Probiotic fermentation milk drink with bowel relaxing and blood fat reduction assisting functions and making method thereof

A technology for assisting blood fat reduction and probiotic beverages, which is applied in the field of food processing, can solve limited problems, and achieve the effects of excellent functional properties, increased inhibition rate, and good flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

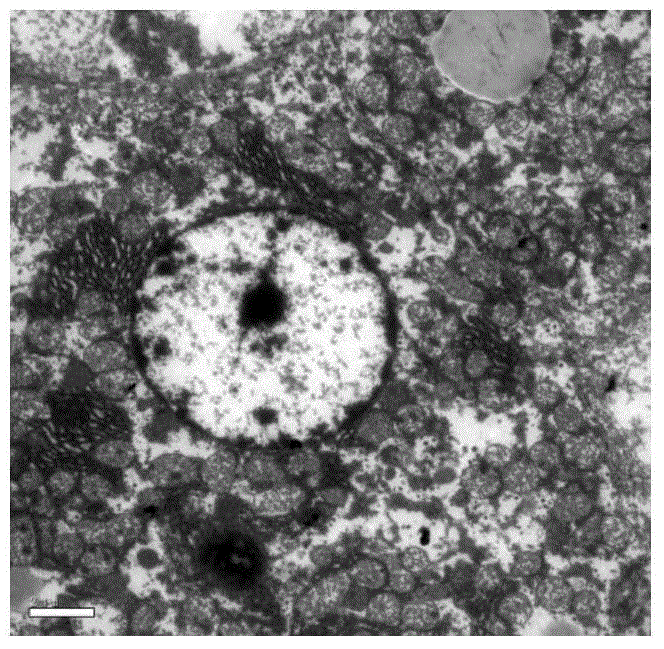

Image

Examples

preparation example Construction

[0027] 2. Preparation of whey powder treatment solution

[0028] The desalted whey powder with 70%-80% lactose content is dissolved in water to prepare a 5%-10% (w / w) whey powder solution, heated at 95°C for 1-3h, cooled for later use.

[0029] 3. Preparation of skim milk enzymatic hydrolyzate

[0030] Prepare 12% (w / w) reconstituted skim milk, heat treatment at 95°C for 5 minutes, add 0.6%-0.8% (w / w) trypsin in the total amount of reconstituted skim milk, enzymolyze at 50°C for 6-8h, after the reaction 95°C, 3-5min to inactivate enzyme treatment, cool down for later use.

[0031] 4. Preparation of fruit and vegetable pulp

[0032] (1) Banana processing method

[0033] Peel the bananas, blanch them in boiling water for 8 minutes to protect the color, beat them according to the material-to-water ratio of 1:3, sterilize them and cool them for later use;

[0034] (2) Processing method of sweet potato

[0035] Wash the sweet potatoes, beat them with a material-to-water ratio ...

Embodiment 1

[0131] Process such as Figure 8 6.7kg of whey powder+60kg of water were dissolved to make a 10% (w / w) whey powder solution, and heated at 95° C. for 3 hours to obtain 66.7 kg of whey powder treatment solution. Dissolve 6kg of skimmed milk powder + 44kg of water to make 12% (w / w) reconstituted skim milk, heat-treat at 95°C for 5 minutes, cool to 50°C, add 300g (0.6% of the total solution) trypsin, and enzymatically hydrolyze at 50°C for 8 hours. After the reaction was completed, 95 ° C, 3 minutes to inactivate the enzyme treatment, to obtain 50 kg of skim milk enzymatic hydrolyzate. Hawthorn powder 1kg + 9kg water (hawthorn powder to water: solid-liquid ratio 1:9) mixed, leached at 80°C for 30 minutes; kudzu root powder 1kg + 9kg water (pudzu root powder to water-solid ratio 1:9), added 8g (0.08% of the total solution) α-amylase and 8g (0.08% of the total solution) of β-amylase, enzymolysis 2h at 65°C; Salvia miltiorrhiza powder 0.5kg+9.5kg water (miltiorrhiza root powder and...

Embodiment 2

[0133] Process such as Figure 8 5.3kg whey powder + 61.4kg water were dissolved to make 8% (w / w) whey powder solution, heated at 95°C for 2h, and 66.7kg whey powder treatment solution was prepared. Dissolve 6kg skimmed milk powder + 44kg water to make 12% (w / w) reconstituted skim milk, heat treatment at 95°C for 5 minutes, cool to 50°C, add 400g (0.8% of the total solution) trypsin, enzymolyze at 50°C for 6h, and react After the end, the enzyme treatment was extinguished at 95°C for 5 minutes to prepare 50 kg of skim milk enzymatic hydrolyzate. Hawthorn powder 1kg+9kg water (hawthorn powder to water-to-liquid ratio 1:9) mixed, leached at 80°C for 30min; pueraria powder 1kg+9kg water (pueraria powder to water-to-liquid ratio 1:9), added 5g (0.05% of the total solution) α-amylase and 5g (0.05% of the total solution) of β-amylase, enzymolysis 3h at 65°C; Salvia miltiorrhiza powder 0.5kg+9.5kg water (military salvia miltiorrhiza powder and water feed liquid ratio 1:19), soak fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com