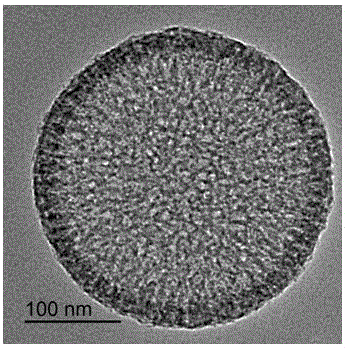

Preparation method of hollow carbon nanospheres with MOFs (metal-organic frameworks) formed through limited-range growth inside

A technology of nanospheres and hollow carbon, which is applied in the direction of nanocarbon and nanotechnology, can solve the problems of MOFs materials without conductivity, material stability cannot be guaranteed, and limit the application of electrochemical fields, so as to achieve good shape control , material low toxicity, uniform size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. Synthesis of mesoporous hollow carbon nanospheres:

[0037] Mix 75 ml of ethanol, 30 ml of deionized water and 3 ml of ammonia water, add 0.6 g of tetraethyl orthosilicate (TEOS) dropwise into the mixture at a constant speed, stir mechanically at room temperature, and react for 10 min to form SiO 2 nanospheres.

[0038] Next, 1 ml of formaldehyde and 0.5 g of resorcinol were added to the above reaction system, and the reaction was carried out under mechanical stirring for 24 h at room temperature. The solid phase after centrifugal washing was dried at 60°C for 12 hours to form SiO 2 @resorcinol-formaldehyde resin.

[0039] The dried SiO 2 @Resorcinol-formaldehyde resin is calcined at a high temperature of 700°C for 5h under the protection of argon atmosphere, and the heating rate is 2°C / min to obtain SiO 2 @Cball.

[0040] Calcined SiO2 @C spheres were dispersed in 50 ml, 2 mol / L sodium hydroxide aqueous solution, etched at 60°C for 16 h, washed with water and e...

Embodiment 2

[0047] 1. Synthesis of mesoporous hollow carbon nanospheres:

[0048] Mix 75 ml of ethanol, 30 ml of deionized water and 3 ml of ammonia water, then slowly add 0.6 g of tetraethyl orthosilicate (TEOS) dropwise into the mixed solution at a uniform speed, stir mechanically at room temperature, and react for 10 min to form SiO 2 nanospheres.

[0049] Next, 1 ml of formaldehyde and 0.5 g of resorcinol were added to the above reaction system, and the reaction was carried out under mechanical stirring for 24 h at room temperature. The solid phase after centrifugal washing was dried at 60°C for 12 hours to form SiO 2 @resorcinol-formaldehyde resin.

[0050] The dried SiO 2 @Resorcinol-formaldehyde resin is calcined at a high temperature of 700°C for 5h under the protection of argon atmosphere, and the heating rate is 2°C / min to obtain SiO 2 @Cball.

[0051] Calcined SiO 2 @C spheres were dispersed in 50 ml, 2 mol / L sodium hydroxide aqueous solution, etched at 60°C for 16 h, wa...

Embodiment 3

[0058] 1. Synthesis of mesoporous hollow carbon nanospheres:

[0059] Mix 75 ml of ethanol, 30 ml of deionized water and 3 ml of ammonia water, add 0.6 g of tetraethyl orthosilicate (TEOS) slowly and dropwise to the mixed solution at a uniform speed, stir mechanically at room temperature, and react for 10 min to form SiO 2 nanospheres.

[0060] Next, 1 ml of formaldehyde and 0.5 g of resorcinol were added to the above reaction system, and the reaction was carried out under mechanical stirring for 24 h at room temperature. The solid phase after centrifugal washing was dried at 60°C for 12 hours to form SiO 2 @resorcinol-formaldehyde resin.

[0061] The dried SiO 2 @Resorcinol-formaldehyde resin is calcined at a high temperature of 700°C for 5h under the protection of argon atmosphere, and the heating rate is 2°C / min to obtain SiO 2 @Cball.

[0062] Calcined SiO 2 @C spheres were dispersed in 50 ml, 2mol / L aqueous hydroxide solution, etched at 60°C for 16 h, washed three t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com