 0.5h until the degree of hydrolysis is about 45%, and then add about 1.66% of the raw whey protein Flavor protease with protein dosage of 3.33% is hydrolyzed together for about 3 hours until the degree of hydrolysis reaches 75%, inactivated in a water bath at 90°C for 10 minutes to terminate the hydrolysis, and then the hydrolyzed solution is treated by membrane filtration with an ultrafiltration membrane. The molecular weight and pore size of the membrane is 8000Da, the working pressure ...

Embodiment 2

[0040] Whey protein is prepared into a 7% solution with water, and the solution is centrifuged and degreased (5000r / min, 55°C). The fat content of the protein solution after degreasing is 0.06%, and the solution after degreasing is kept at 85°C in a hot water bath The protein was denatured for 15 minutes, and the pH value of the defatted and denatured solution was adjusted to 9.0 with 1 mol / L aqueous sodium hydroxide solution. Then put the whey protein solution in a 50°C water bath to keep warm, add about 0.7% of the raw whey protein trypsin to the whey protein solution, hydrolyze it for 1 hour until the hydrolysis degree is about 45%, and then add about 0.7% of the raw whey protein Use 2.3% flavor protease to hydrolyze together for about 2.5 hours until the degree of hydrolysis reaches 71%, inactivate in a water bath at 85°C for 15 minutes to terminate the hydrolysis, and then use the ultrafiltration membrane to filter the hydrolyzed solution. The molecular weight and pore si...

Embodiment 3

[0043] Prepare whey protein into a 2% solution with water, and centrifuge the solution to degrease (5000r / min, 55°C). The fat content of the protein solution after degreasing is below 0.05%. Incubate for 15 minutes to denature the protein, and adjust the pH of the defatted and denatured solution to 7.0 with 1 mol / L aqueous sodium hydroxide solution. Then put the whey protein solution in a water bath at 45°C to keep warm, add about 1.0% of the amount of raw whey protein trypsin to the whey protein solution, hydrolyze it for 1.5 hours until the degree of hydrolysis is about 45%, and then add about 1.0% of the raw whey Flavor protease with a protein dosage of 2.5% is hydrolyzed together for about 3.5 hours until the degree of hydrolysis reaches 73%, inactivated in a water bath at 85°C for 10 minutes to terminate the hydrolysis, and then the hydrolyzed solution is treated by membrane filtration with an ultrafiltration membrane. The molecular weight and pore size of the ultrafiltra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com