Fermentation preparation and extraction method for bacillus subtilis debitterized aminopeptidase

A technology of Bacillus subtilis and aminopeptidase, which is applied in the field of food additives and enzyme preparations, and can solve problems such as affecting food flavor, restricting popularization and application, and unpleasantness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

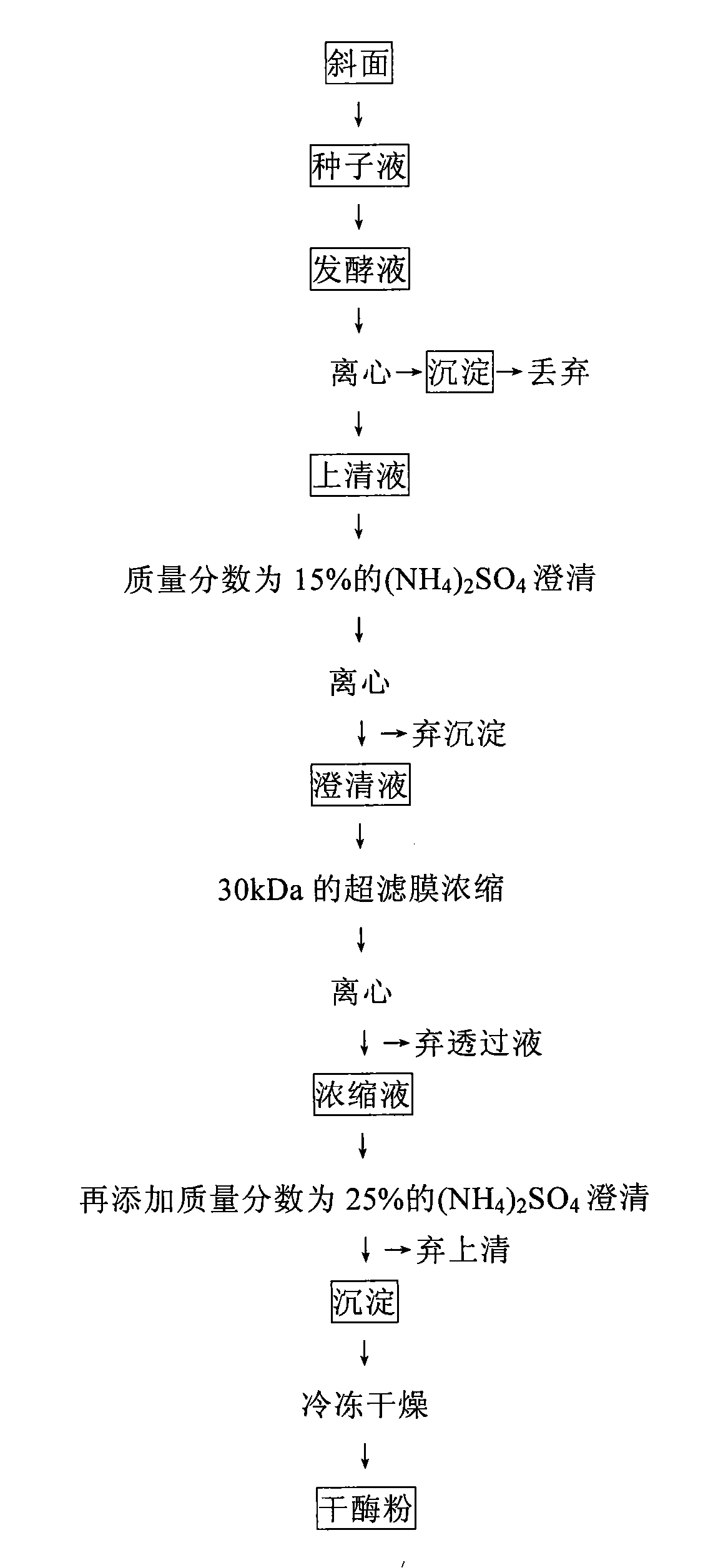

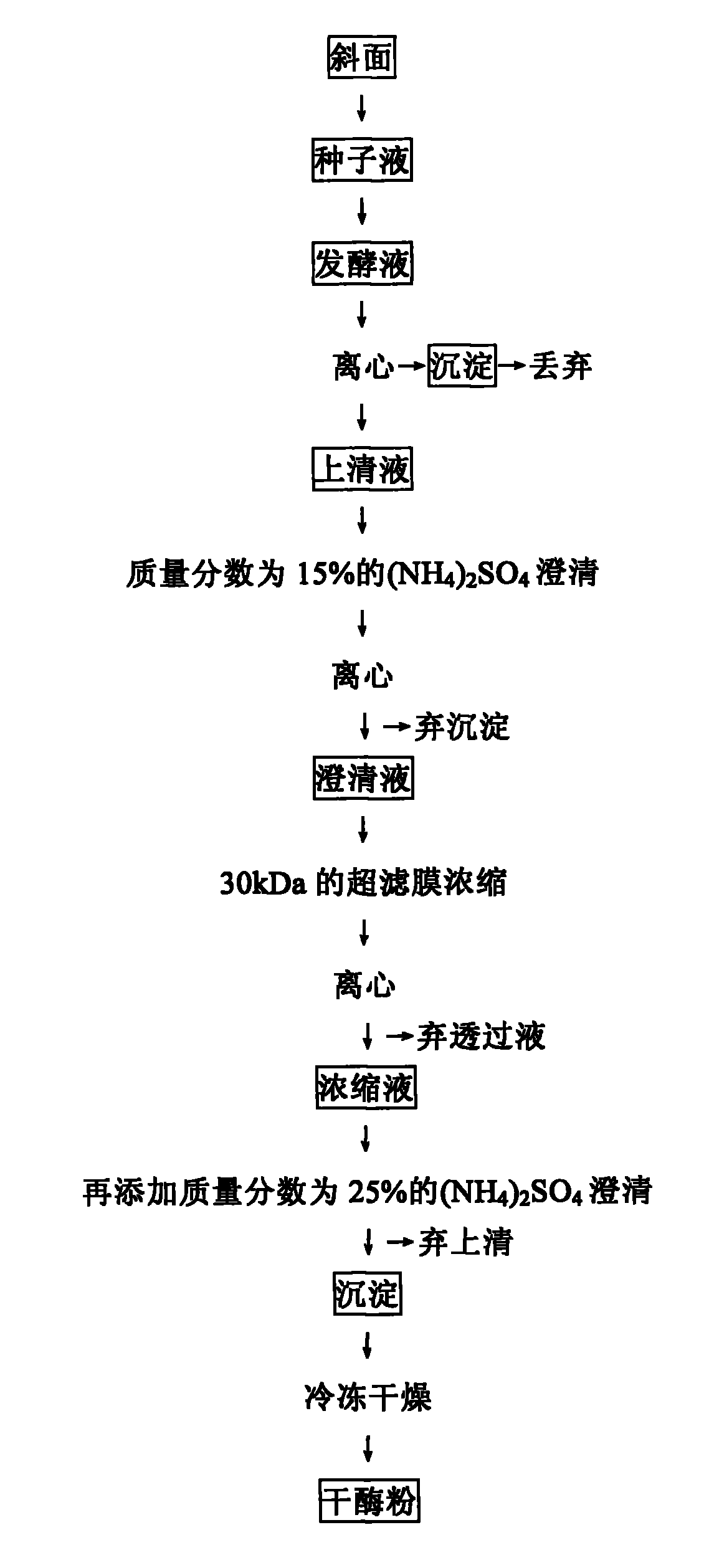

[0033] The slant of Bacillus subtilis Zj016 was inserted into the seed solution, and after expanded cultivation, it was then inserted into 4L fermentation medium according to the inoculum size of 4%. The initial pH is 7.0-8.0, 35-40°C, 400-1000rpm, ventilation rate 2:1, minimum DO is controlled at 60%, DO is coupled with rotational speed, and cultivated for 15 hours. Centrifuge the fermented liquid at 4° C. at 10,000 rpm for 10 min to collect 3.28 L fermented liquid, and add 15% (NH 4 ) 2 SO 4 , 4 DEG C, 10000rpm centrifugation 10min collects clarified liquid, selects the ultrafiltration membrane of 30kDa to carry out concentrating appropriate times, adds mass fraction again in concentrated liquid and is 25% (NH 4 ) 2 SO 4 Salt out, centrifuge at 10,000 rpm at 4°C for 10 minutes to collect the precipitate, and freeze-dry the precipitate to obtain solid aminopeptidase.

Embodiment 2

[0035] The enzyme system and substrate specificity of the aminopeptidase prepared in Example 1 were studied, and its acidic, neutral and alkaline protease activities were measured respectively, and the results showed no related endoprotein activity. Further studies have found that it has exoaminopeptidase activity, and its activity is the strongest for the substrate L-leucine-p-nitroaniline (Leu-pNA), which can reach about 3900U / mL, and for the substrate L-glutamine The activity of amino acid p-nitroaniline (Glu-pNA) is only 391U / mL, while the substrate is L-glycine-proline p-nitroaniline (Gly-Pro-pNA) has no hydrolysis ability, indicating that its opposite end is The more hydrophobic amino acids are more effective.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com