Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

128 results about "Resorcinol-formaldehyde resin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

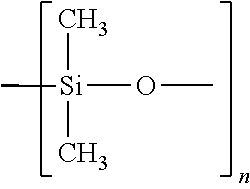

Resorcinol-formaldehyde resin. A phenol-formaldehyde resin, soluble in water, ketones, and alchol; used to make fast-curing adhesives for wood gluing.

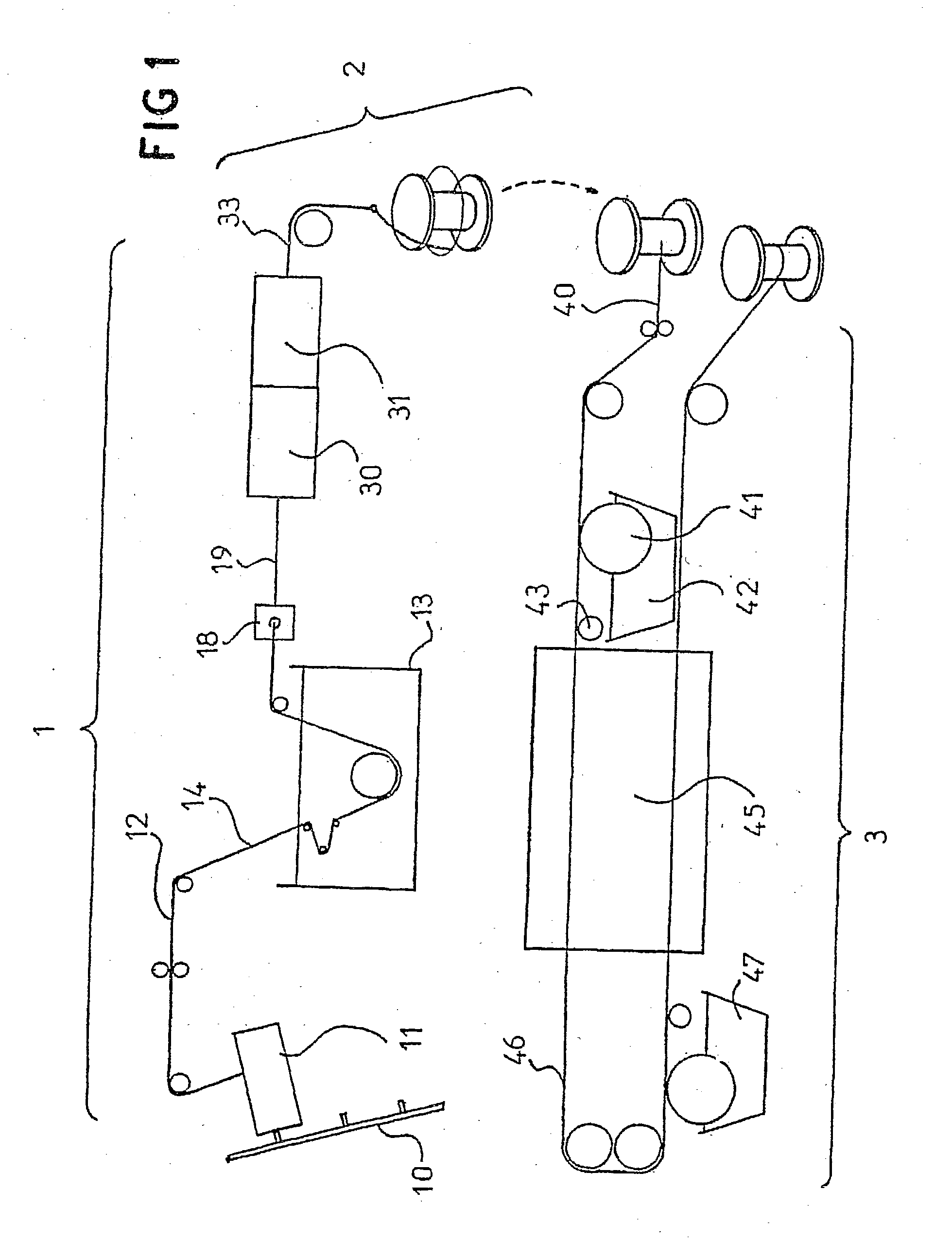

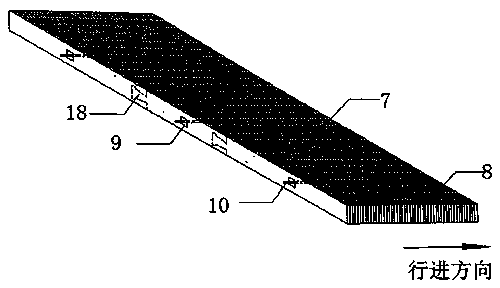

Method for the production of a carbon fiber-based reinforcing element for tires

InactiveUS20040043213A1Reduce riskImprove the lubrication effectCarbon fibresFilament handlingFiberCarbon fibers

A method for the production of a multifilament carbon fibre-based longitudinal reinforcing element, designed to be incorporated in a rubber-based item. Said method comprises the following steps, whereby untwisted carbon fibres are plunged into an impregnating bath contained a solution of resorcinol-formaldehyde resin and rubber latex, the impregnated fibres are then dried and the dried fibres are subsequently twisted. The inventive method is characterised by the fact that it also comprises a step, during the impregnation step, consisting in opening out the carbon fibres by spreading out the constituent filaments thereof in such a way that each fibre has an increased surface area on which the impregnation can be performed.

Owner:SOVOUTRI SOC VOULTAINE DE TRANSFORMES INDS

Label for use on rubber products

Labels comprising (i) a film substrate, e.g., polyester, (ii) a primer layer, e.g., resorcinol-formaldehyde resin, and (iii) a pressure sensitive adhesive, e.g., a natural or synthetic rubber based adhesive, are improved by including a second primer layer of chlororesorcinol between the film substrate and the first primer layer.

Owner:BRADY WORLDWIDE INC

Zero degree belt compound of all-steel radial tire

InactiveCN102086275AMeet processing performance requirementsSolve quality defectsSpecial tyresCyclohexylthiophthalimideAlkylphenol

The invention relates to a zero degree belt compound of all-steel radial tire, which is characterized by being prepared from a plurality of raw materials. The raw materials in formula comprises 10# natural rubber, carbon black N375, carbon black N660, hydrated silica, zinc oxide, modified alkylphenol- formaldehyde resin TKM-M, N-(1,3-dimethylbutyl)-N'-phenyl p phenylenediamine, resorcinol formaldehyde resin, cobalt boroacylate, hexamethoxy methyl melamine, N-t butyl-2-benzothiazolesulfenamide, insoluble sulfur HD OT20 and N-cyclohexylthiophthalimide. The invention is used as zero degree belt compound in all-steel radial tire production. The rubber compound of the invention has the advantages of reducing extrusion temperature of the zero degree belt, improving extrusion speed, increasing surface viscosity of the zero degree belt, prolonging holding time of viscosity, improving rubber-coating effect, and effectively solving the quality problems of point-like copper exposition and poor surface viscosity.

Owner:SICHUAN TYRE & RUBBER CO LTD

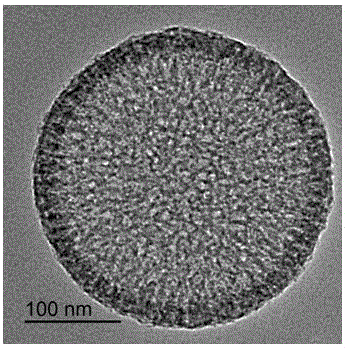

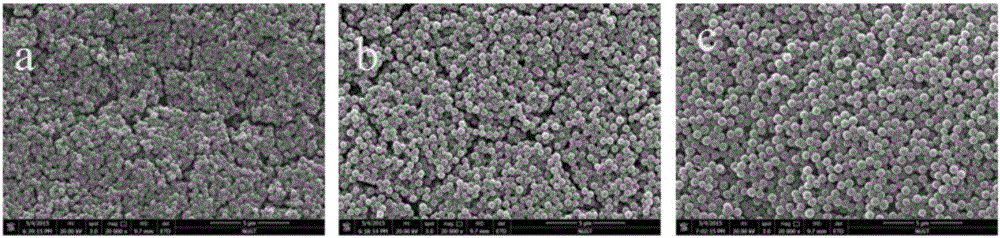

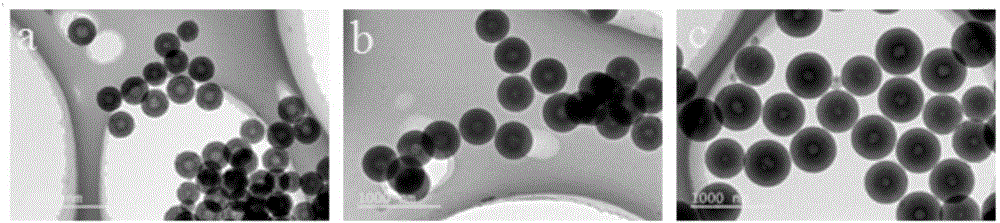

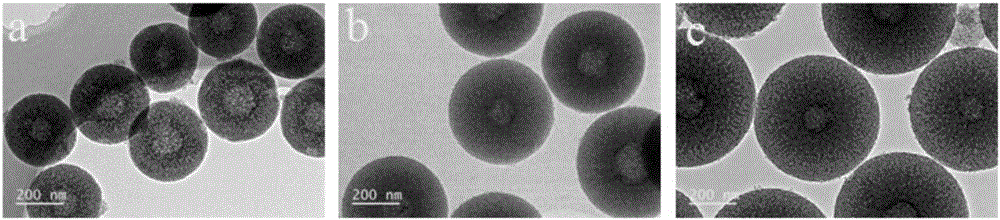

Method for preparing nitrogen-doped hollow mesoporous core-shell carbon spheres

InactiveCN105692590AAdjust particle sizeEasy to operateMaterial nanotechnologyNitrogen sourceMelamine

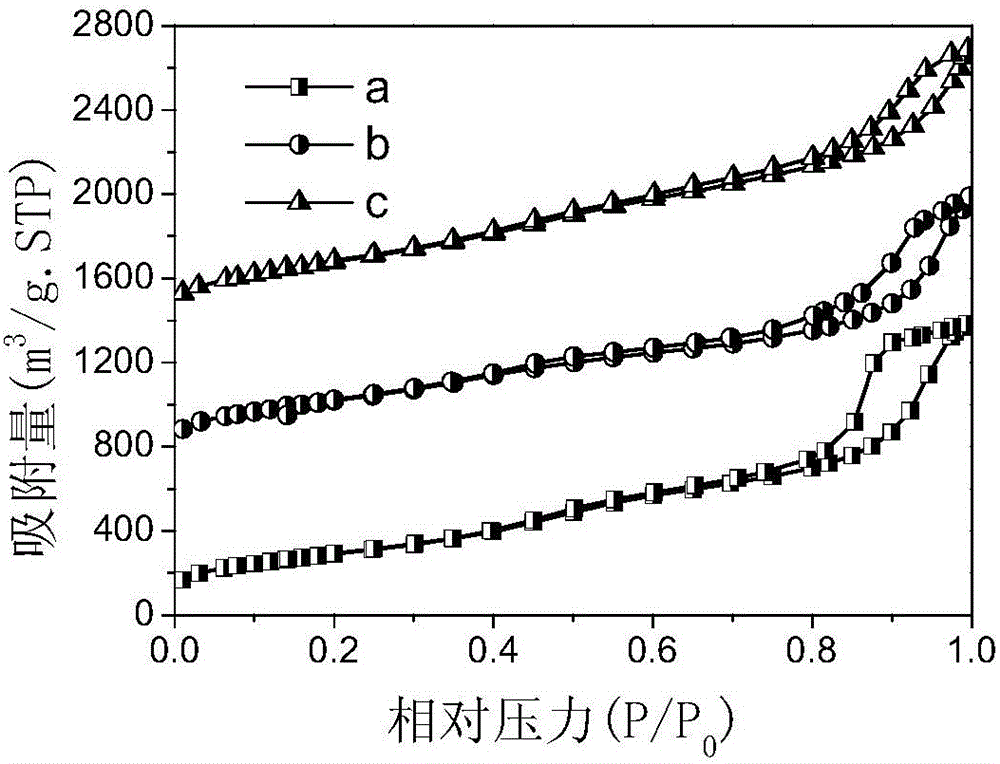

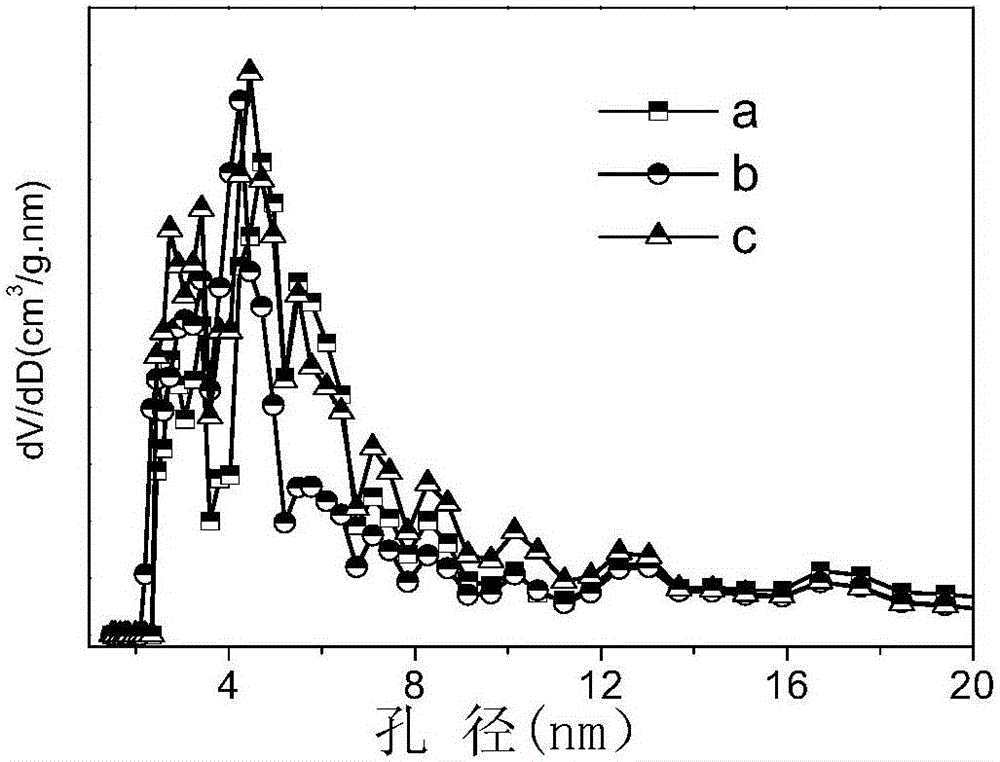

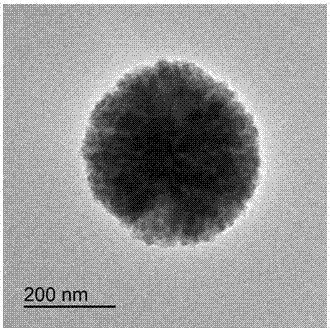

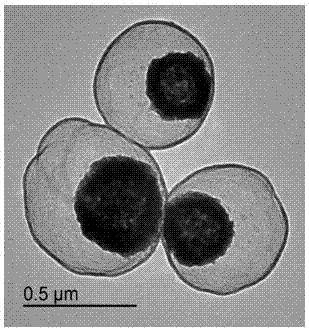

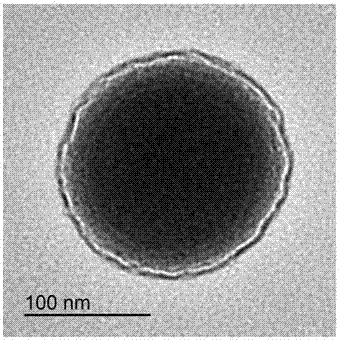

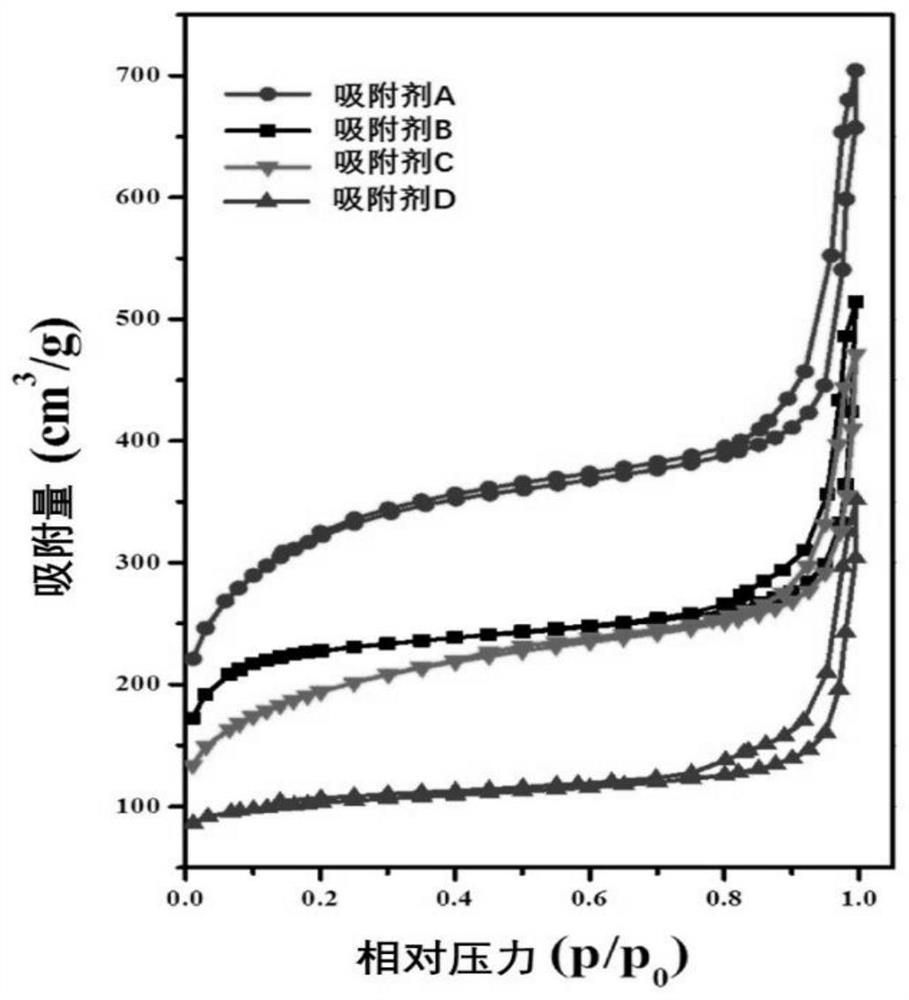

The invention discloses a method for preparing nitrogen-doped hollow mesoporous core-shell carbon spheres. Resorcinol-formaldehyde resin serves as a carbon precursor, melamine serves as a nitrogen source, hexadecyl trimethyl ammonium chloride serves as a template agent, tetraethylortho silicate serves as a structural framework, ammonia water serves a catalyst, and the hollow mesoporous core-shell carbon spheres are synthesized through the soft template method. The structure of the carbon spheres can be effectively regulated by controlling the amount of ammonia water, and the prepared nitrogen-doped hollow mesoporous core-shell carbon spheres have obvious hollow core-shell structures and have the advantages of being high in specific surface area, large in pore volume, uniform in pore size distribution and the like.

Owner:NANJING UNIV OF SCI & TECH

Intermediate adhesive material for retreaded tires

InactiveCN102086353AImprove adhesionImprove driving safetyNatural rubber adhesivesQuinolineHigh doses

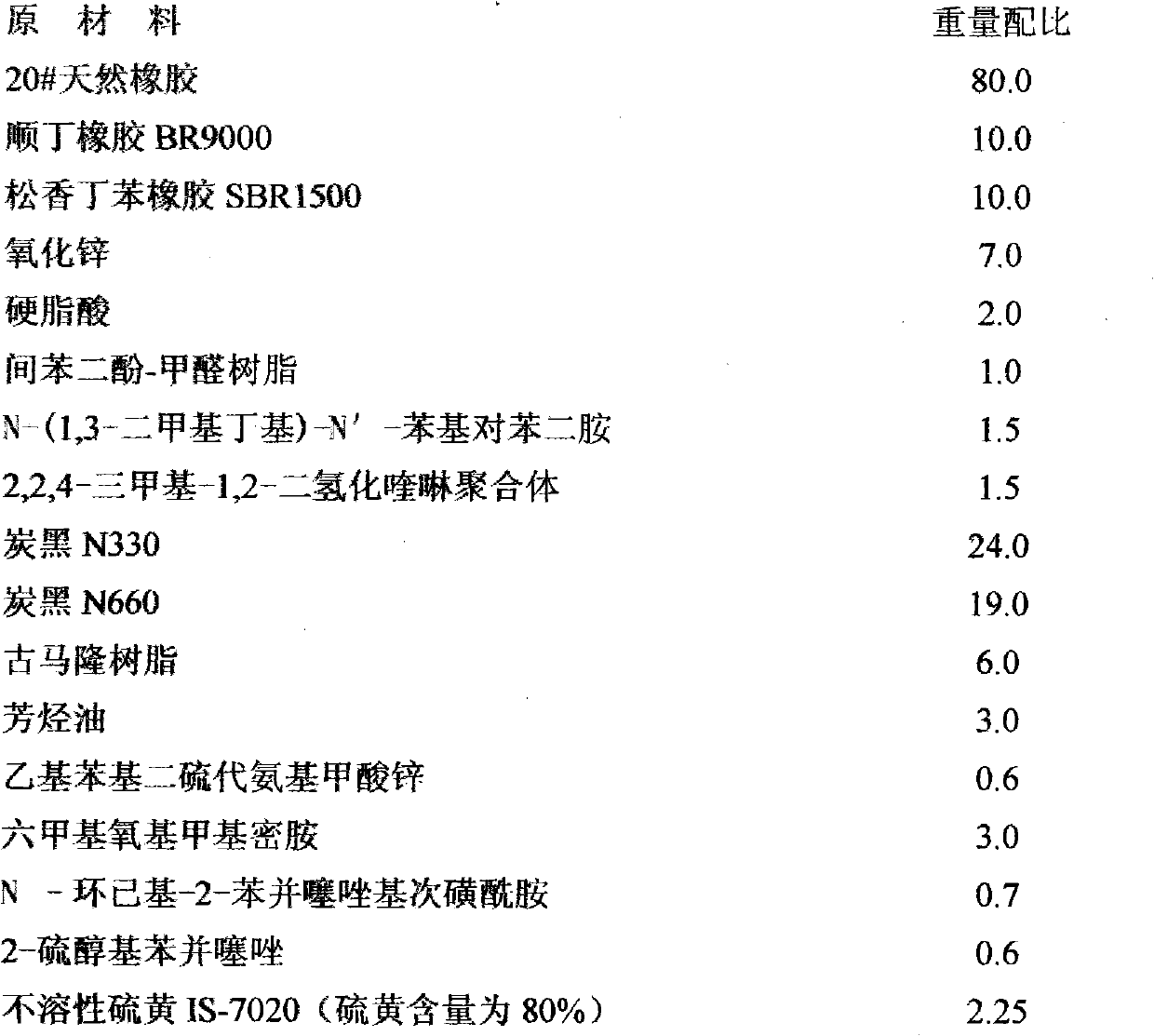

The invention discloses an intermediate adhesive material for retreaded tires. The adhesive material disclosed by the invention contains resorcinol-formaldehyde resin, hexamethoxy methyl melamine, zinc oxide (in high dose ratio), and N-ethyl-N-phenyldithiocarbamic acid zinc salt serving as a low-temperature promoter. The key points of the intermediate adhesive material include: the intermediate adhesive material is prepared from various raw materials including No.20 natural rubber, cis-1,3-butadiene rubber (BR)9000, abietic styrene butadiene rubber (SBR)1500, resorcinol-formaldehyde resin, zinc oxide (in high dose ratio), stearic acid, N-(1,3-dimethylbutyl)-N'-phenyl-p-phenylenediamine,poly(1,2-dihydro-2,2,4-trimethyl-quinoline), poly(2-dihydroquinoline), carbon black N330, carbon black N660, coumarone-indene resin, aromatic oil, zinc ethylphenyl dithiocarbamate, hexamethoxy methyl melamine, N-cyclohexylbenzolthiazole-2-sulfenamide, 2-mercaptobenzothiazole, and insoluble sulphur (IS)-7020( the sulfur content is 80 percent). The adhesive material disclosed by the invention is mainly used in the intermediate adhesive layers of retreated diagonal tires and retreaded steel-belted radial tires and when the adhesive material disclosed by the invention is used, the tire tread and tire body adhering strength of the intermediate adhesive material is improved obviously; the H drawing force of the adhesive material with all-steel cords and nylon cords is improved to reduce the tire tread and tire body separation phenomenon of the finished retreaded diagonal tires and retreaded steel-belted radial tires; and thus, the driving safety and service life of the diagonal tires and the retreaded steel-belted radial tires are improved.

Owner:SICHUAN TYRE & RUBBER CO LTD

Boron phenolics-titanium nano composite temperature and pressure resistant heavy anti-corrosive coating and preparation method thereof

The invention relates to a heavy anti-corrosive nano composite coating technology, in particular to a boron phenolics-titanium nano composite temperature and pressure resistant heavy anti-corrosive coating and a preparation method thereof. The formula of the coating is as follows: 30 to 35 parts of modified phenolic polymer, 4 to 8 parts of nano composite liquid, 5 to 8 parts of reinforced carbon fiber, 20 to 25 parts of rutile titanium dioxide, 5 to 8 parts of silicon carbide powder, 4 to 7 parts of nickel-based alloy powder, 2 to 4 parts of flame retardant, and 15 to 22 parts of mixed solvent; and the materials are mixed in a ratio, dispersed and ground to have the grain size of below 40mu m, mixed with composite curing agent (the ratio is 1:0.5 to 1) which comprises linear phenol formaldehyde resin and resorcinol formaldehyde resin by the ratio of 1 to 3:1, heated and cured for 2 to 3h at 160 to 180DEG C, to prepare the heavy anti-corrosive composite coating. The coating of the invention can resist high temperature, high pressure (5 to 15MPa, 100 to 180DEG C) when the thickness is 0.1 to 2.0mm, and corrosion damage which contains hydrogen sulfide, sulfur dioxide, carbon dioxide, chloride and other strong acidic corrosive media, and the bonding force between the coating and a metal substrate is strong.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of hollow carbon nanospheres with MOFs (metal-organic frameworks) formed through limited-range growth inside

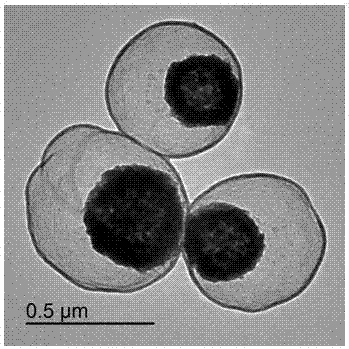

ActiveCN107522867AUniform particle sizeStable structureNanotechnologyNano-carbonMicrosphereMetal-organic framework

The invention discloses a preparation method of hollow carbon nanospheres with MOFs (metal-organic frameworks) formed through limited-range growth inside and belongs to the technical field of nanomaterial production. Tetraethyl orthosilicate, ethanol, deionized water, ammonium hydroxide, resorcinol and methanol are mixed for a reaction, SiO2@resorcinol-formaldehyde resin microspheres are obtained and calcined in argon, SiO2@C nanospheres with a core-shell structure are obtained and dispersed in a sodium hydroxide water solution to be etched, and mesoporous hollow carbon nanospheres are obtained; finally, the mesoporous hollow carbon nanospheres are dispersed in methanol, metallic nitrates and 2-methylimidazole are added for a reaction, and the hollow carbon nanospheres with MOFs formed through limited-range growth inside are obtained. Equipment used in the method is simple, the method is low in cost and simple in operation process, materials required in the reaction process are low in toxicity and harmless, the stoichiometric ratio of multi-component materials can be effectively controlled, and the obtained products are uniform in size, uniformly distributed and are good in morphological control.

Owner:YANGZHOU UNIV

Styrene butadiene rubber emulsion modifying agent

The invention discloses a styrene butadiene rubber emulsion modifying agent which comprises the following components in parts by weight: 35-50 parts of hydroxyethyl methacrylate, 15-30 parts of alkyl resorcinol formaldehyde resin and 3-5 parts of hexamethoxy methyl melamine. The styrene butadiene rubber emulsion modifying agent disclosed by the invention is simple in preparation method and less in environment pollution, and can reduce the ageing speed of styrene butadiene rubber and greatly prolong the service life of the styrene butadiene rubber under the precondition that the rubber quality is ensured.

Owner:WUXI JINSHENG AUX FACTORY

Reclaimed nitrile rubber sealing ring material

The invention discloses a reclaimed nitrile rubber sealing ring material which is prepared from nitrile rubber 3345, reclaimed nitrile rubber, antioxidant SP, antioxidant MB, stearic acid, sulfur powder, palm wax, zinc oxide, processing aid WB16, carbon black N550, carbon black N330, methylpentachlorostearate, promoter TMTD, promoter TETD, promoter DM, nanometer calcium carbonate, modified acrylate, alkyl resorcinol formaldehyde resin, maleic anhydride, a plasticizer, etc. According to the invention, reclaimed nitrile rubber is used as a raw material and formulated raw materials are optimized so as to prepare the reclaimed nitrile rubber sealing ring material with excellent performance, good high temperature resistance and high hardness, which enables cost to be saved.

Owner:CGP WUHU SEALING

Preparing method of hollow magnetic carbon nanospheres with MOFs growing inside in confinement mode

ActiveCN107481827AWith large-scale applicationSave raw materialsInductances/transformers/magnets manufactureMagnetic materialsSodium acetateSodium hydroxide

The invention belongs to the technical field of nano material production, and relates to a preparing method of hollow magnetic carbon nanospheres with MOFs growing inside in a confinement mode. The preparing method includes the steps that FeCl3.6H2O, ethylene glycol, ethyl alcohol and sodium acetate are mixed and subjected to hydrothermal reaction to obtain Fe3O4 spheres, the Fe3O4 spheres, ethyl alcohol, deionized water and ammonia water are mixed to obtain Fe3O4 sphere mixed solution, a silicon source is added dropwises into the Fe3O4 sphere mixed solution to react, then resorcinol and formaldehyde are added to react so as to obtain Fe3O4@SiO2@ resorcinol-formaldehyde resin spheres, Fe3O4@SiO2@C spheres are obtained after calcining under argon and etched by sodium hydroxide water solution to obtain magnetic carbon nanocages; finally the magnetic carbon nanocages react with metallic nitrate and 2-methylimidazole to obtain the hollow magnetic carbon nanospheres which are uniform in size and are distributed uniformly, the morphology of the hollow magnetic carbon nanospheres is controlled well, and the MOFs of the hollow magnetic carbon nanospheres grow inside in the confinement mode. The process is simple, and the materials needed in the reaction process are low in toxicity and harmless.

Owner:YANGZHOU UNIV

Preparation method of palladium-mesoporous silicon oxide hollow multi-core nanometer catalytic material

The invention discloses a preparation method of a palladium-mesoporous silicon oxide hollow multi-core nanometer catalytic material. The preparation method comprises the steps of firstly, synthesizinga RF sphere in an alcohol-aqueous solution; secondly, preparing a multi-core palladium-coated resorcinol-formaldehyde resin (RdRF) nanometer sphere with a core-shell structure; thirdly, coating an upper mesoporous silicon oxide shell layer with the RdRF sphere to obtain a RdRF meso-SiO2 core-shell material with a dual-shell layer; and finally, removing the RF shell layer and a surfactant to obtain a multi-core Pdmeso-SiO2 nanometer sphere with a hollow structure. A synergic template method combining a hard template method and a flexible template method is employed, the palladium-mesoporous silicon oxide hollow multi-core nanometer catalytic material is obtained by an improved Stober method, a hydrothermal method, a sol-gel method and a roasting method, and the synthesis method also can beexpanded to prepare other previous metal and mesoporous silicon oxide hollow materials such as a composite material of Aumeso-SiO2 or Ptmeso-SiO2 having a hollow structure, and has important significance and value.

Owner:5ELEM HI TECH CORP

Preparation method of nitrogen doped hollow mesoporous carbon sphere

InactiveCN105819422AUniform and smooth spherical morphologyEasy to makeMaterial nanotechnologyPorosityNitrogen doped

The invention discloses a preparation method of a nitrogen doped hollow mesoporous carbon sphere. According to the preparation method, resorcinol-formaldehyde resin is taken as the carbon precursor, melamine is taken as the nitrogen source, cetyl trimethyl ammonium chloride is taken as the template, silicate oligomer is taken as the structure support, ammonia liquor is taken as the catalyst, and the size and morphology of hollow carbon nano sphere can be effectively controlled by changing the amount of ammonia liquor. The obtained hollow mesoporous carbon sphere has the characteristics of hollow structure, high porosity, large specific surface area, large pore volume, uniform mesoporous size, and nitrogen doping.

Owner:NANJING UNIV OF SCI & TECH

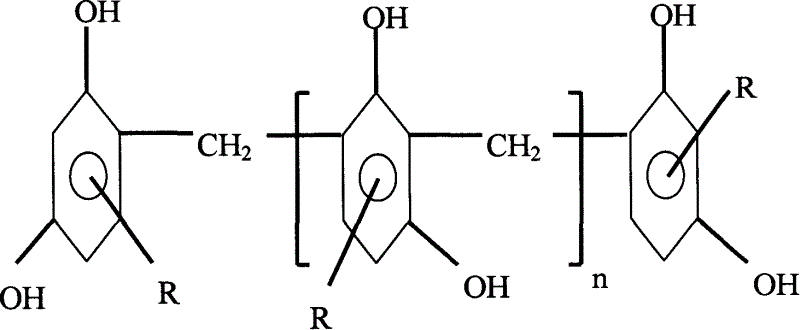

Alkyl resorcinol formaldehyde resin and its production process

The invention provides an alkyl resorcinol formaldehyde resin for the production of rubber products including tires and wire rope conveying belts, as well as the production process. The resin comprises the following substances: resorcinol 22-25 parts, formaldehyde 10-11.5 parts, phenylethene 11-13 parts, oxalic acid 0.5-0.8 part, water 8-12 parts, and 20% of NaOH solvent. The production process comprises alkylation reaction and hydroxylation.

Owner:于文明

Preparation method of zinc oxide modified aramid fiber two-bath dip solution

ActiveCN107177985AUniform particle size distributionImprove stabilityFibre typesUltravioletNano zinc oxide

The invention relates to a preparation method of zinc oxide modified aramid fiber two-bath dip solution. Latex is mixed with water, resorcinol-formaldehyde resin solution and water are added to continue mixing, and ammonia water, isocyanate, modified zinc oxide dispersion liquid and the water are mixed to obtain the aramid fiber two-bath dip solution. The preparation method not only solves the problems of easiness in agglomeration, non-uniform dispersion and poor stability of nano-zinc oxide, but also remarkably improves the boundary adhesion strength and the anti-ultraviolet performance of rubber and aramid fibers.

Owner:ZHEJIANG SCI-TECH UNIV

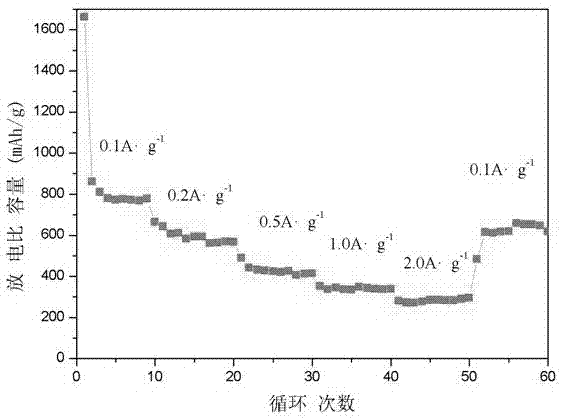

Preparation method of porous carbon-coated antimony telluride nanosheet and application thereof as negative electrode material of metal ion battery

ActiveCN109659540AEasy to prepareRaw materials are cheap and easy to getNegative electrodesSecondary cellsLithiumPorous carbon

The invention discloses a preparation method of a porous carbon-coated antimony telluride nanosheet, and an application of the porous carbon-coated antimony telluride nanosheet as a negative electrodematerial of a metal ion battery. The preparation method is characterized by comprising the steps of: firstly, acquiring an antimony telluride nanosheet by adopting a hydrothermal method; secondly, coating the antimony telluride nanosheet with resorcinol-formaldehyde resin by adopting a liquid phase reaction technology; and finally, converting the resorcinol-formaldehyde resin into porous carbon through high-temperature carbonization, and acquiring the porous carbon-coated antimony telluride nanosheet. The preparation method of the product is simple, the used raw materials are cheap and easy to obtain, the porous carbon-coated antimony telluride nanosheet shows good cyclic stability and high cycle specific capacity when applied to the metal (lithium, sodium) ion battery, and the electrochemical performance is excellent.

Owner:HEFEI UNIV OF TECH

Neoprene adhesive composition and preparation method of neoprene adhesive

InactiveCN104004471AImprove adhesionImprove product qualityNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesAdhesiveNeoprene

The invention discloses a neoprene adhesive composition. The composition comprises neoprene, styrene-butadiene-styrene block copolymer, resorcinol formaldehyde resin, magnesium oxide and zinc oxide, wherein relative to 100 parts by weight of neoprene, the content of the styrene-butadiene-styrene block copolymer is 5-35 parts by weight, the content of resorcinol formaldehyde resin is 30-70 parts by weight, the content of magnesium oxide is 2-8 parts by weight, and the content of zinc oxide is 2-8 parts by weight. Through adding the styrene-butadiene-styrene block copolymer and resorcinol formaldehyde resin into the traditional neoprene adhesive, the adhesive property of the prepared adhesive is better, so that the problem of the ordinary neoprene adhesives that the product quality of rubber products is poor due to the fact that the rubber adhesion is not strong is solved.

Owner:南京市浦口区浦城资产经营有限公司

Adhesive and sealant systems

Adhesive and sealant systems based on epoxy resins, polyurethane, silane-terminated polymers, silicones, unsaturated polyester resins, vinyl ester resins, acrylates, polyvinyl acetate, polyvinyl alcohol, polyvinyl ether, ethylene vinyl acetate, ethylene-acrylic acid copolymers, polyvinyl acetates, polystyrene, polyvinyl chloride, styrene-butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber, polysulfide, polyethylene, polypropylene, fluorinated hydrocarbons, polyamides, saturated polyesters and copolyesters, phenol-formaldehyde resins, cresol- / resorcinol-formaldehyde resins, urea-formaldehyde resins, melamine-formaldehyde resins, polyimides, polybenzimidazoles, polysulfones, which contain 1 wt. % to 15 wt. % of a compacted, hydrophobic pyrogenic silica.

Owner:EVONIK OPERATIONS GMBH

Aramid fiber surface treatment fluid and preparation method thereof

The invention discloses an aramid fiber surface treatment fluid. The aramid fiber surface treatment fluid comprises the following components in parts by weight: a pretreatment liquid: 160 to 180 partsof methylbenzene, 16 to 18 parts of polyaryl polymethylene isocyanate, 4 to 6 parts of epoxy resin, 0 to 4 parts of coumarone resin, 0 to 2 parts of chloridized natural rubber and 0 to 3 parts of nitrile rubber; a retreatment liquid: 180 to 200 parts of deionized water, 10 to 15 parts of water-soluble resorcinol-formaldehyde resin, 10 to 15 parts of 25% to 30% of ammonia water, 180 to 200 parts of butadiene-vinylpyridine copylymer latex and 10 to 13 parts of 36% to 40% formaldehyde. By using the aramid fiber surface treatment fluid, the surface performance is effectively improved, and the bonding performance of aramid fiber is improved.

Owner:烟台泰和工程材料有限公司 +1

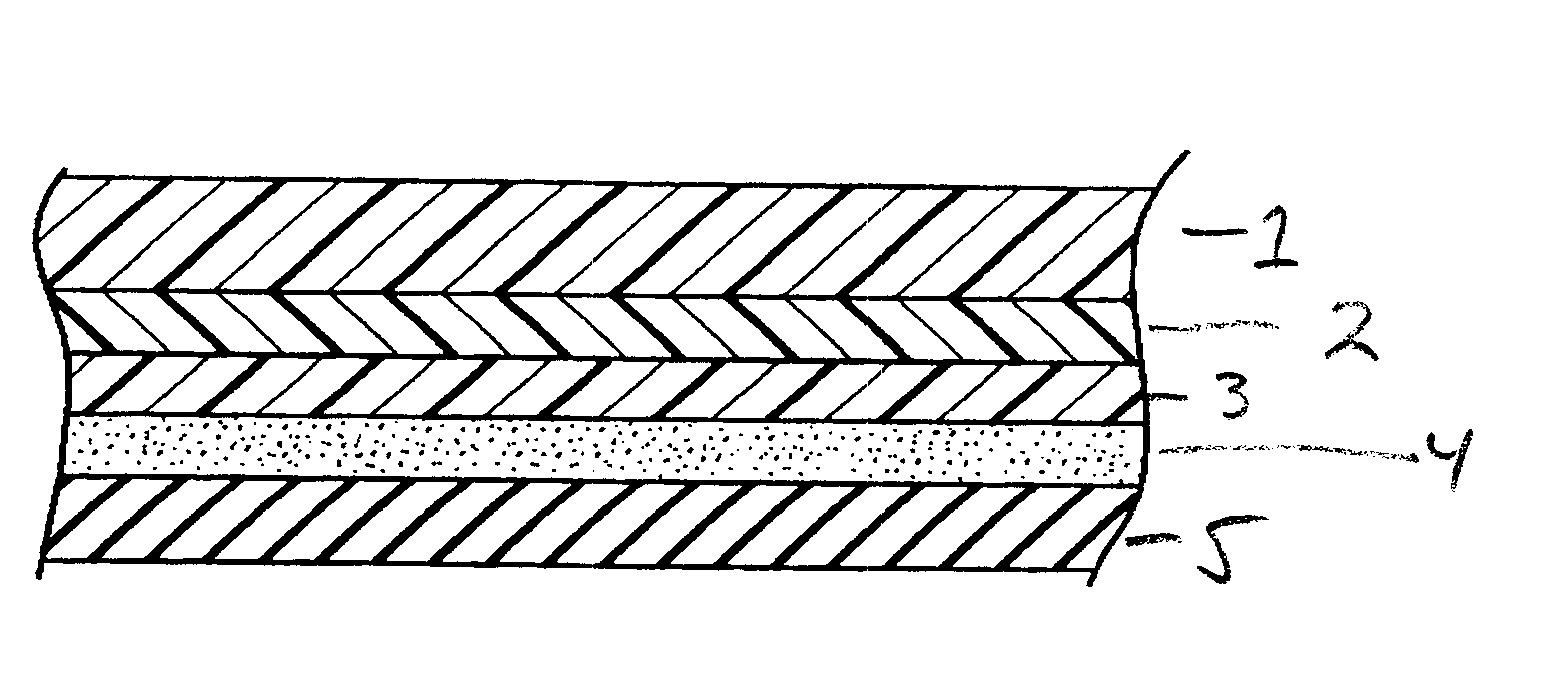

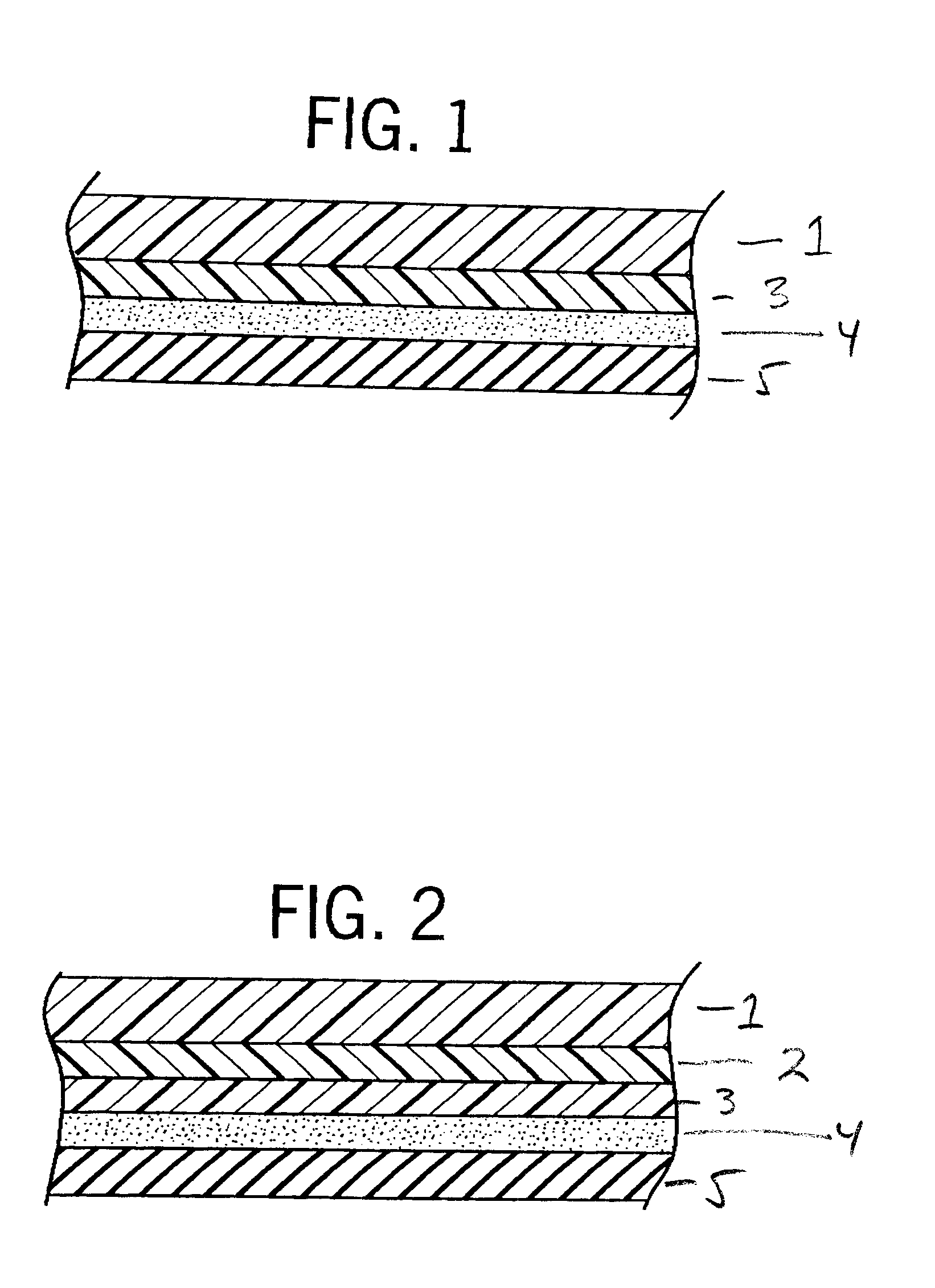

Hydrogenated nitrile butadiene rubber

The present invention relates to a composition containing a hydrogenated nitrile-butadiene rubber (HNBR), a peroxide crosslinking system and a resorcinol-formaldehyde resin, to a process for the preparation of the composition, to the use of the composition as an adhesion promoter, and also to a multilayer product containing the composition according to the present invention.

Owner:LANXESS DEUTDCHLAND GMBH

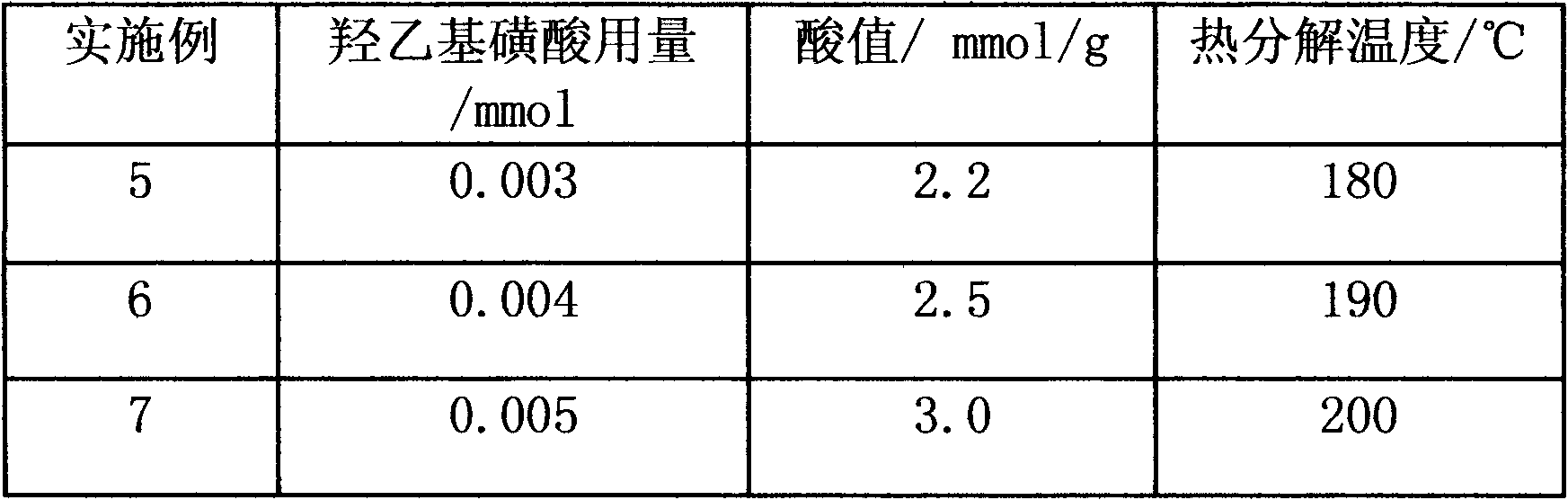

Preparation method of acidic ionic liquid resorcinol formaldehyde resin copolymer material

InactiveCN102627748AHigh acid valueEasy to recycleOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChemical synthesisEvaporation

The invention discloses a preparation method of an acidic ionic liquid resorcinol formaldehyde resin copolymer material, and belongs to the technical field of organic chemical synthesis. The method is characterized by comprising the steps of: reacting vinyl pyridine compound with sultone to obtain ethylenic bond-containing sulfonic ylid; acidulating by sulfuric acid to obtain sulfonic functionalized ionic liquid monomer with anion of acid radical; carrying out self-assembly on the ionic liquid monomer to form an ionic liquid polymer solution; and then adding resorcinol and formaldehyde in theionic liquid oligomer solution; condensing at 65-95 DEG C for 60-120 hours; carrying out rotary evaporation to dryness; and placing at 180-300 DEG C for condensation reaction for 2-32 hours to obtainthe acidic ionic liquid resorcinol formaldehyde resin copolymer material. The material synthesized by the method of the invention has advantages of high thermal stability, high acid value and good catalytic effect.

Owner:SHAOXING UNIVERSITY

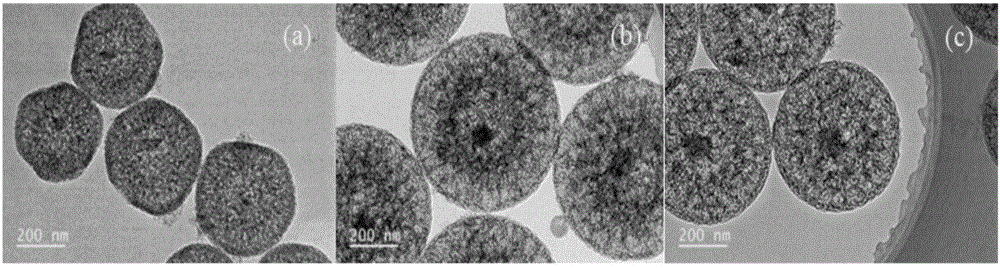

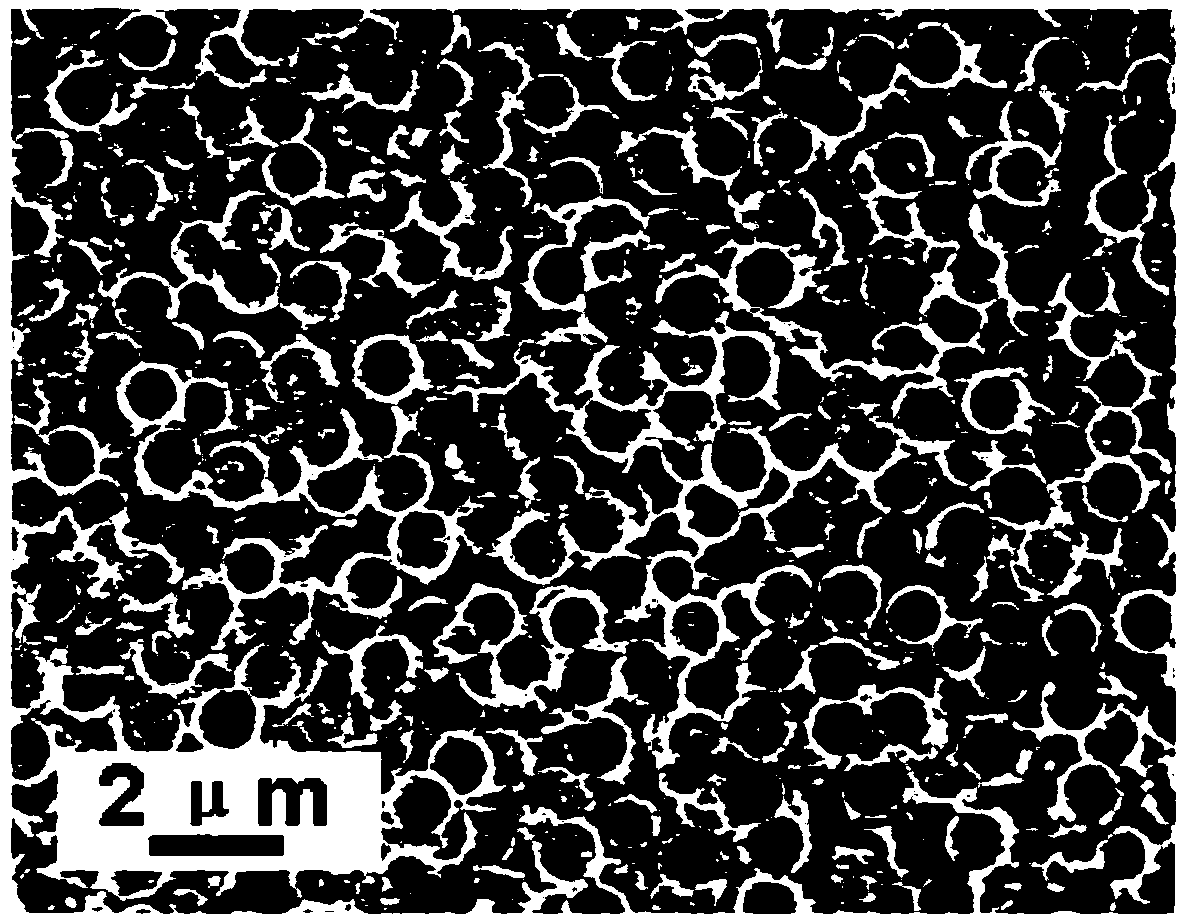

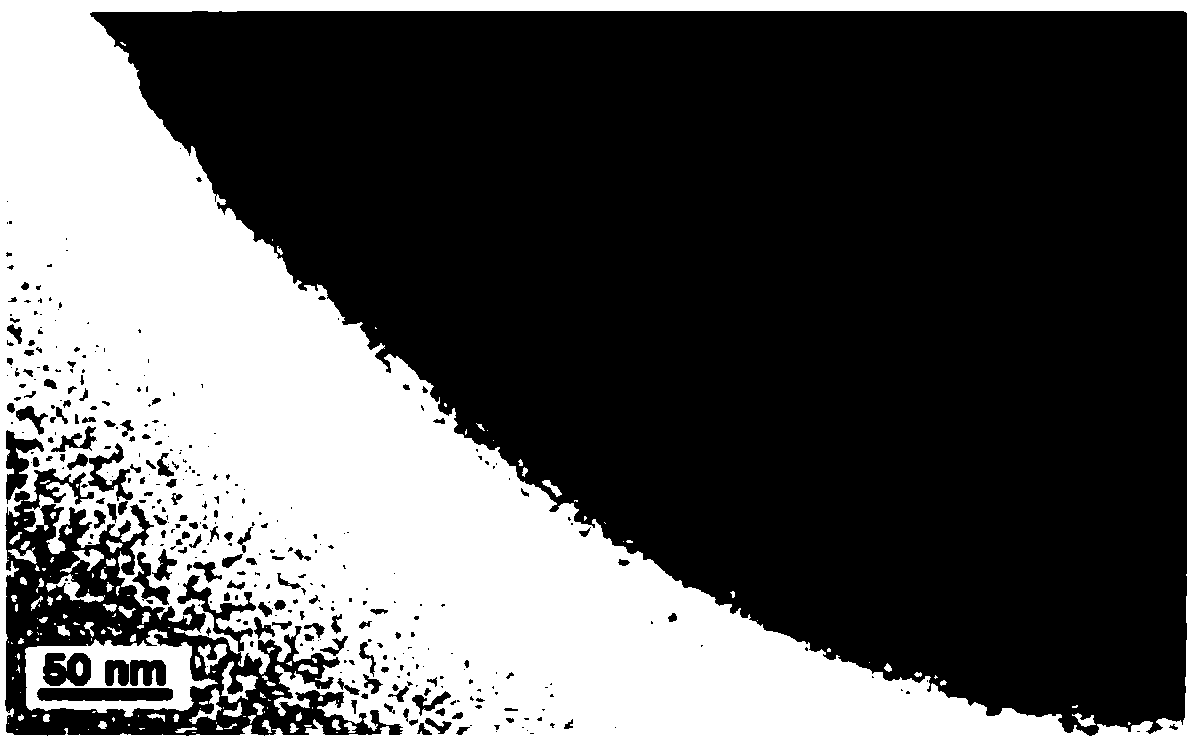

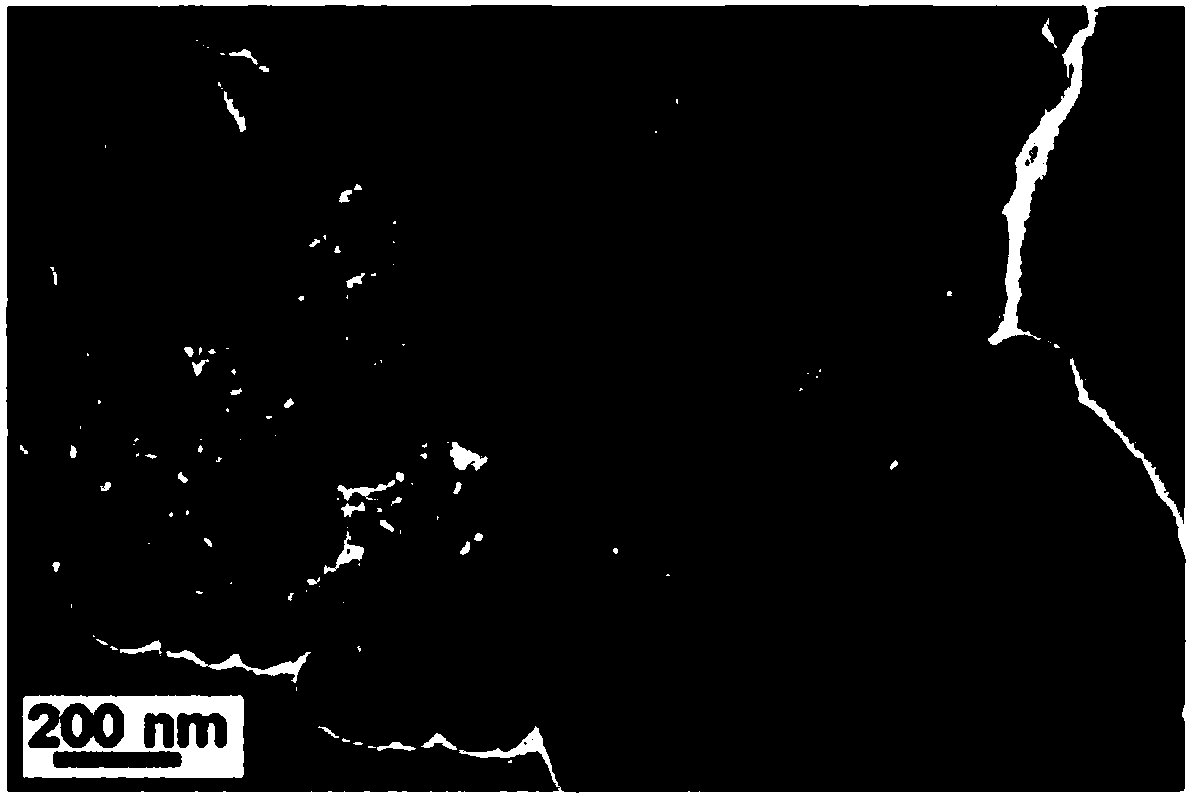

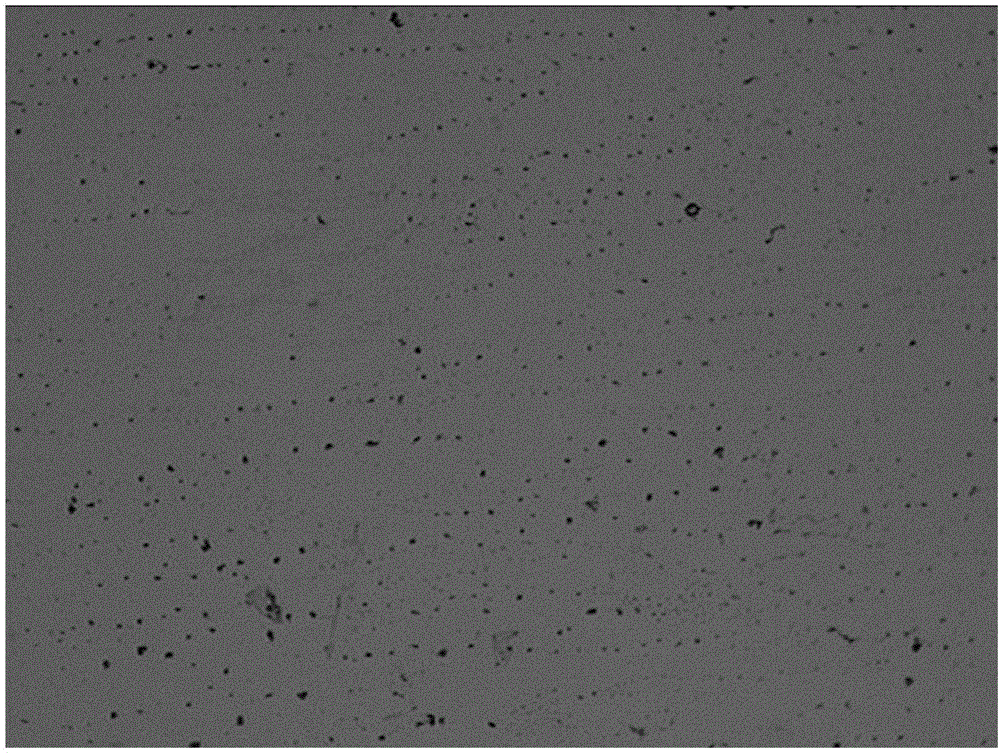

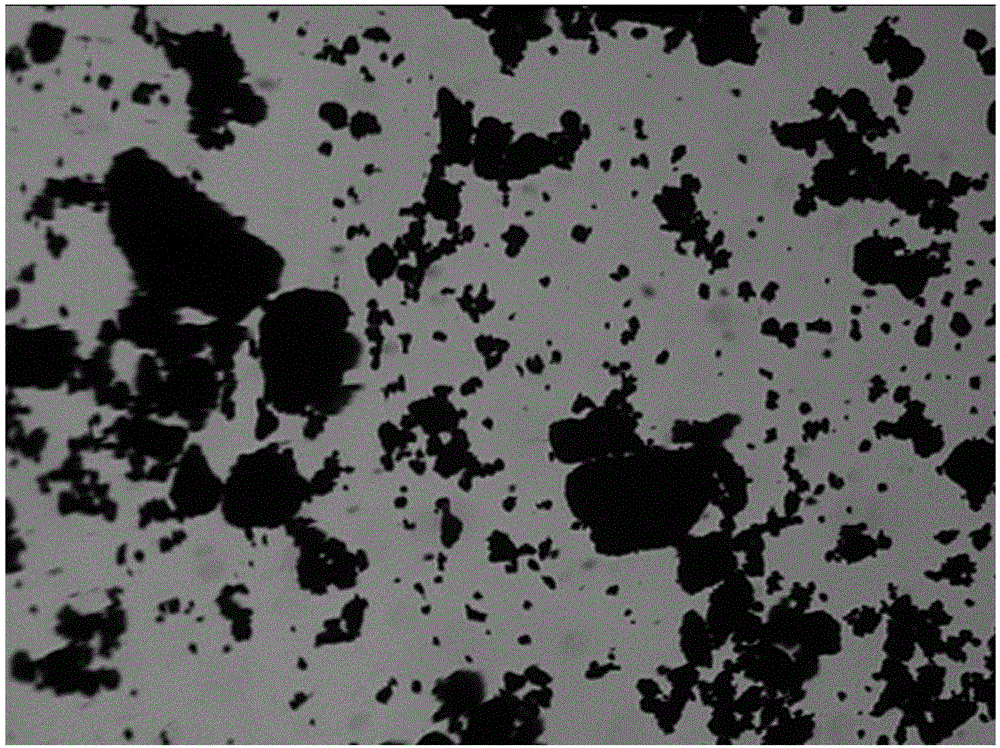

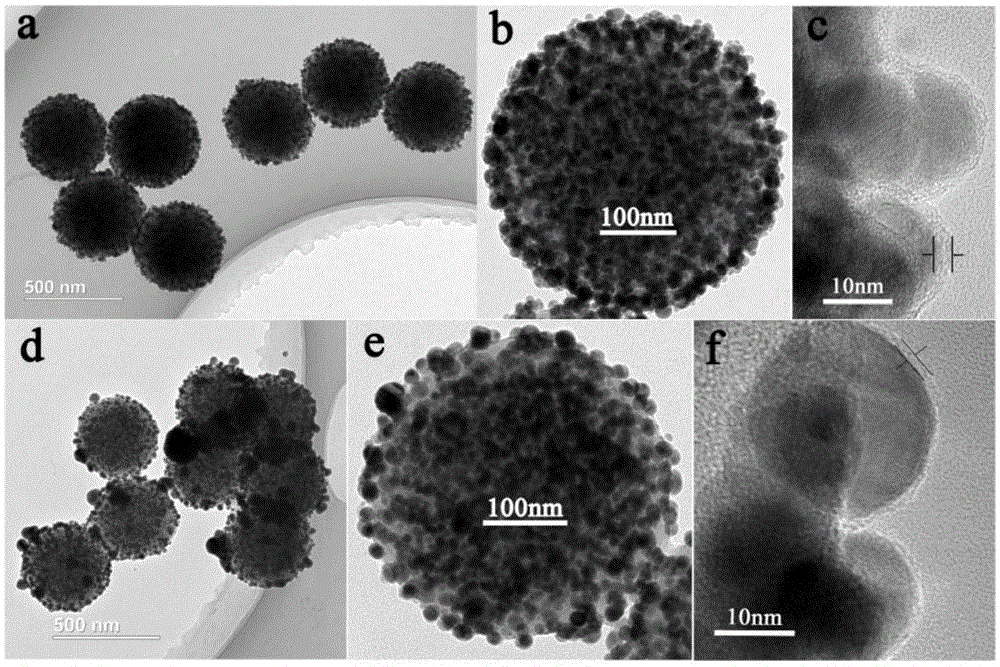

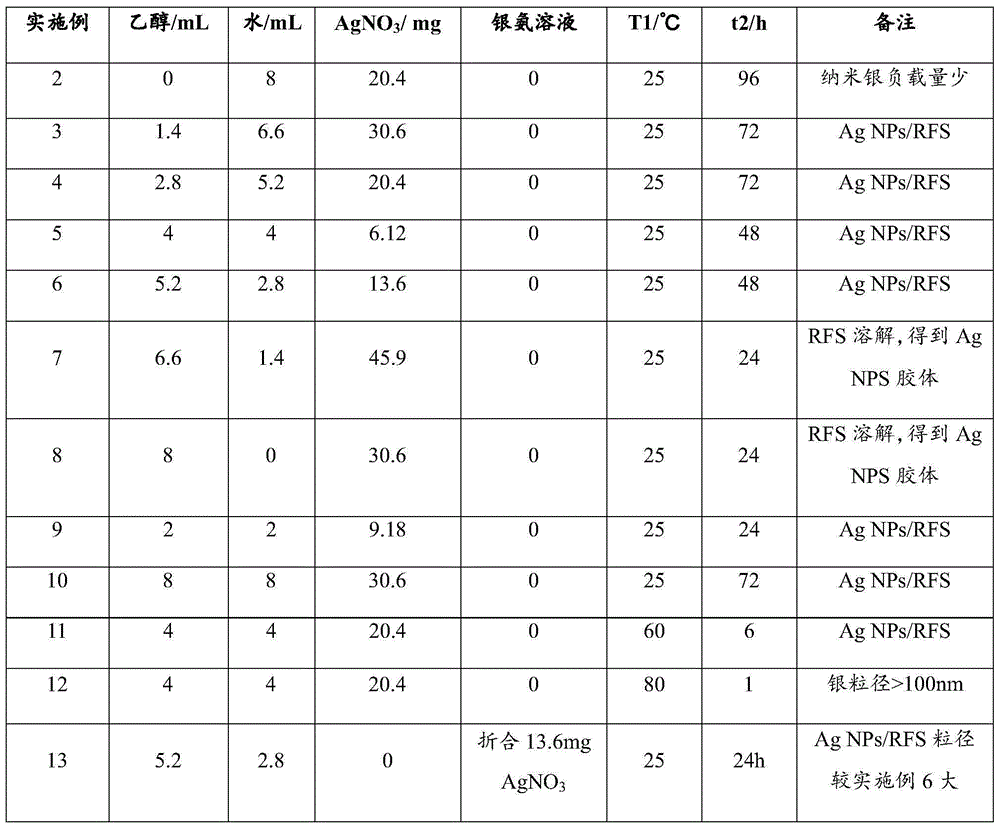

Nano-silver-loaded resorcinol-formaldehyde resin microspheres and nano-silver-loaded mesoporous carbon microspheres

ActiveCN104998591AImprove performanceLow costMicroballoon preparationMicrocapsule preparationMicrosphereRedox

The invention discloses nano-silver-loaded resorcinol-formaldehyde resin microspheres, a preparation method therefore and a preparation method of nano-silver-loaded mesoporous carbon microspheres. The preparation method of the nano-silver-loaded resorcinol-formaldehyde resin microspheres comprises the step of preparing the resorcinol-formaldehyde resin microspheres and the step of conducting the in situ self-redox reaction on the resorcinol-formaldehyde resin microspheres and ion-state silver precursors, and the preparation method of the nano-silver-loaded mesoporous carbon microspheres comprises the step of conducting carbonization treatment on the nano-silver- loaded resorcinol-formaldehyde resin microspheres directly in the oxygen-free atmosphere. According to the preparation method of the nano-silver-loaded resorcinol-formaldehyde resin microspheres and the preparation method of the nano-silver-loaded mesoporous carbon microspheres, no extra reducing agent is needed to be added in, the nano-silver loading condition is mild, the preparation process is effectively simplified, the production efficiency is raised, and the nano-silver-loaded resorcinol-formaldehyde resin microspheres obtained through the preparation are stable in performance and low in cost.

Owner:SHENZHEN UNIV

Preparation method of magnetic carbon nanocages

The invention discloses a preparation method of magnetic carbon nanocages, and belongs to the technical field of nano material production. Fe<3>O<4> nanoballs are used as templates and magnetic inner cores, the inner surfaces of the nanoballs are coated with SiO<2> and resorcinol-formaldehyde resin, and the magnetic carbon nanocages are formed after high-temperature calcination and etching. The structure of the product is characterized in that the inner cores are magnetic, and migration of the carbon nanocages can be achieved under an external magnetic field; the outer walls are mesoporous carbon walls, and ions and small molecules can enter the interiors through the outer walls; large gaps exist between the inner cores and the outer walls, and the gaps can load pharmaceutical molecules and catalysts and can also be used as organic reaction sites. Therefore, the magnetic carbon nanocages of an egg yolk-eggshell structure are a catalyst carrier, a sustained-release drug carrier, a micro-nano reactor and a lithium-ion battery electrode material with broad application prospects.

Resorcinol formaldehyde resin base solid acid and preparation method and application thereof

InactiveCN102070758AImprove thermal stabilityHigh acid value of solid acidOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCooking & bakingChemical synthesis

The invention discloses a resorcinol formaldehyde resin base solid acid and a preparation method and application thereof, belonging to the technical field of chemical synthesis. The invention is characterized in that the preparation method comprises the following steps: by using resorcinol as a raw material, a formaldehyde solution (the mol ratio of the raw material to the formaldehyde solution is (1:1)-(1:3)) as a crosslinking agent and hydroxy-ethyl sulfonic acid (the mol ratio of the raw material to the hydroxy-ethyl sulfonic acid is (1:0.1)-(1:1)) as an active molecule, adding water (the mass ratio of the resorcinol to the water is 1:5-1:20) to prepare a solution; carrying out condensation reaction at 65-95 DEG C for 60-120 hours, and drying by rotary evaporation to obtain the RF (resorcinol formaldehyde) resin; then, carrying out carbonization condensation reaction at 180-300 DEG C for 2-32 hours; and after the reaction, washing with hot water at the temperature higher than 80 DEG C, filtering to remove free acidic materials, and drying the product in a baking oven at 120 DEG C to obtain the resorcinol formaldehyde resin base solid acid. The resorcinol formaldehyde resin base solid acid disclosed by the invention has the advantages of high thermal stability, high acid value, favorable catalysis effect and the like, and can be repeatedly used.

Owner:SHAOXING UNIVERSITY

Resin complex-containing rubber composition and application

The invention provides a resin complex-containing rubber composition. The rubber composition is mainly prepared from the following components: rubber, carbon black, an adhesion promoter, sulfur, vulcanization accelerator, a resin complex and other additive, wherein main components of the resin complex are cashew nut oil modified amino resin, resorcinol-formaldehyde resin and a methylene donor; thecashew nut oil modified amino resin complex plays a role of bridge between a rubber network and a resin network. The rubber composition has such outstanding characteristics as great modulus, strong adhesive force and low thermogenesis.

Owner:BEIJING RED AVENUE INNOVA +2

Assembly type bamboo bridge with variable expansion coefficients

ActiveCN103452035AHigh tensile strengthNo possibility of crackingSynthetic resin layered productsBridge structural detailsPolymer sciencePolymer chemistry

The invention provides an assembly type bamboo bridge. The assembly type bamboo bridge comprises bamboo longitudinal beams (1), bamboo transverse beams (2), bamboo panels (3), transverse pre-stressing tendons (4) and longitudinal pre-stressing tendons (16), the outer surface of a bamboo is sequentially and uniformly coated with a layer of waterborne polyurethane resin, a layer of polyurethane resin, a layer of waterborne polyurethane resin and a layer of resorcinol formaldehyde resin, and the expansion coefficients of the four coating layers are sequentially lessened from the outer surface of the bamboo to outside. The assembly type bamboo bridge provided by the invention has the advantages that the structural strength is large, the ductility is good, a selected material is environment-friendly, standardization degree and assembling degree of structural members are high, the structural integrity is good, the advantages of the material can be fully expressed, and the requirements on normal use and durability of a bridge structure can be met.

Owner:HAIMEN THE YELLOW SEA ENTREPRENEURSHIP PARK SERVICE CO LTD

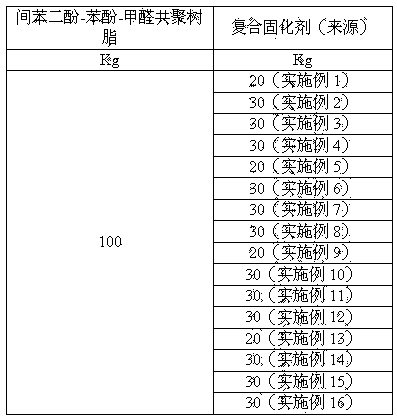

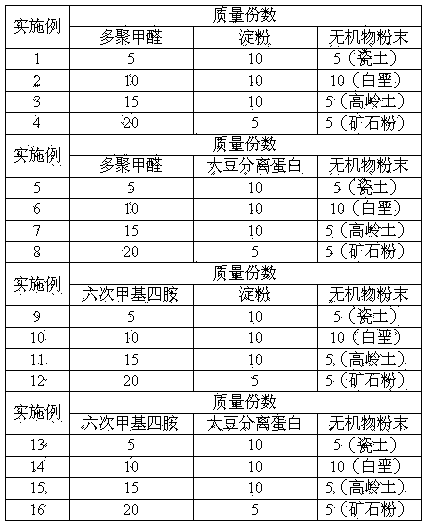

Composite curing agent and preparation method thereof

ActiveCN103881632AImprove mechanical propertiesGood weather resistanceNon-macromolecular adhesive additivesProtein adhesivesHexamethylenetetramineMechanical property

The invention relates to a resorcinol-formaldehyde resin / resorcinol-phenol-formaldehyde resin composite curing agent and a preparation method thereof. The composite curing agent is characterized by comprising the following components in parts by weight: 5-20 parts of polyformaldehyde or hexamethylenetetramine, 5-20 parts of starch or soybean protein isolate and 5-20 parts of inorganic substance powder. The composite curing agent has the advantages of normative technique and the like, and is simple to operate and easy to implement. The active period of the composite curing agent is more than 4 hours when being compounded with the resorcinol-formaldehyde resin and resorcinol-phenol-formaldehyde copolymer resin; and the composite curing agent can satisfy the requirements for active period of HLULAM, wood glulam beams, wood glulam columns, I beams and other wood structure components as well as large-size wood glulam furniture and other products with various shapes and sizes (especially irregular shapes and large size), and enables the bonded structure to have excellent physical and mechanical properties and weather resistance.

Owner:NANJING FORESTRY UNIV

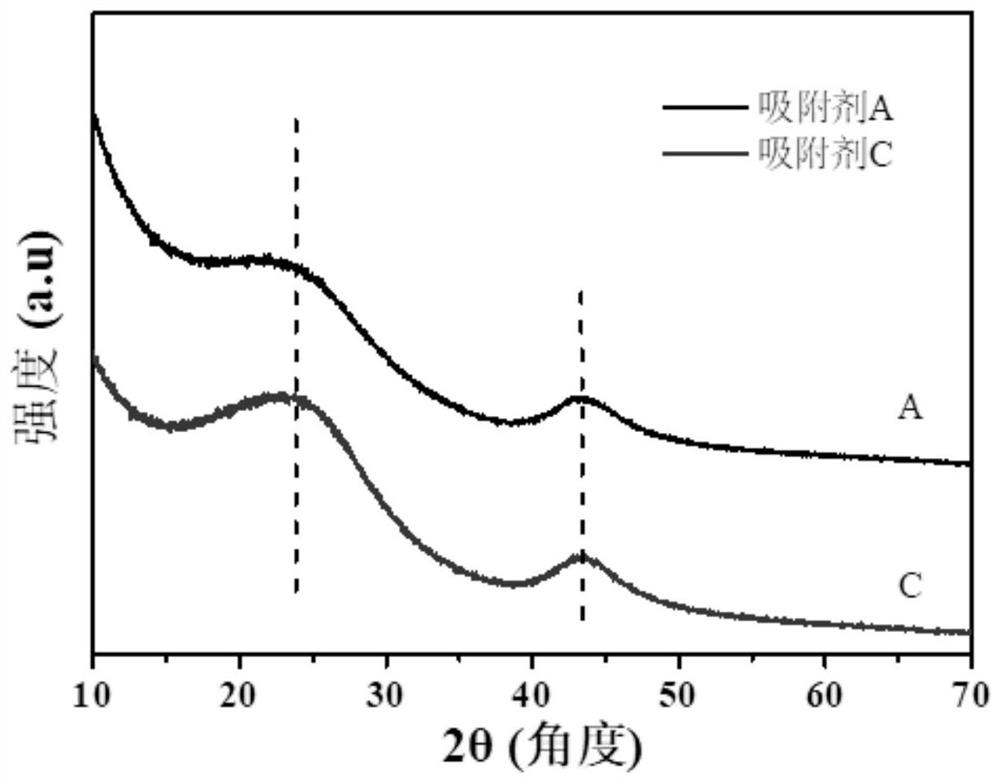

Nitrogen-doped hollow carbon sphere as well as preparation method and application thereof

The invention relates to nitrogen-doped hollow carbon spheres as well as a preparation method and application thereof, and belongs to the technical field of organic / inorganic hybrid materials. The technical problems that in the prior art, a carbon dioxide capture solid adsorbent is high in cost, complex in synthesis process and limited in application are solved. The nitrogen-doped hollow carbon spheres are prepared by the following steps: coating silicon dioxide nanospheres with nitrogen-containing resorcinol formaldehyde resin, carbonizing to obtain silicon dioxide core carbon spheres, enhancing the porosity by KOH and g-C3N4, carrying out nitrogen-doped activation to obtain activated silicon dioxide core carbon spheres, and removing silicon cores by HF. The nitrogen-doped hollow carbon spheres are uniform in particle size, have a unique hollow structure, a large BET surface area and graded porosity, rich pyridine N sites are exposed on a carbon shell, accessibility of nitrogen sitescan be enhanced, mass migration of objects is facilitated, interaction force between the nitrogen-doped hollow carbon spheres and CO2 gas is facilitated, and the nitrogen-doped hollow carbon spheres have efficient selective capture on CO2 in multi-element gas.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

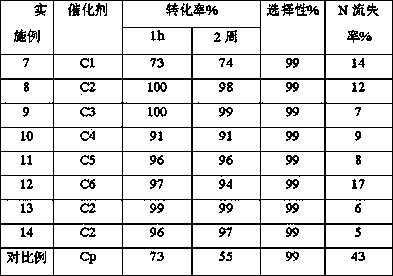

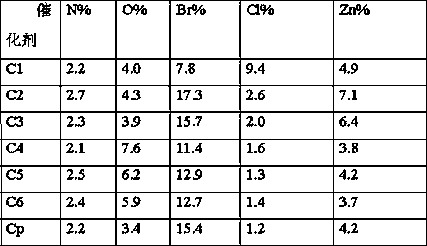

Long-life catalyst for synthesis of propylene carbonate and preparation method thereof

ActiveCN105642359ASimple processNo environmental requirementsOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDistillationPyrazine

The invention discloses a preparation method of a high efficiency catalyst for synthesis of propylene carbonate. The method comprises the steps of: (1) dissolving imidazo[1, 2-a]pyrazine and dibromoalkane in methanol, then subjecting the product to distillation concentration to remove methanol so as to obtain a polyimidazole compound; (2) subjecting the polyimidazole compound prepared by step (1) and chloromethylated polystyrene to backflow in a toluene solvent for 1-3 days, performing filtration and washing, and then conducting vacuum drying at 60-80DEG C for 12-24h to obtain an active component A; (3) smashing the active component A with a zinc salt, resorcinol formaldehyde resin and urotropine together, performing mixing, and conducting tabletting molding to obtain an active precursor B; (4) heating the active precursor B under nitrogen protection to obtain an active precursor P; and (5) soaking the active precursor P in dibromoalkane, and carrying out soaking, separation, washing, drying and smashing so as to obtain a catalyst C. The catalyst prepared by the method has difficultly losable active component.

Owner:CHINA PETROLEUM & CHEM CORP +1

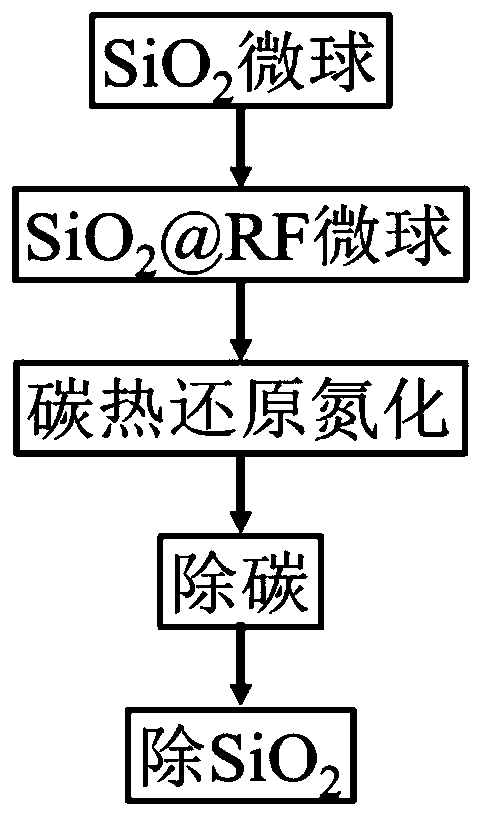

Submicron silicon nitride hollow microspheres and preparation method

The invention relates to submicron silicon nitride hollow microspheres and a preparation method. The preparation method is technically characterized by comprising steps as follows: (1), silicon dioxide microspheres synthesized with a stober method are taken as a silicon source, phenol-formaldehyde resin synthesized from resorcinol and formaldehyde is taken as a carbon source, and a synthesized SiO2@RF(Resorcinol-formaldehyde resin) core-shell structure is taken as a precursor; (2) a certain quantity of the precursor prepared in step (1) is subjected to a carbothermal reduction-nitridation reaction at a certain temperature; (3), powder prepared in step (2) is oxidized to remove carbon and subjected to acid pickling to remove silicon dioxide, and the silicon nitride hollow microspheres are obtained. With the adoption of the technical scheme, the submicron silicon nitride hollow microspheres with controllable and uniform particle size, uniform microstructure and morphology and relativelypure composition can be prepared. The preparation technology is stable, high in repeatability and low in cost and facilitates mass production of the silicon nitride hollow microspheres.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

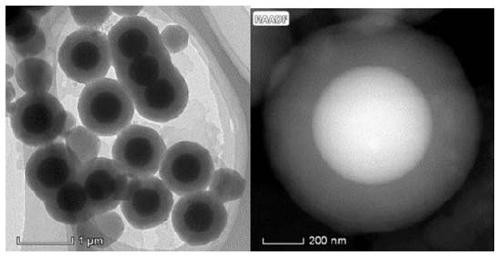

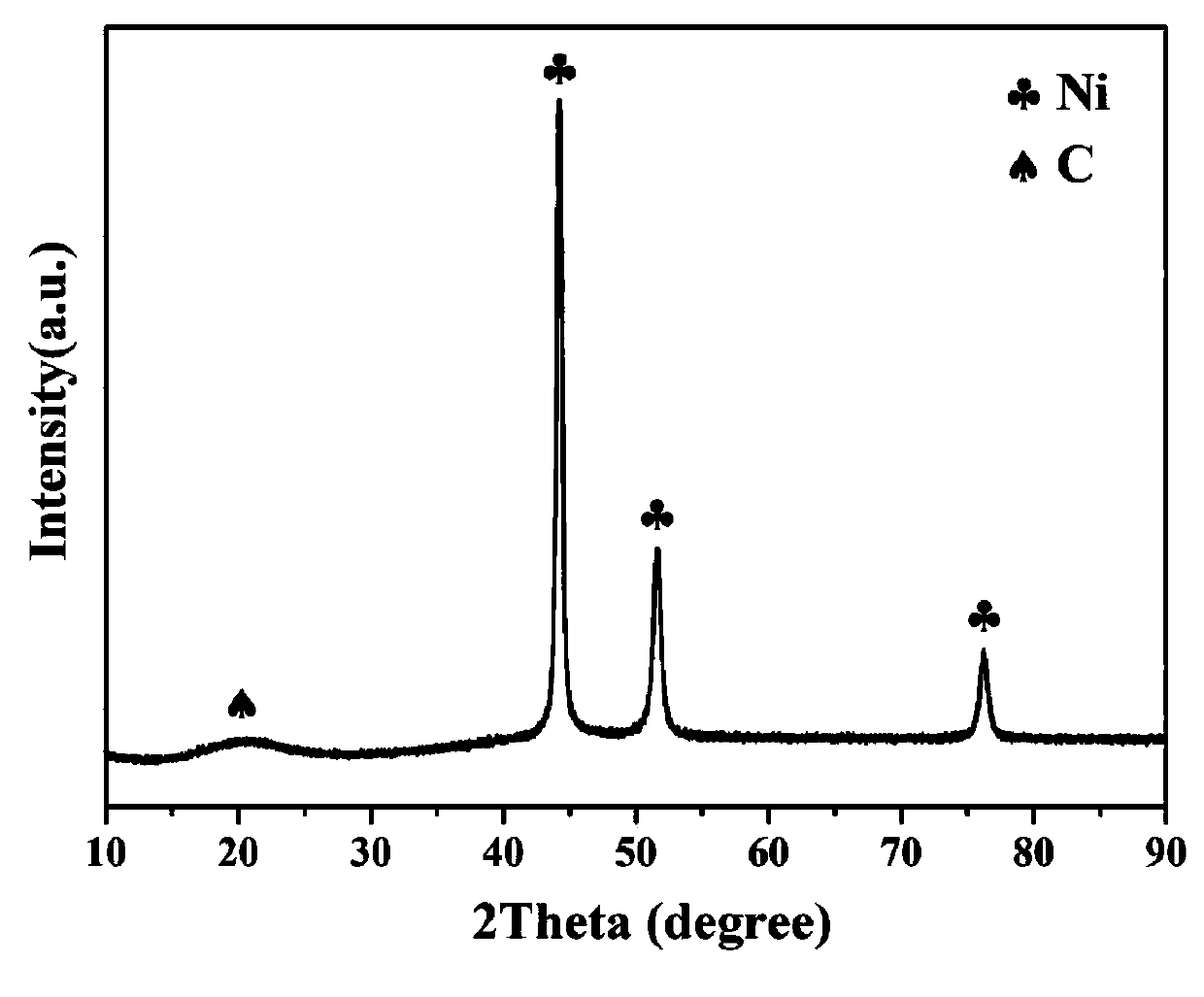

Preparation method of C@Ni composite material and electromagnetic shielding film

ActiveCN110498990AStrong shielding abilityImprove shielding effectOther chemical processesNickel saltForms of energy

Belonging to the technical field of electromagnetic microwave shielding materials, the invention discloses a preparation method of a C@Ni composite material and an electromagnetic shielding film. Thepreparation method of the C@Ni composite material includes the steps of: mixing ammonia water with an ethanol aqueous solution, adding a formaldehyde solution and resorcinol, performing stirring, andcarrying out standing hydrothermal reaction, then taking out the precipitate, conducting cleaning and drying to obtain a monodisperse resorcinol-formaldehyde resin ball, and performing calcination toobtain a precursor ball C, preparing the precursor ball C into an aqueous solution, adding a water-soluble nickel salt and a reducing agent, carrying out standing hydrothermal reaction, then taking out the precipitate, and performing cleaning and drying to obtain the C@Ni composite material. The electromagnetic shielding film is obtained by physical combination of the obtained C@Ni composite material with a macromoleclar polymer polyvinylidene fluoride. The C@Ni electromagnetic shielding film obtained by the invention can realize conversion of electromagnetic energy flow to heat energy, potential energy and other forms of energy by magnetic hysteresis loss, dielectric loss, resistance loss and other mechanisms, and reach the effect of shielding and absorbing electromagnetic wave.

Owner:徐曦

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com