Nitrogen-doped hollow carbon sphere as well as preparation method and application thereof

A technology of nitrogen-doped and carbon spheres, applied in the field of nitrogen-doped hollow carbon spheres and its preparation, can solve the problems of complex synthesis process, high cost, and limited application, and achieve uniform particle size, low cost, and high-efficiency selectivity trapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of nitrogen-doped hollow carbon spheres of the present invention comprises the following steps:

[0037] Step 1, adding ammonia water to the mixed solvent of ethanol and deionized water, stirring evenly to obtain a mixed solution;

[0038] Step 2. Under continuous stirring, add tetraethyl orthosilicate into the mixture, add resorcinol after 5-15 minutes, add formaldehyde after 5-15 minutes, add urotropine after 5-15 minutes, and stir evenly , solidified, centrifuged, washed, and vacuum-dried to obtain a brown polymer;

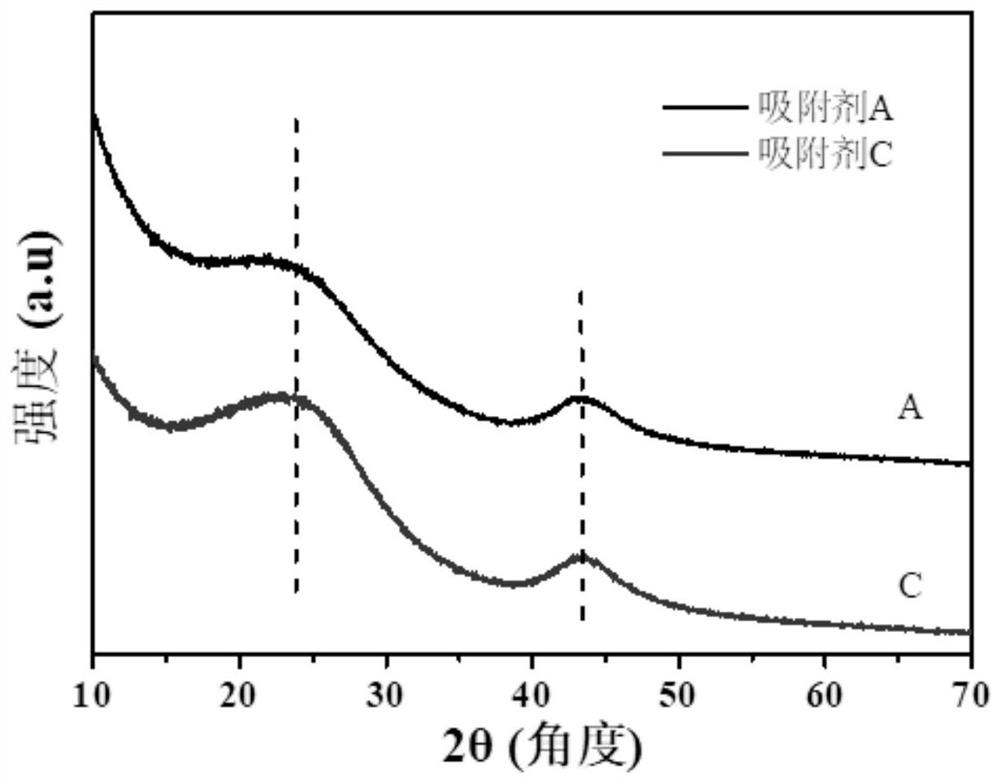

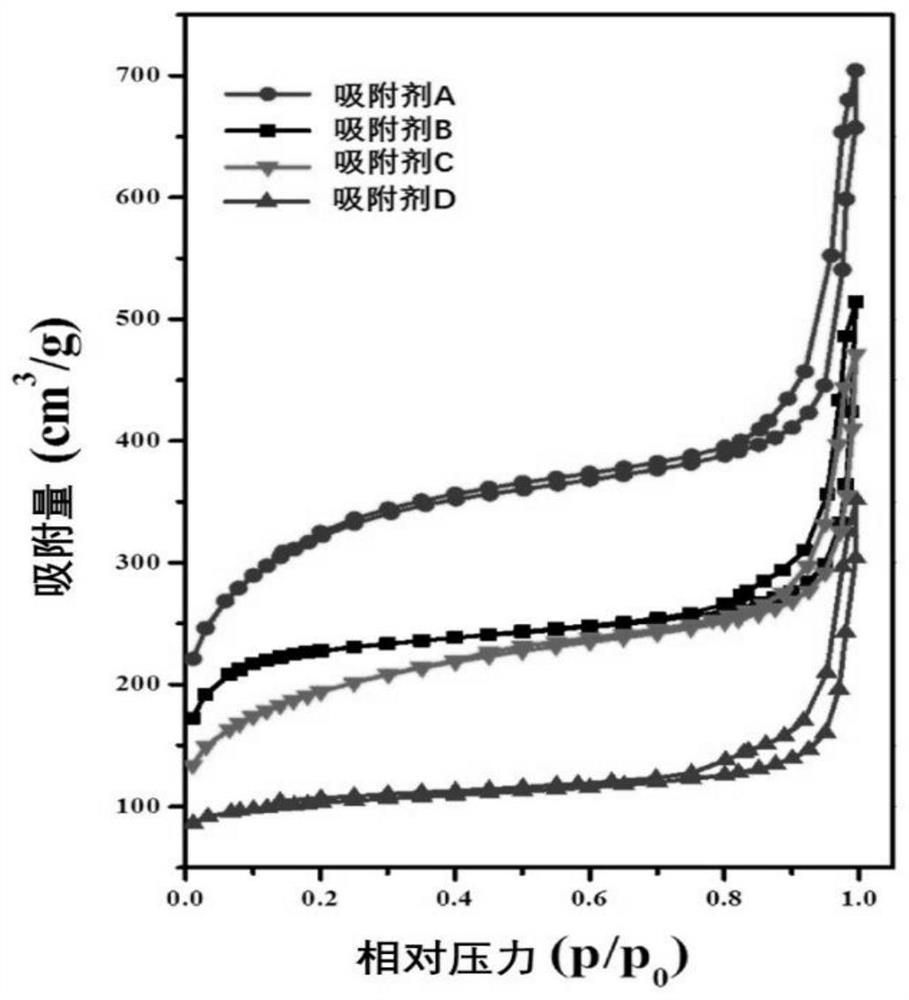

[0039] Step 3, under the protection of an inert gas, carbonize the brown polymer to obtain silica core carbon spheres;

[0040] Step 4. Under the protection of an inert gas, mix the silicon dioxide core carbon spheres with potassium hydroxide, etch, pickle, water wash, and vacuum dry to obtain etched silicon dioxide core carbon spheres;

[0041] Step five, use g-C 3 N 4 Activate the etched silicon dioxide core carbon spheres an...

Embodiment 1

[0055] 1.6 mL of ammonia solution (25 wt %) was added to a mixed solvent of ethanol (26.6 mL) and deionized water (13.3 mL), and stirred at 30° C. at a stirring speed of 600 rpm for 30 min to obtain a mixed solution.

[0056] Under continuous stirring at 600rpm, add 1.4mL TBOT to the mixture, add 0.2g resorcinol after 10min, add 0.28mL formaldehyde after 10min, add 0.075g HMTA after 10min, stir at 600rpm at 30°C for 24h, transfer to an autoclave, hydrothermally treated at 100°C for 24 hours, centrifuged to collect the product, washed with a large amount of ethanol and deionized water until neutral, and dried overnight at 80°C under vacuum to obtain a brown polymer with a silica core and polymer shell structure matter (SiO 2 @RF).

[0057] Under nitrogen protection, the SiO 2 @RF was heated to 700 °C for 1 h at a heating rate of 5 °C / min for carbonization to obtain silica@carbon core-shell nanostructures.

[0058] Fully mix silica@carbon sphere-shell nanostructures with anhy...

Embodiment 2

[0061] 0.8 mL of ammonia solution (25 wt %) was added to a mixed solvent of ethanol (13.3 mL) and deionized water (6.65 mL), and stirred at 30° C. at a stirring speed of 600 rpm for 20 min to obtain a mixture.

[0062] Under continuous stirring, add 0.7mL TBOT into the mixture, add 0.1g resorcinol after 10min, add 0.14mL formaldehyde after 10min, add 0.037g HMTA after 10min, stir magnetically at 600rpm at 30°C for 24h, transfer to an autoclave, and hydrothermally treated at 100°C for 24h, the product was collected by centrifugation, washed with ethanol and deionized water until neutral, and then dried overnight at 80°C under vacuum to obtain a silica core and polymer shell structure Brown polymer (SiO 2 @RF).

[0063] Under nitrogen protection, the SiO 2 @RF was heated to 700 °C for 1 h at a heating rate of 5 °C / min to obtain a silica @ carbon core-shell nanostructure.

[0064] Fully mix silica@carbon spheres with anhydrous KOH at a mass ratio of 1:1, and carbonize at 1 °C / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com