Preparation method of high-purity rice protein

A rice protein, high-purity technology, applied in the field of high-purity rice protein preparation, to achieve the effects of improving dissolution rate and extraction rate, extraction rate and product purity, and large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Non-limiting examples are described as follows:

[0023] 1) Pretreatment: Inject 50L of water into the reaction tank, add 100.0g of sodium bicarbonate, after fully dissolved, put in 5.0kg of raw materials, stir and react at 60°C for 1.0h, so that the soluble sugar in the raw materials is fully dissolved, and the slag is repeated Wash three times with water. After the reaction was completed, the washing solution was removed by plate and frame filter press.

[0024] 2) High-pressure homogenization: The washed rice dregs are calculated based on the loss of 10% of raw materials, and 36L of water is added to the reaction tank, and stirred into a high-pressure homogenizer for homogenization. The homogenization pressure is 60MPa, and the homogenization cycle is performed 3 times.

[0025] 3) Ultrasonic treatment: The homogenized rice dregs solution enters the ultrasonic generator for ultrasonication. Ultrasound at 450W for 15min (pulse 4s).

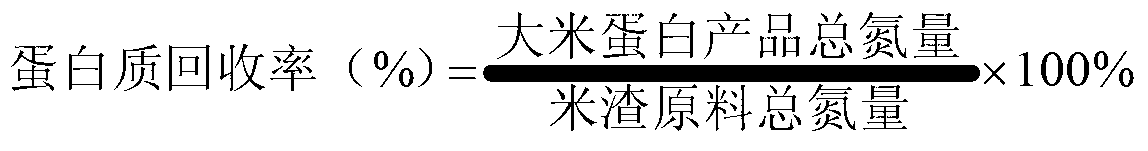

[0026] 4) Enzymolysis: After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com